Environmentally friendly oil seal material and preparation method thereof

An environmentally friendly, oil-sealed technology, applied in the field of rubber composite material processing, can solve the problems of acid and alkali resistance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] In a preferred embodiment, the preparation method of said acrylate-ethylene glycol dimethacrylate-hyperbranched polyacrylate copolymer comprises the following steps at least:

[0049]Add the corresponding weight parts of the monomer and solvent ethanol into the reaction kettle, stir evenly, and add the initiator potassium persulfate to the reaction system, then raise the reaction temperature to 80°C, and carry out the stirring reaction for 5-10 hours to obtain acrylic acid Ester-ethylene glycol dimethacrylate-hyperbranched polyacrylate copolymer.

[0050] In the present application, the white carbon black can be obtained commercially. The white carbon black in this application is commercially available, and the product brand is Degussa AEROSIL R106;

[0051] In the present application, the carbon nanotubes can be obtained commercially.

[0052] In a preferred embodiment, the carbon nanotubes are carboxylated carbon nanotubes; the carboxylated carbon nanotubes are purc...

Embodiment 1

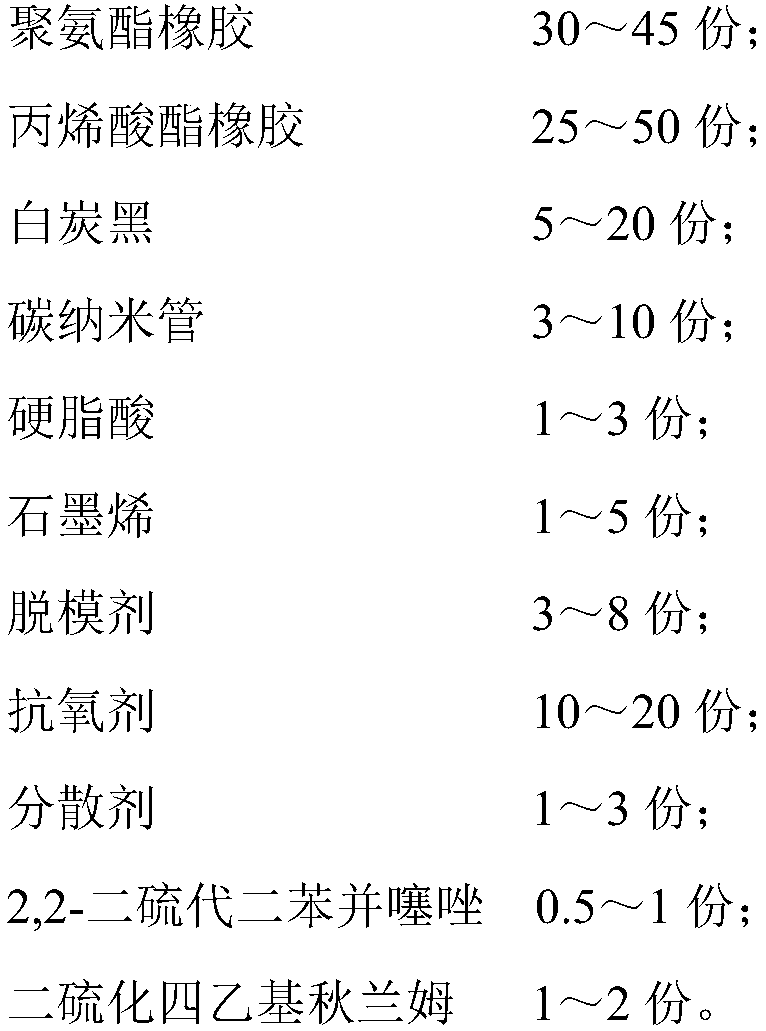

[0074] Embodiment 1 of the present invention provides an environment-friendly oil seal material. The raw materials for the preparation of the environment-friendly oil seal material include at least the following materials in parts by weight:

[0075]

[0076] The polyurethane rubber is thermoplastic polyurethane elastomer rubber; the product grade is: TPU-S85A15.

[0077] Described acrylate rubber is acrylate-ethylene glycol dimethacrylate-hyperbranched polyacrylate copolymer;

[0078] In the acrylate-ethylene glycol dimethacrylate-hyperbranched polyacrylate copolymer, the weight ratio between acrylate, ethylene glycol dimethacrylate, and hyperbranched polyacrylate is 100:20: 3;

[0079] Both the acrylate and ethylene glycol dimethacrylate are commercially available. Hyperbranched polyacrylate was purchased from Xibao Biology, the product brand is SeHBP UV208;

[0080] The preparation method of described acrylate-ethylene glycol dimethacrylate-hyperbranched polyacrylate ...

Embodiment 2

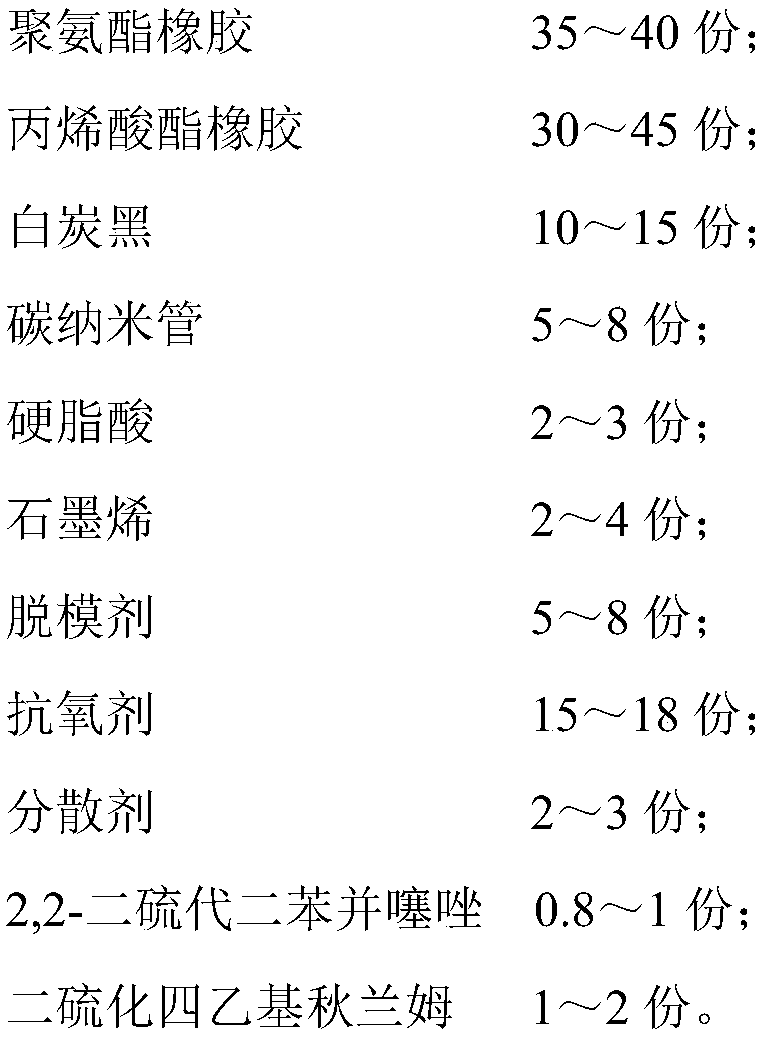

[0097] Embodiment 2 of the present invention provides an environment-friendly oil seal material. The raw materials for the preparation of the environment-friendly oil seal material include at least the following materials in parts by weight:

[0098]

[0099]

[0100] The polyurethane rubber is thermoplastic polyurethane elastomer rubber; the product grade is: TPU-S85A15.

[0101] Described acrylate rubber is acrylate-ethylene glycol dimethacrylate-hyperbranched polyacrylate copolymer;

[0102] In the acrylate-ethylene glycol dimethacrylate-hyperbranched polyacrylate copolymer, the weight ratio between acrylate, ethylene glycol dimethacrylate, and hyperbranched polyacrylate is 100:20: 3;

[0103] Both the acrylate and ethylene glycol dimethacrylate are commercially available. Hyperbranched polyacrylate was purchased from Xibao Biology, the product brand is SeHBP UV208;

[0104] The preparation method of described acrylate-ethylene glycol dimethacrylate-hyperbranched p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com