Preparation method and application of building material

A technology for building materials and mixtures, applied in the field of building materials, can solve problems such as potential safety hazards, economic losses, affecting the normal use of concrete structures, and achieve the effects of improved performance, good application prospects, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

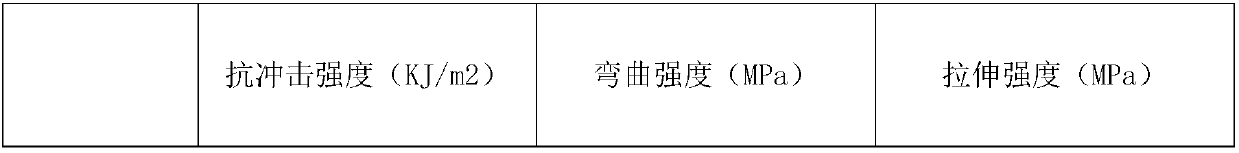

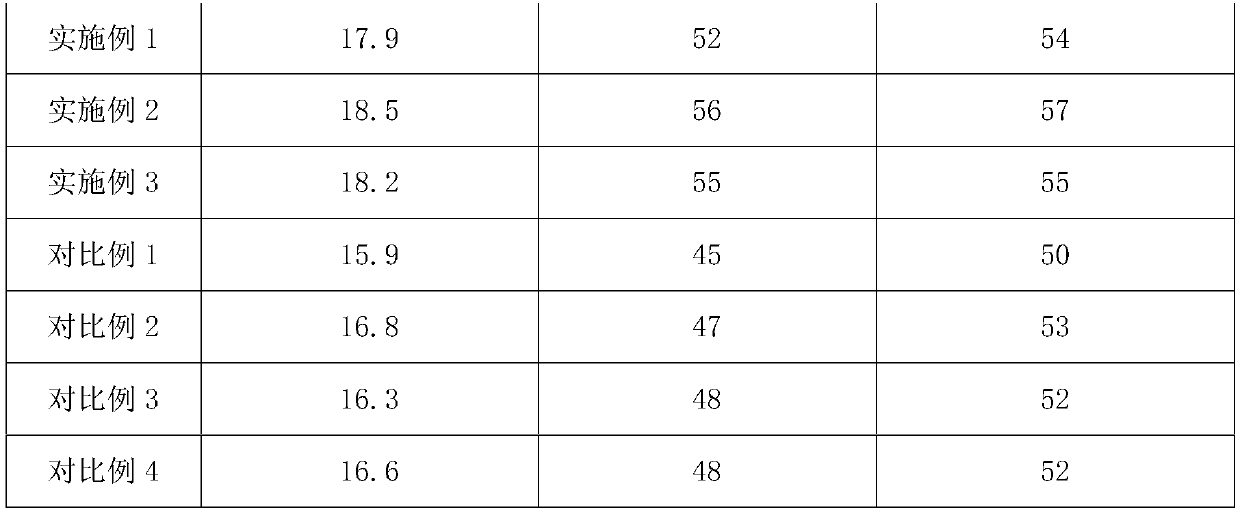

Examples

Embodiment 1

[0021] (1) Add 50 parts of diatomite, 20 parts of dolomite powder, and 12 parts of calcium hypophosphite into the mixer, adjust the speed of the mixer to 300r / min, and stir for 25 minutes to obtain a preliminary mixture

[0022] (2) Grind the preliminary mixture, the speed of the grinder is controlled at 1500r / min, the grinding time is 90min, pass through a 200 mesh sieve, add 30 parts of polyacrylate emulsion, 12 parts of polyhexamethylene biguanide, polystyrene 6 parts of sodium sulfonate, heated up to 60°C, and stirred at this temperature for 45 minutes to obtain the secondary mixture;

[0023] (3) Add the secondary mixture to dimethylformamide that is 15 times its weight, stir for 10 minutes, add 15 parts of maleic anhydride graft compatibilizer, feed nitrogen, keep stirring at 50°C for 3 hours, and then Send it into an oven, dry it completely at 100°C, and cool it out to obtain a modified mixture;

[0024] (4) Transfer the modified mixture to a high-pressure reactor for ...

Embodiment 2

[0027] (1) Add 55 parts of diatomite, 25 parts of dolomite powder, and 15 parts of calcium hypophosphite into the mixer, adjust the speed of the mixer to 300r / min, and stir for 25 minutes to obtain a preliminary mixture

[0028] (2) Grind the preliminary mixture, the speed of the grinder is controlled at 1500r / min, the grinding time is 90min, pass through a 200 mesh sieve, add 35 parts of polyacrylate emulsion, 14 parts of polyhexamethylene biguanide, polystyrene 8 parts of sodium sulfonate, heated up to 60°C, and stirred at this temperature for 45 minutes to obtain the secondary mixture;

[0029] (3) Add the secondary mixture to dimethylformamide that is 15 times its weight, stir for 10 minutes, add 15 parts of maleic anhydride graft compatibilizer, feed nitrogen, keep stirring at 50°C for 3 hours, and then Send it into an oven, dry it completely at 105°C, and cool it out to obtain a modified mixture;

[0030] (4) Transfer the modified mixture to a high-pressure reactor for ...

Embodiment 3

[0033] (1) Add 60 parts of diatomite, 30 parts of dolomite powder, and 18 parts of calcium hypophosphite into the mixer, adjust the speed of the mixer to 300r / min, and stir for 25 minutes to obtain a preliminary mixture

[0034] (2) Grind the preliminary mixture, the speed of the grinder is controlled at 1500r / min, the grinding time is 90min, pass through a 200 mesh sieve, add 40 parts of polyacrylate emulsion, 16 parts of polyhexamethylene biguanide, polystyrene 10 parts of sodium sulfonate, heated up to 60°C, and stirred at this temperature for 45 minutes to obtain a secondary mixture;

[0035] (3) Add the secondary mixture to dimethylformamide that is 15 times its weight, stir for 10 minutes, add 15 parts of maleic anhydride graft compatibilizer, feed nitrogen, keep stirring at 50°C for 3 hours, and then Send it into an oven, dry it completely at 110°C, and cool it out to obtain a modified mixture;

[0036] (4) Transfer the modified mixture to a high-pressure reactor for h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com