Patents

Literature

38results about How to "Excellent halogen-free flame retardant performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Styrene-based non-halogen flame-retardant injection-grade wood-plastic composite material and preparation method thereof

ActiveCN101864118AImprove liquidityGive full play to the flame retardant effectBuilding productHalogen

The invention discloses a styrene-based non-halogen flame-retardant injection-grade wood-plastic composite material and a preparation method thereof. The wood-plastic composite material comprises the following components by mass percentage: 25% to 60% of styrene-based resin, 5% to 50% of vegetable fiber, 0.5% to 20% of compatibilizer, 0% to 30% of toughener, 0.5% to 8% of dispersant, 5% to 40% offlame retardant and flame-retardant synergist and 0% to 1% of antioxidant. Compared with the existing wood-plastic composite material, the styrene-based non-halogen flame-retardant injection-grade wood-plastic composite material prepared by the invention has the characteristics of simple production procedure, lower flame-retardant consumption, good non-halogen flame-retardant effect and wide range of forming manners. Therefore, the invention is suitable for various injection-molded parts, such as the housing of electrical products, furnishings, automobile materials, artworks, complex-structured building products and the like.

Owner:KINGFA SCI & TECH CO LTD +2

Styrene series non-halogen flame retardant injection-grade wood plastic composite and preparation method thereof

The invention discloses a styrene series non-halogen flame retardant injection-grade wood plastic composite and a preparation method thereof. The styrene series non-halogen flame retardant injection-grade wood plastic composite is prepared from the following components in percentage by mass: 25-60 percent of styrene series resin, 5-60 percent of plant fiber, 0.5-20 percent of compatilizer, 0-30 percent of flexibilizer, 0.5-8 percent of dispersing agent, 5-40 percent of fire retardant and synergetic fire retardant and 0-1 percent of antioxidant. Compared with the traditional wood plastic composite, the styrene series non-halogen flame retardant injection-grade wood plastic composite prepared by the invention has the characteristics of simple production flow, less consumption amount of fireretardant, good non-halogen flame retardant effect, wide range of moulding ways, and the like, and is suitable for various injection moulded parts such as shells of electric appliances, parts for vehicles, and parts for furniture and buildings, and the like.

Owner:GUANGDONG KINGFA TECH CO LTD

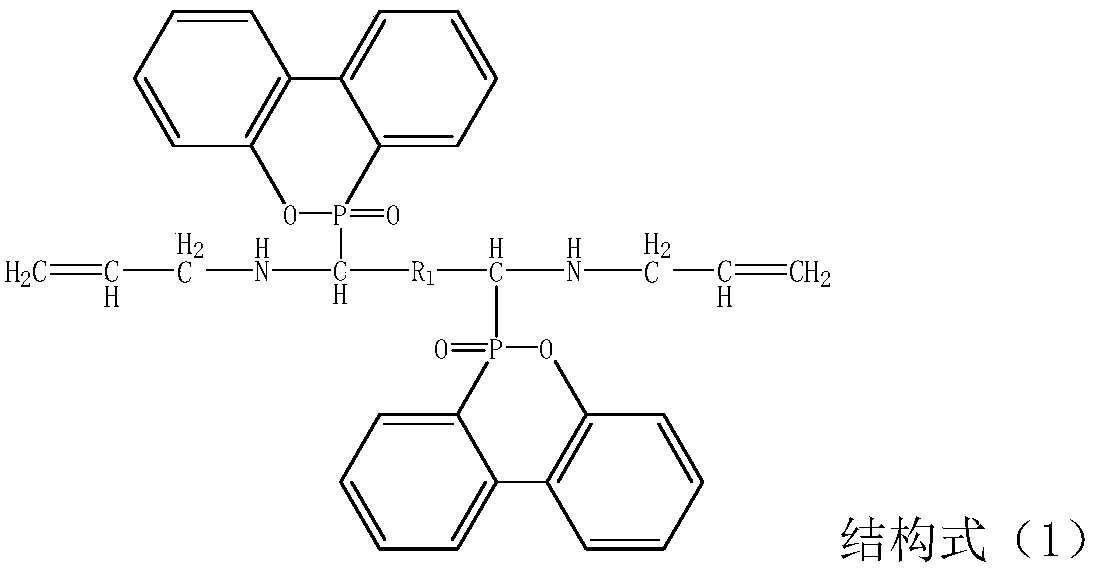

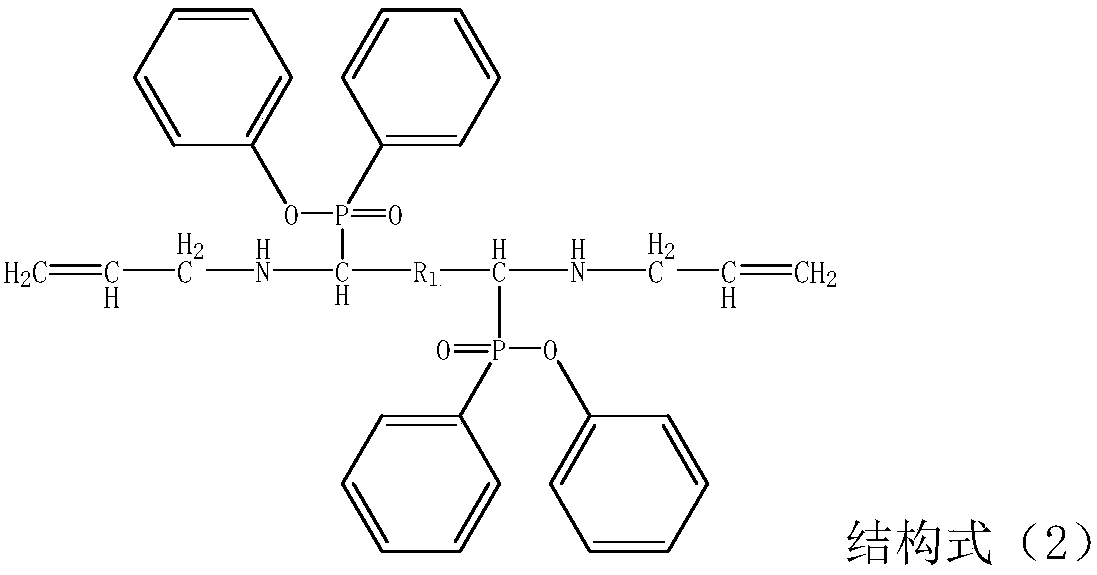

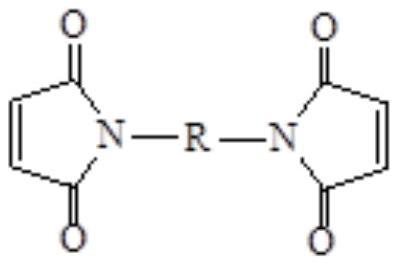

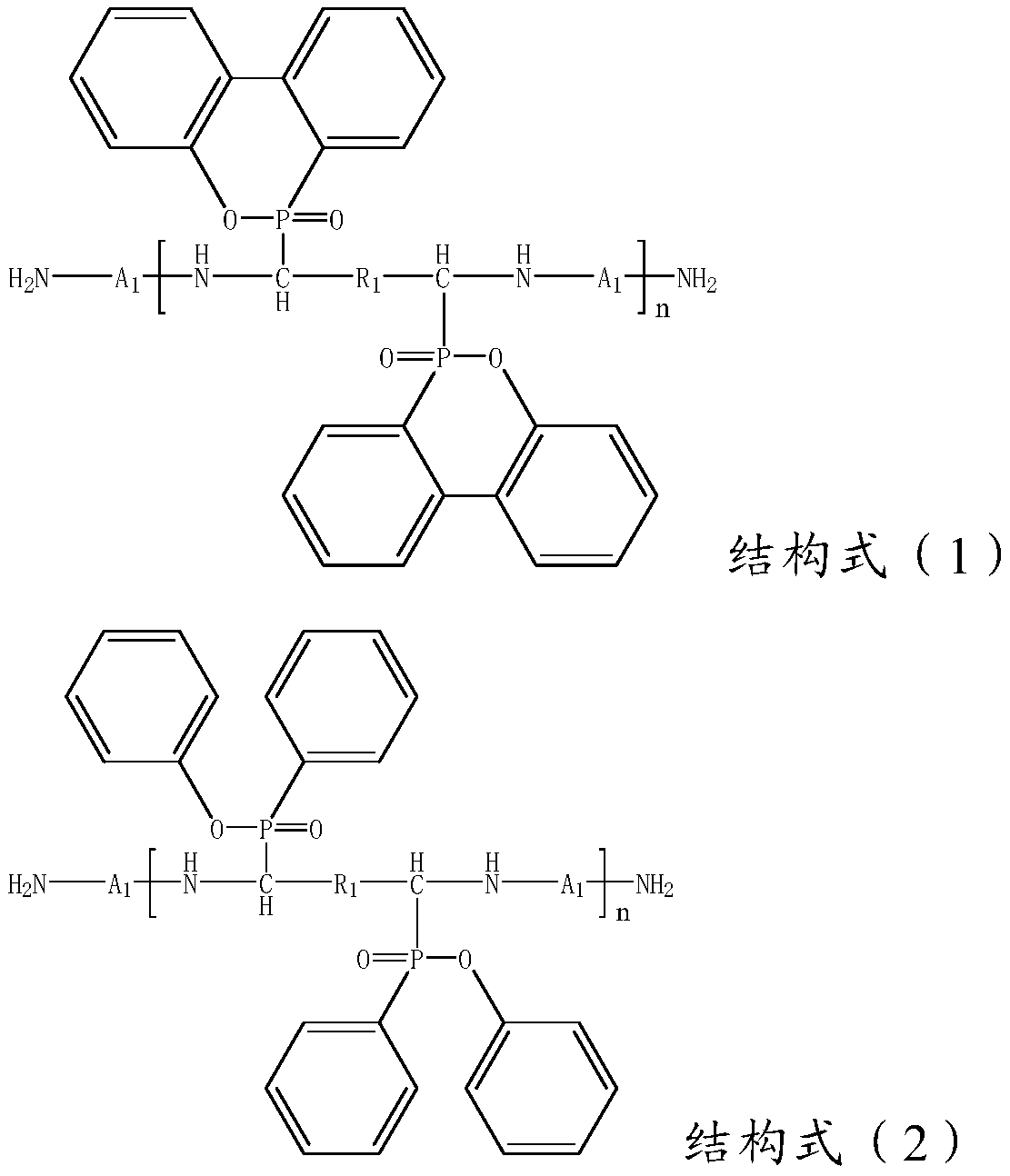

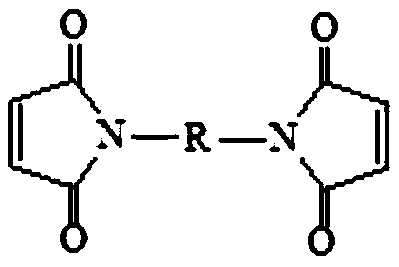

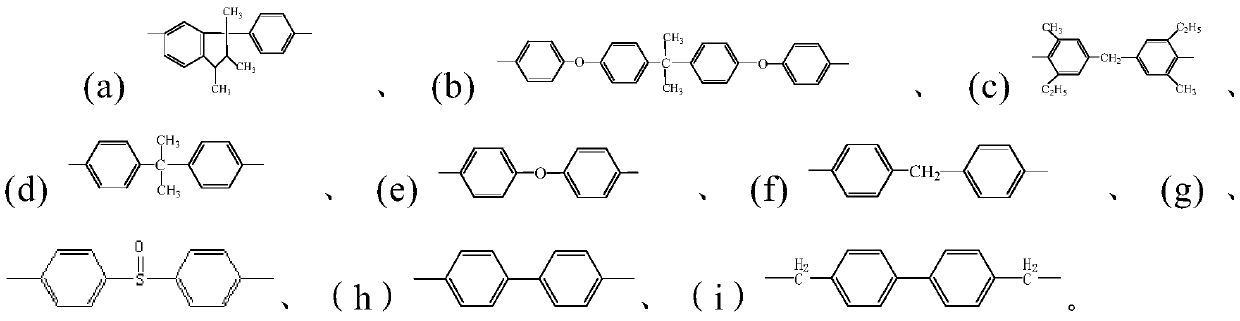

Flame-retardant resin composition and prepreg and laminate prepared using same

ActiveCN109535715AReduced flame retardancyExcellent halogen-free flame retardant performanceSynthetic resin layered productsLaminationEpoxyHydrogen

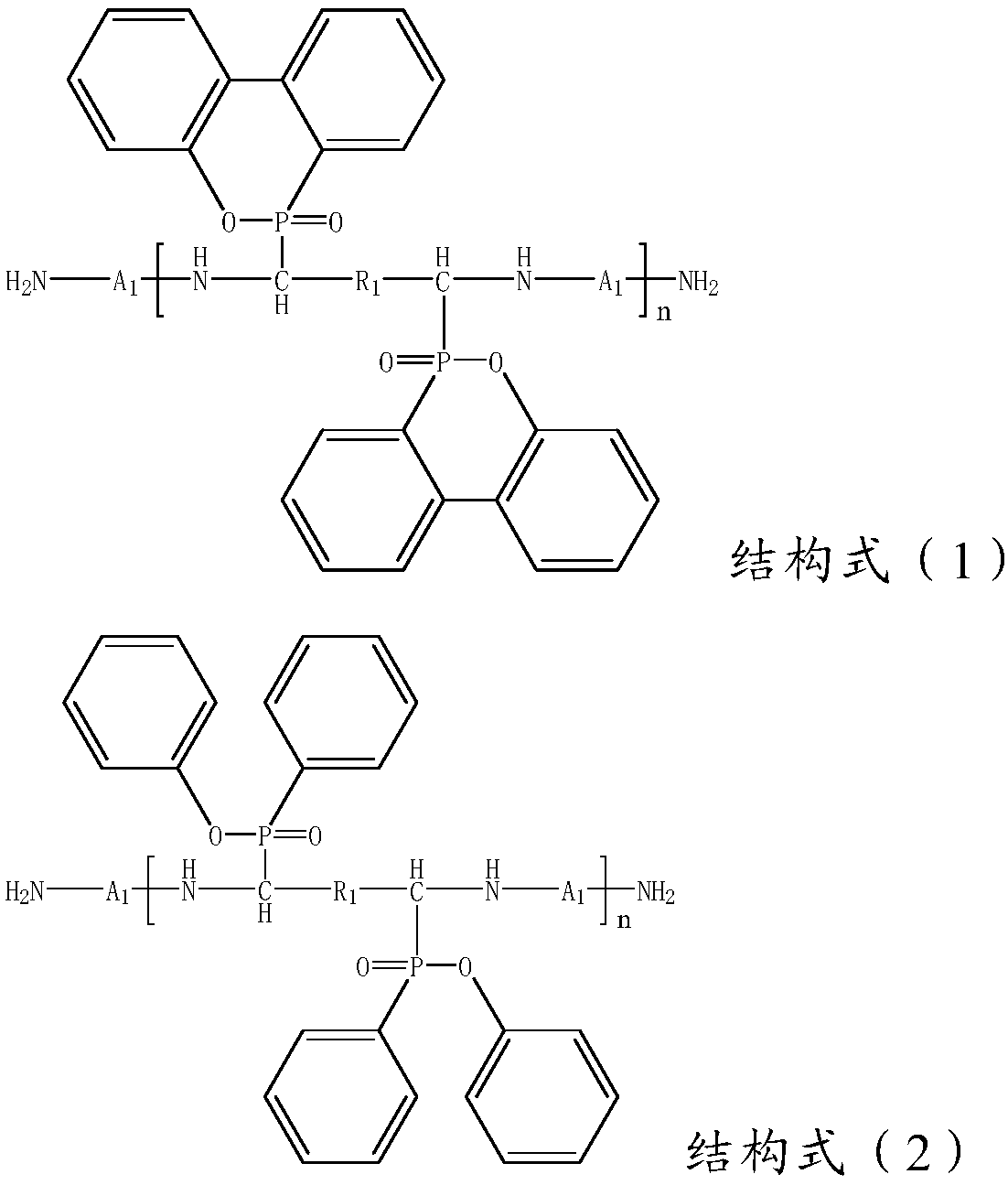

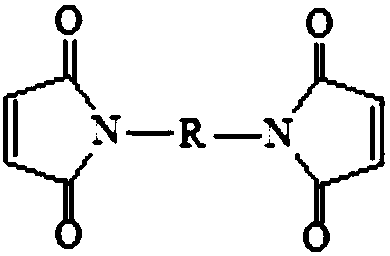

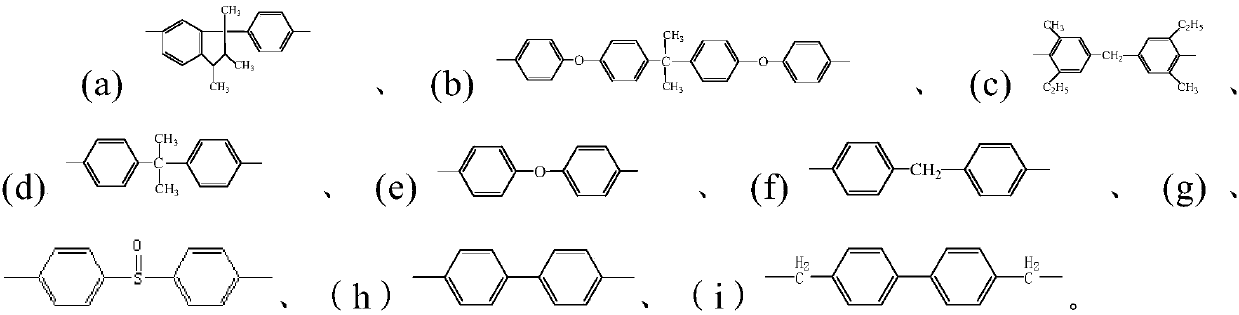

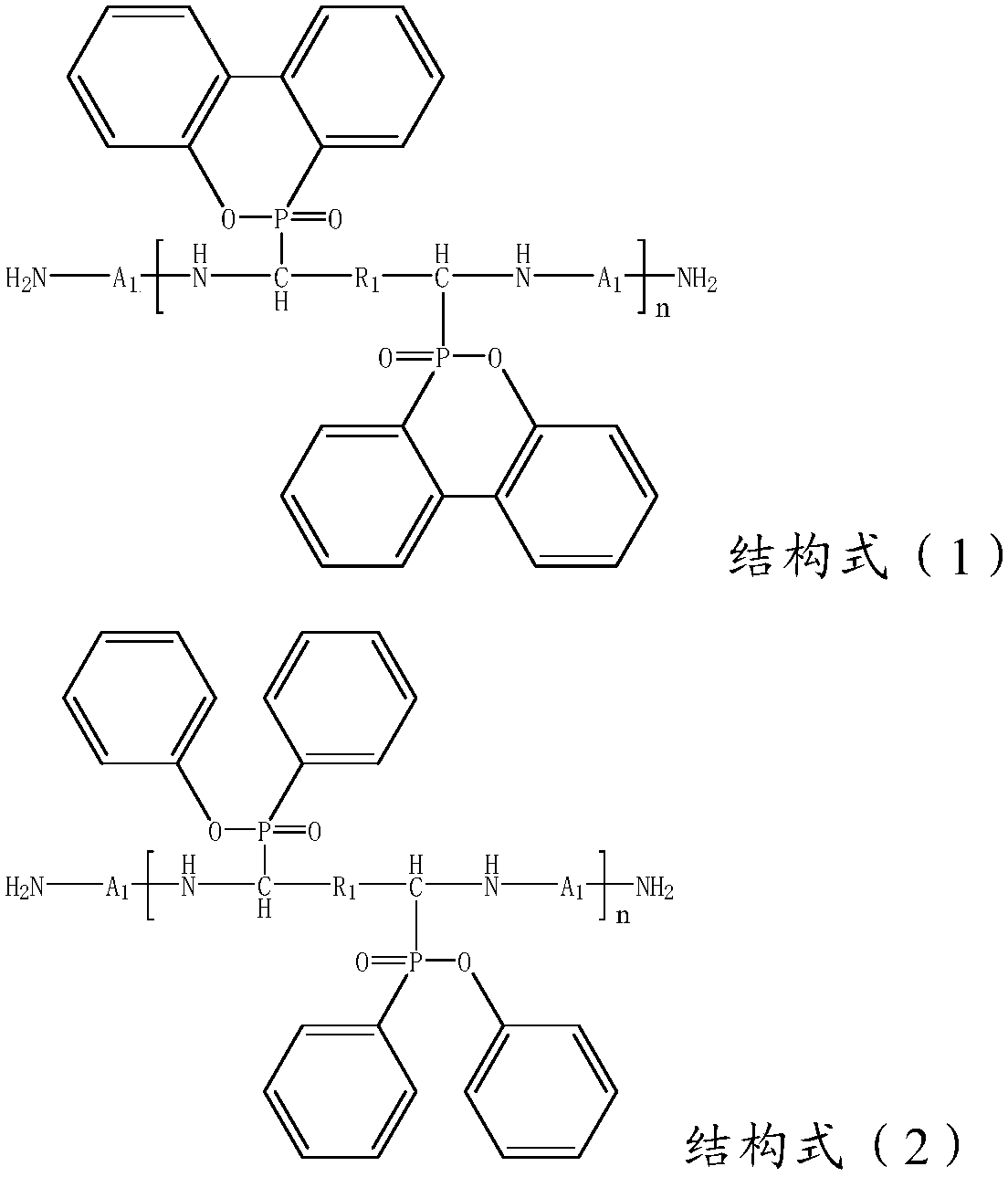

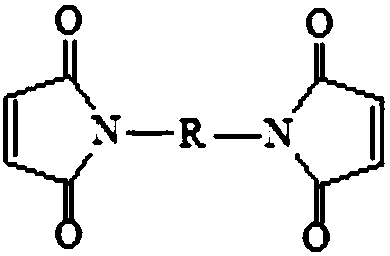

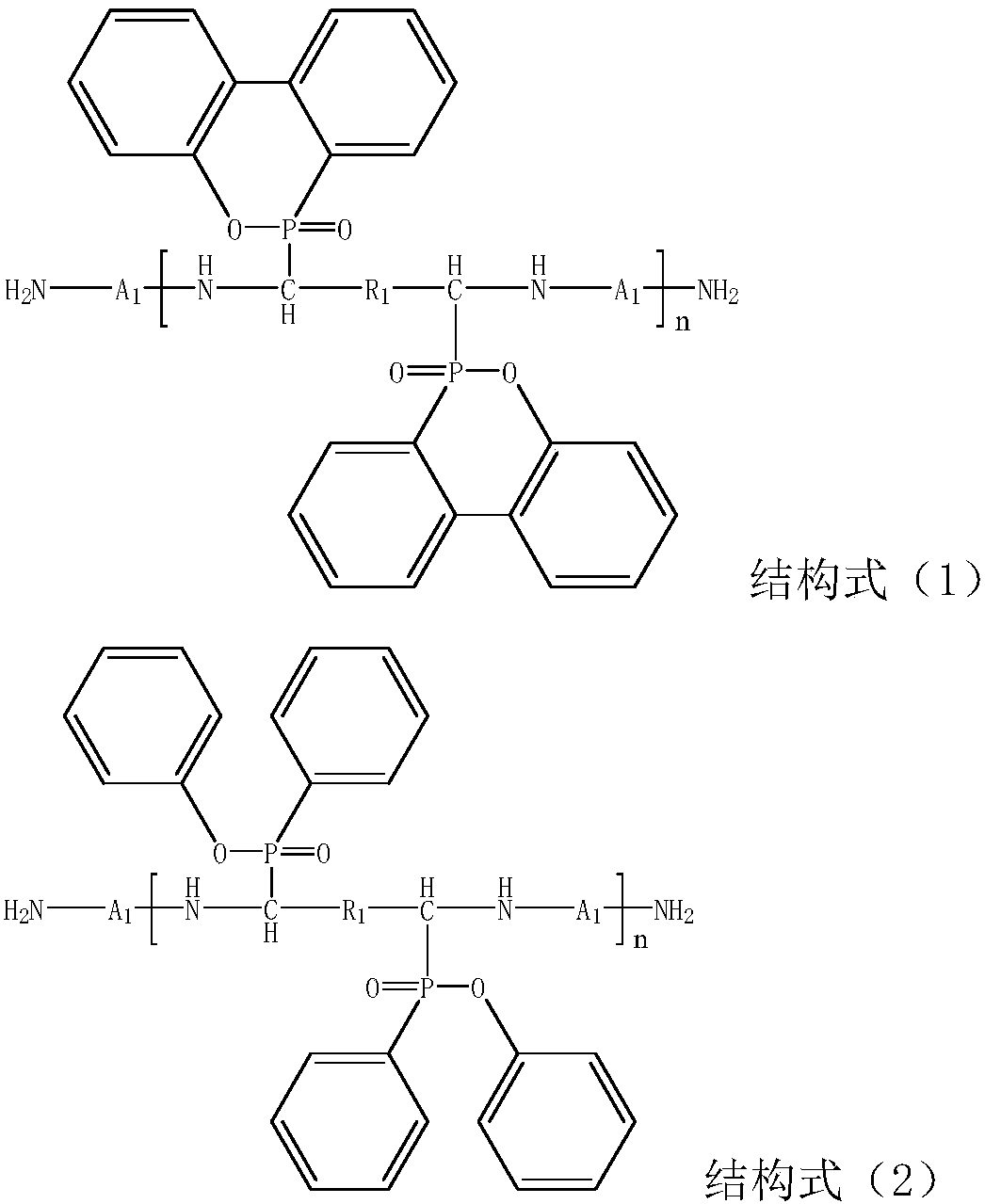

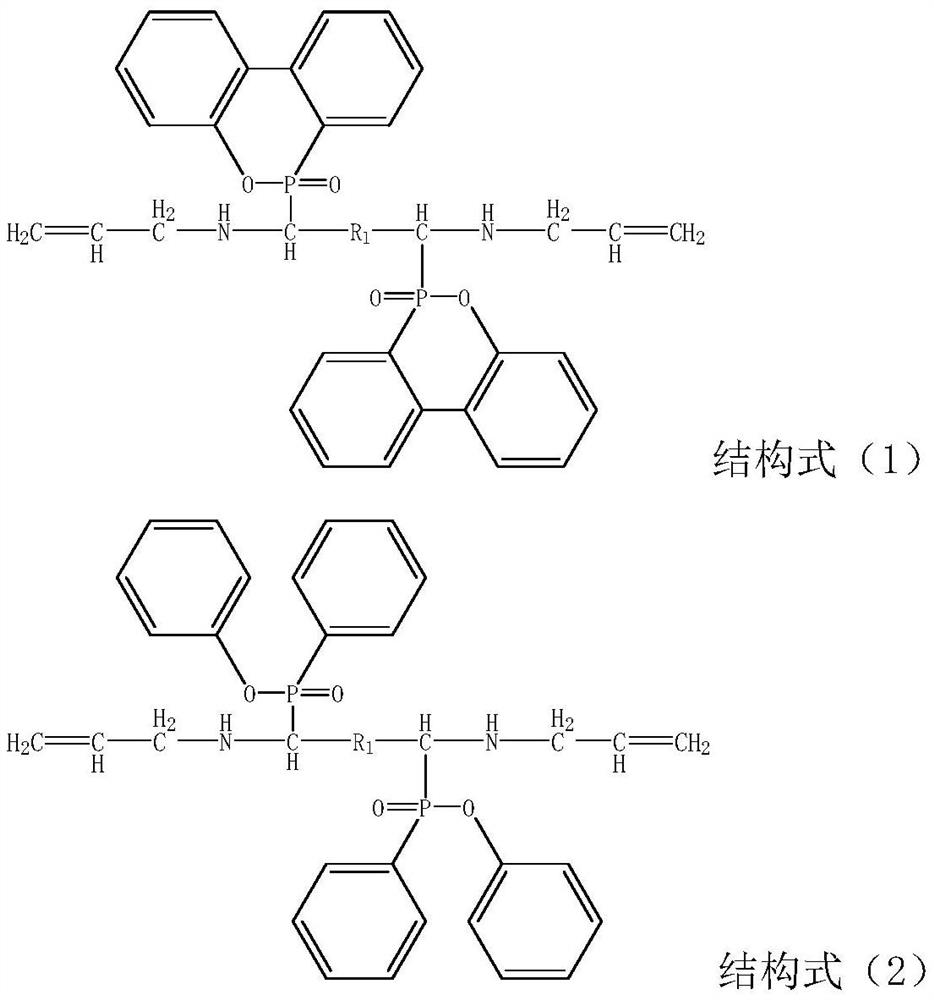

The invention discloses a flame-retardant resin composition, which comprises the following components by solid weight: 100 parts by weight of a modified bismaleimide prepolymer; 5-30 parts of epoxy resin; 0-20 parts of a curing agent, 0-150 parts of a filler; 0.001-5 parts of a curing accelerator; wherein the modified bismaleimide prepolymer is at least prepolymerized by bismaleimide resin and anamine compound. Compared with the prior art, a DOPO or DPPO-containing amine compound reacts not only with the bismaleimide, but also with the active hydrogen of -NH- in the structure reacts and the epoxy group, so that a small amount of epoxy resin and the curing agent are added to obtain a final cured product having high heat resistance and high modulus, the high-performance print circuit boardrequirements such as HDI multilayer substrates and ultra-thin package substrates can be satisfied, and a small amount of epoxy resin and the curing agent can be added to further improve the adhesion of the resin composition and enhances the anti-stripping intensity of a copper-clad board.

Owner:SHENGYI TECH SUZHOU

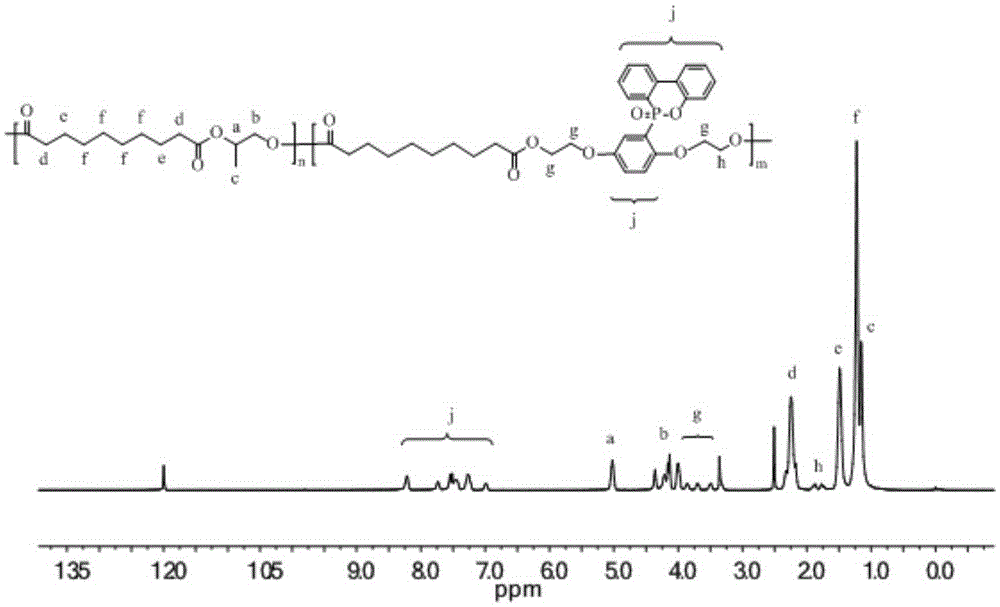

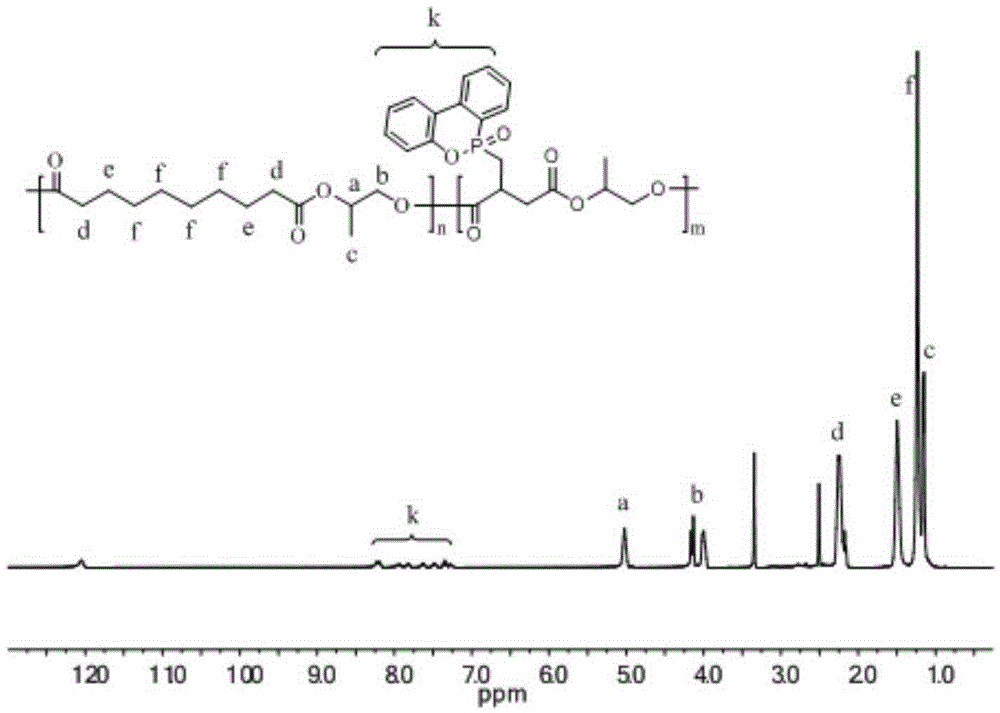

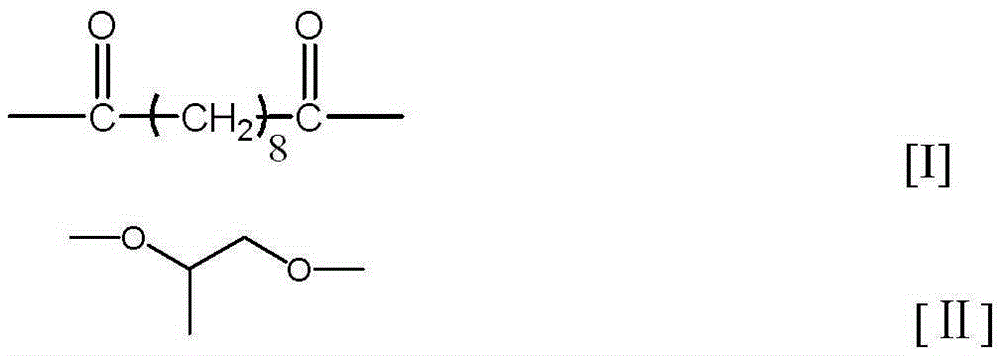

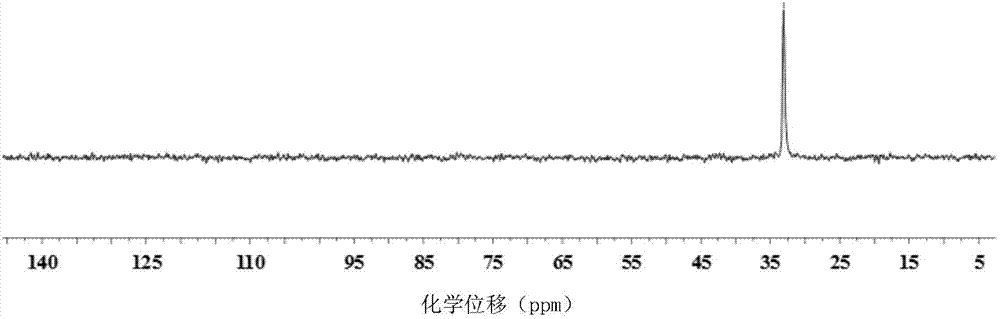

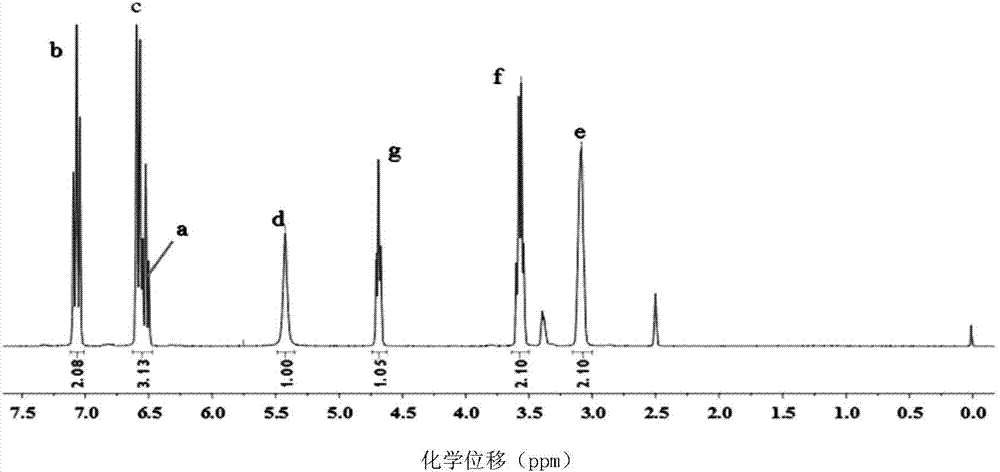

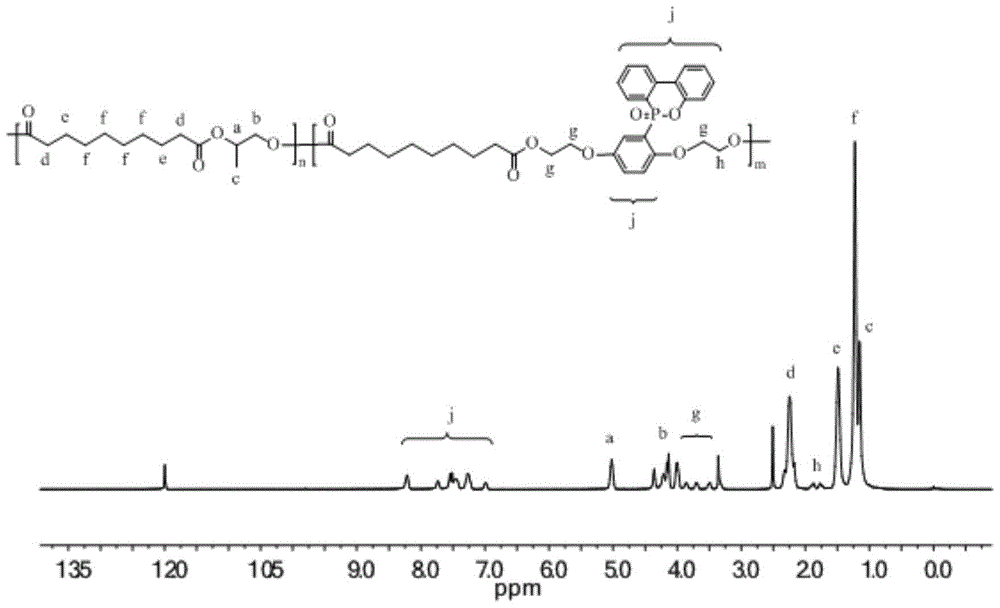

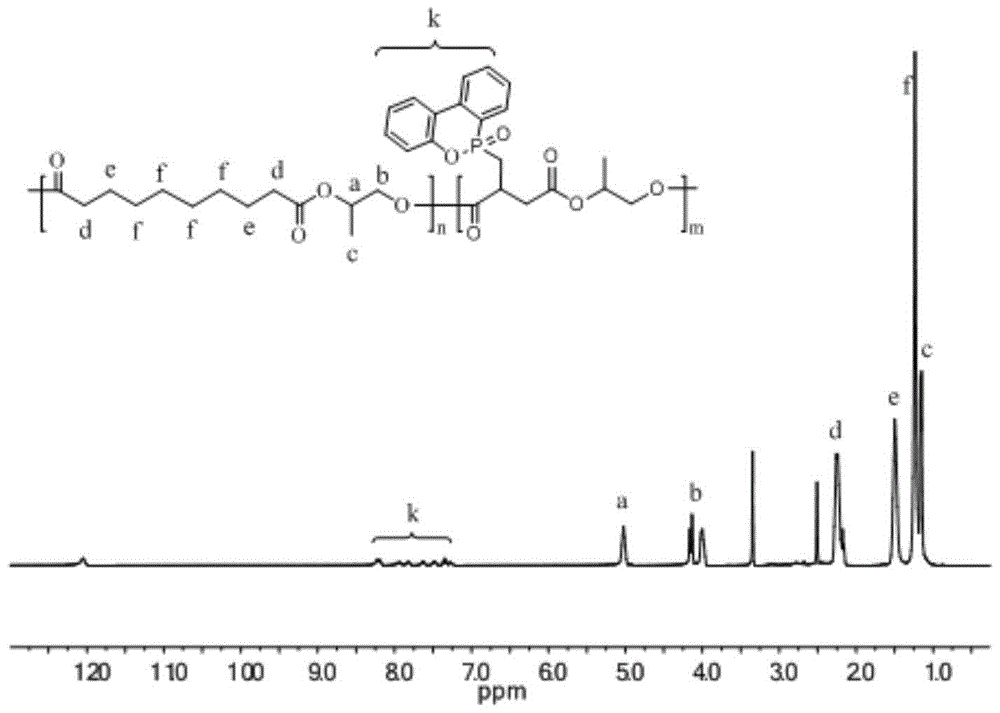

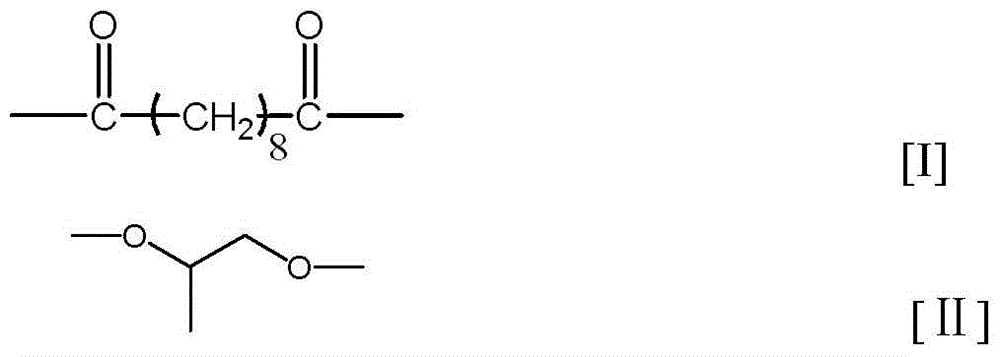

Carboxyl-terminated phosphorus-containing copolyester, preparation method, halogen-free flame retardant biology-based pressure sensitive adhesive composed of carboxyl-terminated phosphorus-containing copolyester and application

ActiveCN105254866AReduce pollutionLow costFilm/foil adhesivesOil/fat/wax adhesivesPolymer scienceCopolyester

The invention discloses carboxyl-terminated phosphorus-containing copolyester which is formed by randomly connecting and combining structural units shown as I, II and III according to carboxyl and hydroxyl functional groups, and the Mw of the carboxyl-terminated phosphorus-containing copolyester is 1.1*10<3>-1.3*10<4> g.mol<-1>. The invention further discloses a preparation method of the carboxyl-terminated phosphorus-containing copolyester, a halogen-free flame retardant biology-based pressure sensitive adhesive composed of the carboxyl-terminated phosphorus-containing copolyester and application. The copolyester is biology-based phosphorus-containing copolyester, the halogen-free flame retardant pressure sensitive adhesive formed by the copolyester and renewable resource epoxidized plant oil not only maintains the basic characteristics and good adhesive strength of a biology base, but also achieves the excellent halogen-free flame retardant properties, and the blank of biology-based halogen-free flame retardant pressure sensitive adhesive products is filled up; in addition, preparation is easy and mature, solvent is not used, the cost is low, pollution to the environment is little, and application and popularization are convenient.

Owner:SICHUAN UNIV

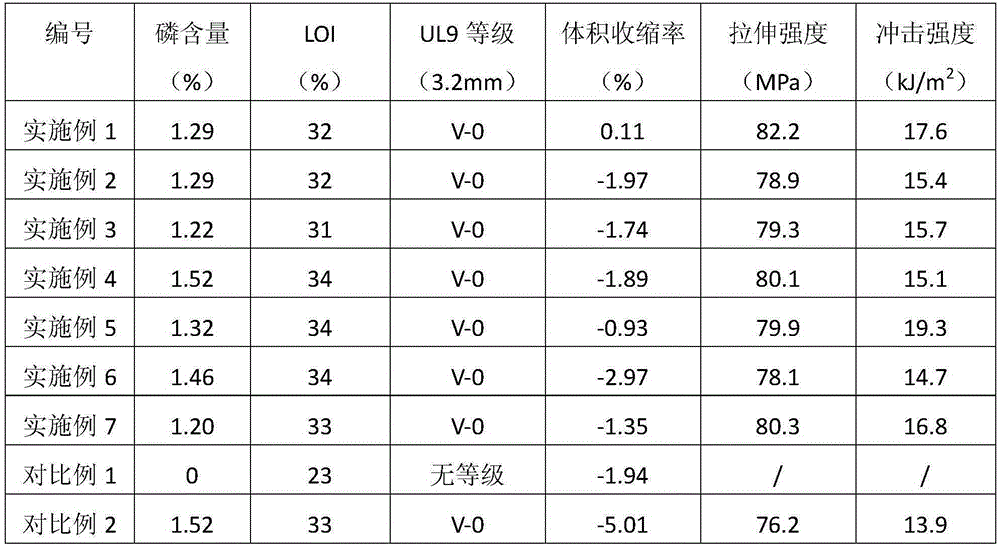

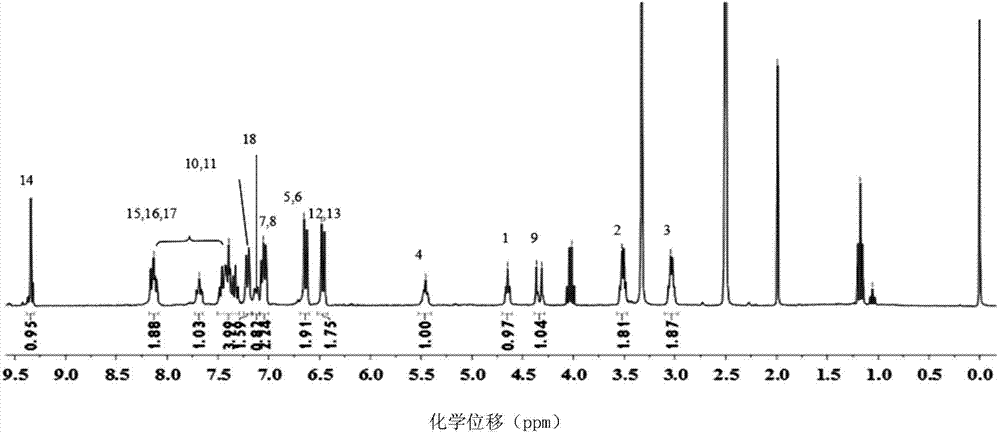

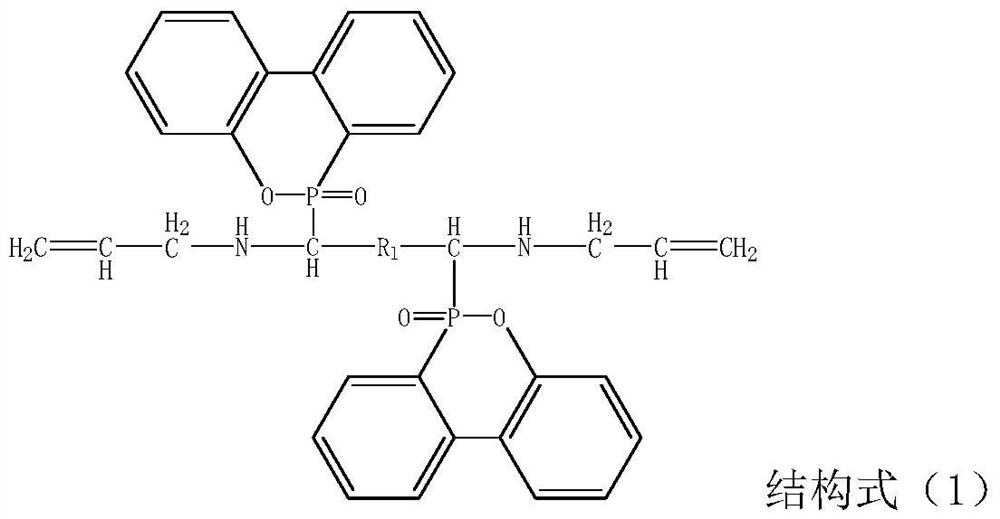

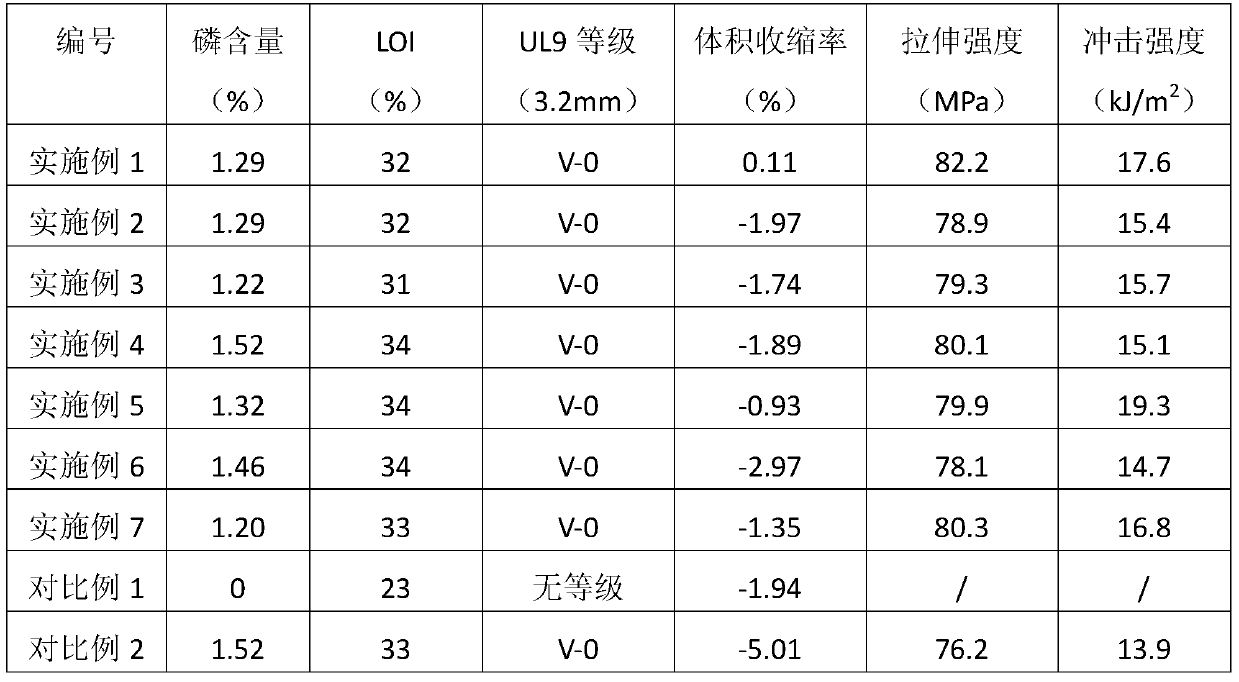

UV-curing halogen-free flame-retardant low-shrinkage epoxy resin composition and preparation method thereof

The invention discloses a UV-curing halogen-free flame-retardant low-shrinkage epoxy resin composition and a preparation method thereof. The composition is prepared from, by mass, 50%-70% of phosphorus-containing flame-retardant epoxy resin prepolymer, 11% -30% of active diluents, 5%-20% of spirocyclic monomers and 2%-4% of positive ion photoinitiator. The preparation method of the phosphorus-containing flame-retardant epoxy resin prepolymer includes the steps of mixing epoxy resin E-51 with 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxider, and raising the temperature to enable the mixture to be reacted to prepare the prepolymer. According to the composition and the preparation method thereof, the product is not only high in flame-retardant efficiency, but also small in effect on mechanical performance of epoxy resin; when the content of phosphorus is 1.3%, the cured product LOI reaches 34%, vertical combustion passes through UL 94V-0 level, curing can be performed rapidly under irradiation of UV, the volume shrinkage rate is quite low in the curing forming process, and even zero shrinkage can be reached.

Owner:SOUTH CHINA UNIV OF TECH

Halogen-free active fire retardant and preparation method thereof

ActiveCN104710651AImprove flame retardant performanceEasy to prepareGroup 5/15 element organic compoundsNitrogenMagnetic stirrer

The invention relates to fire retardants, and in particular relates to a halogen-free active fire retardant and a preparation method thereof. The method comprises the following steps: under the protection of nitrogen, sequentially adding reactants, namely N-hydroxyethylaniline, 4-hydroxybenzaldehyde and a solvent, into a container equipped with a condensate return pipe and a magnetic stirrer; after a heating reaction, adding DOPO to continue the reaction to obtain a light blue solid deposit; and cooling the deposit, keeping the deposit standing, pouring out the upper-layer solvent, washing the deposit with a solvent, and drying the deposit to obtain the halogen-free active fire retardant. Or the method comprises the following steps: under the protection of nitrogen, sequentially adding the reactants, namely N-hydroxyethylaniline, 4-hydroxybenzaldehyde and a solvent, into a container equipped with a condensate return pipe and a magnetic stirrer; after a heating reaction, adding DOPO to continue the reaction to obtain a light blue solution; and concentrating the solution, and precipitating the solution with a precipitator to obtain the halogen-free active fire retardant. The preparation method is simple, and the halogen-free active fire retardant contains a plurality of kinds of active groups, is well compatible with a matrix and has a good halogen-free flame-retardant property.

Owner:XIAMEN UNIV +1

Transparent halogen-free flame-retardant polycarbonate composite material and preparation method thereof

InactiveCN110229491AExcellent halogen-free flame retardant performanceImprove performanceElectric vehicle charging technologyInformation technology support systemElectrical junctionAntioxidant

The invention discloses a transparent halogen-free flame-retardant polycarbonate composite material and a preparation method thereof. The composite material is prepared from the following raw materials by weight: 50-80 parts of polycarbonate, 30-40 parts of a polycarbonate-polysiloxane copolymer, 0.04-0.13 part of a sulfonate flame retardant, 0.1-0.5 part of an antioxidant, 0.15-1.1 parts of a UVstabilizer and 0.2 to 1 part of a lubricant. The transparent halogen-free flame-retardant polycarbonate composite material of the invention is obtained by thoroughly mixing the above components in proportion, then performing extrusion via a twin-screw extruder, and performing granulation and preparation of a standard spline. The transparent halogen-free flame-retardant polycarbonate composite material has the characteristcis of high flame retardancy, high transparency, low temperature impact resistance, environment friendliness, etc., and is very applicable to manufacturing of solar devices, electrical junction boxes, electrical connectors, electric vehicle charger shells, outdoor electrical shells, smart meter shells, smart power grid nodes, photovoltaic frames, miniature circuit breakershells, etc.

Owner:广东聚钛新材料有限公司

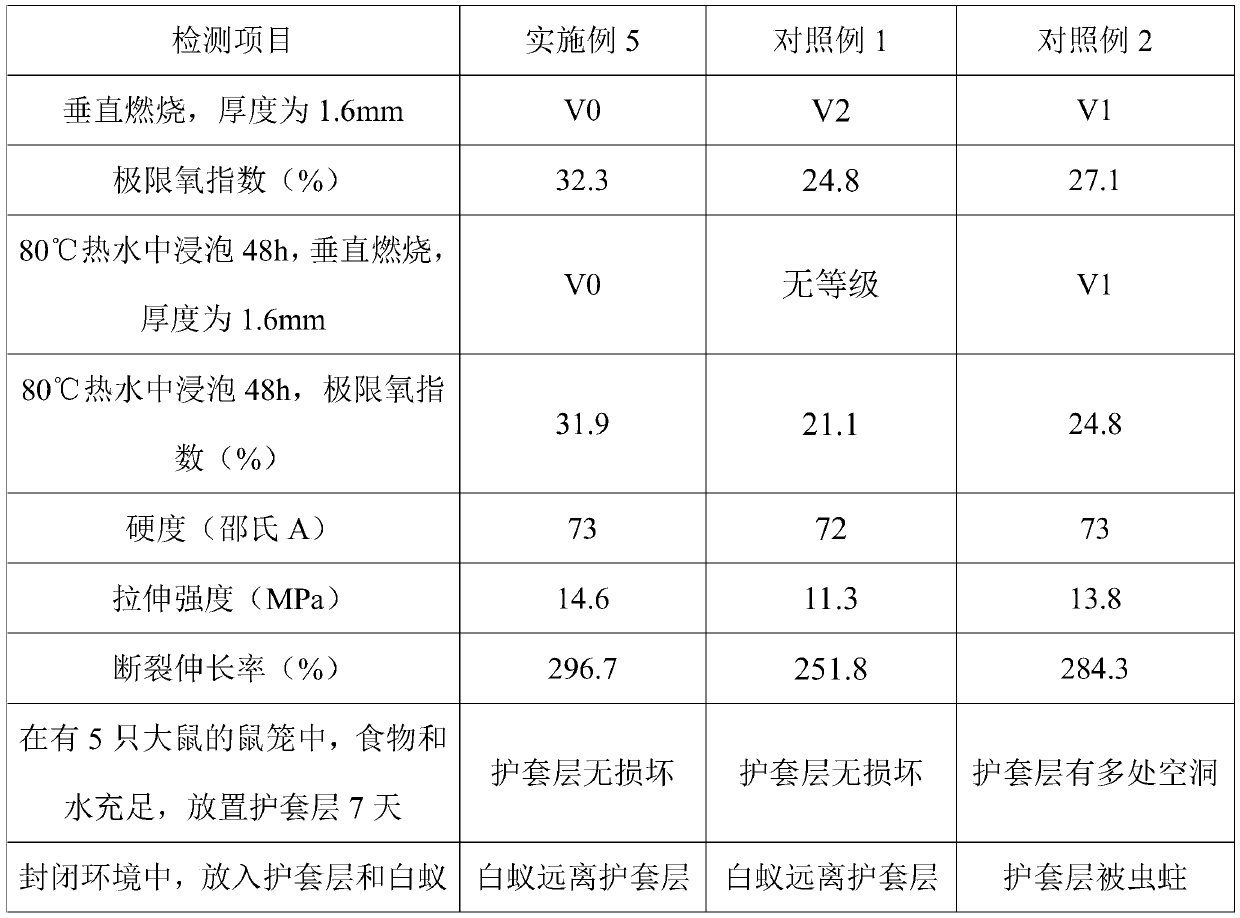

Rat-proof and ant-proof low-smoke halogen-free flame-retardant control cable for warships

ActiveCN110335711AGood compatibilityImprove water resistanceInsulated cablesInsulated conductorsCross-linkElectrical conductor

The invention discloses a rat-proof and ant-proof low-smoke halogen-free flame-retardant control cable for warships, which comprises insulating wire cores, a halogen-free flame-retardant belt and a sheath layer. Each insulating wire core comprises a conductor and an insulating layer arranged outside the conductor by extrusion. The cable core is wrapped with the halogen-free flame-retardant belt. The sheath layer is arranged by extrusion outside the halogen-free flame-retardant belt. The sheath layer comprises the following raw materials by weight: 80-100 parts of ethylene propylene diene monomer, 30-40 parts of filler, 2-6 parts of plasticizer, 1-2 parts of cross-linker, 0.5-0.6 parts of cross-linking auxiliary, 25-35 parts of flame retardant, 2-4 parts of flame retarding auxiliary, 1-3 parts of antioxidant, 2-3 parts of rat and ant repellent, 2-4 parts of compatilizer and 2-4 parts of lubricant. Through the coordination of the substances, the cable of the invention has good halogen-free flame retardancy, rat and ant resistance and mechanical performance.

Owner:ANHUI HUANENG CABLE GRP

Carbon fiber reinforced halogen-free flame retardant polypropylene composite material and preparation method thereof

InactiveCN105542312AExcellent halogen-free flame retardant performanceLow smoke productionPolymer scienceCarbon fibers

The invention relates to a carbon fiber reinforced halogen-free flame retardant polypropylene composite material and a preparation method thereof, belonging to the technical field of high polymer materials. The carbon fiber reinforced halogen-free flame retardant polypropylene composite material consists of the following components: polypropylene, carbon fiber, red phosphorus flame-retardant masterbatch, a dispersing agent, an antioxidant and a pigment. The preparation method of the carbon fiber reinforced halogen-free flame retardant polypropylene composite material comprises the following specific steps: 1) surface oxidation treatment on carbon fiber; 2) preparation of the red phosphorus flame-retardant masterbatch; 3) mixing of raw materials; and 4) preparation of the product. The carbon fiber reinforced halogen-free flame retardant polypropylene composite material provided by the invention not only has good halogen-free flame retardance (the oxygen index is 25 or over which reaches the UL94-0 flame retardant grade standard, but also promises low smoke generation, and thus is an environment-friendly product and meets the export requirements of environmental regulations.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Glass fiber reinforced polyethylene powder

InactiveCN104744772AImprove impact toughnessHalogen-free flame retardant effect is goodCompound (substance)Antioxidant

The invention discloses a glass fiber reinforced polyethylene powder, which comprises the following components by mass: 50%-70% of polyethylene, 5%-15% of glass fiber, 10%-15% of a compound halogen-free flame retardant, 5%-15% of nano-calcium carbonate, 0.1%-0.5% of calcium stearate, 0.1%-1% of an antioxidant, and 0.5%-1% of pentaerythritol stearate. The glass fiber is alkali-free chopped glass fiber that has a diameter of 8-15micrometers and a surface treated by a silane coupling agent. The powder provided by the invention utilizes the blending synergistic effect of glass fiber and nano-carbon fiber, significantly improves the impact toughness, rigidity and heat resistance of the material, and has good halogen-free flame retardant effect, can achieve the UL94V-0 flame retardant grade, and has good use effect and social and economic benefits when applied to construction, transportation, electric wires and cables, chemical machinery and other fields.

Owner:QINGDAO WANLI TECH

Carboxyl-terminated phosphorus-containing copolyester, preparation method, halogen-free flame-retardant bio-based pressure-sensitive adhesive composed of it and application thereof

ActiveCN105254866BReduce pollutionLow costFilm/foil adhesivesOil/fat/wax adhesivesPolymer scienceCopolyester

The invention discloses carboxyl-terminated phosphorus-containing copolyester which is formed by randomly connecting and combining structural units shown as I, II and III according to carboxyl and hydroxyl functional groups, and the Mw of the carboxyl-terminated phosphorus-containing copolyester is 1.1*10<3>-1.3*10<4> g.mol<-1>. The invention further discloses a preparation method of the carboxyl-terminated phosphorus-containing copolyester, a halogen-free flame retardant biology-based pressure sensitive adhesive composed of the carboxyl-terminated phosphorus-containing copolyester and application. The copolyester is biology-based phosphorus-containing copolyester, the halogen-free flame retardant pressure sensitive adhesive formed by the copolyester and renewable resource epoxidized plant oil not only maintains the basic characteristics and good adhesive strength of a biology base, but also achieves the excellent halogen-free flame retardant properties, and the blank of biology-based halogen-free flame retardant pressure sensitive adhesive products is filled up; in addition, preparation is easy and mature, solvent is not used, the cost is low, pollution to the environment is little, and application and popularization are convenient.

Owner:SICHUAN UNIV

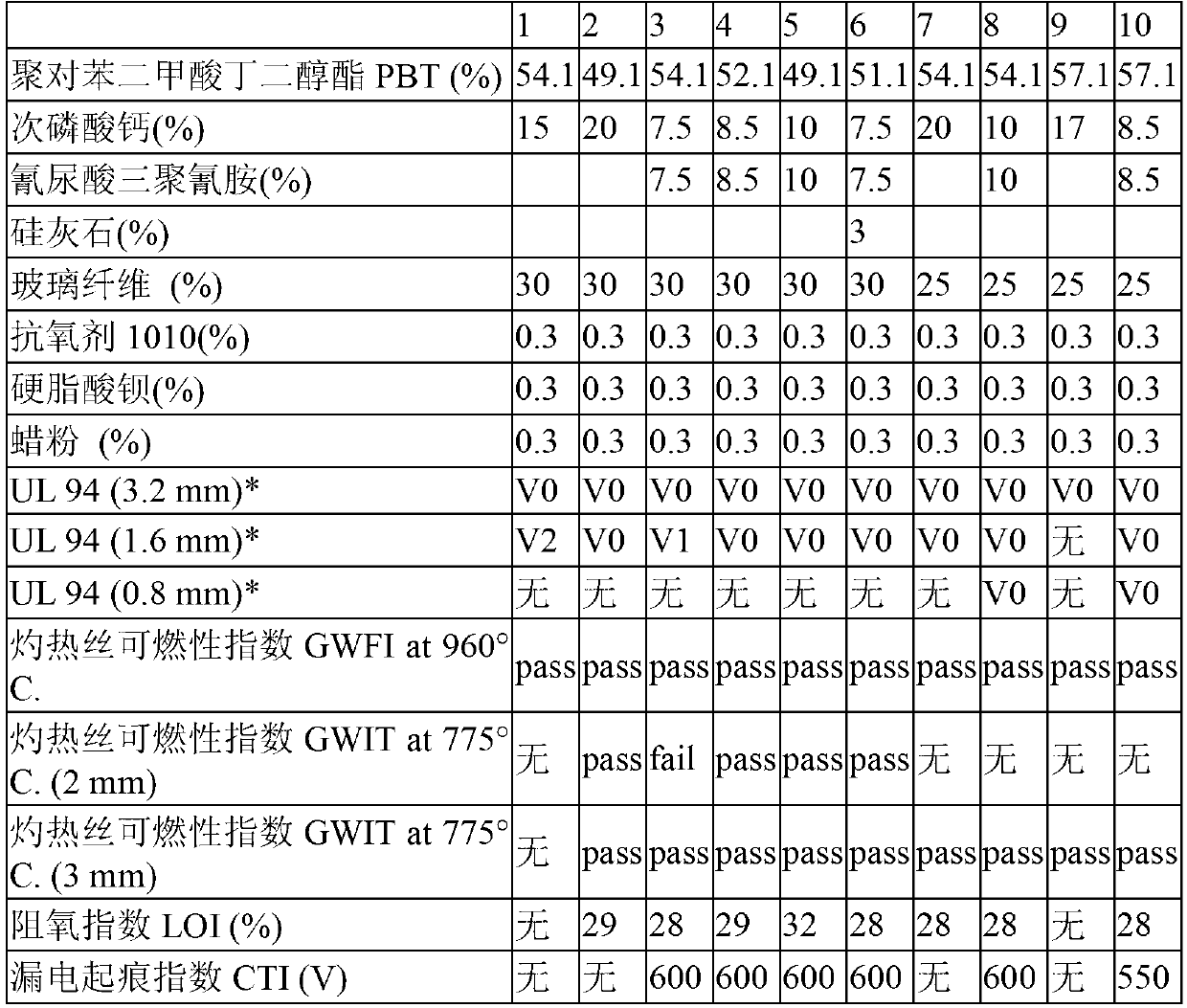

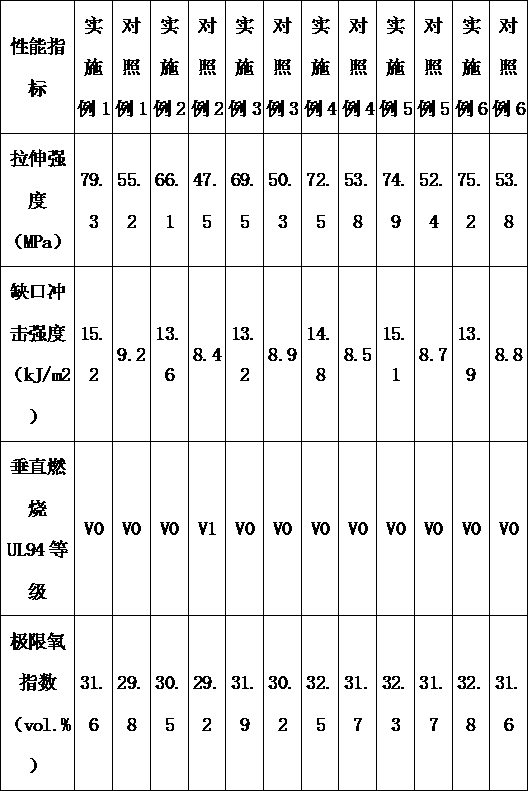

Halogen-free environment-friendly flame-retardant modified thermoplastic polyester resin

InactiveCN103102658AEffect on electrical performanceDoes not affect decompositionChemistryProcessing aid

The invention discloses a halogen-free environment-friendly flame-retardant modified thermoplastic polyester resin. The thermoplastic polyester resin comprises the following components in parts by weight: 5-95% of polyester resin, 0.1-30% of calcium hypophosphite, 0-10% of halogen-free flame-retardant additive, 0.5-10% of one or more of processing aid, thermal and process stabilizing agent, ultraviolet stabilizer, antidripping agent, pigment, releasing agent, rubber elastomeric polymer and nucleating agent and 0-50% of inorganic filler. The product provided by the invention has favorable halogen-free flame-retardant performance, particularly favorable thermal resistance at 775 DEG C under the length of 1.6mm and the thickness of 0.8mm according to the UL94 standard, excellent mechanical property, particularly good impact strength and elasticity modulus and favorable stretchability and electrical property and can pass a CTI (Computer Telephony Integration) value under the condition of 600V.

Owner:天津然跃环保创新科技有限公司

High-efficiency enhanced halogen-free flame-retardant functional master batch for polypropylene direct injection molding and preparation method of functional master batch

ActiveCN109486013ASolve the technical problem of mismatching processing temperatureAvoid damageIonomerGlass fiber

The invention belongs to the technical field of plastic modification and processing and in particular relates to a high-efficiency enhanced halogen-free flame-retardant functional master batch capableof being directly applied to injection molding of polypropylene products and a preparation method of the functional master batch. The functional master batch is prepared by combining a master batch Aand a master batch B, wherein the master batch A comprises the following components in percentage by mass: 50.0-70.0% of glass fibers, 15.0-35.0% of high-fluidity polypropylene, 5.0-10.0% of an elastic ionomer, 3.0-6.0% of atactic polypropylene, 1.0-3.0% of maleic anhydride grafted polypropylene, 1.0-3.0% of polytetrafluoroethylene powder and 0.1-0.3% of an antioxidant. Compared with the traditional plastic functional master batch, the functional master batch prepared by the invention has the advantages that the condition that the modification effectiveness is low because the glass fibers andthe flame retardant perform mutual shearing friction to produce heat in the processing procedures of an enhanced halogen-free flame-retardant polypropylene modified system is avoided, the problem that mutual modification effectiveness damage is caused by mismatching of processing temperatures of the two modified systems is solved, and the modification effectiveness of the two is obviously enhanced.

Owner:江苏万纳普新材料科技有限公司

Flame-retardant antistatic bifunctional modified polyethylene composite material and its preparation method

InactiveCN103881180AHalogen good flame retardantExcellent halogen-free flame retardant performanceNon toxicityPolymer science

The invention discloses a flame-retardant antistatic bifunctional modified polyethylene composite material and its preparation method. The flame-retardant antistatic bifunctional modified polyethylene composite material comprises, by mass, 50-80% of polyethylene, 12-25% of a compounded flame retardant, 2-5% of an antistatic master batch, 0.1-2% of a lubricant, 0.1-0.6% of a primary antioxidant and 0.1-0.5% of an auxiliary antioxidant. Compared with polyethylene composite materials in the prior art, the flame-retardant antistatic bifunctional modified polyethylene composite material has the advantages of very good halogen-free flame retardation property (oxygen index reaching above 28), UL94-0 flame retardation grade standard reaching, small smoke quantity, non-toxicity, no fused drop phenomenon, good dispersibility, good molding processability, high antistatic property, good durability, and surface resistance reaching 10<7>-10<9>omega.m.

Owner:QINGDAO XINZHAN PLASTIC

Nanometer silica modified polyvinyl chloride composite material

The invention discloses a nanometer silica modified polyvinyl chloride composite material. The composite material comprises, by mass, 50-75% of polyvinyl chloride, 5-10% of chlorinated polyethylene, 2-10% of nanometer silica, 5-8% of butadiene-acrylonitrile rubber, 6-9% of melamine cyanurate, 5-10% of DEHP, 0.5-1.5% of a calcium and zinc stabilizer, 0.5-1% of calcium stearate, 0.1-0.5% of an aluminum and titanium composite coupling agent and 0.1-0.5% of an antioxidant, and the particle size of the nanometer silica is 20-80nm. The nanometer silica modified polyvinyl chloride composite material has the advantages of excellent impact toughness, excellent processability, good heat stability, high strength, strong wear and corrosion resistance, and excellent halogen-free flame retardation performance.

Owner:殷培花

Halogen-free and flame-retardant polyethylene powder and preparation method thereof

InactiveCN104844879AExcellent halogen-free flame retardant performanceGood lookingChemical industryAntioxidant

The present invention discloses halogen-free and flame-retardant polyethylene powder and a preparation method thereof, wherein the halogen-free and flame retardant polyethylene powder comprises, by mass, 60-85% of polyethylene, 10-15% of a halogen-free flame-retardant agent, 3-8% of a reinforcing agent, 0.1-1% of a slipping agent, 0.1-1% of an anti-aging agent, 0.1-1% of polyethylene wax, and 0.1-0.5% of an antioxidant, wherein the halogen-free flame-retardant agent is a mixture comprising 50 wt% of poly ammonium phosphate, 30 wt% of a melamine polyphosphate, and 20 wt% of nanometer montmorillonite. The halogen-free and flame-retardant polyethylene powder of the present invention has beneficial effects of good halogen-free flame-retardant property low smoke, no toxicity, environmental protection, excellent mechanical property, good dispersion, low cost, and good appearance good, achieves the UL94-0 flame retardant grade, and can be widely used in the fields of pipes, chemical industry, machinery, packaging, electrical apparatuses, and the like.

Owner:QINGDAO WANLI TECH

Novel flame-retardant door and window profile and preparation method thereof

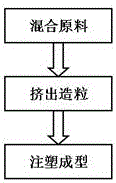

The invention provides a novel flame-retardant door and window profile and a preparation method thereof. The door and window profile comprises polycarbonate, ABS (acrylonitrile butadiene styrene) resin, MBS (methacrylate butadiene styrene) resin, composite flame retardant and composite auxiliaries. The preparation method includes the steps: a) mixing raw materials; b) squeezing granulation; c) injection molding. The door and window profile has fine mechanical property, high heat resistance and excellent halogen-free flame retardation, and is extremely wide in application prospect.

Owner:TAICANG MEISI DOORS & WINDOWS CO LTD

Halogen-free, fire retardation, strengthening and anti-aging PBT composite material

InactiveCN104845302AExcellent halogen-free flame retardant performanceImprove flame retardant performanceAntioxidantPyromellitic dianhydride

The present invention discloses a halogen-free, fire retardation, strengthening and anti-aging PBT composite material, which comprises, by mass, 60-85% of PBT, 8-15% of a halogen-free fire retardation agent, 5-15% of a strengthening agent, 2-5%of SMA, 0.5-2% of an anti-aging agent, 0.5-1.5% of carbodiimide, 0.1-0.5% of pyromellitic dianhydride, 0.1-0.5% of an antioxidant, and 0.1-1% of pentaerythrityl tetrastearate, wherein the halogen-free fire retardation agent is the complex comprising a bisphenol A-bis(diphenyl phosphate) fire retardation agent and a polydimethylsiloxane fire retardation agent according to a mass ratio of 2:1. The halogen-free, fire retardation, strengthening and anti-aging PBT composite material of the present invention has beneficial effects of excellent halogen-free fire retardation, excellent mechanical property, good processability, stable performance, strong hydrolysis resistance, excellent electrical performance, and low cost, can be used in the fields of electronic appliances, household appliances, machinery parts and the like, and has good practical values and prospects.

Owner:QINGDAO WANLI TECH

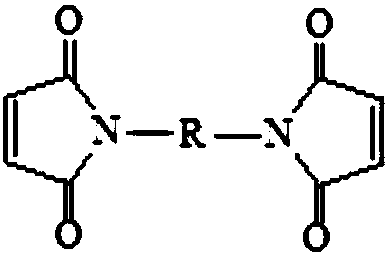

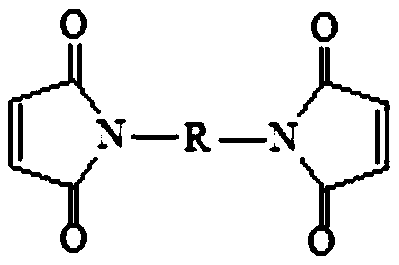

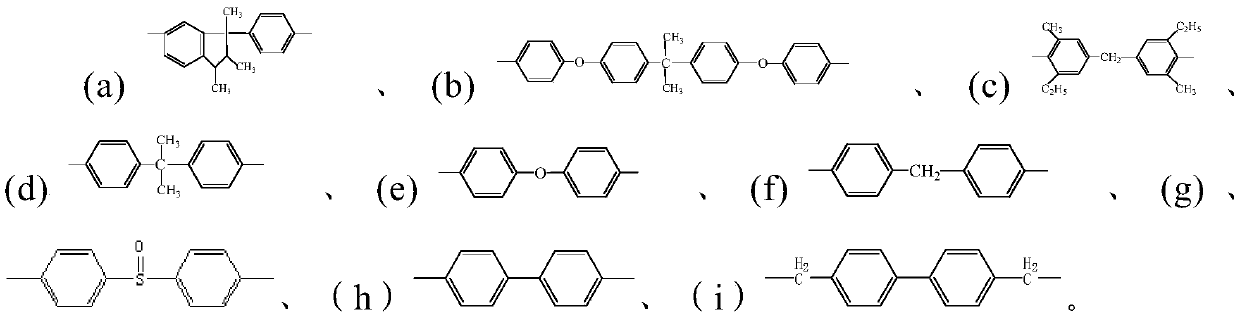

Resin compound, prepreg and laminated board prepared from resin compound

ActiveCN109504087AExcellent halogen-free flame retardant performanceImprove adhesionSynthetic resin layered productsMetal layered productsEpoxyThermal expansion

The invention discloses a resin compound which comprises the following components in parts by solid weight: 100 parts of modified bismaleimide prepolymer, 5-30 parts of epoxy resin, 0-20 parts of curing agent, 0-150 parts of filler and 0.001-5 parts of curing accelerator, wherein the modified bismaleimide prepolymer is prepared by pre-polymerizing at least bismaleimide resin with allyl compounds.Compared with the prior art, the resin compound disclosed by the invention has the advantages of high peel strength, halogen-free fire resistance, high heat resistance, high temperature modulus retention rate, excellent toughness, coefficient of thermal expansion and high modulus retention rate. Especially, the resin compound can meet the requirement for halogen-free fire resistance UL94V-0 whilehas excellent high temperature modulus retention rate and low coefficient of thermal expansion, so that the resin compound can be applied to high-performance circuit materials, such as HDI high multilayer substrates.

Owner:SHENGYI TECH SUZHOU

Preparation method of hydrophobic tannin modified polyphosphazene nano-material and application of hydrophobic tannin modified polyphosphazene nano-material in fireproof flame-retardant coating

ActiveCN112409600APromote formationPromote carbonizationFireproof paintsMaterials scienceMercaptan compound

The invention belongs to the technical field of coatings and discloses a preparation method of a hydrophobic tannin modified polyphosphazene nano-material and application of the hydrophobic tannin modified polyphosphazene nano-material in a fireproof flame-retardant coating. The preparation method of the polyphosphazene nano-material comprises the following steps of: (1) preparing the polyphosphazene nano-material by a precipitation polymerization method: adding phosphonitrilic chloride trimer and vegetable tannin into acetonitrile, carrying out ultrasonic treatment, adding trimethylamine, carrying out ultrasonic treatment, carrying out centrifuging, cleaning precipitates, and drying the precipitates to obtain a product; and (2) carrying outsuper-hydrophobic modification: putting the obtained product into a metal salt solution, performing stirring, filtering and drying, putting an obtained product into an alcoholic solution of a long-chain mercaptan compound, performing stirring and filtering, washing anobtained product with alcohol, and drying the product to obtain the hydrophobic tannin modified polyphosphazene nano material. The polyphosphazene nano material is obtained by tannin modification through the precipitation polymerization method; the smoke suppression performance of the material is improved by utilizing the performance that tannin can be complexed with metal ions;and hydrophobic modification is performed on the material by adopting the long-chain alkyl compound, so that the water resistance of the material is improved.

Owner:BEIHUA UNIV

Flame-retarding type resin prepolymer, resin composition using same, prepreg and laminated board

ActiveCN109593200AReduced flame retardancyExcellent halogen-free flame retardant performanceSynthetic resin layered productsElectrical equipmentVitrificationHeat resistance

The invention discloses a flame-retarding type resin prepolymer. The flame-retarding type resin prepolymer is prepared at least by prepolymerization of bismaleimide resin and amine compound. Comparedwith the prior art, the flame-retarding type resin prepolymer adopts the amine compound containing DOPO or DPPO as a bismaleimide resin modifier, and on the basis of no influence on the property of the bismaleimide resin, phosphorus-containing groups can be well guided into a crosslinking network structure of the bismaleimide resin, therefore, nitrogen element and phosphorus element in one crosslinking network structure generate synergistic flame retardance, the phosphorus content needed by flame retardance of the solid substance to reach UL94V-0 can be reduced, no addition of other flame-retarding agent is needed, and the solid substance with excellent halogen-free flame retardance, high heat resistance, high glass transition temperature, high modulus retention rate under high temperatureand excellent toughness and heat expansion coefficient simultaneously is obtained.

Owner:SHENGYI TECH SUZHOU

Halogen-free flame-retardant type injection molding-class polyolefin wood plastic composite material and preparation method thereof

Owner:GUANGDONG KINGFA TECH CO LTD

A kind of resin composition and prepreg and laminated board prepared by using it

ActiveCN109504087BExcellent halogen-free flame retardant performanceImprove adhesionSynthetic resin layered productsMetal layered productsThermal dilatationImide

The invention discloses a resin compound which comprises the following components in parts by solid weight: 100 parts of modified bismaleimide prepolymer, 5-30 parts of epoxy resin, 0-20 parts of curing agent, 0-150 parts of filler and 0.001-5 parts of curing accelerator, wherein the modified bismaleimide prepolymer is prepared by pre-polymerizing at least bismaleimide resin with allyl compounds.Compared with the prior art, the resin compound disclosed by the invention has the advantages of high peel strength, halogen-free fire resistance, high heat resistance, high temperature modulus retention rate, excellent toughness, coefficient of thermal expansion and high modulus retention rate. Especially, the resin compound can meet the requirement for halogen-free fire resistance UL94V-0 whilehas excellent high temperature modulus retention rate and low coefficient of thermal expansion, so that the resin compound can be applied to high-performance circuit materials, such as HDI high multilayer substrates.

Owner:SHENGYI TECH SUZHOU

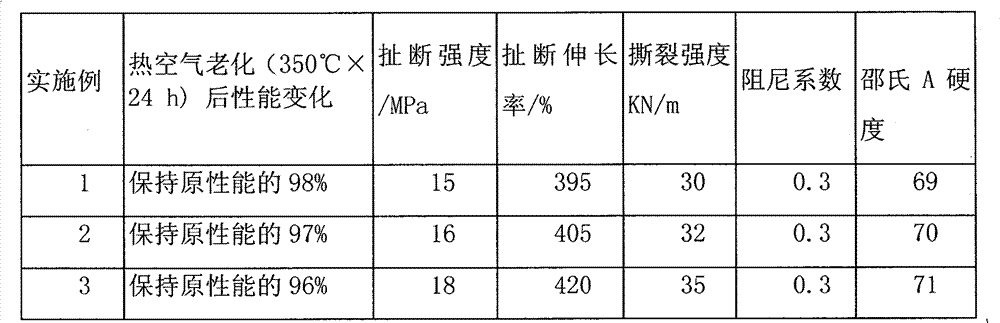

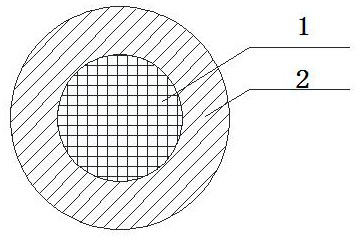

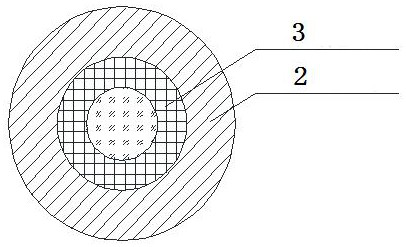

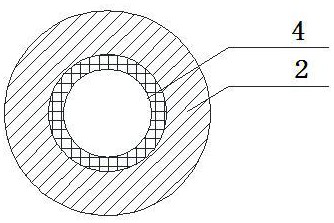

Silicon rubber cable joint

The invention provides a silicon rubber cable joint, which is to solve the technical problems of susceptibility to aging, bubbling and stripping, low tear resistance and the like of the cable joint in the prior art. The cable joint comprises the following raw materials in part by weight: 35 to 40 parts of vinylsiloxane rubber, 25 to 28 parts of white carbon black, 26 to 31 parts of acetylene carbon black, 1.5 parts of anti-aging agent, 0.3 part of promoter, 3 parts of vulcanizing agent, 2.4 parts of magnesium oxide, 1.4 parts of stearic acid, 3.5 to 5 parts of fire retardant and 1.5 to 2.4 parts of softener. All of the anti-aging performance, breaking strength, elongation at break, tear strength and hardness of the silicon rubber cable joint are improved; in addition, the silicon rubber cable joint also has high electrical performance, anti-tracking performance, halogen-free burning performance and thermal aging resistance, and high mechanical strength and hydrophobicity. Thus, the silicon rubber cable joint can be safely used in strict environment required by current electric equipment.

Owner:QINGDAO XINBEN TECH

UV-curable halogen-free flame-retardant low-shrinkage epoxy resin composition and preparation method thereof

ActiveCN105418892BLittle impact on mechanical propertiesHigh flame retardant efficiencyEpoxyCombustion

The invention discloses a UV-curing halogen-free flame-retardant low-shrinkage epoxy resin composition and a preparation method thereof. The composition is prepared from, by mass, 50%-70% of phosphorus-containing flame-retardant epoxy resin prepolymer, 11% -30% of active diluents, 5%-20% of spirocyclic monomers and 2%-4% of positive ion photoinitiator. The preparation method of the phosphorus-containing flame-retardant epoxy resin prepolymer includes the steps of mixing epoxy resin E-51 with 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxider, and raising the temperature to enable the mixture to be reacted to prepare the prepolymer. According to the composition and the preparation method thereof, the product is not only high in flame-retardant efficiency, but also small in effect on mechanical performance of epoxy resin; when the content of phosphorus is 1.3%, the cured product LOI reaches 34%, vertical combustion passes through UL 94V-0 level, curing can be performed rapidly under irradiation of UV, the volume shrinkage rate is quite low in the curing forming process, and even zero shrinkage can be reached.

Owner:SOUTH CHINA UNIV OF TECH

A preparation method of coated flame retardant with excellent electrical properties

ActiveCN109575361BLow dielectric constantLow dielectric lossNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer sciencePerylene derivatives

The invention belongs to the technical field of electronic materials, and specifically relates to a preparation method of a coated flame retardant with excellent electrical properties. The preparation method of a kind of coated flame retardant with excellent electrical properties proposed is: select low Dk, low Df core material; the outer surface of the core material is coated with DOPO derivatives as flame retardant layer; the core material The mass ratio to the flame retardant layer is 1:1~1:100; the bulk density of the coated flame retardant is 50 g / L~1000 g / L; the moisture content of the coated flame retardant is 0.01 wt%~5 wt%; the invention not only effectively solves the problem of the interface between the filler and the matrix and the problem of uneven dispersion, but also solves the problem of large dosage and high cost of DOPO derivatives or other filled flame retardants.

Owner:洛阳熙之奥新材料科技有限公司

A kind of flame retardant resin composition and prepreg and laminate prepared using the same

ActiveCN109535715BReduced flame retardancyExcellent halogen-free flame retardant performanceSynthetic resin layered productsLaminationImidePolymer science

Disclosed are a flame-retardant resin composition, and a prepreg and a laminate which are prepared therefrom. The flame-retardant resin composition, based on the solid weight, comprises: 100 parts of a modified bismaleimide prepolymer, 5-30 parts of an epoxy resin, 0-20 parts of a curing agent, 0-150 parts of a filler, and 0.001-5 parts of a curing accelerator, wherein the modified bismaleimide prepolymer is at least formed by prepolymerizing a bismaleimide resin and an amine compound.

Owner:SHENGYI TECH SUZHOU

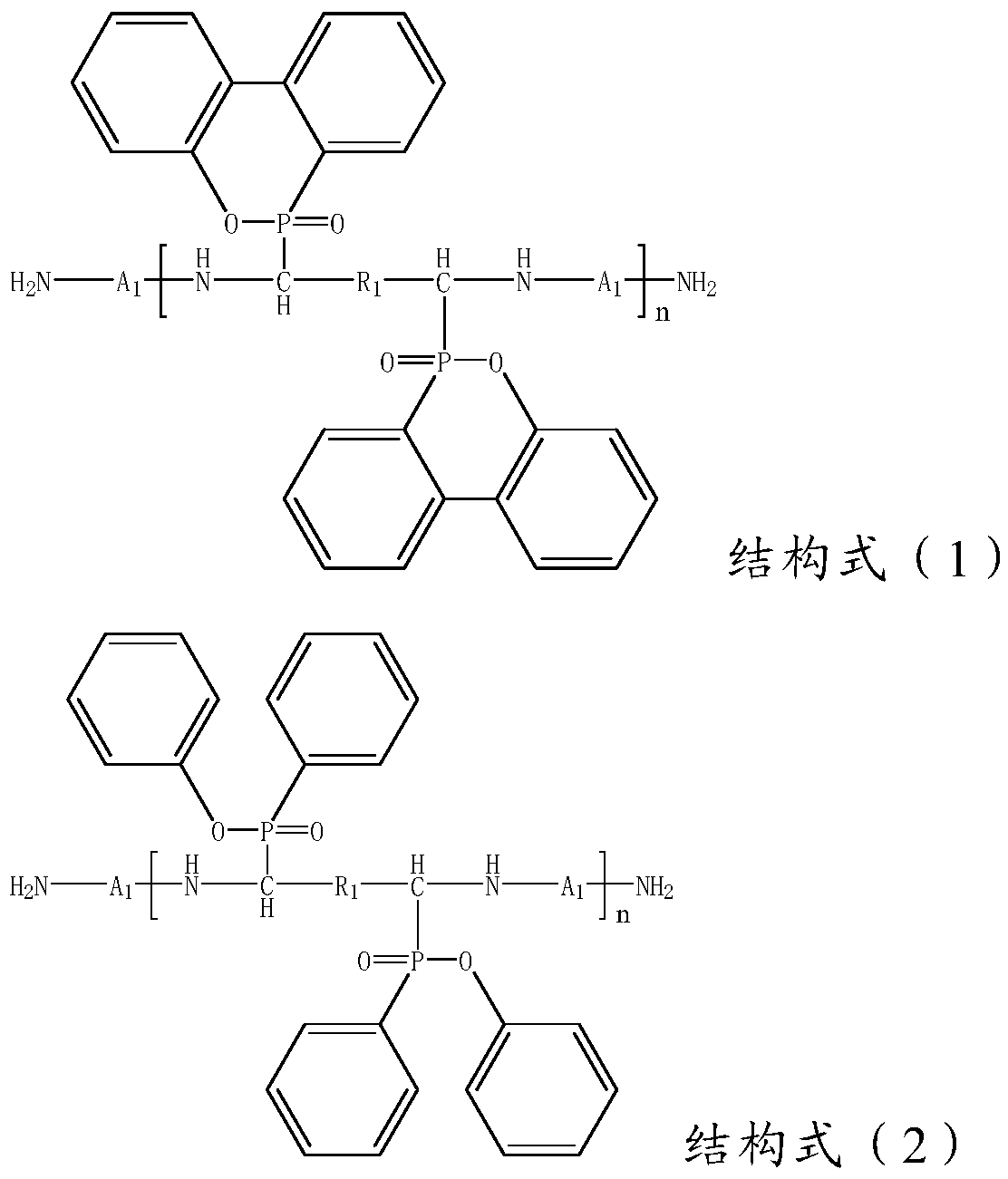

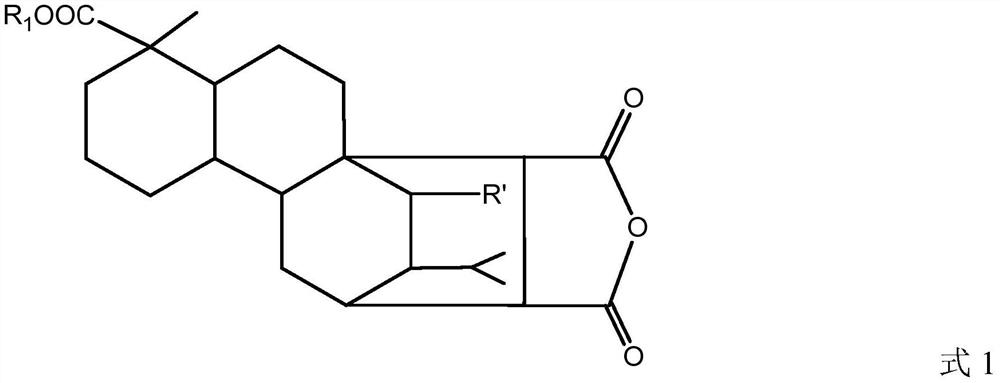

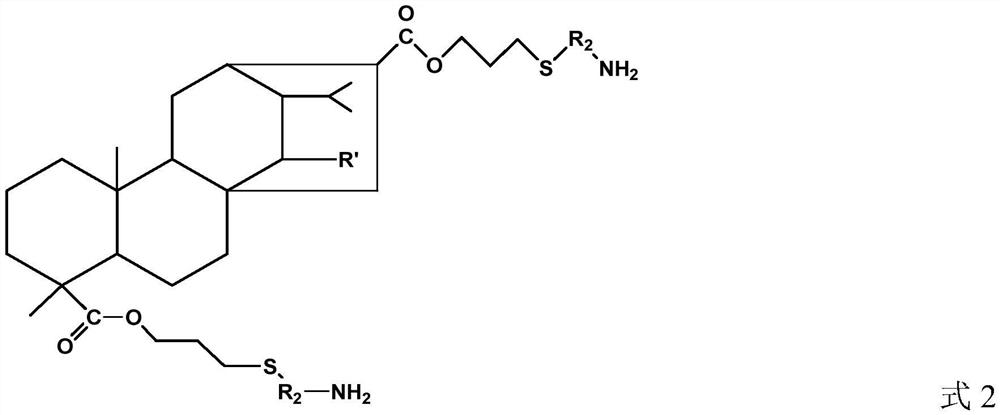

A kind of rosin-based reactive flame retardant curing agent and preparation method thereof

ActiveCN111484530BWide variety of sourcesSimple preparation conditionsGroup 5/15 element organic compoundsPolymer scienceEcological environment

The invention relates to a rosin-based reactive flame-retardant curing agent and a preparation method thereof. The rosin-based reactive flame-retardant curing agent described in the technical scheme of the present invention is prepared by reacting rosin-based acid anhydride or rosin-based amine with DOPO, and is prepared by reacting with DOPO. Phosphorus DOPO reacts with rosin-based acid anhydride or rosin-based amine in one step to obtain a halogen-free flame retardant rosin-based curing agent, which can be used in different epoxy resin or bio-based epoxy resin systems. The hydrogen phenanthrene ring structure of the cured product has high glass transition temperature and mechanical properties, and the cured product system has excellent flame retardant effect, and the flame retardant system is a halogen-free system, which meets the needs of today's ecological environment protection. The curing agent can be well mixed with the epoxy resin during processing, and can not only be used as the curing agent of the epoxy resin, but also can effectively improve the flame retardant performance of the epoxy resin.

Owner:ACC BEIJING SCI & TECH CO LTD

A flame-retardant resin prepolymer and resin composition, prepreg and laminate prepared by using it

ActiveCN109593200BReduced flame retardancyExcellent halogen-free flame retardant performanceSynthetic resin layered productsElectrical equipmentImidePolymer science

Disclosed by the present invention are a flame-retardant resin prepolymer, and a resin composition, prepreg and laminate prepared by using same. The flame retardant resin prepolymer is prepolymerized and formed at least by a bismaleimide resin and an amine compound. On the basis of not affecting the performance of the bismaleimide resin, a phosphorus-containing group may be well introduced into a cross-linked network structure of the bismaleimide resin.

Owner:SHENGYI TECH SUZHOU

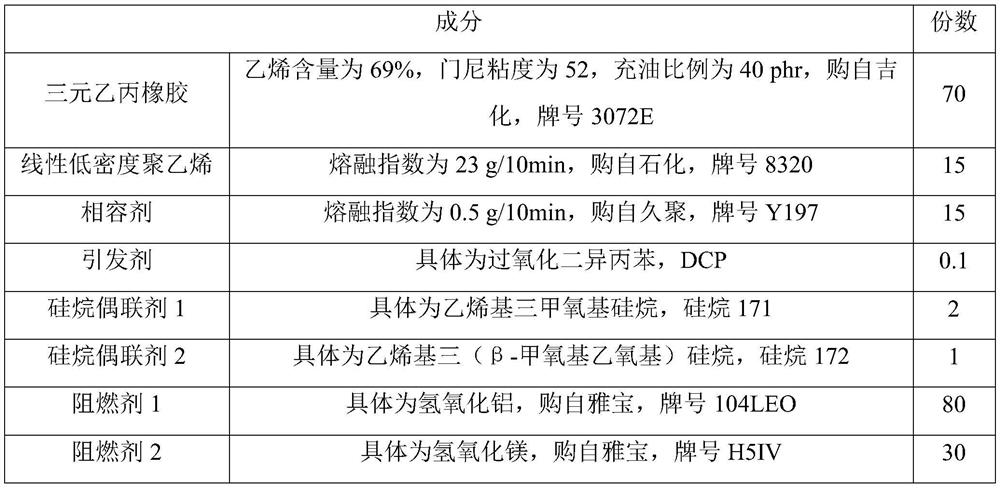

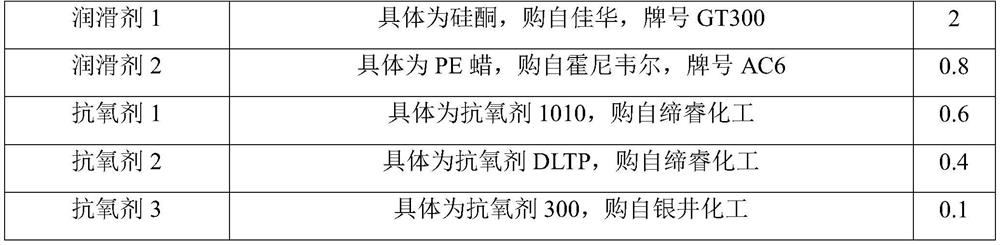

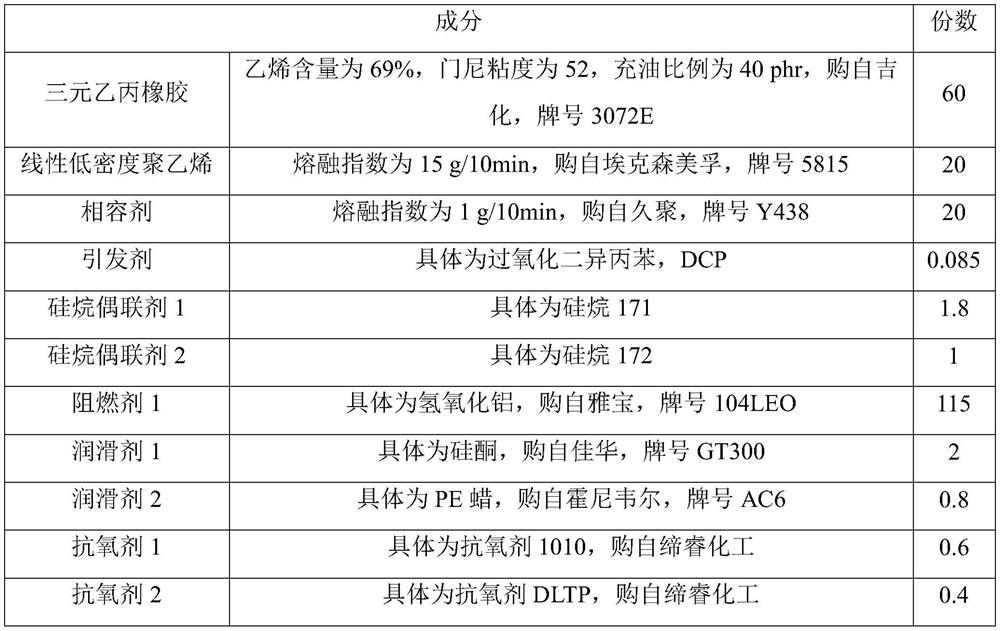

Anti-bending halogen-free flame-retardant sheath material for elevator flat cable as well as preparation method and application of bending-resistant halogen-free flame-retardant sheath material

ActiveCN113637265ANarrow the interface boundaryAvoid phenomena such as crackingRubber insulatorsLinear low-density polyethylenePolymer science

The invention discloses an anti-bending halogen-free flame-retardant sheath material for an elevator flat cable as well as a preparation method and application of the anti-bending halogen-free flame-retardant sheath material. The anti-bending halogen-free flame-retardant sheath material comprises the following raw materials: ethylene-propylene-diene monomer, a compatilizer, a flame retardant, a lubricant and an antioxidant, the ethylene content of the ethylene-propylene-diene monomer is 65-75%, the oil charge ratio is greater than or equal to 40 phr, and the Mooney viscosity is 40-75. The sheath material further comprises linear low density polyethylene, an initiator and a silane coupling agent. The sheath material is prepared by partially or completely grafting the linear low density polyethylene and the ethylene propylene diene monomer with the silane coupling agent under the action of the initiator before extrusion, and then conducting blending and extruding with other raw materials, or is prepared by subjecting all the materials in the raw materials to mixing, banburying and reaction and then conducting extruding. A sheath for the elevator flat cable prepared from the sheath material is simple in material formula, easy to process and low in cost, and particularly has excellent wear resistance, halogen-free flame retardance, high and low temperature resistance, excellent flexibility, excellent mechanical property and the like.

Owner:苏州通优新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com