Anti-fatigue PVC (polyvinyl chloride) cable jacket material and preparation method thereof

A cable sheath material, anti-fatigue technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve problems such as poor fatigue resistance, fatigue aging cracking, etc., and achieve good fatigue resistance, long service life, excellent heat resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

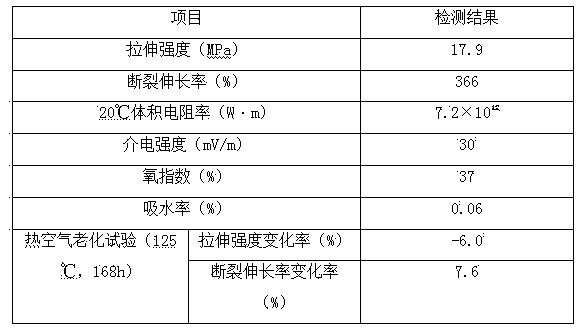

[0012] An anti-fatigue PVC cable sheath material, made of the following raw materials in weight (kg): SG-4 type polyvinyl chloride 49, polyhydroxyethyl methacrylate 34, acrylate rubber 20, volcanic ash 14, polyhexyl Propylene glycol ester 12, calcium stearate 2.5, barium stearate 2.5, pentaerythritol monooleate 4, cetyl palmitate 3.5, magnesite 12, carbon nanofiber 8, diethylene glycol dibenzoate 16. Calcium hypophosphite 12. Hydrogenated terphenyl 3. Dimethylpropane carboxylate 4. Hexamethylphosphoric triamide 8. 1,1-bis(4-hydroxyphenyl)cyclohexane 2. Flame retardant 17;

[0013] The preparation method of the flame retardant is as follows: a, weigh boehmite, brucite, and montmorillonite in a mass ratio of 4:3:2, mix them evenly, pulverize them, pass through a 150-mesh sieve, and then add water to make an oar Concentration is 50% slurry, then add 4% ZnO, 20% NaOH and 15% Na 2 Sn(OH) 6 , heated in a water bath to 70°C, stirred for 6 hours, cooled to room temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com