Method for determining arsenic content by using turbidimetry method

A turbidimetric and turbidimetric technology, which is used in the measurement of color/spectral properties, material analysis by observing the effect on chemical indicators, and analysis by chemical reaction of materials, etc. It can solve the problem that the accuracy of arsenic content is difficult to obtain. Effective protection, increasing waste liquid treatment time and treatment chemicals, and inability of testers to choose effectively, to reduce the impression of observation results, reduce salt precipitation, and avoid slow response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

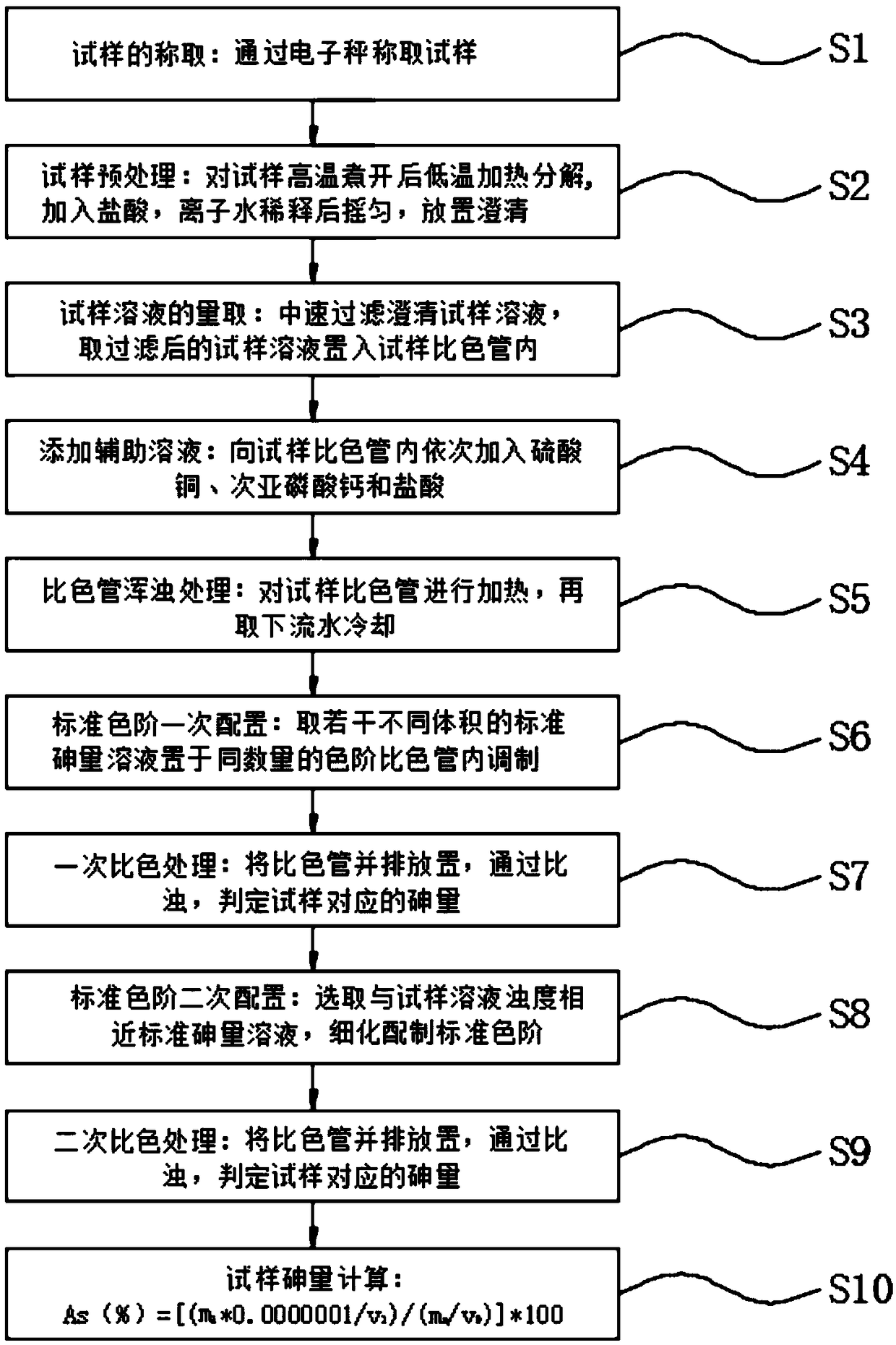

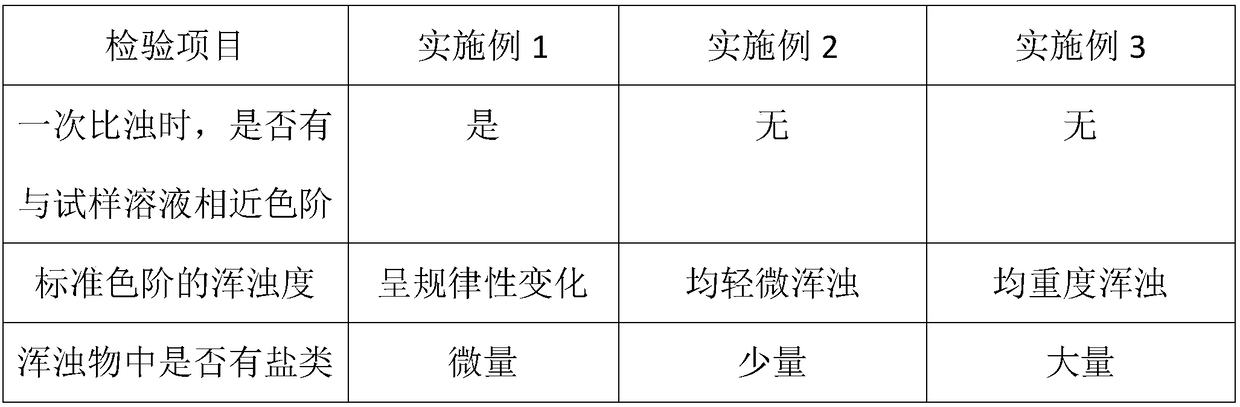

[0040] Embodiment 1: as figure 1 As shown, the present invention provides a kind of technical scheme, the method for measuring arsenic amount by nephelometric method, comprises the steps:

[0041] S1: Weighing of the sample: Weigh the sample through an electronic scale;

[0042] S2: Sample pretreatment: After boiling the sample at high temperature, heat it at low temperature to decompose, add hydrochloric acid, dilute with deionized water, shake well, and place it for clarification;

[0043] S3: Measure the sample solution: filter and clarify the sample solution at a medium speed, take the filtered sample solution and add it to the sample colorimetric tube;

[0044] S4: Add auxiliary solution: Add copper sulfate, calcium hypophosphite and hydrochloric acid to the sample colorimetric tube in sequence;

[0045] S5: Colorimetric tube turbidity treatment: heat the colorimetric tube of the sample, and then remove the flowing water to cool it;

[0046] S6: One-time configuration of...

Embodiment 2

[0072] Embodiment 2: as figure 1 As shown, the present invention provides a kind of technical scheme, the method for measuring arsenic amount by nephelometric method, comprises the steps:

[0073] S1: Weighing of the sample: Weigh the sample through an electronic scale;

[0074] S2: Sample pretreatment: After boiling the sample at high temperature, heat it at low temperature to decompose, add hydrochloric acid, dilute with deionized water, shake well, and place it for clarification;

[0075] S3: Measure the sample solution: filter and clarify the sample solution at a medium speed, take the filtered sample solution and add it to the sample colorimetric tube;

[0076] S4: Add auxiliary solution: add copper sulfate, calcium hypophosphite and hydrochloric acid to the sample colorimetric tube in sequence;

[0077] S5: Colorimetric tube turbidity treatment: heat the sample colorimetric tube, and then remove the flowing water to cool;

[0078] S6: One-time configuration of standar...

Embodiment 3

[0104] Embodiment 3: as figure 1 As shown, the present invention provides a kind of technical scheme, the method for measuring arsenic amount by nephelometric method, comprises the steps:

[0105] S1: Weighing of the sample: Weigh the sample through an electronic scale;

[0106] S2: Sample pretreatment: After boiling the sample at high temperature, heat it at low temperature to decompose, add hydrochloric acid, dilute with deionized water, shake well, and place it for clarification;

[0107] S3: Measure the sample solution: filter and clarify the sample solution at a medium speed, take the filtered sample solution and add it to the sample colorimetric tube;

[0108] S4: Add auxiliary solution: Add copper sulfate, calcium hypophosphite and hydrochloric acid to the sample colorimetric tube in sequence;

[0109] S5: Colorimetric tube turbidity treatment: heat the colorimetric tube of the sample, and then remove the flowing water to cool it;

[0110] S6: One-time configuration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com