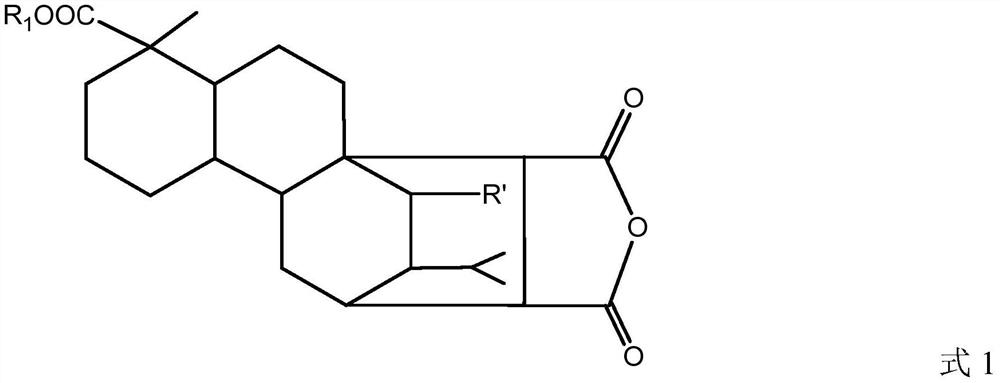

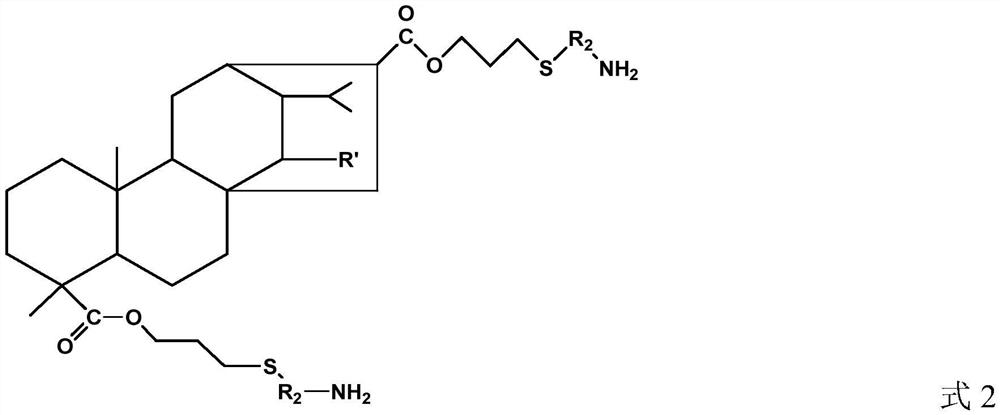

A kind of rosin-based reactive flame retardant curing agent and preparation method thereof

A reactive flame retardant and curing agent technology, which is applied in chemical instruments and methods, organic chemistry, compounds of Group 5/15 elements of the periodic table, etc., can solve the problems of reducing the mechanical properties and temperature resistance of materials, and achieve excellent Halogen-free flame retardant properties, good application prospects, the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add 150mL of toluene as a solvent to a 500mL three-necked flask. The three-necked flask is equipped with a thermometer, a spherical condenser, a magnetron, and a gas inlet pipe. Then add 38.6g of maleopimaric anhydride slowly into the three-necked flask. After it is completely dissolved, slowly drip Add the toluene solution of 21.6g DOPO, heat to 60°C for reflux, react at reflux temperature for 6 hours, after the reaction, return to room temperature, spin off excess solvent, vacuum dry at 80°C for 4 hours, recrystallize and purify to obtain the target product.

[0044]A catalyst composed of 60 grams of the flame retardant curing agent of the above structure, 100 grams of epoxy resin, 2 grams of tetramethylammonium chloride and 1 gram of triethylamine was mixed uniformly to obtain a mixed resin. The mixture was pre-cured at 90° C. for 1 hour, and then post-cured at 130° C. for 1 hour to obtain a cured rosin-based curing agent resin.

[0045] After testing, the cured prod...

Embodiment 2

[0047] Add 150mL of toluene as a solvent to a 500mL three-necked flask. The three-necked flask is equipped with a thermometer, a spherical condenser, a magnetron, and a gas inlet pipe. Then, 42.6g of rosin-based amine is added to the three-necked flask. After it is completely dissolved, slowly add 30.6g of DOPO. The toluene solution was heated to 70°C under reflux, reacted at the reflux temperature for 8 hours, after the reaction was completed, returned to room temperature, the excess solvent was evaporated by rotary evaporation, vacuum dried at 80°C for 4 hours, and recrystallized to obtain a pale yellow powder.

[0048] Mix 80 grams of the flame retardant curing agent with the above structure and 100 grams of epoxy resin to obtain a mixed resin. The mixture was pre-cured at 90° C. for 40 minutes, and then post-cured at 120° C. for 2 hours to obtain a cured rosin-based curing agent resin.

[0049] After testing, the cured product prepared as a flame retardant curing agent for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com