A preparation method of coated flame retardant with excellent electrical properties

A flame retardant and coating type technology, applied in the field of coating flame retardant preparation, can solve the problems of large amount of DOPO derivatives, high cost, uneven dispersion, etc., to solve the interface problem and uneven dispersion, solve the Large dosage, good halogen-free flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

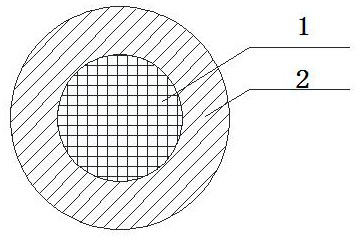

[0045] Such as figure 1 As shown, this embodiment provides a coated flame retardant, the core material is phenolic resin powder with a particle size Dv(90) of 18 μm, and the outer surface of the core material is coated with DOPO-terephthalene A coating layer of methanol; the particle size Dv(90) of the coated flame retardant is 30 μm, the moisture content is 0.40%, and the bulk density is 350 g / L.

[0046] The preparation method of described coating type flame retardant comprises the steps:

[0047]1) Evenly disperse 10g of phenolic resin powder into 100ml of toluene to make suspension A, preheat to 60°C;

[0048] 2) Add 43.2g DOPO and 200ml toluene into a 500ml four-neck flask equipped with a stirrer, thermometer and reflux condenser, heat and stir to a temperature of 60°C until DOPO is completely dissolved;

[0049] 3) Add the suspension A to the above (2), stir evenly, and heat up to the reaction temperature of 90°C;

[0050] 4) Within 1.5 hours, slowly add 13g of tereph...

Embodiment 2

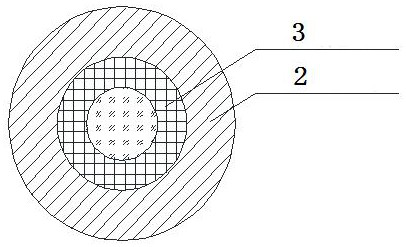

[0053] Such as figure 2 As shown, this embodiment provides a coated flame retardant, the core material adopts core-shell rubber powder with a particle size Dv(90) of 0.25 μm, and the outer surface of the core material is coated with DOPO-pair A coating of phthalaldehyde. The particle size Dv(90) of the coated flame retardant is 1 μm, the moisture content is 0.15%, and the bulk density is 100 g / L.

[0054] The preparation method of described coating type flame retardant comprises the steps:

[0055] 1) Evenly disperse 5g of core-shell rubber powder into 100ml of tetrahydrofuran to make suspension A, and preheat to 70°C;

[0056] 2) Add 54.0g DOPO and 200ml tetrahydrofuran into a 500ml four-neck flask equipped with a stirrer, thermometer and reflux condenser, heat and stir to a temperature of 70°C until DOPO is completely dissolved;

[0057] 3) Add the suspension A to the above (2), stir evenly, and heat up to the reaction temperature of 90°C;

[0058] 4) Within 1.5 hours, ...

Embodiment 3

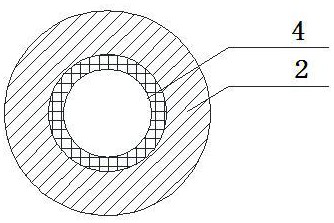

[0061] Such as image 3 As shown, this embodiment provides a coated flame retardant, the core material uses hollow glass microspheres with a particle size Dv(90) of 25 μm, and the outer surface of the core material is coated with DOPO-benzoquinone the cladding layer. The particle size Dv(90) of the coated flame retardant is 35 μm, the moisture content is 0.25%, and the bulk density is 500 g / L.

[0062] The preparation method of described coating type flame retardant comprises the steps:

[0063] 1) Evenly disperse 15g of hollow glass microspheres into 100ml of N,N-dimethylformamide to make suspension A, preheat to 80°C;

[0064] 2) Add 43.2g DOPO and 200ml N, N-dimethylformamide into a 500ml four-neck flask equipped with a stirrer, a thermometer and a reflux condenser, heat and stir to a temperature of 80°C until DOPO is completely dissolved;

[0065] 3) Add the suspension A to the above (2), stir evenly, and heat up to the reaction temperature of 100°C;

[0066] 4) Within...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com