Sulfuration type hydrodesulfurization catalyst as well as preparation method and application thereof

A hydrodesulfurization and catalyst technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve unfavorable catalyst hydrodesulfurization activity, reduce active metal utilization rate, and low active metal utilization rate and other problems, to achieve the effect of reducing interaction, increasing sulfidation degree, and improving desulfurization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method of a vulcanized hydrodesulfurization catalyst. The catalyst includes a carrier, an active metal and an auxiliary metal. The preparation method comprises the following steps:

[0029] Step 1, adding an active metal-containing compound and a vulcanizing agent into the first solvent, and heating to reflux to obtain an active metal sulfide;

[0030] Step 2, dispersing the active metal sulfide on the carrier, then impregnating the compound solution containing the promoter metal, and roasting to obtain a sulfurized hydrodesulfurization catalyst.

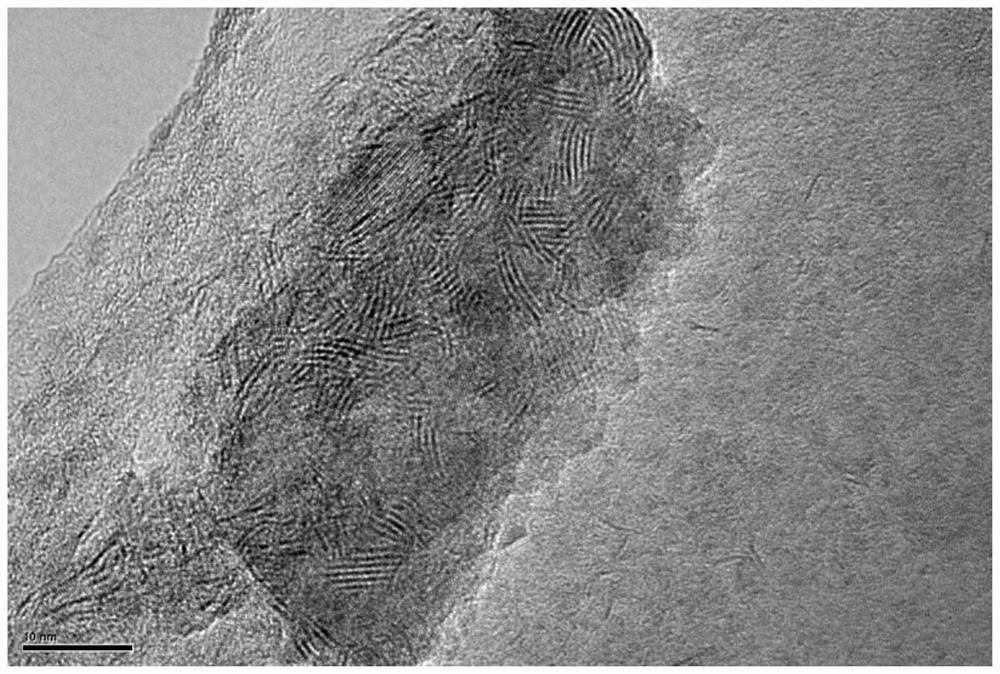

[0031] The present invention uses the active metal sulfide produced by the reaction of the active metal compound and the vulcanizing agent as the precursor, and loads it on the carrier to prepare the sulfurized hydrodesulfurization catalyst, which avoids the use of the oxygen-containing metal compound as the precursor and reduces the active metal The interaction with the carrier increases ...

Embodiment 1

[0048] This embodiment provides a method for preparing a sulfurized hydrodesulfurization catalyst, the method comprising the following steps:

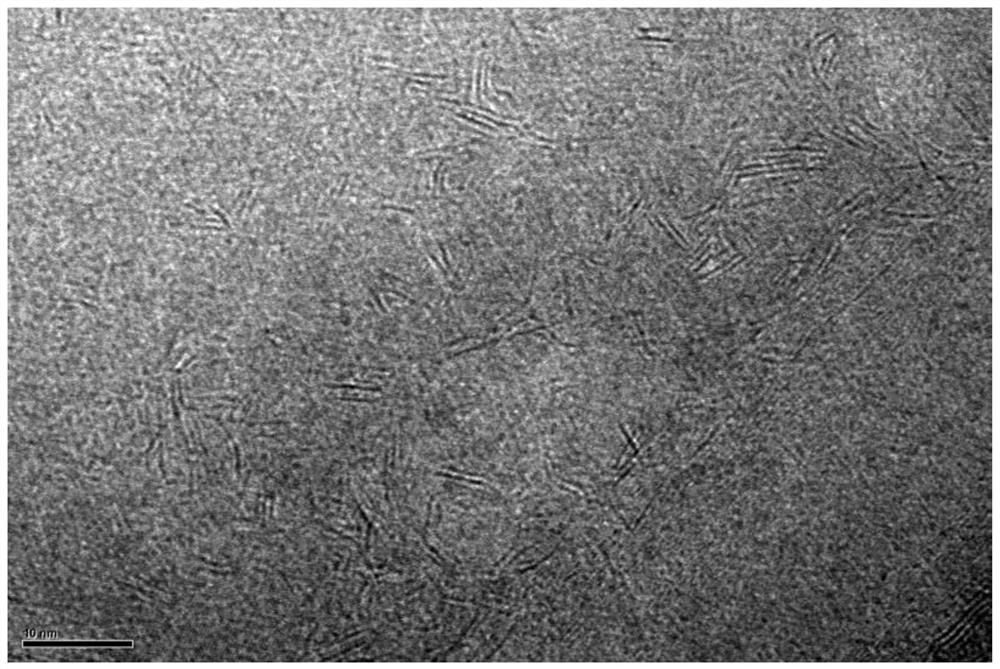

[0049] Step 1, first weigh 1.06g molybdenum hexacarbonyl (Mo(CO) 6 ) and 2.37g of tetraethylthiuram disulfide were dissolved in 40mL of acetone, and the above solution was placed in a nitrogen atmosphere, heated to reflux at 58°C for 2.5h, cooled to room temperature and allowed to stand for 5h, filtered with suction and washed with n-pentane, The obtained pink powder was dried in a vacuum oven at 120°C for 8 h to obtain the metal sulfide Mo(Et 2 NCS 2 ) 4 powder.

[0050] Step 2, weigh 1.89g Mo(Et 2 NCS 2 ) 4 Dissolve in 80mL of anhydrous acetonitrile, sonicate for 30min, then add 2.00g of 20-40mesh γ-Al 2 o 3 The particles were suspended, and the suspension was transferred to a polytetrafluoroethylene-lined stainless steel reactor, and the reactor was placed in a rotating oven at 220°C to react for 12 hours. After the reaction...

Embodiment 2

[0061] This embodiment is basically the same as embodiment 1, except that the embodiment 1 "impregnates nickel nitrate (Ni(NO) according to Ni / (Ni+Mo)=0.33 ) 2 ·6H 2 O)" was replaced with "according to Ni / (Ni+Mo)=0.4 impregnated nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O)".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com