UV-curing halogen-free flame-retardant low-shrinkage epoxy resin composition and preparation method thereof

A technology of shrinking epoxy resin and epoxy resin, which is applied in the field of halogen-free flame-retardant low-shrinkage epoxy resin composition, can solve the problems of flammability and large curing shrinkage, and achieve low shrinkage, stable size, and good mechanical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

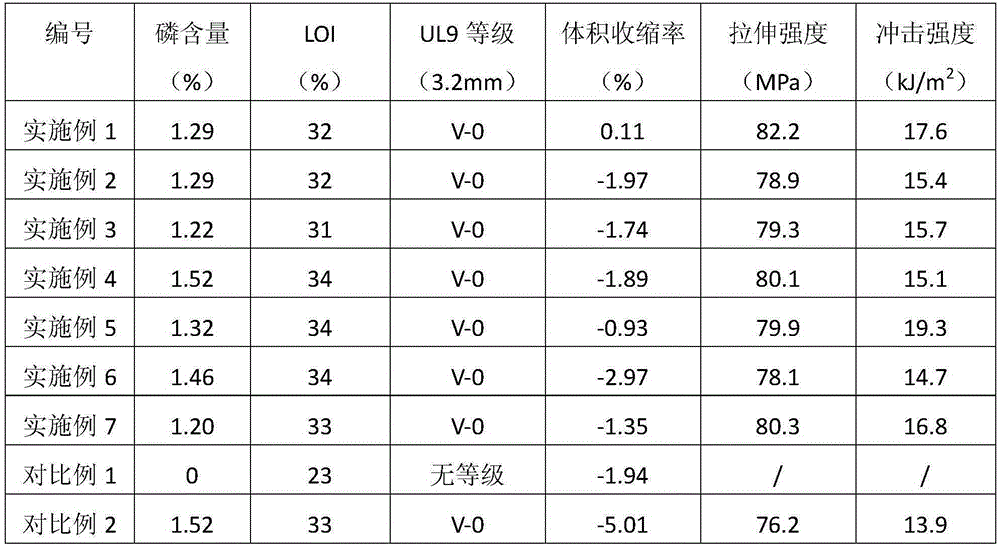

Examples

Embodiment 1

[0025] 56g phosphorus-containing flame-retardant epoxy resin prepolymer DOPOER-2.3%, 10g phenyl glycidyl ether, 10g ethylene glycol diglycidyl ether, 20g 3,9-diethyl-3,9-dipropyleneoxymethyl ‐1,5,7,11‐tetraoxaspiro[5,5]undecane and 4g triphenylsulfonium hexafluoroantimonate were stirred evenly at a speed of 300r / min to obtain UV-curable halogen-free flame retardant Low shrinkage epoxy resin composition, keep away from light.

Embodiment 2

[0027] 56g phosphorus-containing flame retardant epoxy resin prepolymer DOPOER-2.3%, 15g phenyl glycidyl ether, 15g ethylene glycol diglycidyl ether, 10g 3,9-diethyl-3,9-dimethylol- 1,5,7,11‐tetraoxaspiro[5,5]undecane and 4g triphenylsulfonium hexafluoroantimonate were stirred evenly at a speed of 300r / min to obtain a UV-curable halogen-free flame-retardant low Shrink the epoxy resin composition and store away from light.

Embodiment 3

[0029]61g phosphorus-containing flame retardant epoxy resin prepolymer DOPOER-2.0%, 10g phenyl glycidyl ether, 12g glycerol triglycidyl ether, 15g 3,9-diethyl-3,9-dipropyleneoxymethyl ‐1,5,7,11‐tetraoxaspiro[5,5]undecane and 2g 4‐methyl‐4'‐isobutyldiphenyliodonium hexafluorophosphate were stirred at a speed of 300r / min The ultraviolet light-curable halogen-free flame-retardant low-shrinkage epoxy resin composition is obtained, which is stored away from light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com