Patents

Literature

43 results about "Tetraethylthiuram disulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetraethylthiuram disulfide ≥97% Synonym: Bis(diethylthiocarbamoyl) disulfide, Bis(diethylthiocarbamyl) disulfide, Disulfiram, TETD CAS Number 97-77-8. Linear Formula (C 2 H 5) 2 NCSS 2 CSN(C 2 H 5) 2. Molecular Weight 296.54 . Beilstein Registry Number 1712560 . EC Number 202-607-8. MDL number MFCD00009048. PubChem Substance ID 24278722

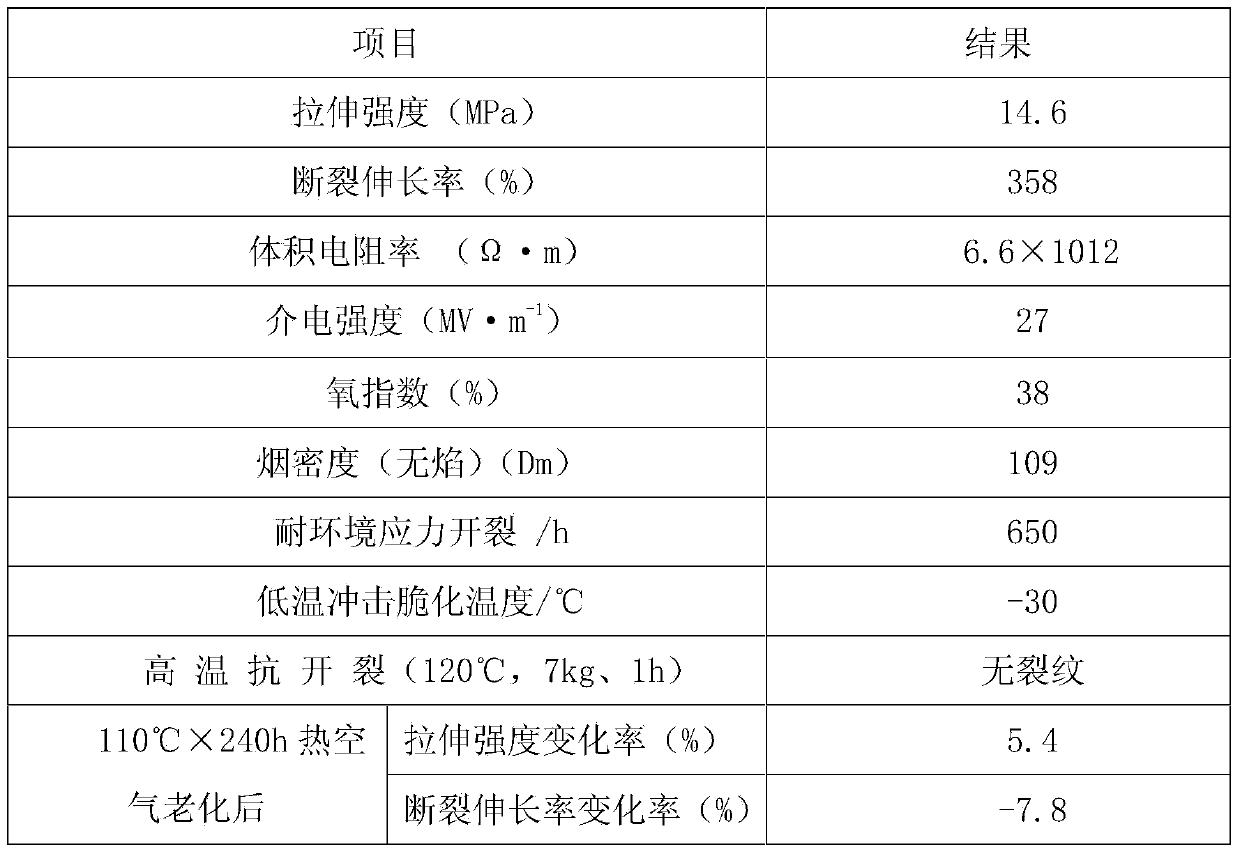

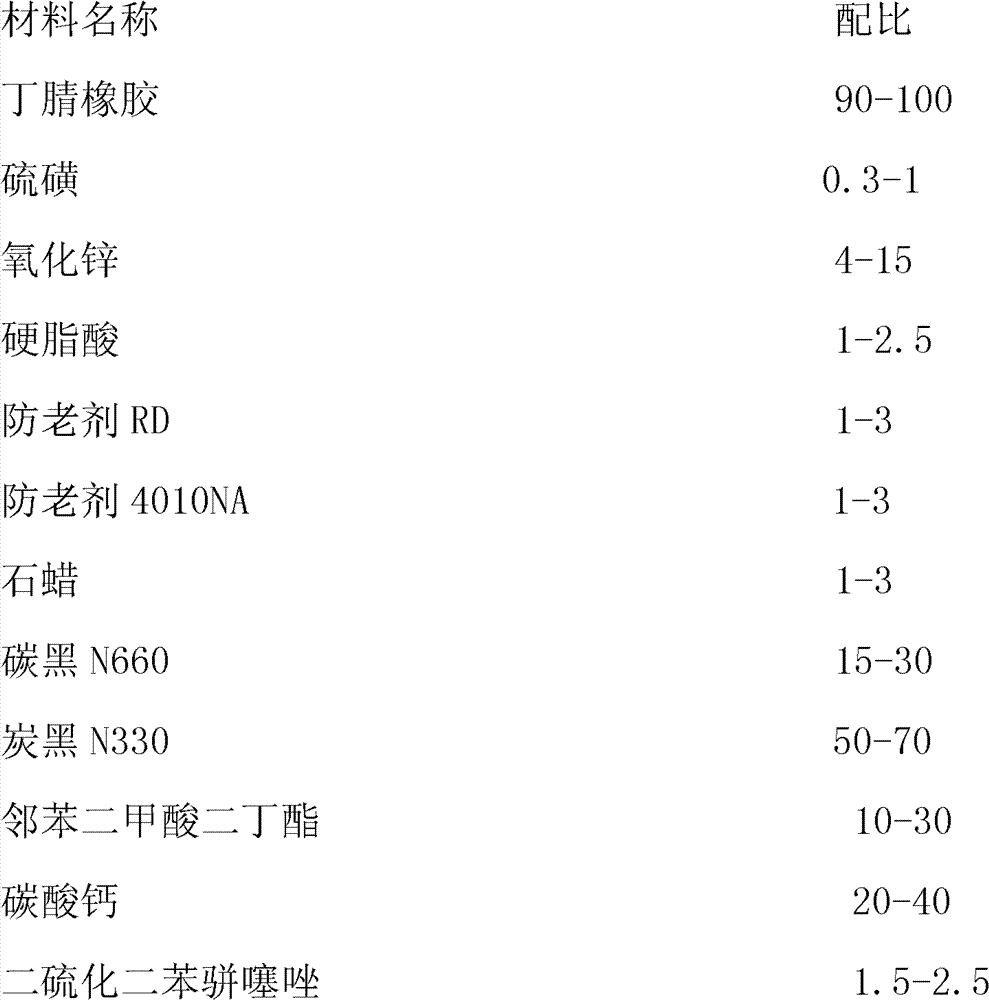

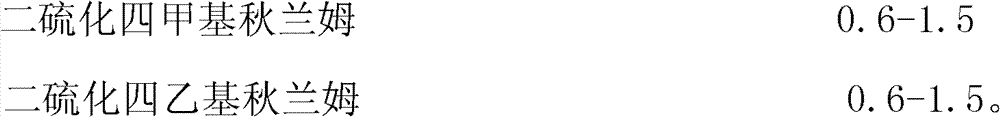

Oil resistant rubber

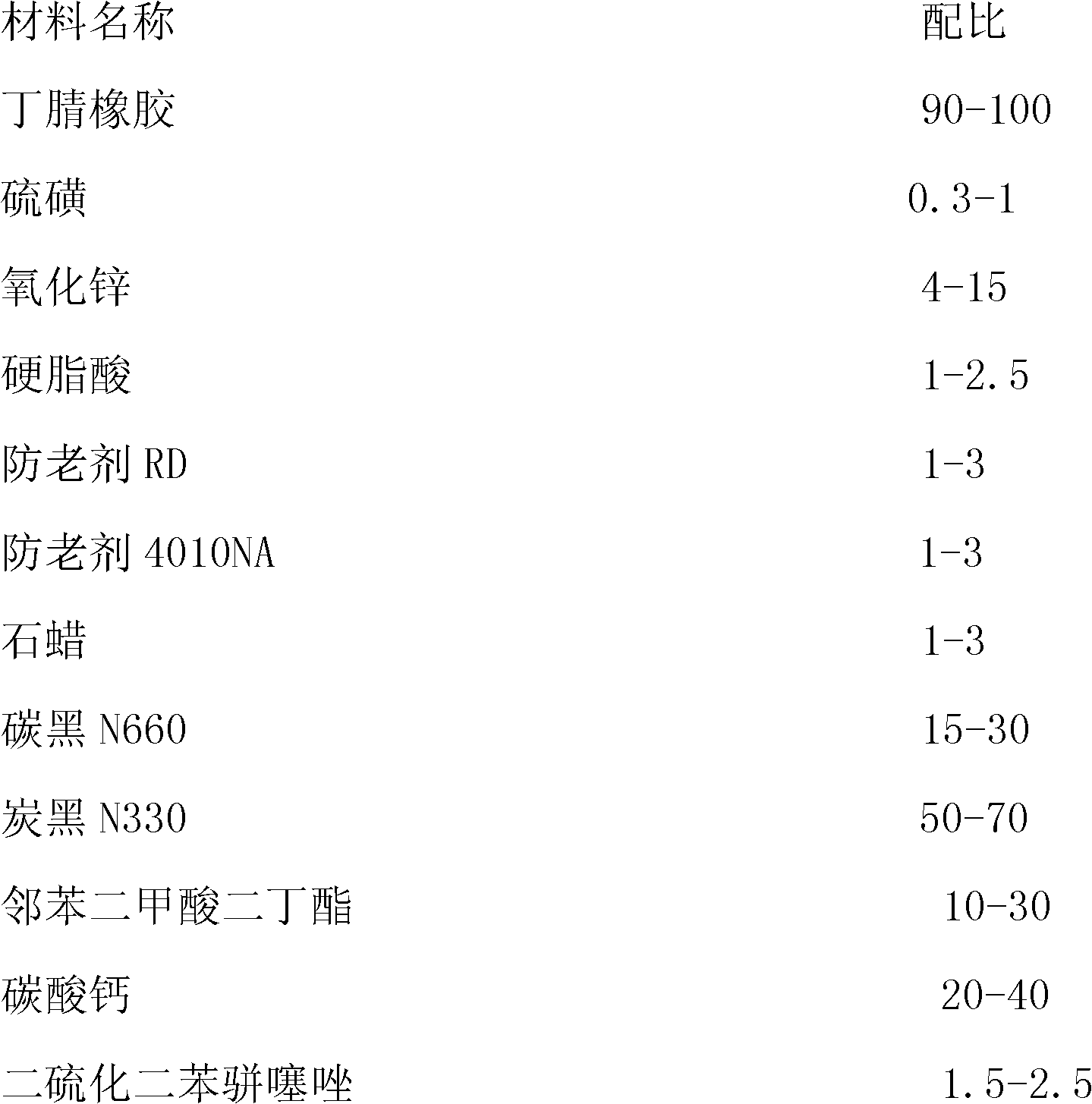

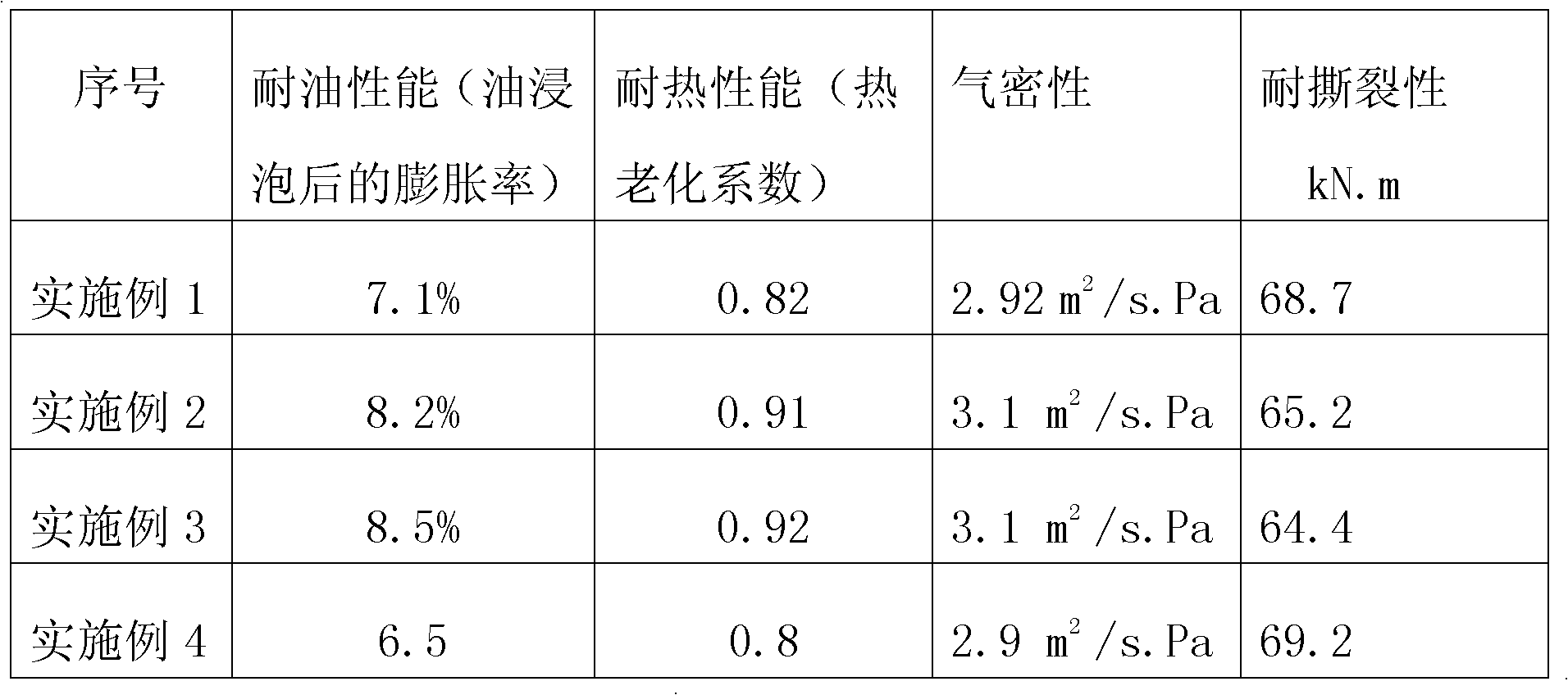

The invention discloses an oil resistant rubber, which contains the following substances in part by weight: nitrile rubber, sulfur, zinc oxide, stearic acid, anti-aging agent RD, anti-aging agent 4010NA, paraffin, carbon black N660, carbon black N330, dibutyl phthalate, calcium carbonate, dibenzothiazyl disulfide, tetramethylthiuram disulfide and tetraethylthiuram disulfide. Compared with the prior art, the oil resistant rubber has the advantages that: the oil resistance of the oil resistant rubber produced by using the rubber formula is less than 8.5 percent, and the oil resistant rubber has good heat resistance and air tightness.

Owner:芜湖禾田汽车工业有限公司

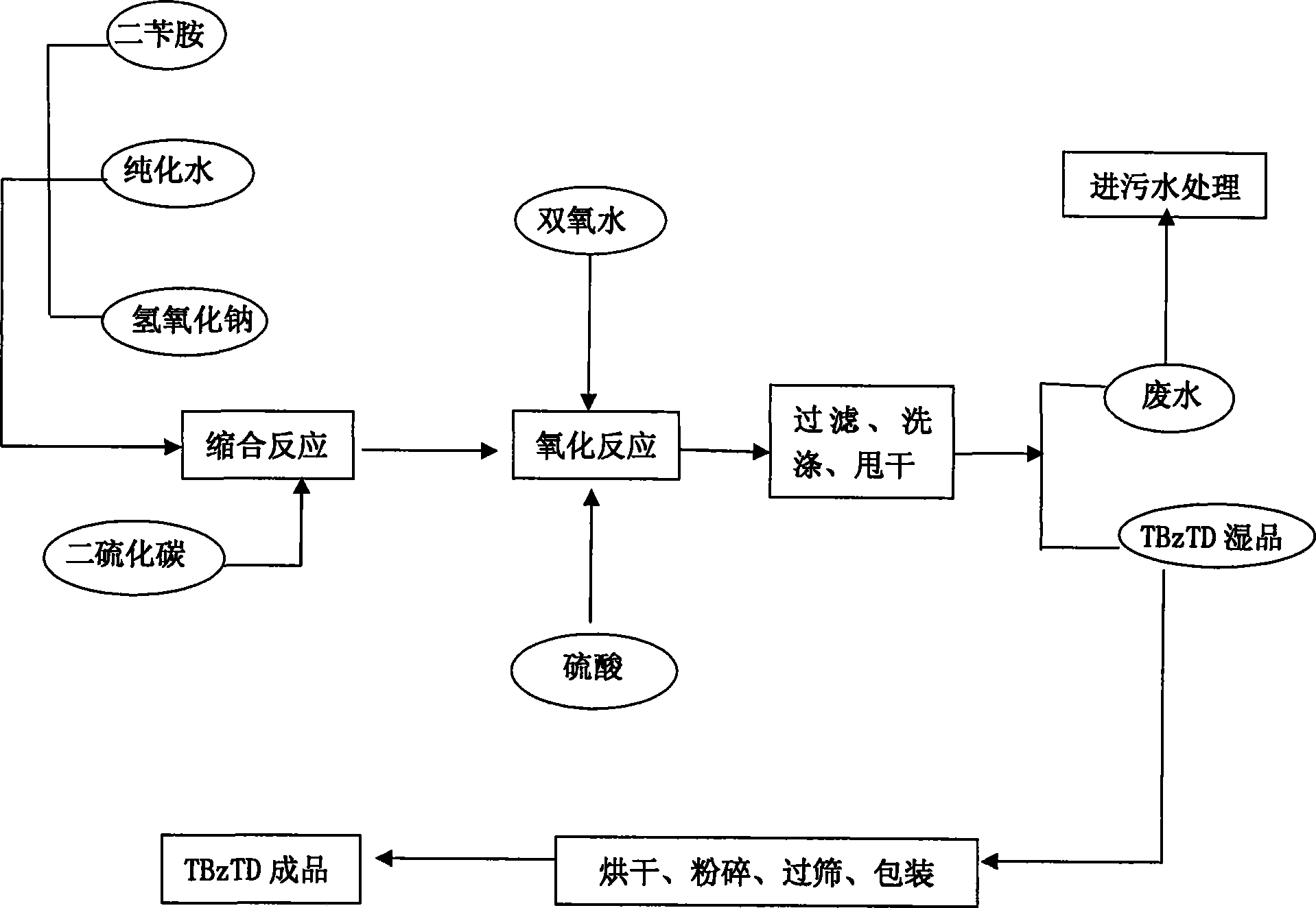

Preparation of rubber vulcanization accelerator tetrabenzylthiuram disulfide

The invention relates to a method for preparing a thiofide of tetraethylthiuram disulfide. The method uses raw materials with the mol ratio as follows: the mol ratio of dibenzyl amine, carbon bisulfide, sodium hydroxide, hydrogen peroxide and sulphuric acid is 1:1-1.30:1.0-1.2:0.5-0.6:0.28-0.35mol. The method comprises the technical process as follows: under normal pressure, the dibenzyl amine and the sodium hydroxide are sequentially added into a reaction kettle which contains purified water under the state of being stirred; subsequently, the temperature is reduced to 20 DEG C to 30 DEG C, liquid carbon bisulfide is dropwise added for 2 to 3 hours; after dropwise adding, reactant continues to be stirred for 0.5 hour; then, at the temperature of 58 DEG C to 63 DEG C, the hydrogen peroxide is dropwise added into the reactant for oxidation reaction which lasts 3 to 4 hours; when the oxidation reaction is going to finish, the sulphuric acid is added to adjust the pH value of reaction solution to be within the range of 6.5-7.5, and the reaction is finished; then the reaction is taken for 1 hour again by heat preservation for solid-liquid separation, and the solid is dried, crushed, filtered and packed to obtain a product. The method can improve the quality, the yield and the performance of the product effectively, reduce the potential safety hazard during the production process greatly, save energy, reduce consumption, reduce the waste water and exhaust emission during the production process and meet the national relative policy of environmental protection.

Owner:WILLING NEW MATERIALS TECH CO LTD

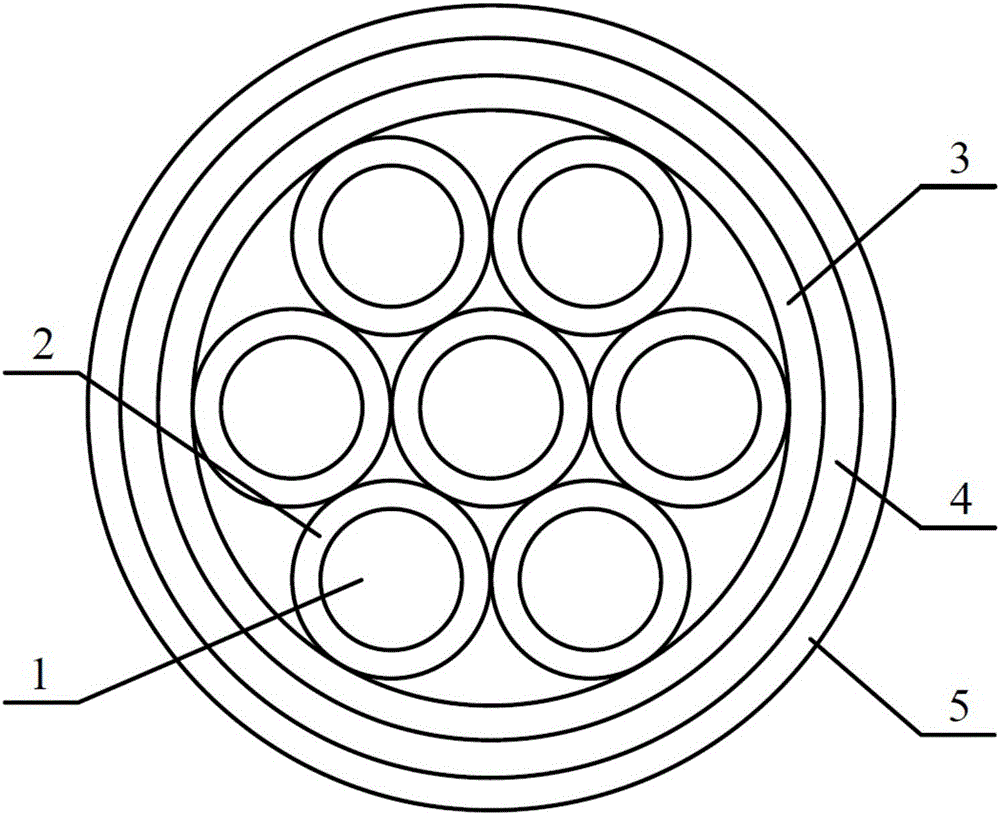

High-strength ageing-resistant cable

InactiveCN105139939AImprove mechanical propertiesImprove aging resistanceInsulated cablesInsulated conductorsFiberEpoxy

The invention discloses a high-strength ageing-resistant cable, which comprises a cable core, wherein the cable core comprises a conductor and an insulating layer, wherein the conductor is located in the middle part; the insulating layer coats outside the conductor; an inner sheath layer is arranged outside the cable core; a steel belt armor layer is arranged outside the inner sheath layer; an outer sheath layer is arranged outside the steel belt armor layer, and is fabricated by a modified natural rubber material; and the modified natural rubber material comprises the following steps: natural rubber, epoxy resin, fluorine micro-powder, white carbon black, a nylon short fiber, a modified calcium carbonate whisker, modified nano titanium dioxide, nanometer aluminum oxide, stearic acid, zinc oxide, sulphur, N,N'-m-phenylenedimaleimide, dicumyl peroxide, 4,4'-diaminodiphenylmethane, butadiene sulfone, an accelerant tetraethylthiuram disulfide (TETD), an accelerant MZ, an accelerant NS, a load-type anti-aging agent, an anti-aging agent RD, a plasticizer and a silane coupling agent. The high-strength ageing-resistant cable disclosed by the invention is high in strength, good in ageing resistance and long in service life.

Owner:合肥市再德高分子材料有限公司

Method of Treating Cancer Using Dithiocarbamate Derivatives

InactiveUS20070232692A1Readily available and easily used treatmentEffective treatmentHeavy metal active ingredientsBiocideThiocarbamateAnticarcinogen

Dithiocarbamate, particularly tetraethylthiuram disulfide, and thiocarbamate anions thereof, strongly inhibit the growth of cancer cells of a variety of cell types. Such inhibitory effect is enhanced by heavy metal ions such as copper ions, cytokines and ceruloplasmin. A method is presented for using tetraethylthiuram disulfide to reduce tumor growth, and to potentiate the effect of other anticancer agents.

Owner:THE UNIV OF UTAH

Modified nitrile rubber cable material

The invention relates to a cable material, and in particular relates to a modified nitrile rubber cable material. The cable material comprises the following raw material in parts by weight: 40-45 parts of nitrile rubber, 12-15 parts of natural rubber, 24-28 parts of fluororubber, 23-25 parts of mica powder, 12-15 parts of vermiculite powder, 6-8 parts of zinc borate, 30-35 parts of N330 carbon black, 1-2 parts of an accelerator TMTD (Tetraethylthiuram Disulfide), 3-5 parts of phthalate, 3-5 parts of propanediol sebacate polyester, 1-2 parts of monobutyltin oxide, 1-2 parts of sulphur, 3-4 parts of magnesium oxide, 1-2 parts of zinc oxide, 1-2 parts of an antioxidant 1010, 3-4 parts of zinc stearate, 1-2 parts of calcium stearate and 4-5 parts of an assistant. The cable material improves the characteristics of nitrile rubber and mixes the advantages of natural rubber and fluororubber. The prepared cable material has the advantages of high temperature resistance, ageing resistance, good stability and the like, and can satisfy the using demands in special occasions.

Owner:安徽文峰电子科技集团有限公司

Oil-resistant rubber cushion

InactiveCN103540038AGood oil resistanceImprove heat resistanceHeat resistanceEthylene-propylene-diene-monomer

The invention relates to an oil-resistant rubber cushion which comprises 90 parts of ethylene propylene diene monomer, 75 parts of tetrapropyl fluororubber, 7 parts of calcium carbonate, 3 parts of dibenzothiazyl disulfide, 5 parts of paraffin and 6 parts of plasticizing and softening agent. The rubber pipe clamp also comprises 3 parts of stearic acid. The rubber pipe clamp also comprises 5 parts of tetraethylthiuram disulfide. Compared with the prior art, the high-temperature-resistant rubber foot pad enhances the oil resistance of the natural rubber to 8-10%, and has favorable heat resistance and air tightness.

Owner:QINGDAO BOYUTE RUBBER & PLASTIC PRODS

Anti-aging electric insulation rubber

The invention relates to the technical field of rubber processing, in particular to an anti-aging electric insulation rubber. The insulation rubber comprises rubber base gum, white carbon black, di-tert-butylperoxy diisopropyl benzene, hydroxy silicone oil, diphenyl silanediol, talcum powder, zinc oxide, stearic acid, modified kaolin, a coupling agent, a rubber accelerator, sulfur and an antioxidant. Specifically, the rubber base gum consists of ethylene propylene diene monomer, chlorinated polyethylene rubber and methyl vinyl silicone rubber; the hydroxy silicone oil adopts high viscosity hydroxy silicone oil with a viscosity of 750-800CS under a normal temperature state; the rubber accelerator is tetraethylthiuram disulfide or zinc dimethyldithiocarbamate; and the antioxidant is an antioxidant A, antioxidant D or antioxidant H. On the basis of ensuring the insulation performance and mechanical properties of the product, the aging resistance is further improved, and the product can maintain longer service life in the outdoor environment.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

Anti-cracking silicone rubber cable material and preparation method thereof

InactiveCN103467998AGuaranteed insulation performanceGuaranteed flame retardant performanceRubber insulatorsCrack resistanceNano al2o3

The invention discloses an anti-cracking silicone rubber cable material and a preparation method of the material. The anti-cracking silicone rubber cable material is prepared by the following raw materials in parts by weight: 65-75 parts of methyl vinyl silicone rubber, 20-30 parts of nylon 66, 10-15 parts of isotactic polypropylene, 15-20 parts of magnesium hydrate, 5-10 parts of sodium molybdate, 8-12 parts of melamine cyanurate, 2-3 parts of magnesium oxide, 10-15 parts of diisononyl phthalate, 1.5-2.5 parts of methyl tin mercaptide, 5-8 parts of polyethene wax, 0.5-1.5 parts of antioxidant BHT (butylated hydroxytoluene), 0.8-1.2 parts of valcanizer DTBP (di-t-butyl peroxide), 1-2 parts of accelerator TETD (tetraethylthiuram disulfide), 0.5-1.5 parts of scorch retarder CTP (cytidine triphosphate), 15-20 parts of carbon black N660, 12-18 parts of vermiculite powder, 5-10 parts of nano aluminum oxide and 4-7 parts of composite packing. The cable material has excellent cracking resistance and mechanical properties, is free from cracking in a low temperature impact test at -30 DEG C, a high temperature impact test at 120 DEG C and a bending test, can be applied to harsh environments such as low temperature, salt mist, wetness, hot and mould, and is durable in use.

Owner:JING FENG GRP

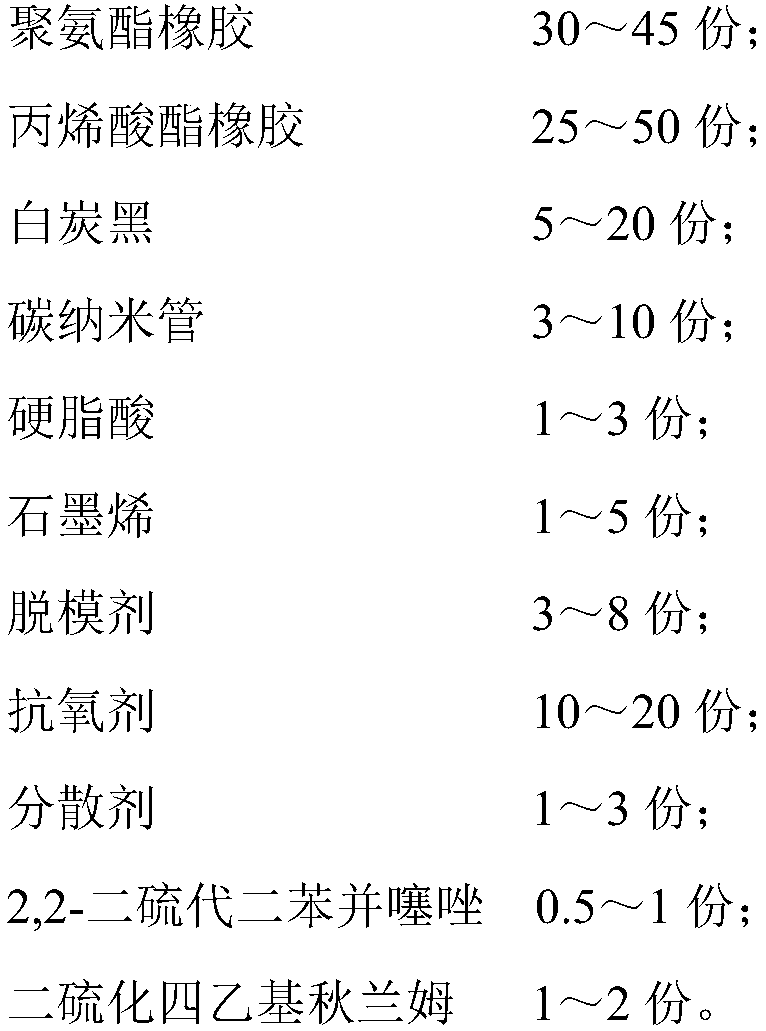

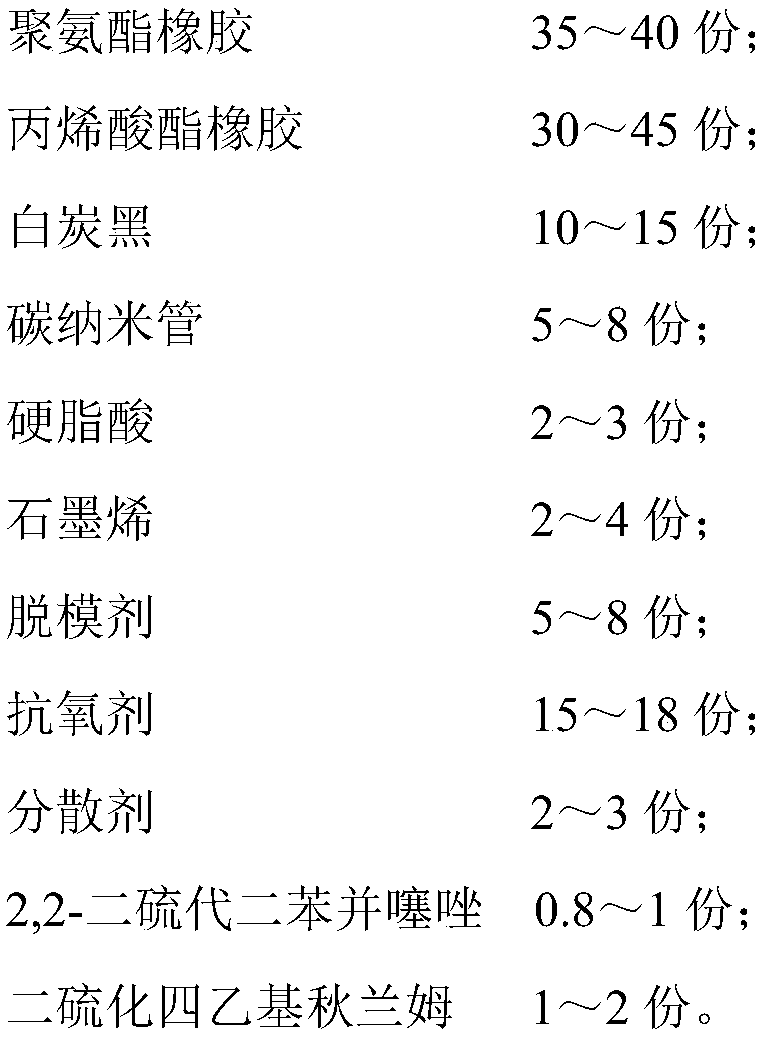

Environmentally friendly oil seal material and preparation method thereof

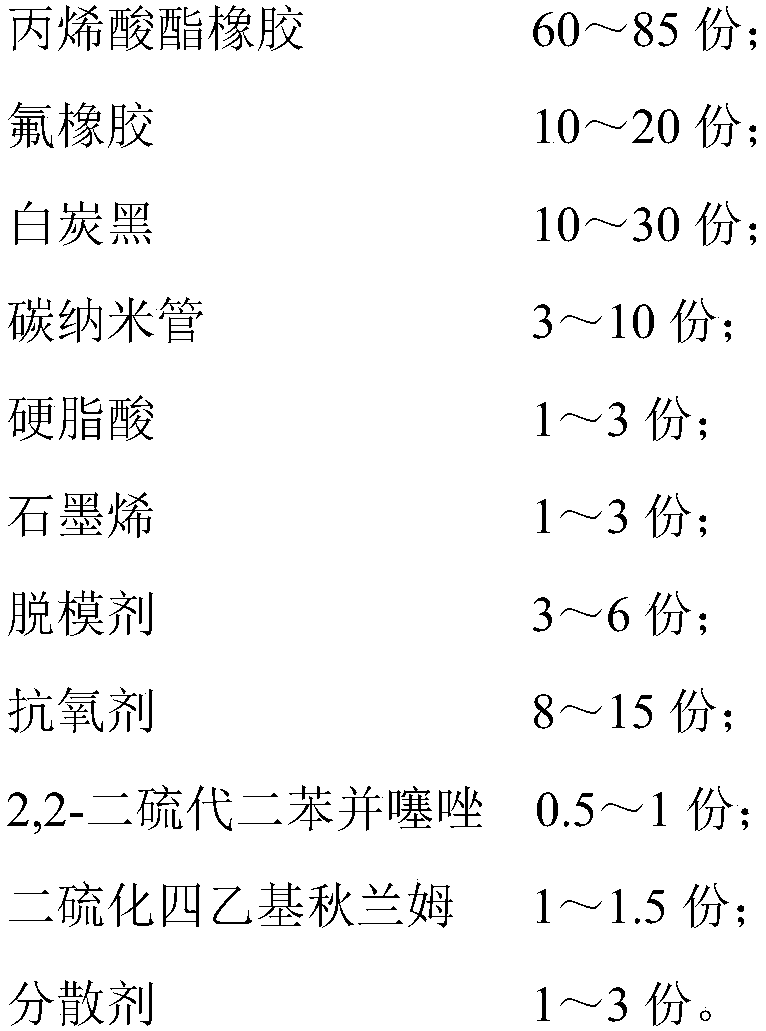

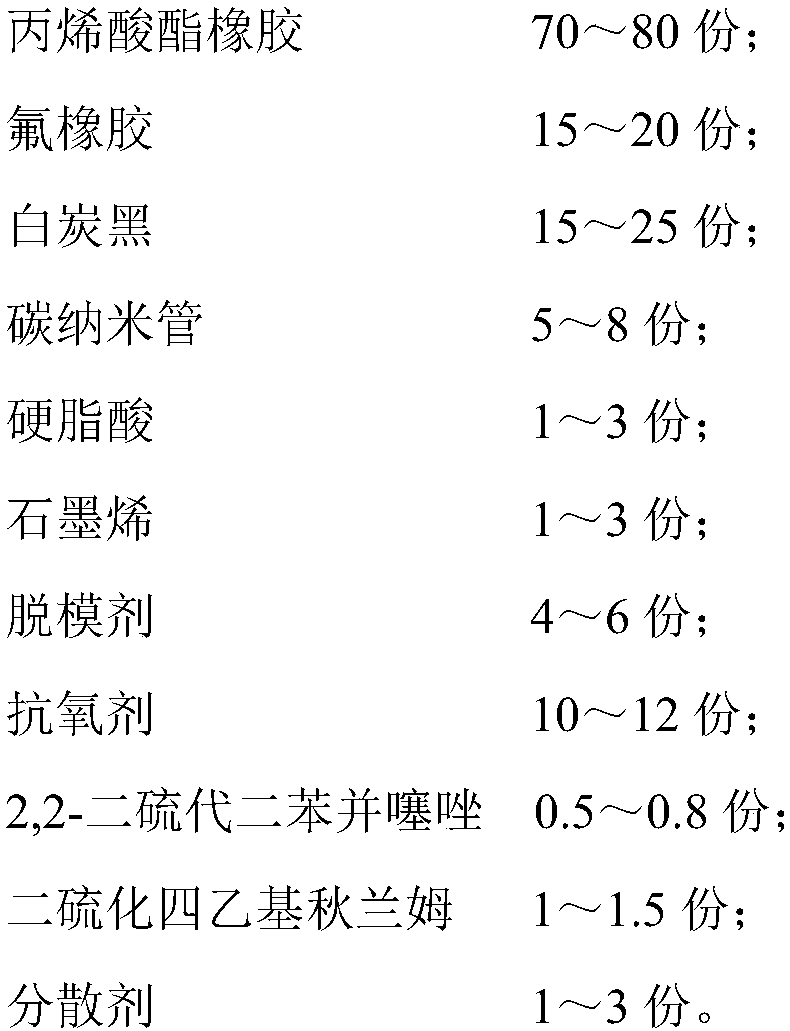

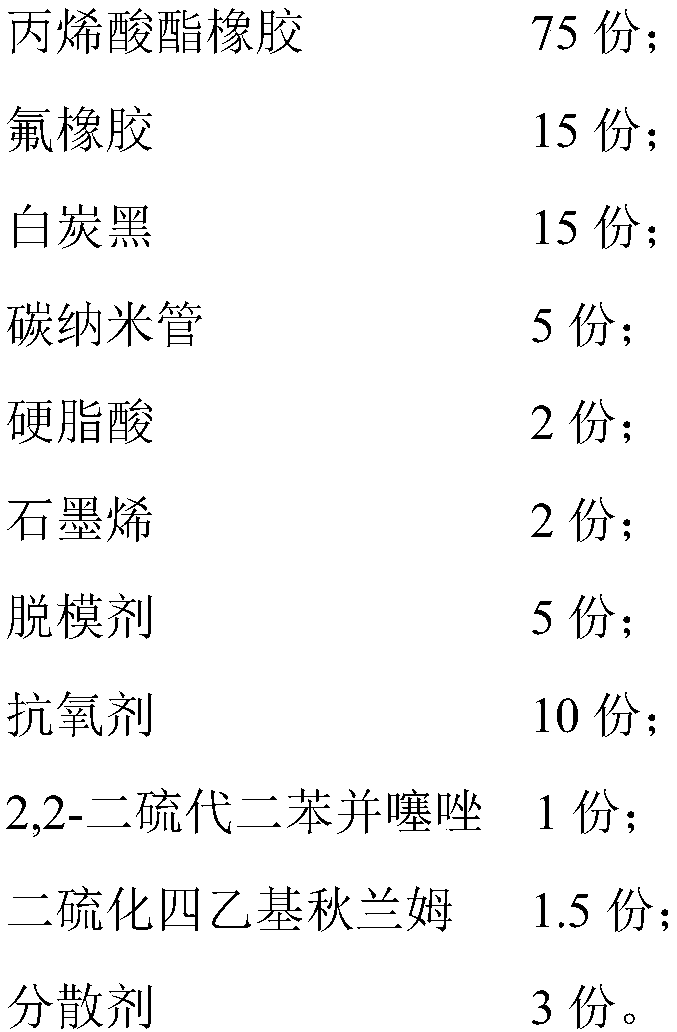

The invention relates to the field of processing of rubber composite materials, in particular to an environmentally friendly oil seal material and a preparation method thereof. The environmentally friendly oil seal material at least comprises the following preparation raw materials in parts by weight: 60-85 parts of polyacrylate rubber, 10-20 parts of fluororubber, 10-30 parts of white carbon black, 3-10 parts of carbon nanotubes, 1-3 parts of stearic acid, 1-3 parts of graphene, 3-6 parts of a release agent, 8-15 parts of an antioxidant, 0.5-1 part of 2,2-dithiobisbenzothiazole, 1-1.5 parts of tetraethylthiuram disulfide and 1-3 parts of a dispersing agent.

Owner:RIZHAO DONGDU RUBBER & PLASTIC PROD

High-strength automobile tire and its preparation method

ActiveCN106397872BImprove high temperature resistanceImprove anti-agingSpecial tyresGlycerolTemperature resistance

The invention discloses a high strength automobile tire and a preparation method thereof. The preparation method comprises the following steps: 1) peeling and crushing green bamboo and calcining the green bamboo in protective gas to obtain bamboo charcoal, 2) roasting titanium dioxide, barium carbonate, lithium carbonate and the bamboo charcoal in protective gas to obtain modified barium metatitanate, 3) carrying out gelatinization on tetraethylthiuram disulfide, starch, caryophyllene, methylcellulose and water to obtain a modified vulcanizing agent, and 4) carrying out primary mixing on butadiene rubber, an ethylene-propylene copolymer, poly(ethylene glycol methyl ether), pentaerythritol triacrylate, glycerol, nanometer calcium carbonate, dimethyldiethoxysilane, zinc sulfide, dicumyl peroxide and sulfur, then adding the modified barium metatitanate and the modified vulcanizing agent into the mixture, carrying out secondary mixing and carrying out molding and cooling to obtain the high strength automobile tire. The high strength automobile tire has excellent high temperature resistance, aging resistance and mechanical properties.

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

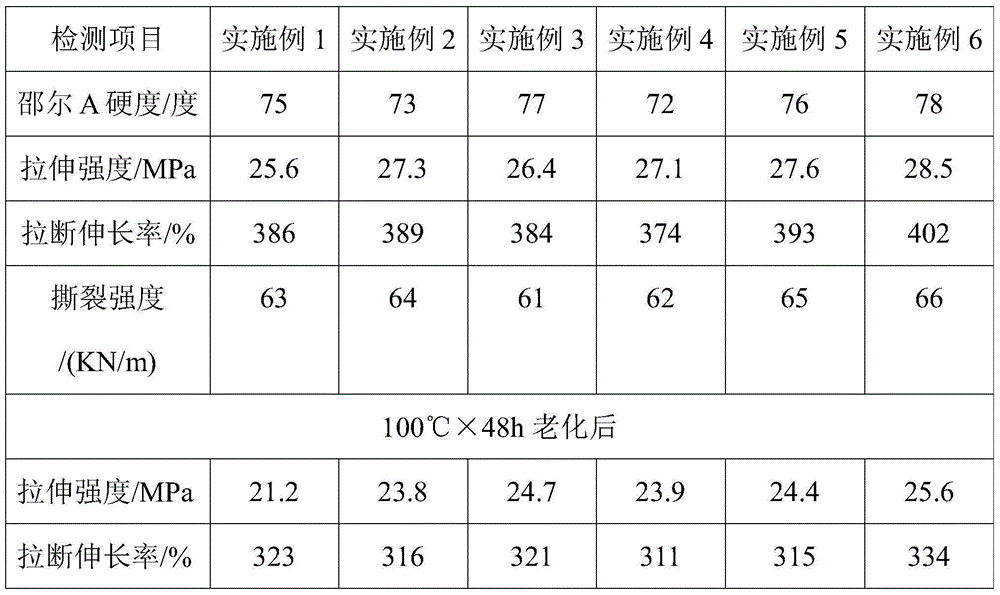

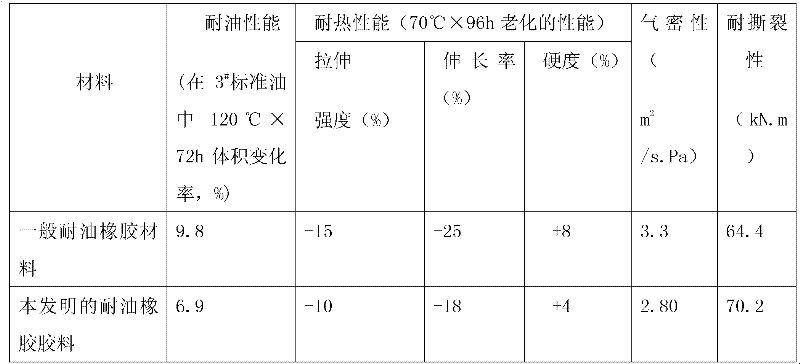

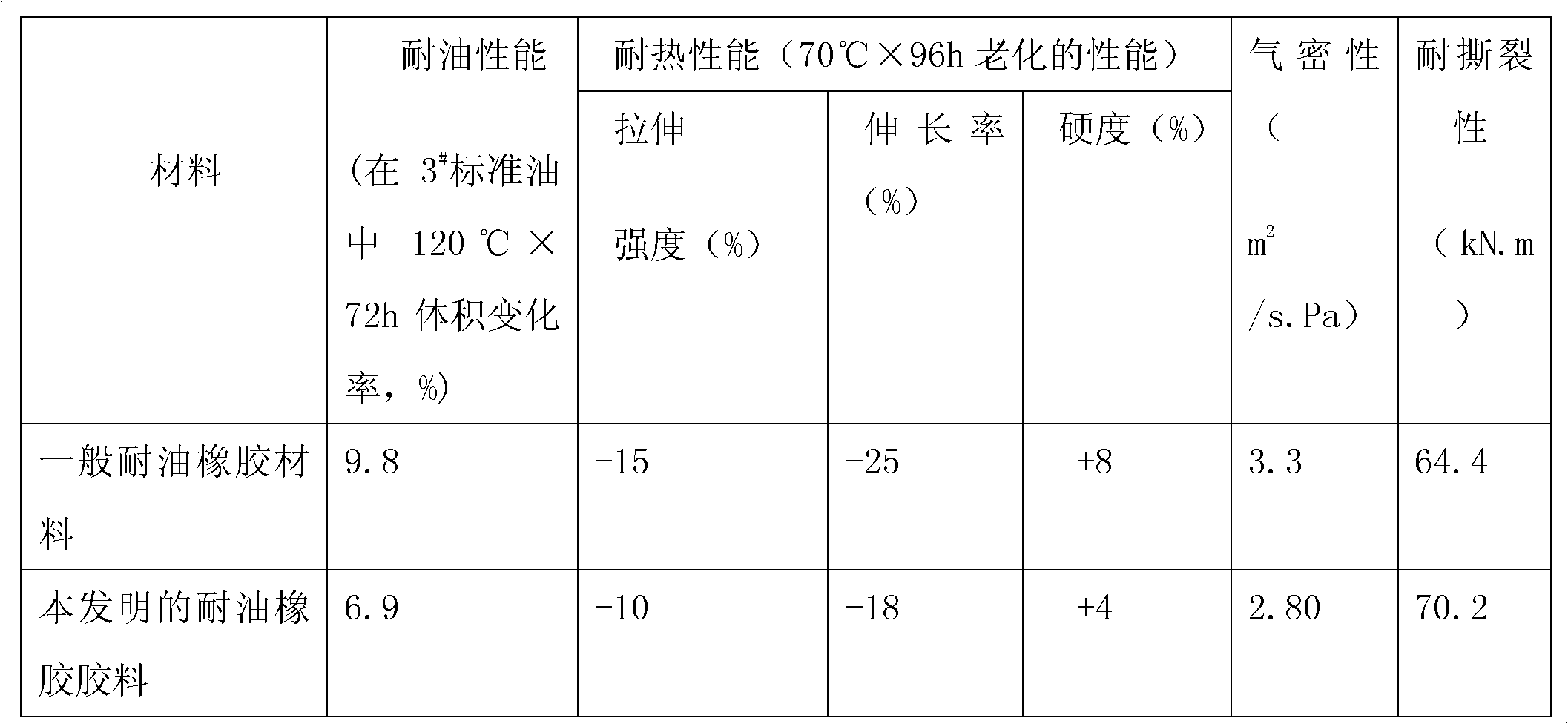

Rubber sizing material for oil-resistant sealing element and preparation method thereof

InactiveCN102585314AGood oil resistanceImprove heat resistanceOther chemical processesMicrocrystalline waxPolymer science

The invention discloses a rubber sizing material for an oil-resistant sealing element. The rubber sizing material comprises the following raw materials in part by weight: 75 to 85 parts of NBR3606 (Nitrile-Butadiene Rubber 3606), 75 to 85 parts of NBR2707, 0.7 to 0.9 part of dichloromethyl dimethylbenzene, 3 to 4 parts of magnesium oxide, 7 to 9 parts of zinc oxide, 1 to 2 parts of zinc stearate,2 to 4 parts of age resister RD, 1 to 2 parts of age resister MB, 1.5 to 1.7 parts of microcrystalline wax, 1.7 to 1.9 parts of rubber processing auxiliary WB212, 95 to 105 parts of carbon black N550, 48 to 52 parts of carbon black N330, 55 to 65 parts of dioctyl-phthalate, 2.3 to 2.5 parts of accelerator DM, 1.5 to 1.7 parts of accelerator TMTD (Tetramethyl Thiuram Disulfide) and 1.5 to 1.7 parts of accelerator TETD (Tetraethylthiuram Disulfide). The formula of the rubber sizing material disclosed by the invention has high curing rate. The obtained sizing material has excellent other comprehensive performances. The oil-resistant sealing element produced from the sizing material has excellent oil resistance and heat resistance and good air-tightness. Meanwhile, the production cost is reduced and the production efficiency is improved.

Owner:CGP WUHU SEALING

Rubber for lifting rings for automobile exhaust pipes

The invention discloses rubber for lifting rings for automobile exhaust pipes, which belongs to the technical field of rubber pipe products for automobiles. The rubber disclosed by the invention is prepared from ethylene-propylene-diene-terpolymer rubber, chlorosulfonated polyethylene rubber, intermediate super carbon black N200, general furnace black N660, indirect zinc oxide, tetramethyl thiuram disulfide, tetraethylthiuram disulfide, 2-mercaptobenzimidazole, zinc stearate, 2,2'-Dithio-dibenzo thiazole, a trithiocyanuric acid, paraffin oil, magnesium powder, and sulphur as raw materials in parts by weight. Compared with rubber for lifting rings for automobile exhaust pipes manufactured in the prior art, when the rubber disclosed by the invention is used for preparing lifting rings for automobile exhaust pipes by using the mutual synergistic effect of the raw materials, the heat resistance of the lifting rings for automobile exhaust pipes is effectively improved, and the aging resistance of the lifting rings for automobile exhaust pipes is also promoted.

Owner:LIUZHOU YINGHANG AUTO PARTS

Seal primer for switch cabinet and preparation method thereof

InactiveCN103540228AImprove alkali resistanceImprove salting-out resistanceEpoxy resin coatingsPolyester coatingsEpoxyEngineering

The invention discloses a seal primer for a switch cabinet. The seal primer is prepared from the following raw materials in parts by weight: 65-69 parts of E-20 epoxy resins, 3-4 parts of tetra(2-ethoxyl) adipamide, 2-3 parts of tri(2-ethoxyl) isocyanuric acid, 2-3 parts of zinc naphthenate, 4-5 parts of dimethyl sulfoxide, 6-8 parts of m-amino methylamine, 1-2 parts of lignosulfonate, 1-2 parts of accelerants tetraethylthiuram disulfide (TETD), 10-12 parts of petroleum resins, 58-63 parts of alkyd resins, 7-9 parts of dimethylbenzene, 12-14 parts of ethyl acetate and 3-4 parts of auxiliaries. According to the auxiliaries, the optical performance is improved, so that the oil paint can be uniformly dispersed, the stability of the oil paint is maintained, and the membrane formation effect is improved; and compared with the prior art, the seal primer has the advantages of high anti-alkali and anti-salting performance, high paint adhesion force and high sealing performance.

Owner:ANHUI MINGDU ELECTRICAL

High-temperature-resistant automobile tire and preparation method thereof

ActiveCN106397871AImprove high temperature resistanceImprove anti-agingSpecial tyresPolyethylene oxideGlycerol

The invention discloses a high-temperature-resistant automobile tire and a preparation method thereof. The preparation method comprises the steps that 1, green bamboos are peeled and smashed and then are calcined in the presence of shielding gas to obtain bamboo charcoal; 2, nano titanium dioxide, barium carbonate, lithium carbonate and the bamboo charcoal are calcined in the presence of shielding gas to obtain modified barium metatitanate; 3, tetraethylthiuram disulfide, starch, caryophyllene, methylcellulose and water are subjected to gelatinization processing to obtain a modified vulcanizing agent; 4, butadiene rubber, a methyl acrylic acid-butadiene-styrene copolymer, polyethylene oxide, pentaerythritol triacrylate, glycerol, nano calcium carbonate, dimethyldiethoxylsilane, zinc sulfide, benzoyl peroxide and sulfur are mixed primarily, then the modified barium metatitanate and the modified vulcanizing agent are added for secondary mixing, and finally forming and cooling are performed to obtain the high-temperature-resistant automobile tire. The automobile tire prepared by adopting the method has excellent high-temperature-resistant, aging-resistant and mechanical properties.

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

Oil resistant rubber

The invention discloses an oil resistant rubber, which contains the following substances in part by weight: nitrile rubber, sulfur, zinc oxide, stearic acid, anti-aging agent RD, anti-aging agent 4010NA, paraffin, carbon black N660, carbon black N330, dibutyl phthalate, calcium carbonate, dibenzothiazyl disulfide, tetramethylthiuram disulfide and tetraethylthiuram disulfide. Compared with the prior art, the oil resistant rubber has the advantages that: the oil resistance of the oil resistant rubber produced by using the rubber formula is less than 8.5 percent, and the oil resistant rubber hasgood heat resistance and air tightness.

Owner:芜湖禾田汽车工业有限公司

Low-temperature-resistant modified polyethylene cable sheath material

InactiveCN103724772AImprove performanceImprove insulation performanceInsulated cablesInsulatorsLow-density polyethyleneCrack resistance

The invention relates to a cable material, in particular to a low-temperature-resistant modified polyethylene cable sheath material. The material contains the following raw materials by weight: 34-38 parts of low-density polyethylene, 5-8 parts of polyvinyl acetate, 20-23 parts of poly(1-butene), 6-8 parts of slag powder, 10-15 parts of zeolite powder, 4-5 parts of magnesium carbonate, 3-4 parts of 3-aminopropyltrimethoxysilane, 1-2 parts of accelerant TETD (Tetraethylthiuram Disulfide), 0.5-1.5 parts of accelerant CBS (N-Cyclohexyl-2-Benzothiazole Sulfonamide), 1-2 parts of silane coupling agent KH550, 1-2 parts of benzo[d]imidazole-2-thiol, 6-9 parts of nanometer silicon dioxide, 12-15 parts of rapeseed oil, 1.3-1.7 parts of accelerant TMTD (Tetramethylthiuram Disulfide), 13-17 parts of tributyl citrate and 14-16 parts of auxiliaries. The advantages of the raw materials, such as the low-density polyethylene, the poly(1-butene) and the polyvinyl acetate are combined by the insulating material. The prepared material has the characteristics of flexibility, wear resistance, low-temperature crack resistance, chemical corrosion resistance, great insulating properties and safety and reliability in use, can be widely used for manufacturing various cable sheath insulating materials, and has a wide market demand prospect.

Owner:ANHUI TELI CABLE

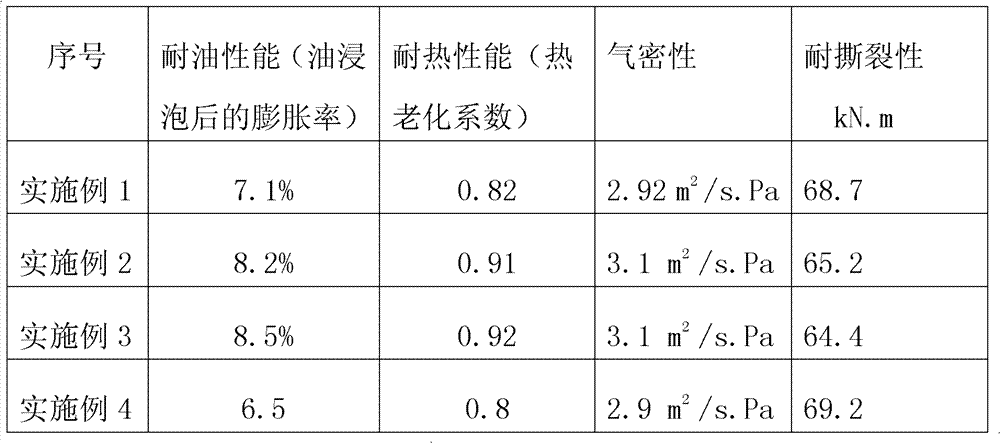

Electrical insulating gloves

InactiveCN104212173AImprove performanceImprove insulation performanceProtective garmentEngineeringZinc

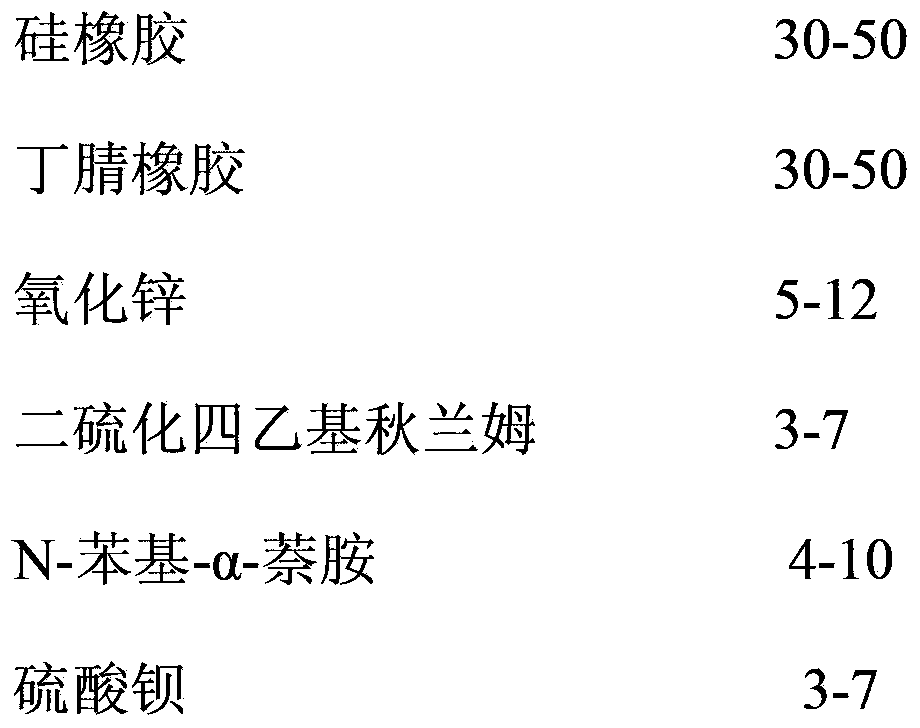

The invention discloses electrical insulating gloves; the electrical insulating gloves comprise the raw materials according to the weight fraction: 30-50 of silicone rubber, 30-50 of acrylonitrile butadiene rubber, 5-12 of zinc oxide, 3-7 of tetraethylthiuram disulfide, 4-10 of N-phenyl-alpha-naphthylamine, 3-7 of barium sulfate, and 3-10 of LiB(C6H5)4. With adopting of the specific rubber matrix and the specific additives, and with cooperation of specific contents, the prepared gloves are allowed to have excellent electrical insulating property and wear-resisting property.

Owner:WUXI XINYA SAFETY PROD

Acid and alkali resistant rubber gloves

InactiveCN104212068AImprove performanceGood acid and alkali resistanceGlovesProtective garmentPolymer scienceZinc

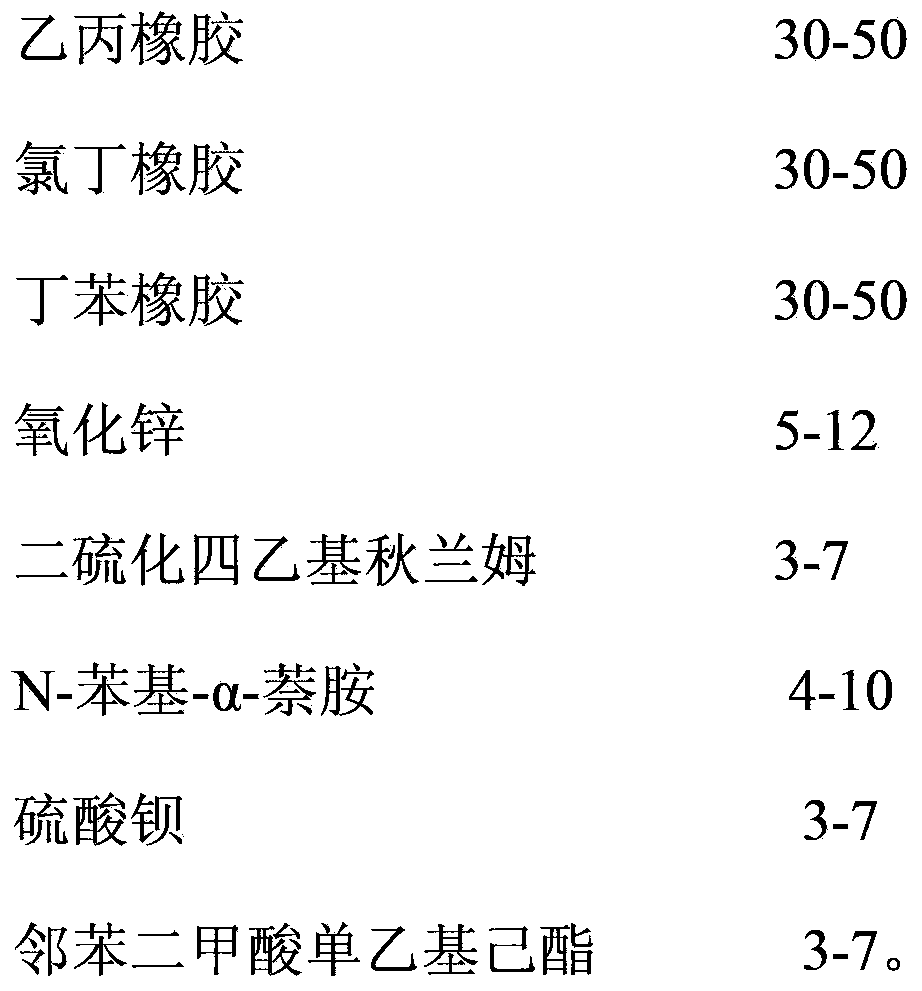

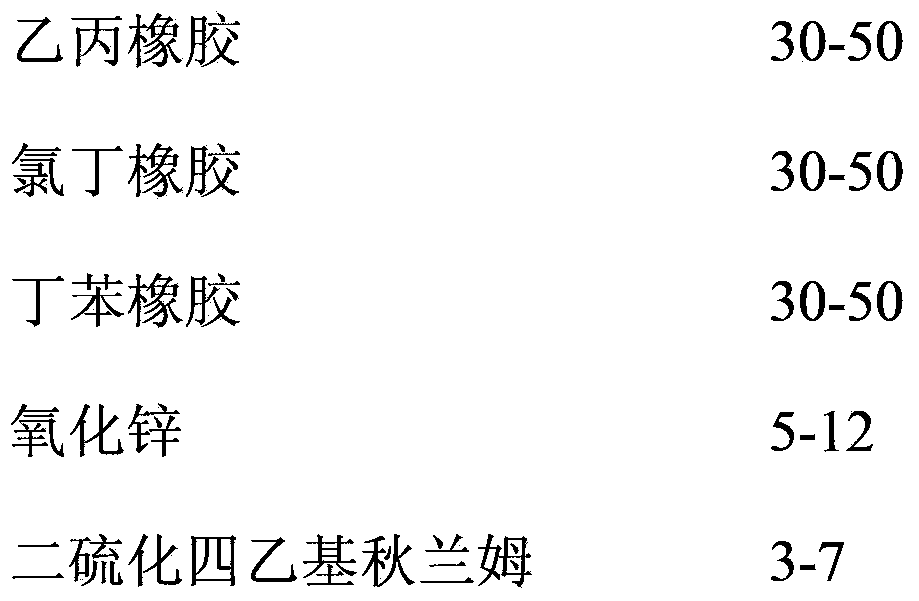

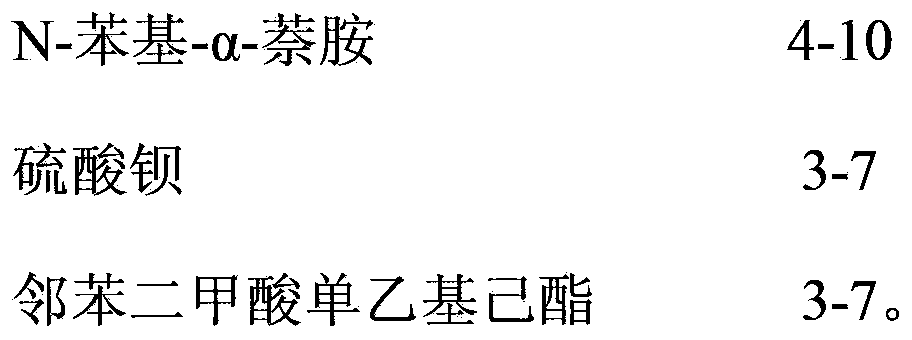

The invention discloses an acid and alkali resistant rubber gloves. The acid and alkali resistant rubber gloves comprise the raw materials by the weight fraction: 30-50 of ethylene propylene rubber, 30-50 of chloroprene rubber, 30-50 of styrene-butadiene rubber, 5-12 of zinc oxide, 3-7 of tetraethylthiuram disulfide, 4-10 of N-phenyl-alpha-naphthylamine, 3-7 of barium sulfate, and 3-7 of monoethylhexyl phthalate. With adopting of the specific rubber matrix and the specific additives, and with cooperation of specific contents, the prepared rubber gloves have excellent acid and alkali resistant performance, and can be applicable to long-term use in acid and alkali environments.

Owner:WUXI XINYA SAFETY PROD

Refractory wear-resistant plastic material

The invention discloses a refractory wear-resistant plastic material which comprises the following raw materials in parts by weight: 60-70 parts of nylon, 15-20 parts of nitrocellulose resin, 2-6 parts of zinc oxide, 14-20 parts of corundum fine powder, 9-13 parts of melamine cyanurate, 6-12 parts of silicon carbide, 3-7 parts of ammonium heptamolybdate, 12-25 parts of boron carbide, 23-29 parts of glass fibers, 12-23 parts of ceramic fibers, 23-27 parts of aluminum oxide, 1-3 parts of titanium dioxide, 3-7 parts of tetraethylthiuram disulfide, 4-10 parts of N-phenyl-alpha-naphthylamine, 3-7 parts of barium sulfate, 3-7 parts of mono-ethylhexyl phthalate, 0.5-2 parts of antimonous oxide, 2-5 parts of decabromodiphenyl ether, 1-5 parts of dimethyl silicone oil and 1-2 parts of diethyldithiocarbamic acid. The plastic material prepared by the invention has the characteristics that the smoke amount is low, smoke is purified, and no droplet combustion exists; a prepared plastic floor is difficult to deform and crack; refractory plastic is low in cost, long in service life and good in elasticity.

Owner:桐城市弘业塑胶有限公司

High-temperature-resistant wear-resistant anti-aging rubber material and preparation method thereof

InactiveCN109852067AImprove low temperature resistanceGood compatibilityPolymer scienceWear resistant

The invention provides a high-temperature-resistant wear-resistant anti-aging rubber material and a preparation method thereof, and relates to the technical field of rubber materials. The rubber material is prepared from the following raw materials, in parts by weight: 30-60 parts of silicone rubber, 10-20 parts of fluorine rubber, 5-15 parts of fluorosilicone rubber, 5-10 parts of stearic acid, 4-8 parts of magnesium hydroxide, 3-5 parts of tert-butyl peroxybenzoate, 1-2 parts of tetraethylthiuram disulfide, 3-5 parts of zinc oxide, 0.1-0.5 part of N-(cyclohexylthio)phthalimide, 3-5 parts ofliquid paraffin, 5-7 parts of di-tert-butyl-p-cresol, 4-6 parts of triethylene glycol di-2-ethylhexoate, 2-5 parts of dibutyltin dilaurate, 5-15 parts of chlorinated paraffin, 5-10 parts of sulfur, 15-20 parts of a filler, 5-10 parts of sepiolite fibers, 3-5 parts of copper powder, 3-8 parts of polytetrafluoroethylene, 0.5-0.9 part of an anti-aging agent, and 3-5 parts of a bacteriostatic agent. The preparation method of the high-temperature-resistant wear-resistant anti-aging rubber material includes the four steps of internal mixing, mixing, vulcanization, and injection molding. The rubber material provided by the invention has the characteristics of high-temperature resistance, wear resistance and aging resistance, and has the bacteriostatic and flame-retardant functions.

Owner:安徽省宁国宁阳量清模具科技有限公司

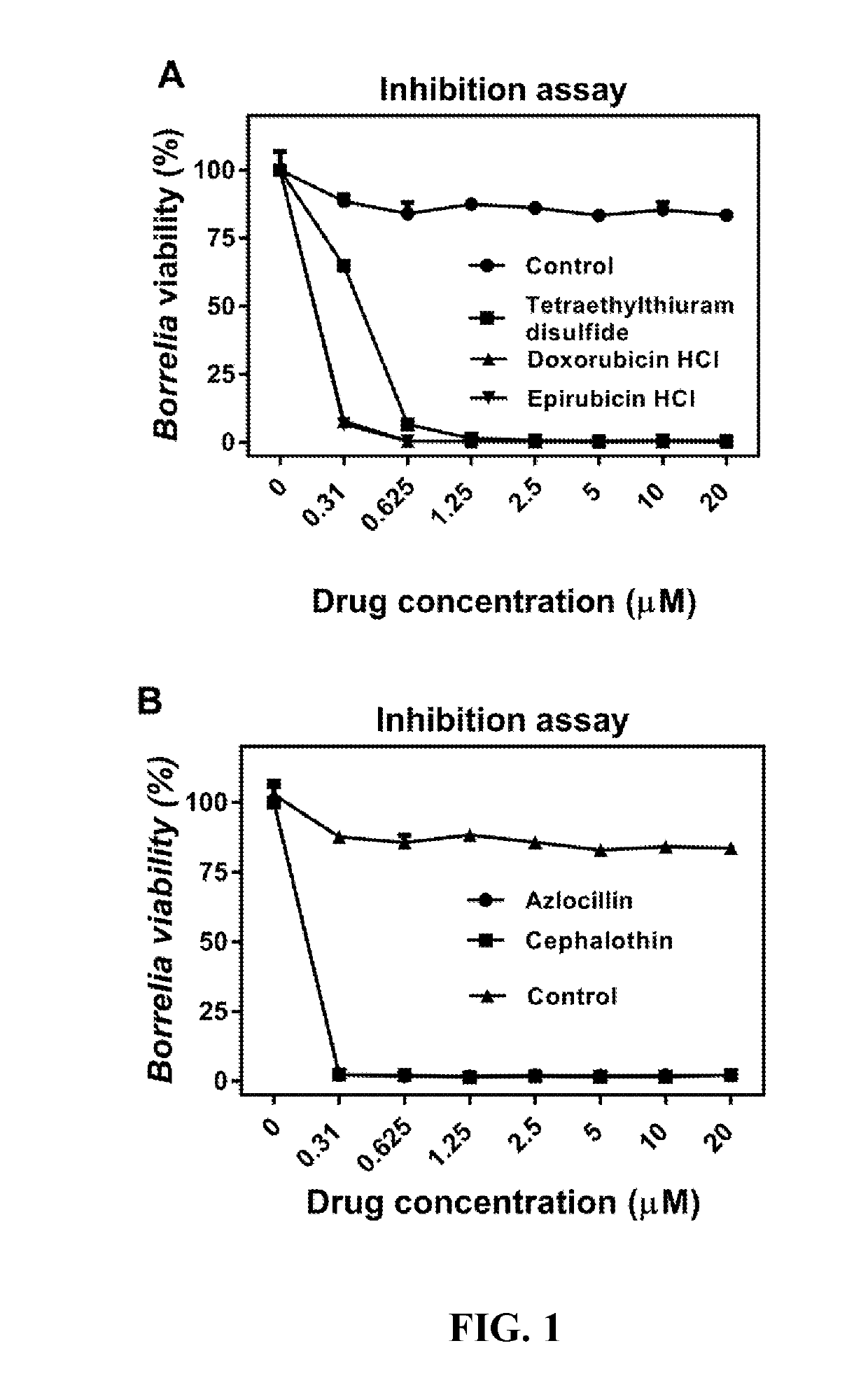

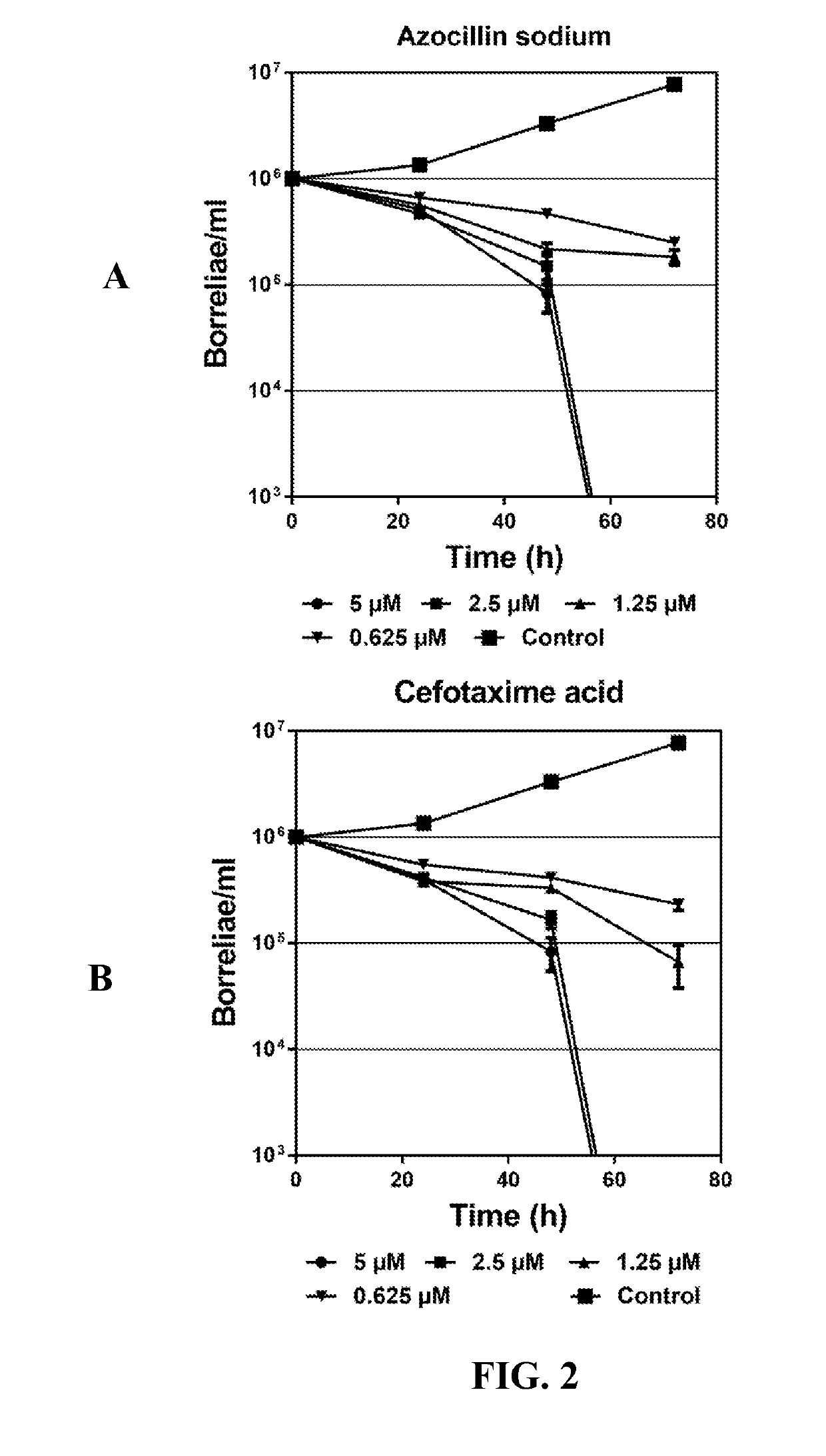

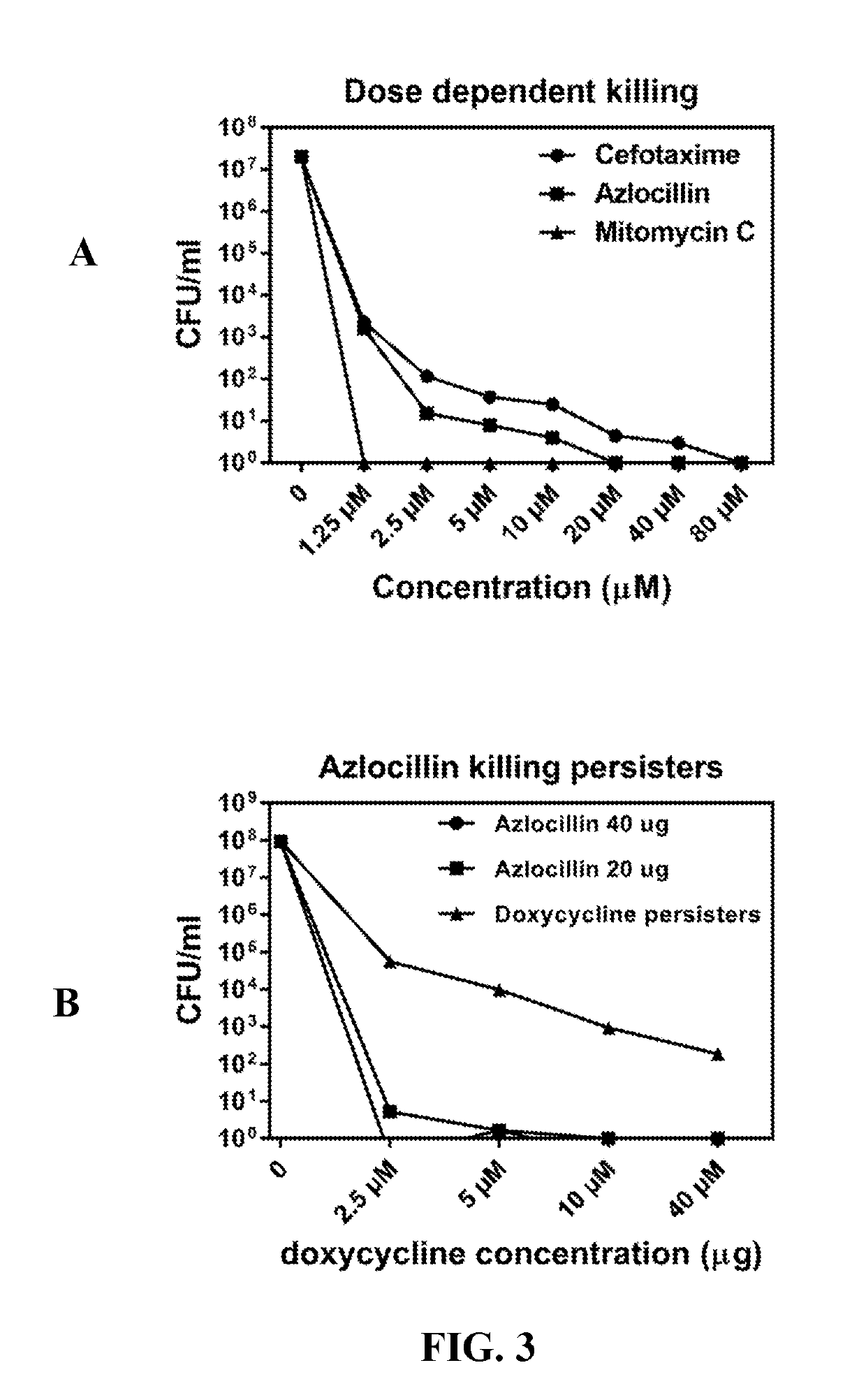

Methods and drug compositions for treating lyme disease

InactiveUS20190117630A1Antibacterial agentsHeterocyclic compound active ingredientsCefotaximeAzlocillin

Disclosed herein are methods and drug compositions for treating Lyme disease and post-treatment Lyme disease syndrome (PTLDS) or chronic Lyme disease (CLD). In one embodiment, a method of treating a subject with Lyme disease involves administering an effective amount of a therapeutic agent selected from the group consisting of tetraethylthiuram disulfide, doxorubicin, epirubicin, azlocillin, cephalothin, josamycin, cefotaxime, cefazolin, erythromycin, calcimycin, gramicidin, cefdinir, gambogic acid, ceftazidime, ticarcillin, valinomycin, moxifloxacin, linezolid, idarubicin, tosufloxacin, loratadine, ceftriaxone, and combinations thereof, and pharmaceutical salts, hydrates, and solvates thereof.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Method for granulating rubber vulcanization accelerator TETD (Tetraethylthiuram Disulfide)

InactiveCN102059074AReduce pulverization rateHigh granulation rate at one timeGranulation with special binding agentsParaffin waxVulcanization

The invention discloses a method for granulating a rubber vulcanization accelerator TETD (Tetraethylthiuram Disulfide), comprising the following steps of: (1) adding a cementing agent into a TETD wet material, sufficiently stirring, and adding into a granulator to ensure that the material is squeezed out from a machine head template hole to form even cylindrical granules through screw conveying; and (2) drying, separating by utilizing screen cloth and directly packaging the granular product to obtain an end product, wherein the TETD is an abbreviation of tetraethylthiuram disulfide and the cementing agent is made from the following constituents in parts by mass: 80-100 parts of polyvinyl alcohol, 80-100 parts of povidone, 70-90 parts of vinyl acetate, 40-50 parts of liquid paraffin, 1-5 parts of emulsifying agent, 0.5-1 part of polyoxyethylene, 0.1-0.5 part of NaHCO3 and 180-200 parts of water. By means of the method for granulating the rubber vulcanization accelerator TETD, the manpower and material resources are saved; the energy consumption is reduced; the once granulation rate of the product is high; the average hardness is about 2N and the quality index accords with the standard of a first-grade product in China.

Owner:KEMAI CHEM

High-wear-resisting type oil sealing material and preparation method thereof

The invention relates to the field of processing of rubber composite materials and in particular relates to a high-wear-resisting type oil sealing material and a preparation method thereof. The invention provides the high-wear-resisting type oil sealing material; preparation raw materials of the high-wear-resisting type oil sealing material at least comprise the following raw materials in parts byweight: 60 to 85 parts of acrylate rubber, 10 to 20 parts of fluororubber, 10 to 30 parts of white carbon black, 3 to 10 parts of carbon nanotubes, 1 to 3 parts of stearic acid, 1 to 3 parts of graphene, 3 to 6 parts of de-molding agent, 8 to 15 parts of antioxidant, 0.5 to 1 part of 2,2-dithiobisbenzothiazole, 1 to 1.5 parts of tetraethylthiuram disulfide and 1 to 3 parts of dispersant.

Owner:RIZHAO DONGDU RUBBER & PLASTIC PROD

Preparation process of rubber damping pad of generator

InactiveCN108276620AModerate hardnessLittle change in hardnessHexafluoropropyleneChlorinated paraffins

The invention relates to a preparation process of a rubber damping pad of a generator. The rubber damping pad of the generator consists of the following components in parts by weight: 70-80 parts of natural rubber, 10-20 parts of ethylene propylene diene monomer rubber, 10-20 parts of a tetrafluoroethylene-hexafluoropropylene copolymer, 6-10 parts of boron fibers, 6-10 parts of zinc oxide, 1-3 parts of stearic acid, 2-6 parts of an anti-aging agent RD, 11-15 parts of white carbon black, 11-15 parts of attapulgite, 30-40 parts of light calcium carbonate, 6-10 parts of chlorinated paraffin, 20-30 parts of liquid coumarone, 1-3 parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 2-8 parts of a silane coupling agent, 0.1-0.7 part of tetramethylthiuram disulfide and 0.1-0.5 part of tetraethylthiuram disulfide. The rubber damping pad has the advantages that the rubber damping pad of the generator is prepared through the preparation process provided by the invention, the high-temperature-resistant performance is excellent, the damping effect is good, and the elastic property is good.

Owner:江苏金泽重机集团有限公司

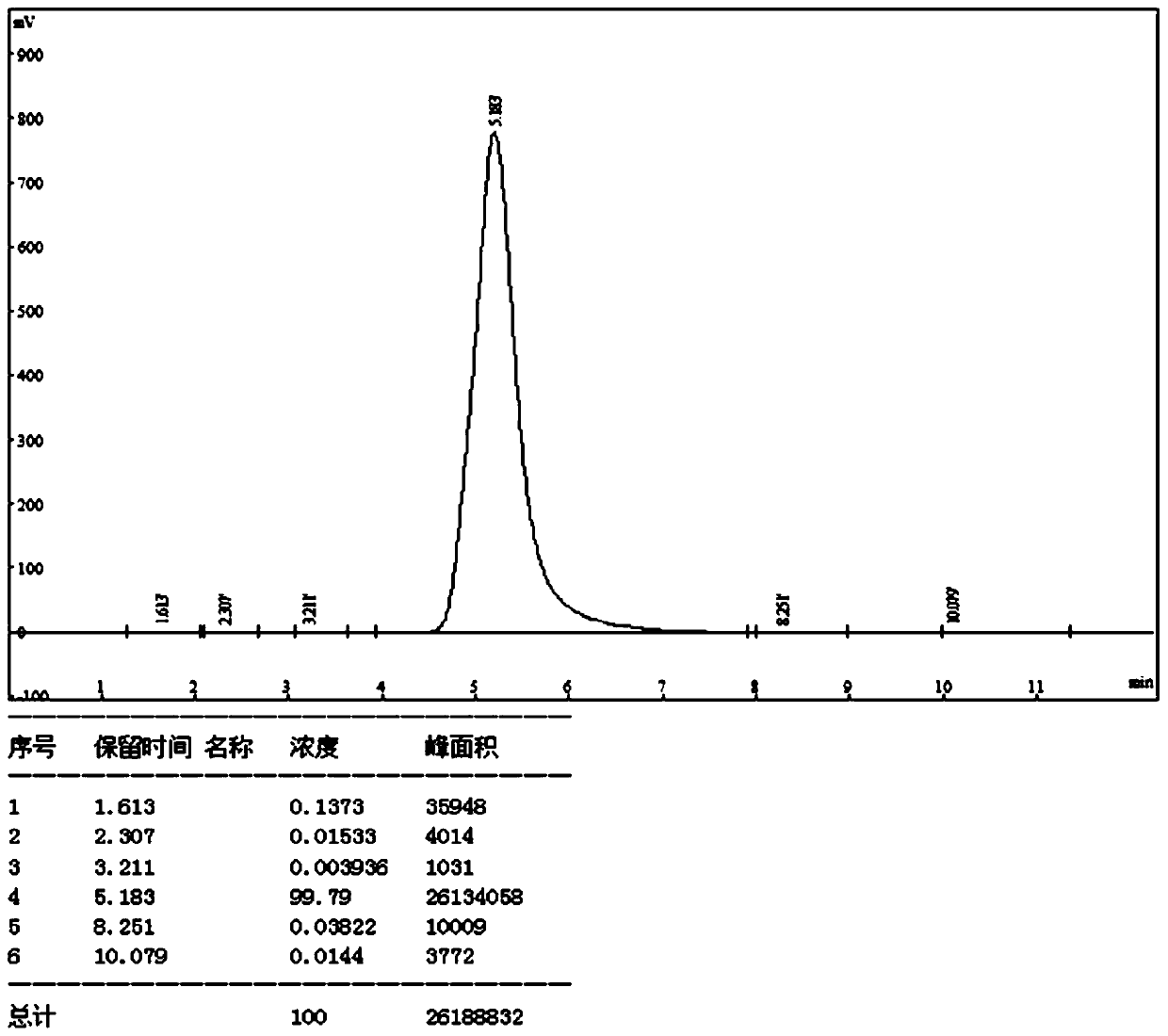

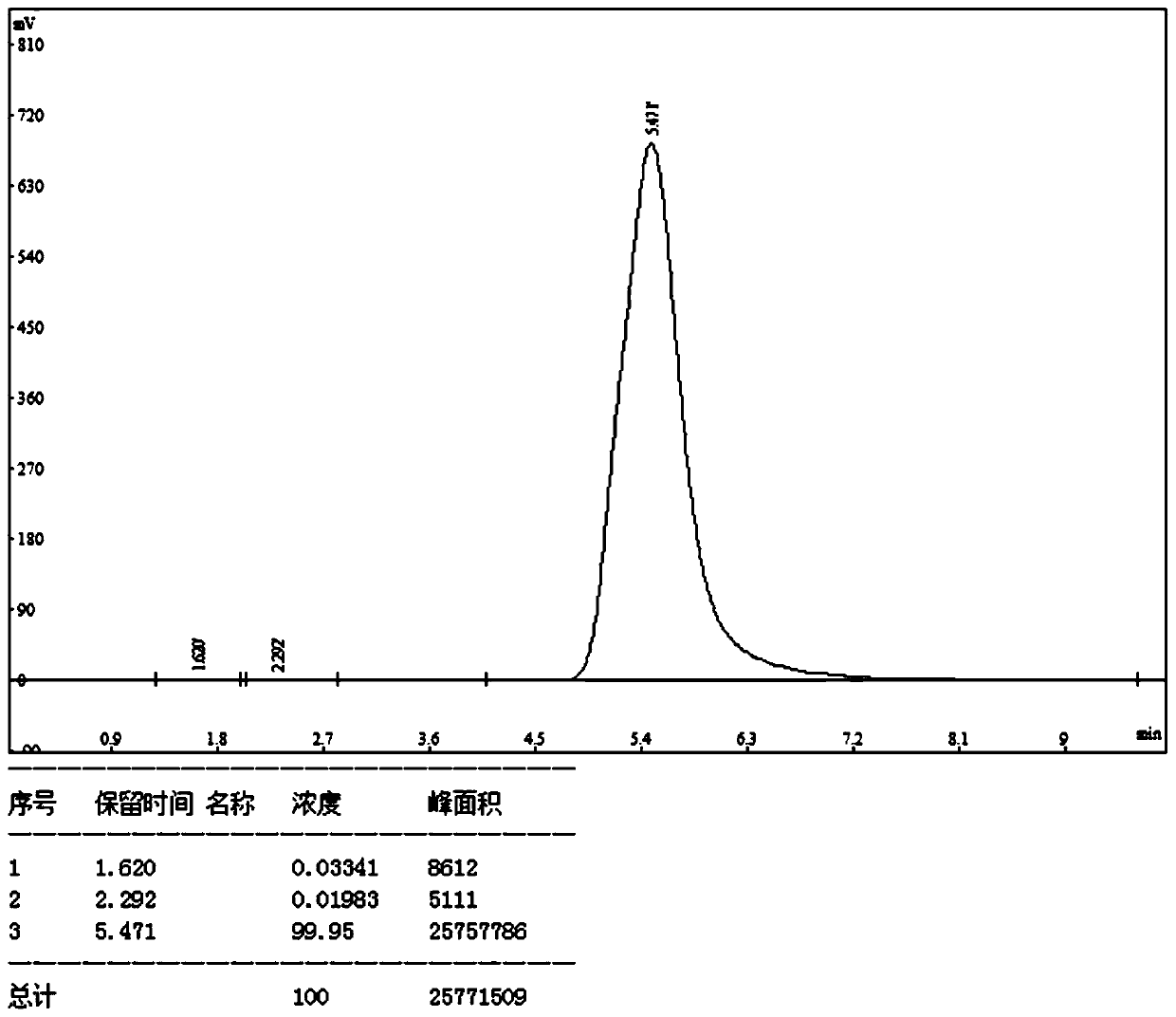

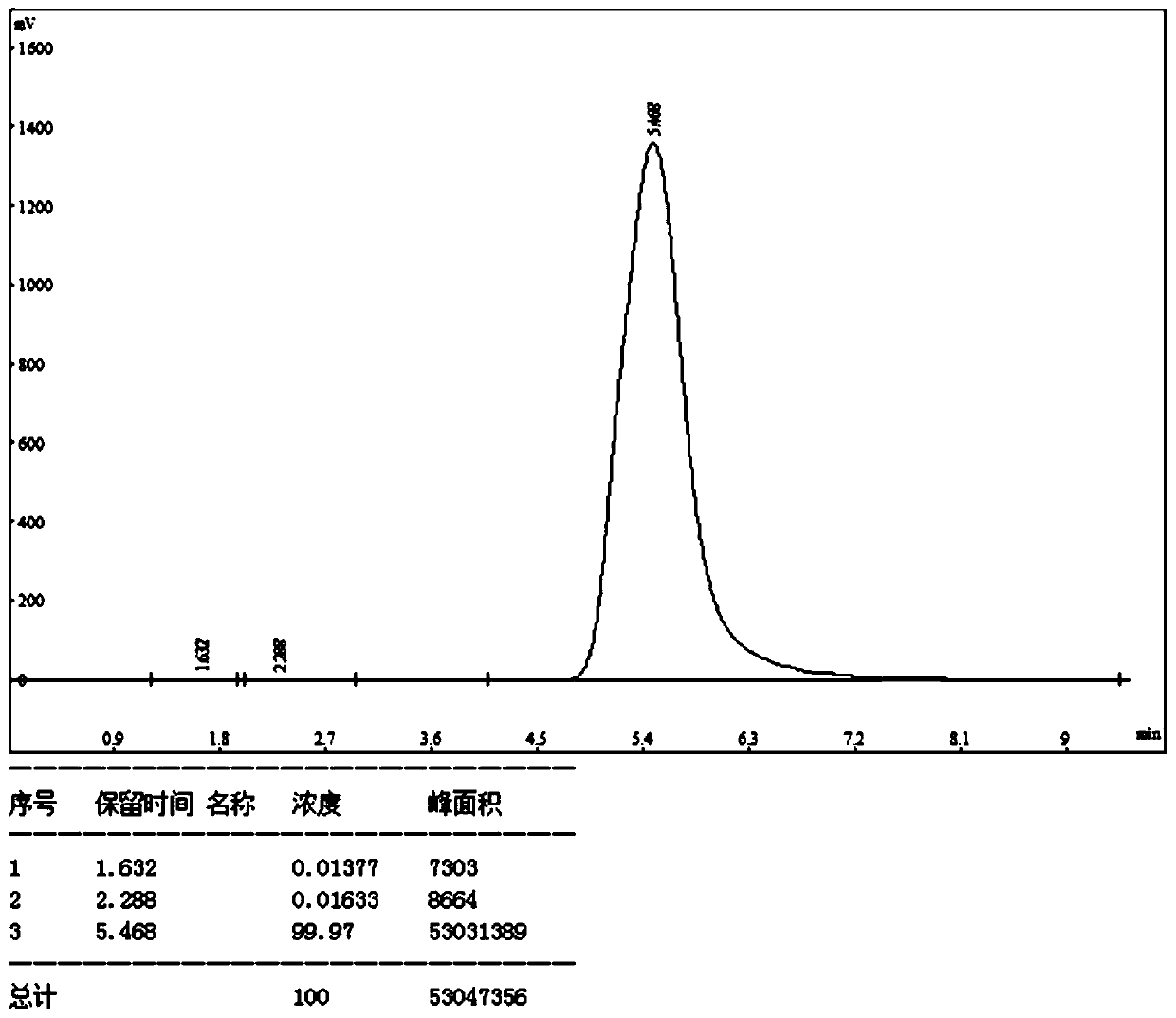

The preparation method of tetraethylthiuram disulfide

The present invention relates to the field of rubber additives, specifically, it provides a preparation method of tetraethylthiuram disulfide, the reaction raw materials diethylamine, carbon disulfide and hydrogen peroxide are reacted under the action of a bimetallic catalyst to obtain the Tetraethylthiuram disulfide. The above method uses a bimetallic catalyst to promote efficient and continuous reaction, increase the conversion rate of raw materials, make condensation reaction and oxidation reaction easier to carry out, thereby increasing the yield of products. The method is simple and convenient to operate, can greatly increase the yield of products, reduce production costs, there is no "three wastes" discharge during the preparation process, the mother liquor can be reused, and there is no pollution to the environment. At the same time, the prepared products have stable quality and high purity. , the composition is uniform, and this method can be applied in large-scale production practice.

Owner:WILLING NEW MATERIALS TECH CO LTD

Alloy material for plastic valve and preparation method of alloy material

The invention discloses an alloy material for a plastic valve. The alloy material is characterized by comprising components in parts by mass as follows: butadiene styrene rubber, a tertiary fluoro emulsion, etherified melamine resin, polybutylene terephthalate, coal ash, zirconia ceramic micro powder, boron silicide, cobaltic yttrium glycinemethane dithioate, tetraethylthiuram disulfide, trichloropropylphosphate, carbon fibers, 350-mesh iron powder, an antioxidant and isopropyl tri(dioctylpyrophosphate) titanate. The invention further discloses a preparation method of the alloy material for the plastic valve. A test result show that the prepared alloy material for the plastic valve has higher compression strength and good wear resistance, the preparation process is simple, the cost is low, and the alloy material is suitable for industrial production.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

Heat-conducting composite plastic with insulating function

InactiveCN106317751AEnhanced interactionImprove thermal conductivityDecabromodiphenyl etherDiethyldithiocarbamic Acid

The invention discloses heat-conducting composite plastic with an insulating function. The heat-conducting composite plastic is prepared from, by weight, 60-70 parts of ABS resin, 15-20 parts of BPS resin, 2-6 parts of alum, 14-20 parts of magnesium hypophosphite, 9-13 parts of melaMine cyanurate, 6-12 parts of silicon carbide, 3-7 parts of ammonium heptamolybdate, 2-9 parts of magnesium stearate, 12-25 parts of ethyl 3-ethoxypropionate, 1-3 parts of lactic acid, 23-29 parts of glass fibers, 12-23 parts of ceramic fibers, 23-27 parts of aluminum oxide, 1-3 parts of titanium dioxide, 3-7 parts of tetraethylthiuram disulfide, 4-10 parts of N-phenyl-alpha-naphthylamine, 3-7 parts of barium sulfate, 3-7 parts of phthalic acid ethyl caproic ester, 0.5-2 parts of antimonous oxide, 2-5 parts of decabromodiphenyl ether, 1-5 parts of simethicone and 1-2 parts of diethyldithiocarbamic acid. Unique molecular design is adopted, interaction force between thermoplastic plastic and filler is increased, a heat channel is formed through high-efficiency contact between the filler, and thermal conductivity is greatly improved.

Owner:桐城市弘业塑胶有限公司

Method for preparing medical fatigue-resistant plastic

InactiveCN108822479ADoes not cause necrosisImprove fatigue strengthEscherichia coliUltraviolet lights

The invention discloses a method for preparing a medical fatigue-resistant plastic. The medical fatigue-resistant plastic comprises the following raw materials: ABS (Acrylonitrile Butadiene Styrene),diethylene glycol, epoxy tetrahydro-o-calcium stearate, alpha-chlorine-ethyl hexyl acrylate, zinc-carrying antibacterial master batch, borate, calcium stearate, an iron fiber, triphenyl phosphate, anantioxidant DNP (Dinonyl Phthalate), tetraethylthiuram disulfide, potassium nitrate, expanded perlite, barite, silicon carbide and an ultraviolet light absorber. After being used for 250-300 thousandhours, the medical fatigue-resistant plastic is high in fatigue resistance, has an elastic modus of 2-3 GPa, has an escherichia coli antibacterial rate of 99-99.5%, has a staphylococcus aureus antibacterial rate of 98.8-99.2%, has a pseudomonas aeruginosa antibacterial rate of 98-99%, has a salmonella typhimurium antibacterial rate of 93-97%, has a klebsiella pneumonia antibacterial rate of 94-98%, has a bacillus subtilis antibacterial rate of 97-99% and has a sarcina antibacterial rate of 94-96%.

Owner:SUZHOU JONATHAN NEW MATERIALS TECH

Special shock-absorption and buffering rubber jacket for motorcycle and preparation method of special shock-absorption and buffering rubber jacket

The invention belongs to the technical field of rubber products, mainly relates to a shock-absorption and buffering rubber jacket with rubber and metal heat vulcanization adhesiveness and a preparation method of the shock-absorption and buffering rubber jacket and discloses a special shock-absorption and buffering rubber jacket for a motorcycle. The rubber jacket is prepared from components in parts by weight as follows: 100 parts of styrene-butadiene rubber, 60-70 parts of carbon black, 1.5-2.5 parts of a processing aid, 6.5 parts of an anti-aging agent, 3.1-3.7 parts of an accelerant, 0.5-0.6 parts of sulfur, 4-5 parts of zinc oxide and 1.5 parts of stearic acid, wherein the processing aid is prepared from 1.0-1.5 parts of AT-B and 0.5-1.0 part of TM-80, the anti-aging agent is preparedfrom 2.5 parts of 4010, 2.0 parts of 4020 and 2.0 parts of RD, and the accelerant is prepared from 0.7-0.9 parts of TMTD (tetramethyl thiuram disulfide), 0.6-0.8 parts of TETD (tetraethylthiuram disulfide), 0.5-0.6 parts of DTDM and 1.3-1.4 parts of CZ. In order to solve problems in the prior art and improve the heat vulcanization adhesiveness of the special shock-absorption and buffering rubber jacket for the motorcycle, the special shock-absorption and buffering rubber jacket which is ozone-resistant, weather-resistant and good in warping strength for the motorcycle is provided.

Owner:重庆辉盛汽车零部件有限公司

Oil-resisting heat-resisting seal piece size and preparation method thereof

The invention discloses an oil-resisting heat-resisting seal piece size and a preparation method thereof. The oil-resisting heat-resisting seal piece size comprises the following raw material components in parts by weight: 75-85 of NBR (nitrile-butadiene rubber) 3606, 75-85 of NBR 2707, 0.7-0.9 of sulphur, 3-4 of magnesium oxide, 7-9 of zinc oxide, 1-2 of zinc stearate, 2-4 of antiager RD, 1-2 of antiager MB, 1.5-1.7 of microcrystal wax, 1.7-1.9 of rubber processing agent WB, 95-105 of carbon black N550, 48-52 of carbon black N330, 55-65 of dioctyl ester, 2.3-2.5 of accelerating agent DM, 1.5-1.7 of accelerating agent TMTD (tetramethyl thiuram disulfide) and 1.5-1.7 of accelerating agent TETD (tetraethylthiuram disulfide). The rubber size formula disclosed by the invention is rapid in vulcanizing speed; the obtained size is good in other comprehensive performances; and an oil-resisting seal piece produced by using the size is good in oil resistance and heat resistance and good in gas tightness, and simultaneously, production cost is reduced, and production efficiency is improved.

Owner:CGP WUHU SEALING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com