Halogen-free environment-friendly flame-retardant modified thermoplastic polyester resin

A thermoplastic polyester and polyester resin technology, applied in the field of thermoplastic polyester resin, can solve the problems of lack of comprehensive performance, difficult to handle, and the effect is not too ideal.

Inactive Publication Date: 2013-05-15

天津然跃环保创新科技有限公司

View PDF12 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The effect of this product is not very ideal, and it also has the following disadvantages: it is easily volatile when exposed to heat, usually exists in a liquid state and is difficult to handle, it is easily hydrolyzed and may affect the thermodynamic properties of the final product

Although new high-molecular-weight substances have been introduced to make many improvements in their performance, such as condensate oil phosphate having a structure similar to bisphenol A, due to the impact resistance, thermal stability, weather resistance and flammability of related products. The unbalanced combination makes the product not have a good overall performance in the end

[0007] 4. Red phosphorus is a flame retardant additive with good flame retardant effect. Patent documents WO98 / 30632, WO99 / 27016, JPA11-335531, and US2003 / 0018108 have introduced it. However, due to its inherent deep red color, the relevant Polymer products are difficult to utilize in their natural state and light-colored state

However, aluminum hypophosphite alone has little effect in combination with melamine cyanurate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

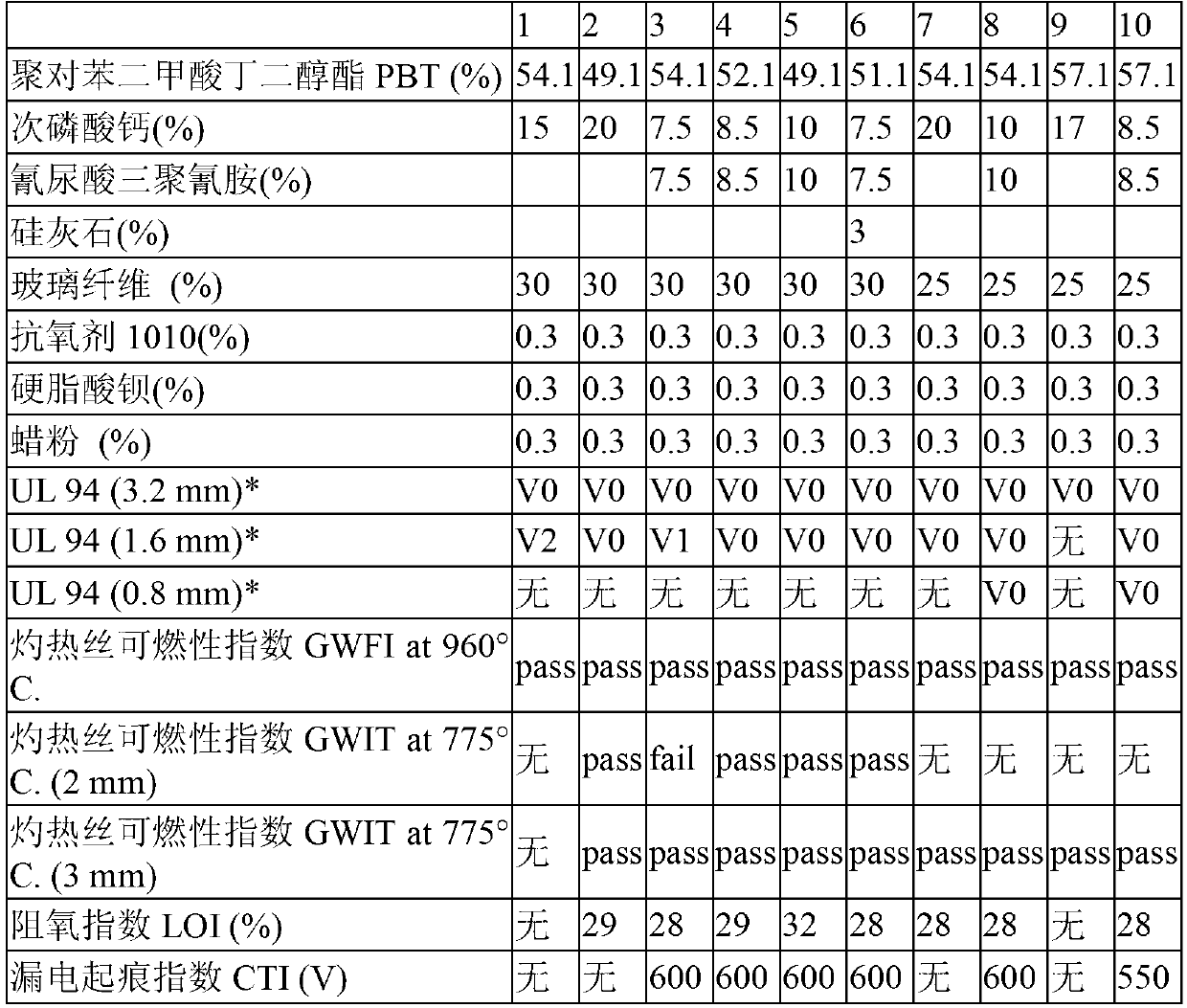

[0113] The components in the following table are extruded into granular form by parallel twin-screw plastic extruder at 250-270°C. After the pellets are dried, they are injection molded into required samples using:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a halogen-free environment-friendly flame-retardant modified thermoplastic polyester resin. The thermoplastic polyester resin comprises the following components in parts by weight: 5-95% of polyester resin, 0.1-30% of calcium hypophosphite, 0-10% of halogen-free flame-retardant additive, 0.5-10% of one or more of processing aid, thermal and process stabilizing agent, ultraviolet stabilizer, antidripping agent, pigment, releasing agent, rubber elastomeric polymer and nucleating agent and 0-50% of inorganic filler. The product provided by the invention has favorable halogen-free flame-retardant performance, particularly favorable thermal resistance at 775 DEG C under the length of 1.6mm and the thickness of 0.8mm according to the UL94 standard, excellent mechanical property, particularly good impact strength and elasticity modulus and favorable stretchability and electrical property and can pass a CTI (Computer Telephony Integration) value under the condition of 600V.

Description

technical field [0001] The invention relates to the technical field of flame retardants, in particular to a halogen-free environmentally friendly flame-retardant modified thermoplastic polyester resin. Background technique [0002] Halogen-free environmentally friendly flame retardant additives are becoming more and more popular in the market. Important properties of these products are usually demanded as follows: high flame retardant effect for reinforced and non-reinforced products, inherent light color, good thermal stability, good mechanical and electrical properties and low cost. [0003] In addition to halogen-containing flame retardant additives, the types of halogen-free and environmentally friendly flame retardant additives applied to thermoplastic polyester resin modification are as follows: [0004] 1. Inorganic flame retardant. This type of compound is usually a metal hydroxide, such as magnesium hydroxide and calcium hydroxide; this type of compound is usually...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L67/02C08L69/00C08L27/18C08K13/06C08K9/06C08K3/32C08K5/523C08K5/3492C08K5/134C08K5/01C08K5/103C08K5/098C08K7/10C08K7/14

Inventor 郭雨铭

Owner 天津然跃环保创新科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com