Attapulgite modification based PP (polypropylene) melt-blown filter cartridge and preparation method thereof

The technology of melt-blown filter element and attapulgite is applied in the field of PP melt-blown filter element modified based on attapulgite and its preparation, which can solve the problems of restricting the development of PP filter element, filtering liquid pollution, breeding microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

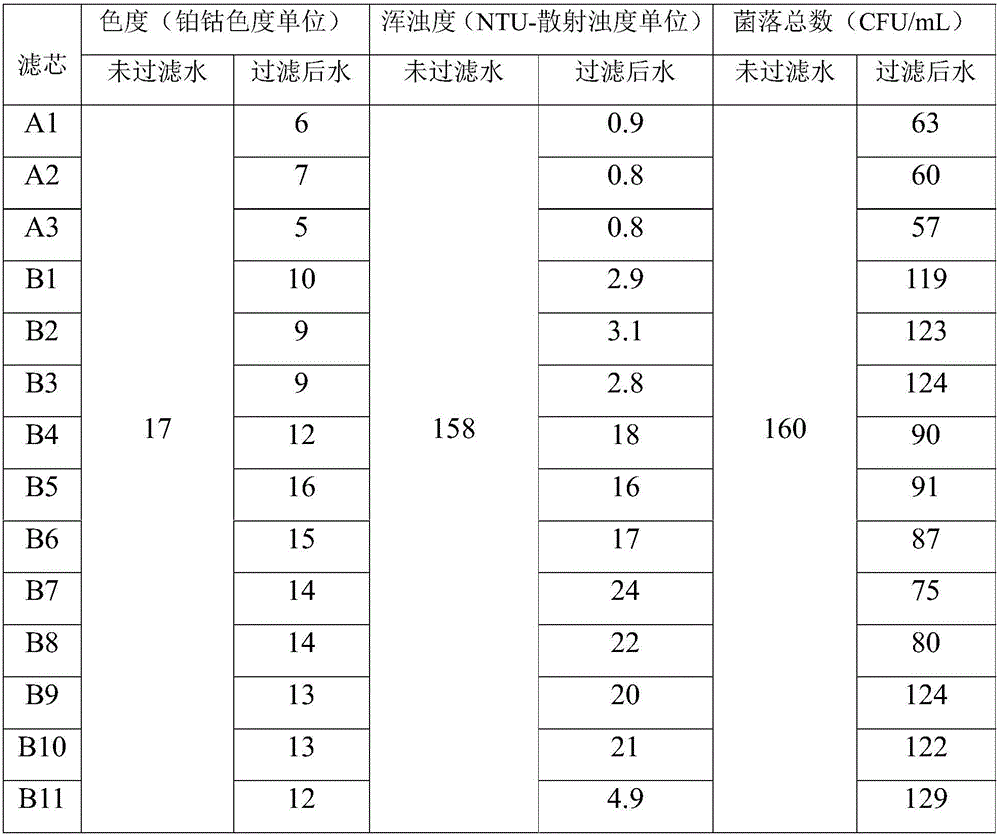

Examples

preparation example Construction

[0017] The invention provides a method for preparing a PP melt-blown filter element modified based on attapulgite, comprising:

[0018] 1) spraying the polymer coating on the surface of attapulgite, then drying, soaking in dilute sulfuric acid solution, and filtering to obtain activated attapulgite;

[0019] 2) spray silver nitrate solution and hydrazine sulfate solution on the surface of activated attapulgite at the same time, and let it stand to prepare silver-modified attapulgite;

[0020] 3) decocting and filtering the Chinese herbal medicine in water to obtain the Chinese herbal medicine extract and the Chinese herbal medicine filter cake;

[0021] 4) In the presence of protective gas, place the silver-modified attapulgite at 240-255°C for calcination for 25-40 minutes, then place the calcined product in Chinese herbal medicine extract for impregnation and filtration to obtain Chinese herbal medicine-modified attapulgite earth;

[0022] 5) PP (polypropylene), AES (acryl...

Embodiment 1

[0041] 1) Polymer coating (containing polyvinyl alcohol, 1.2% by weight of p-aminophenol platinum, 0.7% by weight of palladium (II)-2-(5-bromo-2-pyridylazo)-5-diethylaminophenol ) sprayed on the surface of attapulgite, then dried at 125°C for 6h, soaked in 50°C and 18% by weight dilute sulfuric acid solution for 2h, and filtered to obtain activated attapulgite, wherein attapulgite, polymer The weight ratio of paint and dilute sulfuric acid solution is 100:4:200;

[0042] 2) Spray 5% by weight of silver nitrate solution and 2.5% by weight of hydrazine sulfate solution on the surface of activated attapulgite at the same time, and let it stand at 30° C. for 5 hours to obtain silver-modified attapulgite, wherein activated attapulgite, The weight ratio of silver nitrate solution and hydrazine sulfate solution is 100:7:11;

[0043] 3) Mix lemongrass, scallion, licorice, mulberry leaves, forsythia, golden boil grass, red peony, red euphorbia, Magnolia officinalis and water according...

Embodiment 2

[0047] 1) Polymer coating (containing polyvinyl alcohol, 0.8% by weight of p-aminophenol platinum, 0.2% by weight of palladium (II)-2-(5-bromo-2-pyridylazo)-5-diethylaminophenol ) sprayed on the surface of attapulgite, then dried at 120°C for 5h, placed in 45°C and 15% by weight of dilute sulfuric acid solution for 1h soaking, and filtered to obtain activated attapulgite, wherein attapulgite, polymer The weight ratio of paint and dilute sulfuric acid solution is 100:3:150;

[0048] 2) Spray 4% by weight of silver nitrate solution and 2% by weight of hydrazine sulfate solution on the surface of activated attapulgite at the same time, and let it stand at 25° C. for 4 hours to obtain silver-modified attapulgite, wherein activated attapulgite, The weight ratio of silver nitrate solution and hydrazine sulfate solution is 100:5:10;

[0049] 3) Mix lemongrass, scallion, licorice, mulberry leaves, forsythia, golden boiling grass, red peony, red euphorbia, magnolia officinalis and wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com