Carboxyl-terminated phosphorus-containing copolyester, preparation method, halogen-free flame retardant biology-based pressure sensitive adhesive composed of carboxyl-terminated phosphorus-containing copolyester and application

A technology of copolyester and terminal carboxyl group is applied in the fields of phosphorus-containing copolyester and its preparation and composition of pressure-sensitive adhesive, which can solve the problems of lack of flame retardancy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

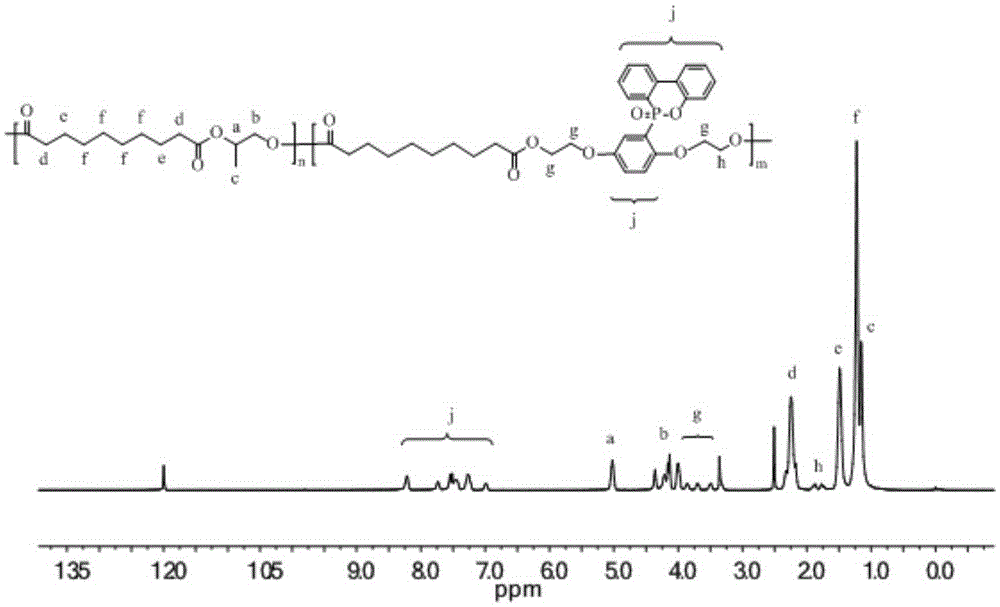

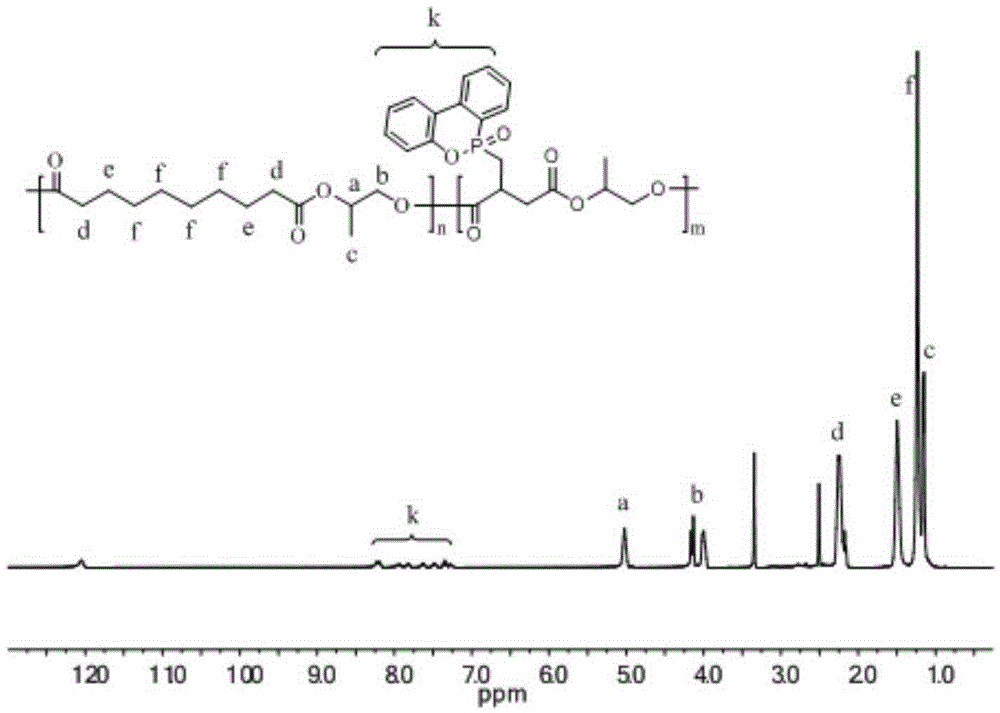

Method used

Image

Examples

Embodiment 1

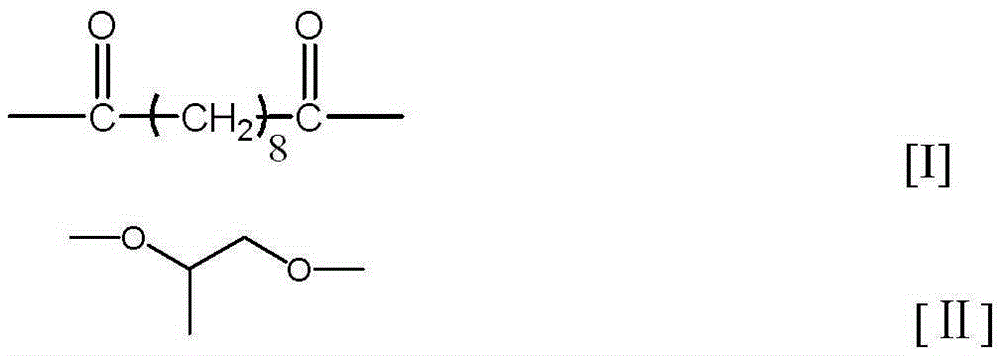

[0058] Add 209.3g (1.04mol) of sebacic acid, 76.1g (1.00mol) of 1,2-propanediol and 34.6g of DDP (0.10mol) into the reaction vessel, then stir the esterification reaction at 180°C for 4h under the protection of nitrogen, and add 0.1ml tetrabutyl titanate toluene solution (0.2g·ml -1 ), and the solution was heated to 220°C, polycondensed in low vacuum for 0.5h, and polycondensed in high vacuum for 4h to obtain the flame-retardant copolyester of carboxyl-terminated phosphorus-containing poly(trimethylene sebacate).

[0059] M of the copolyester w 5.9×10 3 g·mol -1 .

Embodiment 2

[0061] Add 202.2g (1.00mol) of sebacic acid, 76.1g (1.00mol) of 1,2-propanediol and 51.9g of DDP (0.15mol) into the reaction vessel, then stir the esterification reaction at 180°C for 4h under the protection of nitrogen, and add 0.1ml tetrabutyl titanate toluene solution (0.2g·ml -1 ), and the solution was heated to 220°C, polycondensed in low vacuum for 0.5h, and polycondensed in high vacuum for 4h to obtain the flame-retardant copolyester of carboxyl-terminated phosphorus-containing poly(trimethylene sebacate).

[0062] M of the copolyester w 7.0×10 3 g·mol -1 .

Embodiment 3

[0064] Add 186.0g (0.92mol) of sebacic acid, 76.1g (0.10mol) of 1,2-propanediol and 69.3g of DDP (0.20mol) into the reaction vessel, then stir the esterification reaction at 180°C for 4h under the protection of nitrogen, and add 0.1ml tetrabutyl titanate toluene solution (0.2g·ml -1 ), and the solution was heated to 220°C, polycondensed in low vacuum for 0.5h, and polycondensed in high vacuum for 4h to obtain the flame-retardant copolyester of carboxyl-terminated phosphorus-containing poly(trimethylene sebacate).

[0065] M of the copolyester w 7.5×10 3 g·mol -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com