Patents

Literature

64 results about "Calcium hypophosphite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

IDENTIFICATION AND USE: Calcium hypophosphite (Ca(H2PO2)2) is a solid. This is a DEA List 1 chemical substance. It is used as a corrosion inhibitor, and in nickel plating. Calcium hypophosphite is also used as a pharmaceutic aid (retards oxidation of ferrous salts). It has been used as a veterinary dietary supplement.

Method for producing calcium hypophosphite

The invention relates to the production method of calcium hypophosphite; the production method includes the following technical steps: 1. material preparing which is detailed as follows: deionized water is firstly added in a mixer, unslaked lime powder, the weight of which accounts for 4% of the deionized water, is added under the stirring condition to prepare lime cream, and the lime cream is pumped into a reaction kettle by a pump, ready for use; 2. first neutralization reaction; 3. second neutralization reaction; 4. concentration which is detailed as follows: a vacuum pump of a concentration kettle is started, the filtrate from the second neutralization reaction is pumped into the concentration kettle in virtue of the vacuum in the kettle and is concentrated at vacuum condition after a steam valve is opened; 5. drying and packaging step is detailed as follows: the materials are put in a centrifuge for spin drying when the temperature of the feed liquid in a cooling kettle is below 60 DEG C to obtain the finished product with 92-95% of calcium hypophosphite, then the material is put into a dryer and dried for 20-25 min by the hot air with the temperature of 60-80 DEG C to obtain refined calcium hypophosphite finished product with the content of over 99.0 %. The production method has the advantages of low equipment investment, short process flow and simple production principle. Due to high quality, the finished product produced can be used as food additive, pharmaceuticals and chemical agents.

Owner:江苏和纯化学工业有限公司

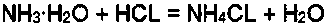

High-rigidity steel belt reinforced polyethylene spiral corrugated pipe and preparation method thereof

ActiveCN104534192AMeet the processing technology requirementsAvoid breakingRigid pipesPropanoic acidPhosphoric acid

The invention discloses a high-rigidity steel belt reinforced polyethylene spiral corrugated pipe and a preparation method thereof. The high-rigidity steel belt reinforced polyethylene spiral corrugated pipe comprises an inner polyethylene pipe, formed steel belts and an outer polyethylene pipe. The formed steel belts are wound around the outer surface of the inner polyethylene pipe at equal intervals and wrapped by the outer polyethylene pipe. The inner polyethylene pipe and the outer polyethylene pipe respectively comprise, by weight, 80-86 parts of high density polyethylene, 8-10 parts of magnesium hydrate, 4-6 parts of compatilizers, 3-4 parts of dibutyltin dilaurate, 2-4 parts of calcium hypophosphite, 2-3 parts of polyoxyethylene, 5-6 parts of polyethylene-graft-maleic anhydride, 7-9 parts of alkyl phosphoric acid, 3-6 parts of superfine talcum powder, 5-7 parts of lustering agents for plastic, 6-8 parts of aluminium-zirconium coupling agents, 4-5 parts of vinyltriethoxysilane, 4-7 parts of beta (3,5 di-tert-butyl-4-hydroxycyclohexyl phenyl ketone) propionic acid octadecyl ester, 5-8 parts of color master batches and 10-12 parts of assistant master batches. According to the high-rigidity steel belt reinforced polyethylene spiral corrugated pipe and the preparation method of the high-rigidity steel belt reinforced polyethylene spiral corrugated pipe, the technology is simple, the production cost is low, pipes are not likely to be fractured, adhesive bonding is firm, the layering problem is not likely to be produced, and using is safe and reliable.

Owner:HANGZHOU TONGYU IND

Method for producing ceramics through granite powder waste

InactiveCN106242508ALower firing temperatureReduce dosageCeramic materials productionClaywaresPyrophylliteZircon

The invention discloses a method for producing ceramics through purified granite powder waste. 10-35 parts by weight of zircon sand, 5-30 parts by weight of high-whiteness potassium-sodium feldspar powder, 3-25 parts of kaolin, 5-25 parts of pyrophyllite, 3-25 parts of gypsum, 3-20 parts of nutshell powder, 2-20 parts of iron mine milltailings, 1-15 parts of zinc oxide, 1-15 parts of magnesium oxide, 1-15 parts of barium oxide, 1-10 parts of pentalyn, 1-10 parts of ammonium citrate and 1-10 parts of calcium hypophosphite are weighed; kaolin, pyrophyllite and gypsum are taken to be mixed and crushed, and wet ball milling, drying, calcining, water quenching, drying and crushing are carried out; zircon sand, high-whiteness potassium-sodium feldspar powder and iron mine milltailings are taken to be mixed and crushed, and size mixing, microwave treatment, size mixing, ultrasonic treatment and drying are carried out; the prepared powder and the remaining raw materials are stirred, mixed, subjected to compression moulding and sintered, and the ceramics are obtained. The ceramics have the very prominent mechanical property, the production cost is reduced, the service life is prolonged, and the method is widely applied to producing whiteware, domestic ceramics and craft ceramics.

Owner:吴海屏

Anti-fatigue PVC (polyvinyl chloride) cable jacket material and preparation method thereof

InactiveCN104371217AImprove fatigue resistanceNo crackingPlastic/resin/waxes insulatorsCarbon fibersAcrylic rubber

The invention discloses an anti-fatigue PVC (polyvinyl chloride) cable jacket material and a preparation method thereof. The anti-fatigue PVC cable jacket material is prepared from the following raw materials in parts by weight: 42-56 parts of SG-4 type polyvinyl chloride, 24-38 parts of polyhydroxyethyl methylacrylate, 16-24 parts of acrylic rubber, 11-17 parts of vulcanic ash, 10-15 parts of polypropylene glycol adipate, 2-3 parts of calcium stearate, 2-3 parts of barium stearate, 3-5 parts of pentaerythritol ester monooleate, 2.5-4.5 parts of hexadecyl palmitate, 10-15 parts of magnesia, 5-10 parts of carbon nanofiber, 13-19 parts of diethylene glycol dibenzoate, 10-15 parts of calcium hypophosphite, 2-4 parts of hydrogenated terphenyl, 3-5 parts of dimethylpropane carboxylic ether, 6-12 parts of hexamethylphosphoric triamide, 1.5-2.5 parts of 1,1-di(4-hydroxyphenyl)cyclohexane and 15-20 parts of a flame retardant. The cable jacket material disclosed by the invention is good in fatigue resistance, cannot generate cracks and ruptures after 50-100 thousands of times of repeated bending, has characteristics of excellent heat resistance, ageing resistance, chemical corrosion resistance, wear resistance and the like, and is long in service life and wide in application range.

Owner:安徽电信器材贸易工业有限责任公司

Flame retardant polymer compositions

The instant invention relates to polymer compositions comprising a calcium hypophosphite, an aluminium inorganic salt and an additive improving the flame retardant properties of the composition other than the hypophosphite salts.

Owner:RHODIA OPERATIONS SAS

Method for joint production of hypophosphite of calcium, magnesium and aluminum

InactiveCN106006589AThe synthetic process route is simpleAvoid harmHypophosphorous acidSodium Hypophosphite MonohydrateMagnesium salt

The invention relates to a method for joint production of hypophosphite of calcium, magnesium and aluminum. The method provided by the invention employs sodium hypophosphite, a calcium salt, and a magnesium salt to carry out double decomposition reaction to prepare calcium hypophosphite and magnesium hypophosphite, and avoids the harm of using hypophosphorous acid as the reactant, also gives consideration to the technological shortcoming that after preparation of calcium hypophosphite and magnesium hypophosphite, a lot of hypophosphite still exists in waste liquid and cannot be completely extracted, after preparation of calcium hypophosphite and magnesium hypophosphite, a joint production technique is employed for the first time to prepare hypophosphite of aluminum. The preparation method has the advantages of mild reaction conditions, little pollution, pure product, high utilization rate of hypophosphite ions, high comprehensive yield, greatly reduced cost, and simple and practicable process route, and is convenient for mass production.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Low-smoke halogen-free flame-retardant crack-resistant cable material and preparation method thereof

InactiveCN105906920AImprove mechanical propertiesLow smoke productionInsulated cablesInsulated conductorsColemaniteAntimony

The invention discloses a low-smoke halogen-free flame-retardant crack-resistant cable material and a preparation method thereof. The low-smoke halogen-free flame-retardant crack-resistant cable material is prepared from the following raw materials in parts by weight: 65-75 parts of high-density polyethylene, 30-40 parts of ethylene-vinyl acetate copolymer, 7-9 parts of phenyl alkyl sulfonate, 4-6 parts of diethanolamine borate, 3-5 parts of magnesium dimethyl acrylate, 8-10 parts of magnesium hydroxide, 40-50 parts of tolyl diphenyl phosphate, 4-7 parts of 3-aminopropyltriethoxy silane, 7-9 parts of trimethylsilane-base cage-type polysilsesquioxane, 6-8 parts of organic antimony stabilizer, 5-7 parts of p-phenylenediamine, 30-40 parts of nano colemanite, 8-10 parts of Ome mineral fiber, 8-10 parts of hexachlorocyclotriphosphonitrile, 6-8 parts of carnauba wax, 10-12 parts of polyarylether ether nitrile, 7-8 parts of zirconium carbide, 5-8 parts of fibrous plaster, 4-6 parts of calcium hypophosphite and 8-12 parts of high-wear-resistance carbon black. The cable material has the advantages of favorable flame-retardant effect, less fuming and favorable cracking resistance.

Owner:卢永杰

Efficient flame-retardant nylon 6 resin and preparation method thereof

The invention relates to a low-halogen efficient nylon 6 resin composition and a preparation method thereof. 2,2',3,3',4,4',5,5',6,6'-decabromobibenzyl and calcium hypophosphite are adopted as main flame retardant and compounded with NOR116 to prepare the efficient flame-retardant nylon 6 resin composition. The composition contains bromine, phosphorus and nitrogen, has good compatibility, and is high in thermal stability and hydrolytic resistance. The amount of added 2,2',3,3',4,4',5,5',6,6'-decabromobibenzyl is obviously reduced, adding of antimony trioxide is not needed, in this way, the fuming amount is substantially reduced, and a good flame-retardant effect is still achieved. In addition, the flame-retardant nylon 6 resin further has good ultraviolet resistance, is not prone to discoloring, and is quite high in thermal stability and capable of meeting the machining requirements for all kinds of materials.

Owner:ZHEJIANG AILA BUILDING ENERGY SAVING TECH

Rust remover

The invention discloses a rust remover. The rust remover is characterized in that the rust remover comprises the following raw materials in parts by mass: 2-13 parts by mass of sodium silicate, 12-20 parts by mass of phosphoric acid, 1-10 parts by mass of lauryl sodium sulfate, 14-35 parts by mass of calcium hypophosphite, 2-15 parts by mass of potassium tetraborate and 200-400 parts by mass of water. The rust remover provided by the invention cannot cause harm to steel.

Owner:南通中兴多元复合钢管有限公司

Novel domestic wastewater treatment agent

InactiveCN107720918AReduce processing costsShort cycleWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationSodium BentoniteAluminum silicate

The invention discloses a novel domestic sewage treatment agent, which comprises the following raw materials in parts by weight: 3-10 parts of polyacrylamide, 4-6 parts of alkanolamide, 30-60 parts of aluminum silicate, and 15-15 parts of ferric chloride 25 parts, 6-9 parts of bentonite, 3-6 parts of diatomite, 15-25 parts of ferric chloride, 2-4 parts of fly ash, 20-40 parts of adsorbate, 15-25 parts of plant fiber, calcium hypophosphite 3‑8 parts, 3‑9 parts of Sophora flavescens, 7‑15 parts of polyaspartic acid. Adding fly ash to the sewage treatment agent of the present invention increases the ability to aggregate with organic pollutants in sewage, so that the flocculation ability is greatly enhanced, and the addition of plant fibers makes the condensed organic matter not condensed under the conditions of high sewage flow rate and high temperature. Comes apart easily.

Owner:张浩

Modified sepiolite used for a polyethylene corrugated pipe material and a preparing method of the modified sepiolite

Modified sepiolite used for a polyethylene corrugated pipe material and a preparing method of the modified sepiolite are disclosed. The modified sepiolite is prepared from following raw materials by weight: 85-105 parts of sepiolite, 10-15 parts of nanometer zirconium dioxide, 18-26 parts of shell powder, 4-7 parts of perfluoro alkyl ethyl acrylate, 2-5 parts of tallow fatty acid, 9-16 parts of glucose pentaacetate, 10-15 parts of gum dammar, 6-12 parts of shellac, 5-10 parts of walnut shell powder, 4-8 parts of ozokerite, 1-2 parts of distearyl dimethyl ammonium chloride, 40-50 parts of polybutylene terephthalate, 25-35 parts of an ethylene-ethenol copolymer, 10-15 parts of polybrominated diphenyl ethers, 5-10 parts of calcium hypophosphite, 2-3 parts of zinc laurate and 5-7 parts of auxiliary agents. The modified sepiolite and the method can significantly improve the dispersing property of the sepiolite in a polyethylene base material, intensifying adhesion of sepiolite-polyethylene interfaces, effective overcome problems that are hard dispersion, easy layering, much dust, and the like of the sepiolite at present, and improve mechanical strength, wear resistance, fatigue resistance, elasticity, machinability, and other properties of the polyethylene material.

Owner:HEFEI HEAN MACHINERY MFG

Fireproof flame-retardant aerocrete building block and preparation method thereof

ActiveCN104556916AImprove fire and flame retardant performanceHigh refractorinessCeramicwareAluminatePolystyrene

The invention discloses a fireproof flame-retardant aerocrete building block and a preparation method thereof. The fireproof flame-retardant aerocrete building block is prepared from the following raw materials in parts by weight: 50-70 parts of potash feldspar, 16-22 parts of iron aluminate cement, 11-17 parts of calcium hypophosphite, 15-20 parts of boehmite, 10-15 parts of borax, 18-24 parts of sericite, 22-28 parts of chalk powder, 16-22 parts of coconut shell flour, 4-7 parts of polyethyleneimine, 2-4 parts of sodium wolframate, 1-2 parts of triethanolamine, 3-5 parts of konjaku flour, 1.5-2.5 parts of modified aluminum powder, 2.5-4.5 parts of sodium polystyrene sulfonate and 3-5 parts of calcium carbide powder. The aerocrete building block has excellent flame retardancy and high fire resistance, and the flame retardancy grade reaches Grade A; and the aerocrete building block has the advantages of high strength, favorable heat resistance, favorable thermal-insulation property, favorable sound-insulation effect, aging resistance, seepage resistance, crack resistance, earthquake resistance, corrosion resistance and the like.

Owner:安徽中龙建材科技有限公司

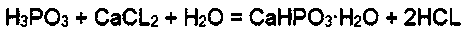

Preparation method of calcium phosphite

InactiveCN103723696ASimple methodEasy to operatePhosphorous acidAmmonium halidesPhosphorous acidChloride

The invention discloses a preparation method of calcium phosphite. The preparation method is characterized in that the calcium phosphite is prepared from phosphorous acid, calcium chloride and ammonium hydroxide through reaction, wherein a reaction equation is H3PO3+CaCl2+2NH3.H2O=CaHPO3.H2O+2NH4Cl+H2O, wherein the mol ratio of the phosphorous acid to the calcium chloride to the ammonium hydroxide is 1:1:(2.0-2.1), the mass concentration of the phosphorous acid is 40-60 percent, the mass concentration of the calcium chloride is 40-50 percent and the mass concentration of the ammonium hydroxide is 10-30 percent. The preparation method disclosed by the invention is simple, easy to operate, lower in requirements of reaction conditions, high in purity of the calcium hypophosphite, suitable for industrialized production, and free from generating three wastes.

Owner:杨洋

Copper plating technology of hardware

The invention discloses a copper plating technology of hardware. The technology comprises following steps that S1, the hardware is subjected to alkali washing, oil contamination is removed, after acidpickling, oxide on the surface of the hardware is removed, the hardware is heated and dried, and gas remaining on the surface of the hardware in the acid pickling process can be exhausted; S2, activating treatment is carried out; S3, washing is carried out; fourthly, electroplating is carried out, wherein electrolytic copper serves as an anode, the hardware serves as a cathode, the electrolytic copper and the hardware are put into an electrolytic cell to be electroplated, an electroplating electrolyte solution contains 40 to 60g / L of CuSO4.5H2O, 80 to 100 mL / L of glyoxylic acid, 50 to 60 g / Lof calcium hypophosphite, 20 to 40 g / L of nickel chloride, 50 to 80 g / L of boric acid, and 0.5 to 0.8 g / L of 1,4-butynediol. According to the copper plating technology of the hardware, virulent chemical medicines are not needed, health of a worker is ensured, and the technology is green and environment-friendly.

Owner:嘉兴市劼力机械科技有限公司

Preparation process for flame-retardant nylon resin

The present invention relates to a preparation process of flame-retardant nylon resin. According to the present invention, decabromodiphenylethane and calcium hypophosphite are used as main flame retardants, and by compounding with NOR116, an efficient flame-retardant nylon 6 resin composition is obtained. The composition is good in bromine, phosphorus and nitrogen compatibility, high in thermal stability and good in hydrolysis resistance. As the adding amount of decabromodiphenylethane is significantly reduced and no antimony trioxide needs to be added, the smoke generation amount is greatly reduced while a good flame-retardant effect is still achieved. Besides, the flame-retardant nylon 6 resin provided by the present invention further has good ultraviolet resistance, so that the product is not easy to change color and is extremely high in thermal stability, and the processing requirements of various materials can be met.

Owner:HUZHOU CHANGSHENG CHEM

Hypophosphite modified polylactic acid composite material and preparation method thereof

The invention discloses a hypophosphite modified polylactic acid composite material and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 12-22 parts of sodium hypophosphite, 5-16 parts of calcium hypophosphite, 3-11 parts of aluminum hypophosphite, 2-11 parts of graphene, 3-18 parts of kenaf fibers, 2-9 parts of cotton fibers, 1-8 parts of palm fibers, 6-18 parts of silicon carbide and 25-48 parts of polylactic acid. The hypophosphite modified polylactic acid composite material has the advantages that: firstly, the hypophosphite modified polylactic acid composite material is good in flame resistance, and is free of a dripping phenomenon during combustion; secondly, the composite material is free of halogen release after being combusted, and is environmentally friendly; and thirdly, the composite material is good in compatibility with a flame-resistant material in a using process, is not liable to migrate, and has enough thermal stability.

Owner:苏州奥宇包装科技有限公司

Preparation method of light-colored rosin glyceride

InactiveCN104087182AReduce oxidationLight colorNatural resin chemical modificationLead nitrateVacuum pump

The invention discloses a preparation method of light-colored rosin glyceride, belonging to the technical field of deep processing of rosin. The preparation method comprises the following steps: putting zeolite into a lead nitrate solution, soaking, then taking out, firstly baking until the water content is 20-30%, then roasting at 300-450 DEG C, and cooling to obtain a substance A for later use; putting rosin into a reaction kettle, controlling the air intake quantity of nitrogen, heating and melting, adding the substance A, rising temperature and then performing heat-preservation reaction 1; adding glycerin, zinc oxide, sodium thiosulfate and calcium hypophosphite, firstly performing heat-preservation reaction at 200-220 DEG C, then rising the temperature to 270-280 DEG C and performing heat-preservation reaction; and performing vacuum pumping to remove low-boiling-point substances, cooling, and discharging material to obtain the light-colored rosin glyceride. According to the preparation method disclosed by the invention, oxidation of rosin is furthest reduced so as to prepare the light-colored rosin glyceride with very light colors.

Owner:GUANGXI ZHONGCHANG RESIN

Preparation method and application of building material

The invention discloses a preparation method and application of a building material. The method includes the steps of stirring diatomite, dolomite powder and calcium hypophosphite to obtain a primarymixture, then making the primary mixture subjected to grinding and screening and adding polyacrylate emulsion, polyhexamethylene biguanidine hydrochloride and sodium polystyrenesulfonate; raising thetemperature for stirring to obtain a secondary mixture, then adding dimethylformamide with the weight 15 times that of the secondary mixture, and adding a maleic anhydride grafting compatilizer afterstirring; introducing inert gas, stirring the mixture at the constant temperature of 50 DEG C, conveying the mixture into a drying box for complete drying, and discharging the material for cooling toobtain a modified mixture; transferring the modified mixture into a high-pressure reaction kettle for a hydrothermal reaction, introducing the product of the hydrothermal reaction into a double-screwextruder, conducting extrusion and pelleting and then obtaining a finished product of the building material. The prepared building material is high in strength and light in weight and has a great application prospect in architectural engineering.

Owner:付主枝

Environment-friendly antistatic noise-reducing coating for machine room and preparation method thereof

InactiveCN104559762AHigh hardnessSimple preparation processElectrically-conductive paintsPhosphoric Acid EstersPolyvinyl alcohol

The invention discloses an environment-friendly antistatic noise-reducing coating for a machine room and a preparation method thereof. The environment-friendly antistatic noise-reducing coating is characterized by comprising the following raw materials in parts by weight: 2-3 parts of ammonium polyphosphate, 3-5 parts of iron powder, 1-2 parts of polyvinyl alcohol, 2-3 parts of mica powder, 1-2 parts of chlorothalonil, 2-4 parts of waterborne polyamide, 2-3 parts of methyl ethyl ketoxime, 1-2 parts of sodium alkyl naphthalene sulfonate, 0.2-0.4 part of dimethyl silicone oil, 2-3 parts of polyethylene wax emulsion, 5-7 parts of talcum powder, 2-3 parts of calcium hypophosphite, 2-3 parts of monoalkyl ether phosphate triethanolamine salt, 2-3 parts of propanediol butyl ether, 27-32 parts of organic silicone emulsion, 25-30 parts of pure acrylic emulsion, 16-20 parts of deionized water and 4-7 parts of aids. According to the coating disclosed by the invention, the preparation process is simple in flow, the reaction time is effectively shortened, the coating is stable in performance, good in economic benefits, environment-friendly, green and pollution-free, water serves as a diluent, the cured coating is high in hardness, high in wear resistance and high in glossiness, and the coating has the characteristics of water resistance, solvent resistance, noise reduction, antistatic property, rust prevention and the like and is wide in application range and simple and convenient to coat and clean.

Owner:安徽省东瑞装饰材料有限公司

Preparation method of pale rosin ester

InactiveCN104087180AReduce oxidationLight colorNatural resin chemical modificationThermal insulationBoiling point

The invention discloses a preparation method of pale rosin ester, belonging to the technical field of deep processing of rosin. The method comprises the following steps: putting rosin in a reaction kettle, controlling the nitrogen gas input, and heating to 200-220 DEG C to carry out thermal insulation reaction; and adding polyalcohol, zinc oxide, sodium thiosulfate and calcium hypophosphite, carrying out thermal insulation reaction at 200-220 DEG C, heating to 270-280 DEG C, carrying out thermal insulation reaction, vacuumizing to remove low-boiling-point substances, cooling, and discharging to obtain the pale rosin ester. By maximally lowering the oxidation of rosin, the color of the prepared pale rosin ester is very light.

Owner:GUANGXI ZHONGCHANG RESIN

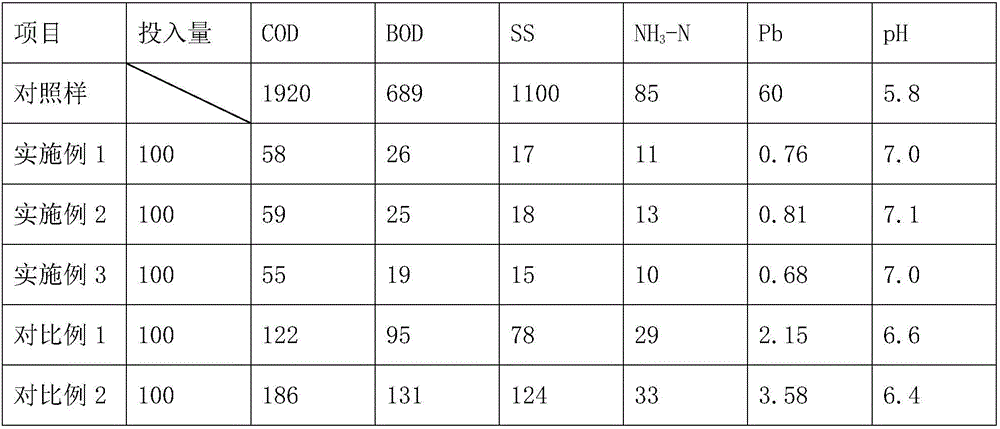

Efficient urban sewage treating agent and preparing method thereof

InactiveCN106517375ASimple processEasy to useWater treatment parameter controlWater/sewage treatmentWater qualityTreated water

The invention discloses an efficient urban sewage treating agent. The treating agent is prepared from the following raw materials of, by weight, 3-5 parts of polyacrylamide, 5-10 parts of alkyl alcohol amide, 2-6 parts of coconut oil, 5-10 parts of ferric chloride, 5-8 parts of clay, 2-5 parts of diatomite, 0.1-0.5 part of disodium ethylenediamine tetraacetate, 1-3 parts of fly ash, 2-8 parts of calcium hypophosphite, 2-5 parts of radix sophorae flavescentis and 2-7 parts of methyl 2-hydroxyisobutyrate. According to the sewage treating agent, by compounding the raw materials, the coordinating function is brought into play, the content of COD, BOD, SS and the like in urban sewage can be effectively reduced, and treated water can be recycled repeatedly. The sewage treating process is simple, and use is convenient. Moreover, the production cost is lower, the sewage treating period is short, and the urban sewage treating effect is better. Meanwhile, the influence of the raw materials on operators is avoided, the influence on the environment is avoided even if a large number of the treating agents are used, and the treating agent is more environmentally friendly.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

Strong rust remover

The invention discloses a strong rust remover. The strong rust remover is prepared from the following raw materials in parts by volume: 15-20 parts of sulfamic acid, 15-20 parts of boric acid, 2-13 parts of sodium silicate, 12-20 parts of phosphoric acid, 1-10 parts of sodium dodecyl sulfate, 20-25 parts of calcium hypophosphite, 2-15 parts of potassium tetraborate and 400-500 parts of deionized water. The strong rust remover has very strong decontamination ability and erosion ability, and can quickly penetrate into fastened threaded connectors to corrode rust so as to play a loosening role.

Owner:长沙丰畅车辆工程技术有限公司

Process for phosphating highway guardrails by adopting room-temperature multi-functional phosphating liquid

InactiveCN104250785ALower working temperatureSave energyMetallic material coating processesPhosphoric acidSodium nitrite

The invention discloses a process for phosphating highway guardrails by adopting a room-temperature multi-functional phosphating liquid. The phosphating liquid adopted in the process comprises the composition: 135-145 g / L of a 85% phosphoric acid, 35-45 g / L of zinc oxide, 30-40 g / L of magnesium oxide, 20-24 g / L of calcium hypophosphite, 8-12 g / L of triethanolamine, 3-5 g / L of sodium nitrite, 5-7 g / L of sodium fluoride, 2-4 g / L of sodium chlorate, 2.5-3.5 g / L of citric acid, 1.5-2.5 g / L of ammonium molybdate, 5-7 g / L of peregal, 6.5-7.5 g / L of OP-10, and the balance water. The process comprises the steps: preparing the phosphating liquid, adjusting the pH value to 3.0-4.0 by ammonium acetate, making the temperature be 15-40 DEG C, then placing highway guardrail blank pieces into the phosphating liquid, arranging a stirrer in a phosphating tank to make the phosphating liquid flowing, controlling the phosphating processing time to be 20-30 minutes, taking out, and then air-drying.

Owner:WUXI LUOSHE TECH VENTURE

Tree grafting wound healing solution

InactiveCN106748029AMoisturizeAvoid lossMagnesium fertilisersLiquid fertilisersWound healingSodium molybdate

The invention provides a tree grafting wound healing solution which is a nutrient solution used for healing flower and tree grafting wounds. The formula of the tree grafting wound healing solution comprises the following materials by weight percentage: 0.01-0.02% of copper sulfate, 0.02-0.03% of calcium hypophosphite, 0.0001-0.0003% of sodium molybdate, 0.02-0.03% of ferrous sulfate, 0.01-0.04% of magnesium sulfate, and the balance of deionized water. A preparation method is as follows: putting the above formula materials into a stainless steel container, evenly stirring, and filtering through a 80-mesh filter screen to remove the impurity, so as to obtain the nutrient solution. When the tree grafting wound healing solution is used, the grafted flower and tree trimming wound is soaked in the nutrient solution to exert the effects of preserving and sterilizing, meanwhile, the survival rate of the soaked wound is high after grafting, and the tree grafting wound healing solution is favorable for rapidly healing and growing the wound.

Owner:扬州大学(如皋)花木产业研究院

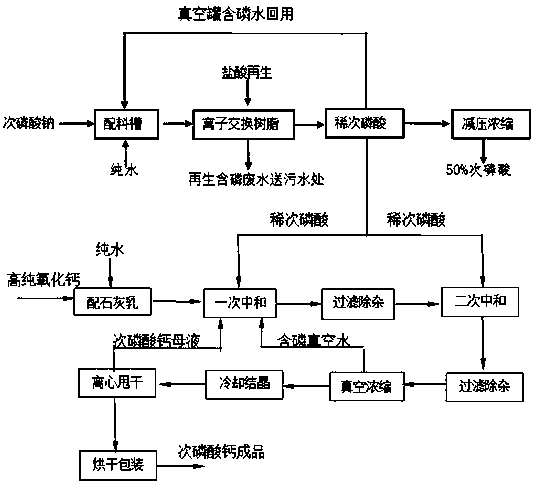

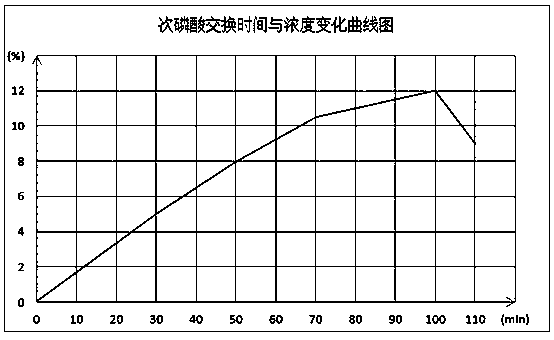

Low-cost production method for co-production of hypophosphorous acid and calcium hypophosphite

PendingCN110282610AReduce manufacturing costReduce consumptionHypophosphorous acidPhosphoric acidStrong acids

The invention discloses a low-cost production method for the co-production of hypophosphorous acid and calcium hypophosphite. The production method of the hypophosphorous acid comprises the following steps: 1) preparing an aqueous solution of sodium hypophosphite; 2) enabling the aqueous solution of the sodium hypophosphite to pass through hydrogen type strong-acid ion exchange resin to obtain dilute hypophosphorous acid; 3) performing vacuum concentration and filtration on the dilute hypophosphorous acid to obtain commercial hypophosphorous acid with the content of 50%; 4) regenerating the ion exchange resin with hydrochloric acid through resin, and then flushing with pure water. The production method of the calcium hypophosphite comprises the following steps: 1) preparing lime milk; 2) neutralizing; 3) filtering and removing impurities; 4) performing vacuum concentration to obtain phosphorus-containing vacuum water; 5) cooling and crystallizing; 6) performing centrifuge dripping to obtain mother liquor of the calcium hypophosphite; 7) drying filter cake subjected to centrifuge dripping to obtain a calcium hypophosphite finished product and packaging; 8) reusing the mother liquor. The production method disclosed by the invention has the advantages that the production cost of the hypophosphorous acid is greatly reduced; the energy consumption such as steam and electric power is reduced; the product quality is reliable and the process is simple; the production capacity of a hypophosphorous acid concentrating device can be greatly improved.

Owner:江苏和纯化学工业有限公司

Organic composite biological fertilizer based on agriculture straw

InactiveCN104402588AHigh organic contentNutritional diversitySuperphosphatesExcrement fertilisersWheat BransLivestock

A disclosed organic composite biological fertilizer based on agriculture straw is characterized by comprising the following substances in parts by weight: 25-36 parts of calcium hypophosphite, 100-150 parts of livestock and poultry excrement, 30-50 parts of corn straw, 30-40 parts of beans straw, 20-30 parts of vegetable cake, 1-2 parts of trace elements, 5-9 parts of sodium dihydrogen phosphate, 2-7 parts of disodium hydrogen phosphate, 3-8 parts of sodium polyphosphate and rice bran, 10-16 parts of wheat bran, 1-2 parts of naphthylacetic acid, and 3-8 parts of humic acid. The organic composite biological fertilizer is rich in beneficial microbes, comprehensive and balanced in nutrition and persistent in effect, and is capable of improving the organic matter content in soil.

Owner:曲少春

Preparation technology of normal-temperature multifunctional phosphatization liquid for highway guardrails

InactiveCN104250787AImprove performanceLower working temperatureMetallic material coating processesAcetic acidSodium chlorate

The invention discloses a preparation technology of a normal-temperature multifunctional phosphatization liquid for highway guardrails. The preparation technology comprises the following steps: 1, uniformly mixing 135-145g / L of phosphoric acid and citric acid in an acid resistant container according to weight percentages; 2, slowly adding 35-45g / L of pasty zinc oxide while stirring, wherein the pasty zinc oxide is obtained through blending zinc oxide with water; 3, slowly adding 30-40g / L of pasty magnesium oxide while stirring, wherein the pasty magnesium oxide is obtained through blending magnesium oxide with water; 4, adding 20-24g / L of calcium hypophosphite, 8-12g / L of triethanolamine, 3-5g / L of sodium nitrite, 5-7g / L of sodium fluoride, 2-4g / L of sodium chlorate, 2.5-3.5g / L of citric acid, 1.5-2.5g / L of ammonium molybdate, 5-7g / L of peregal, 6.5-7.5g / L of OP-10 and the balance of water, and stirring until complete dissolving; and 4, adjusting the pH value of the obtained solution to 3.0-4.0 by acetic acid.

Owner:WUXI LUOSHE TECH VENTURE

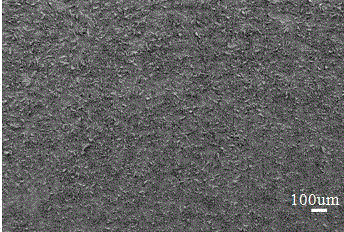

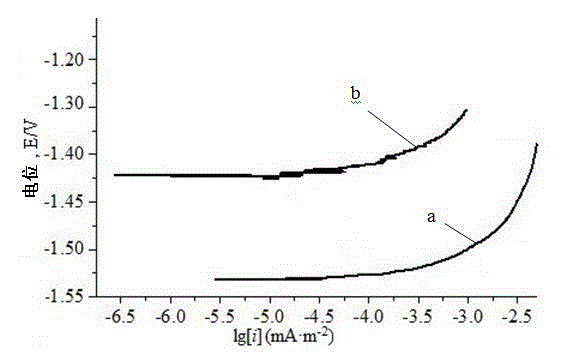

Chromium-free chemical conversion treatment method for magnesium alloy surface

InactiveCN104928663ALower operating temperaturePhosphating time is shortMetallic material coating processesMg alloysHexamethylenetetramine

The invention relates to a chromium-free chemical conversion treatment method for a magnesium alloy surface. The chromium-free chemical conversion treatment method for the magnesium alloy surface comprises the steps of surface pretreatment, alkaline washing for oil removing, water washing, acid pickling, water washing, phosphorization and water washing. Treating fluid used for phosphorization is composed of 20-80 g.L<-1> of sodium dihydrogen phosphate, 1-167 g.L<-1> of calcium hypophosphite and 0.1-10 g.L<-1> of hexamethylenetetramine. The phosphorization treatment temperature is 10-60 DEG C, the pH value is 2.8-7.0, and the phosphorization time is 1-50 minutes. A phosphating film surface prepared through the method is uniform, compact and high in corrosion resistance and can be used independently or serve as the bottom layer of a coating film, and the adhesive force of the coating film to a base body is improved. The reaction temperature is low, the condition is mild, the elements of a phosphating solution are simple, and the technique universality is high; no special requirements exist for equipment and the technique, and industrialized application is facilitated; production cost is reduced; meanwhile, energy resources are saved.

Owner:SOUTH CHINA UNIV OF TECH

Energy-saving environment-friendly building material and preparation method thereof

The invention provides an energy-saving environment-friendly building material and a preparation method thereof. The energy-saving environment-friendly building material is prepared from building timber waste, waste plastic, straw, sludge, calcium carbonate, graphene, sepiolite, coal ash, silicon dioxide, calcium hypophosphite, polydimethyldiallyl ammonium chloride, phase-change solution, saturated sodium hydroxide solution, a waterborne adhesive, dispersion solubilizer solution, an alkali activator and water. The building material has advantages of high strength and low energy consumption andcan be applied to buildings to effectively reduce building energy consumption on the premise that building strength is guaranteed, raw materials are mainly construction waste and domestic waste, environmental friendliness and energy saving are realized, and preparation cost is sharply reduced. In addition, a preparation process is simple and suitable for large-scale popularization and production.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

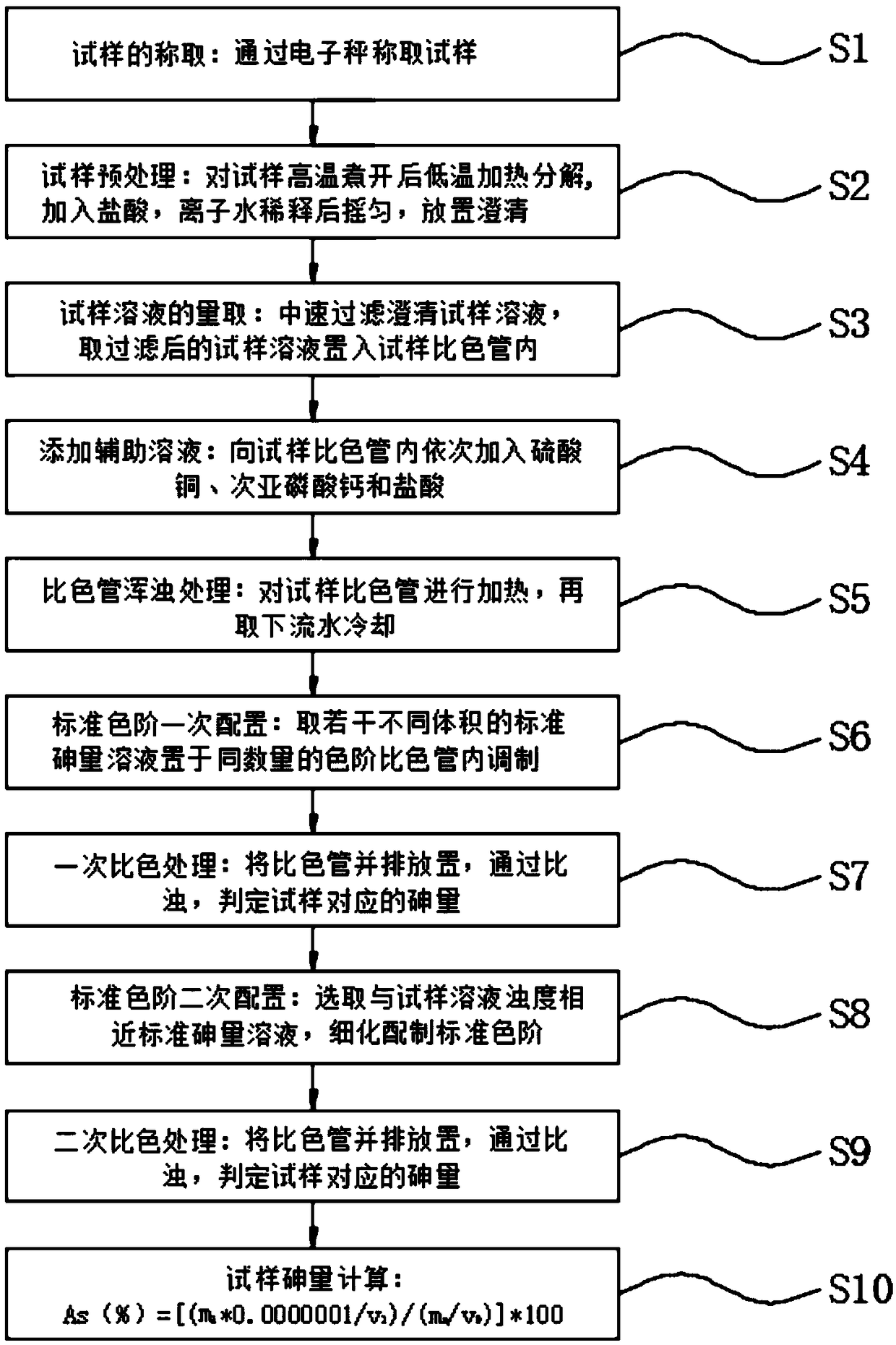

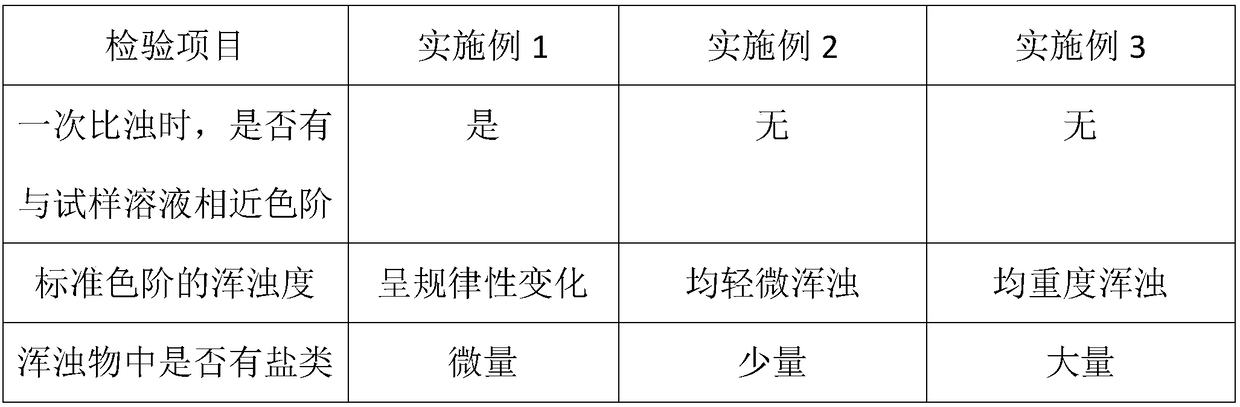

Method for determining arsenic content by using turbidimetry method

InactiveCN109115765AReduce precipitationReduce impressionMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsSodium phosphatesTurbidity

The invention discloses a method for determining arsenic content by using a turbidimetry method. The method comprises the following steps: weighing samples; pretreating samples; measuring a sample solution; adding an auxiliary solution; carrying out colorimetric tube turbidity treatment, standard color primary preparation, primary turbidity treatment, standard color secondary preparation and secondary turbidity treatment, and calculating the arsenic content of the samples. The method disclosed by the invention is scientific and reasonable, and is safe and convenient to use; by adopting secondary turbidity and selecting appropriate concentration of hydrochloric acid, the adequacy of reduction reaction is ensured; the precipitation of the salt is reduced so as to further improve the accuracyof the arsenic content and facilitate clearer calculation of the arsenic content in the samples; in addition, a white baffle plate is added in the turbidity process to serve as an observation background, so that the observation is more accurate during visual turbidity and the influence of subjective factors of testers on observation results is reduced. By adopting calcium hypophosphite, the phenomena of reaction failure or even easily cracked accidents due to over-high temperature in the previous sodium phosphate heating process are avoided.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com