Patents

Literature

108results about "Phosphorous acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

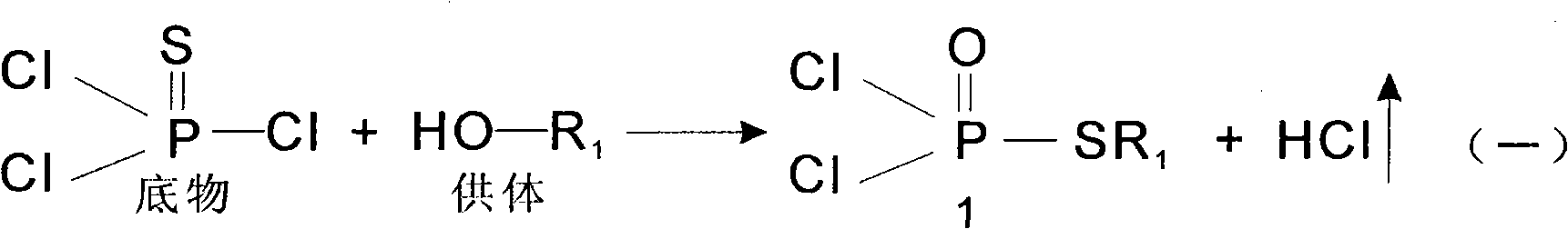

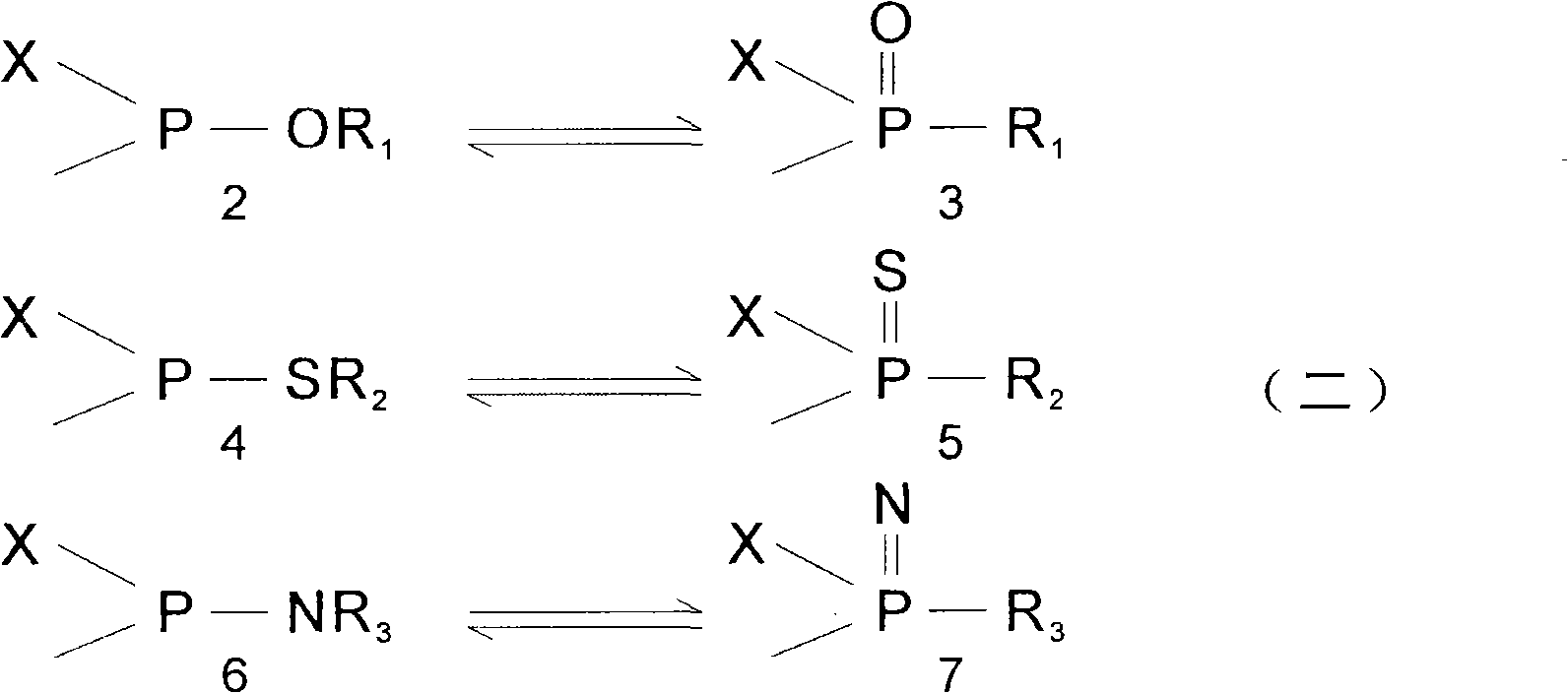

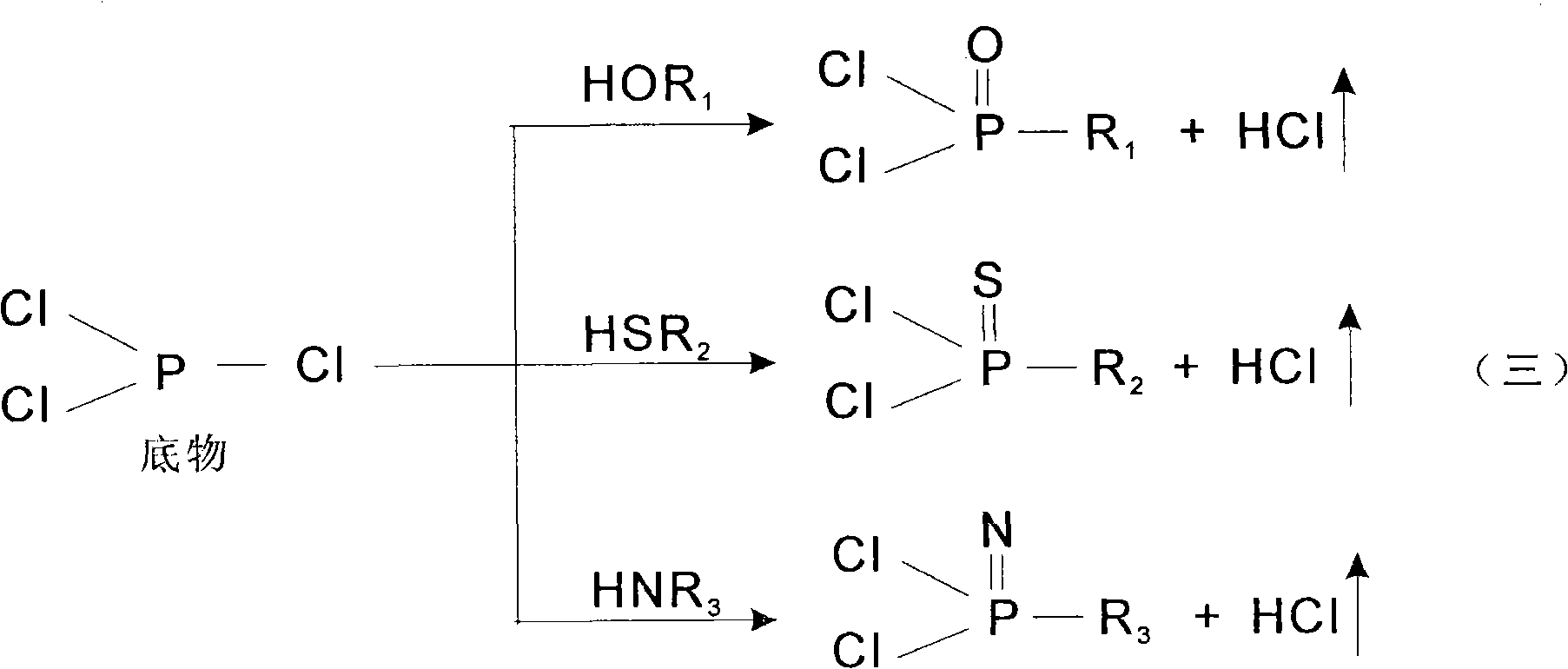

Isomerization reaction

The invention discloses a highly selective novel reaction with an important application value in organic phosphorus synthesis methodology. The reaction can be applied in important pesticide commodities of acephate, glyphosate, glufosinate-ammonium, chloramine phosphorus, profenofos, and the like. With the reaction, innovative technical synthetic routes can be designed. With the reaction, standards of clean production technologies can be satisfied, and the production cost is greatly reduced compared to existing technical routes.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Salts of pyrophosphonic acid as flame retardants

ActiveUS20160032076A1PhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPyrophosphateFire retardant

Owner:LANXESS SOLUTIONS US INC

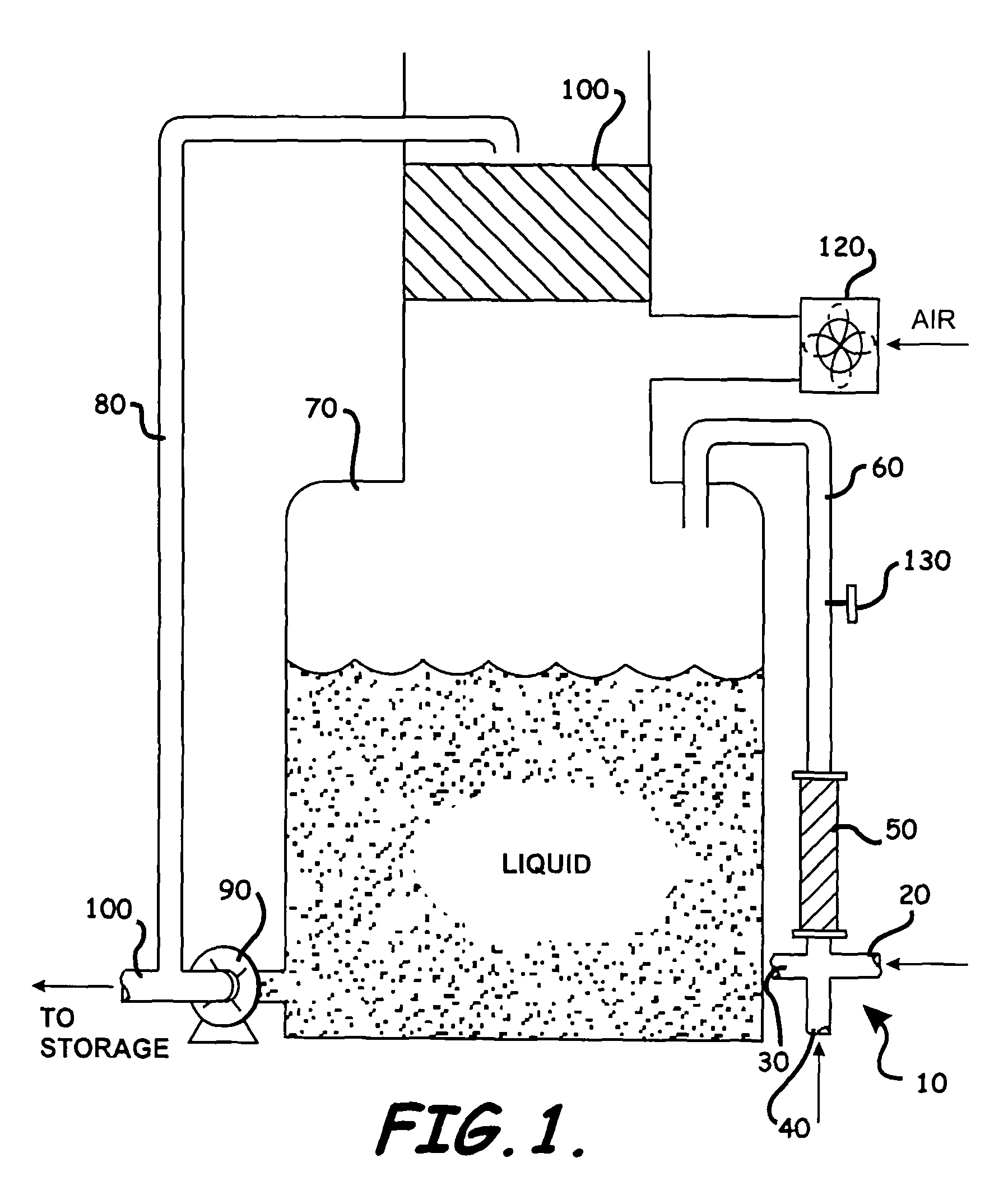

Acid combination one step reaction process for agricultural use products and associated methods

ActiveUS8216972B1High analysisSolution clarificationBiocideMagnesium fertilisersFungicidePhosphorous acid

A process for the manufacture of an aqueous composition that is a combination of a fungicide and fertilizer comprising the following steps:(1) dissolving phosphorous acid in phosphoric acid to form a solution of an acid mixture;(2) reacting the acid mixture of step (1) with an aqueous hydroxide solution creating an exothermic reaction under pressure; and,(3) cooling the reaction product to between about 35° C. to about 65° C.The reaction product prepared according to the above process can also be used as a bactericide.

Owner:PLANT FOOD SYST

Acid combination one step reaction process for agricultural use products and associated methods

ActiveUS8193119B2Minimizes or eliminates wasteful “free water”Avoid reactionBiocidePhosphatesPhosphorous acidContinuous reactor

A process for the manufacture of an aqueous composition that is a combination of a fungicide and fertilizer comprising the following steps:(1) dissolving phosphorous acid in phosphoric acid to form a solution of an acid mixture;(2) reacting the acid mixture of step (1) with an aqueous potassium hydroxide solution at a temperature of about 65° C. to about 260° C. in a continuous reactor while maintaining the ratio of potassium to phosphorous in various mole ratios thereby forming a reaction mixture comprising potassium phosphates, potassium polyphosphates, potassium phosphites, and potassium polyphosphites and potassium phosphate phosphite copolymers; and,(3) cooling the reaction mixture rapidly at least 1° C. to 60° C., to below about 35° C. to about 65° C.Using a similar process a composition having fungicidal properties is prepared by reaction phosphoric acid with potassium hydroxide.The reaction mixtures prepared according to each of the above processes are also part of this invention.

Owner:PLANT FOOD SYST

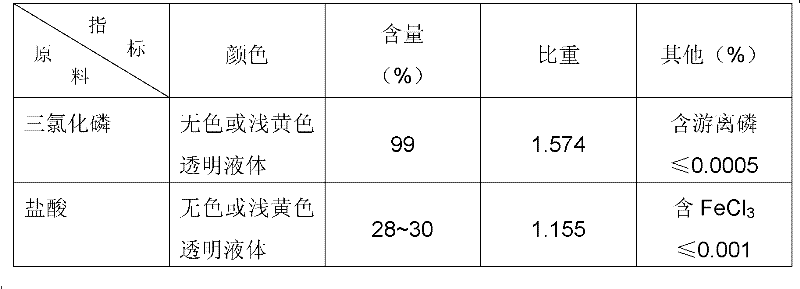

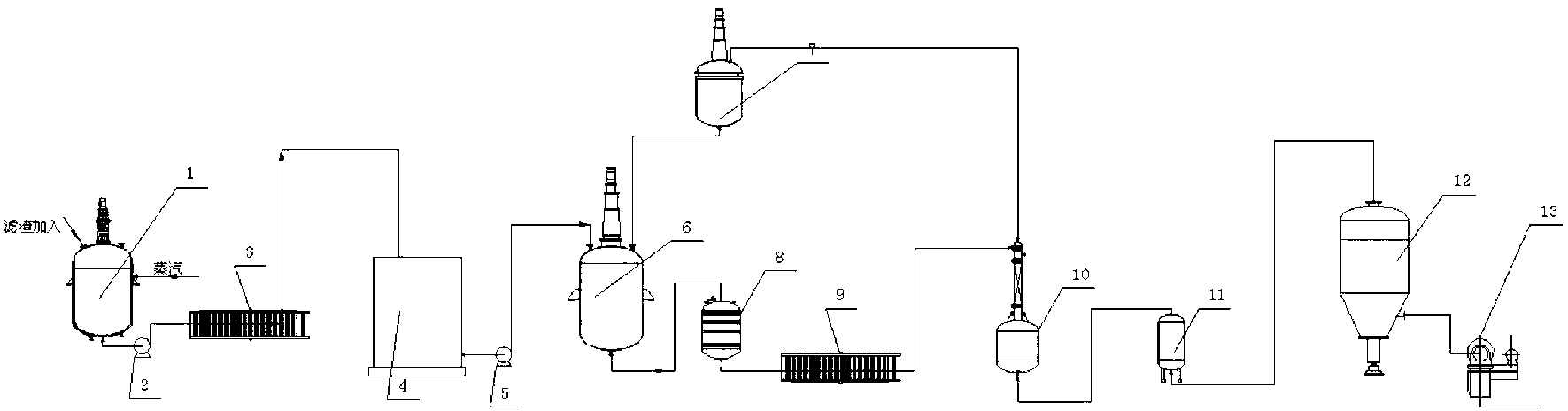

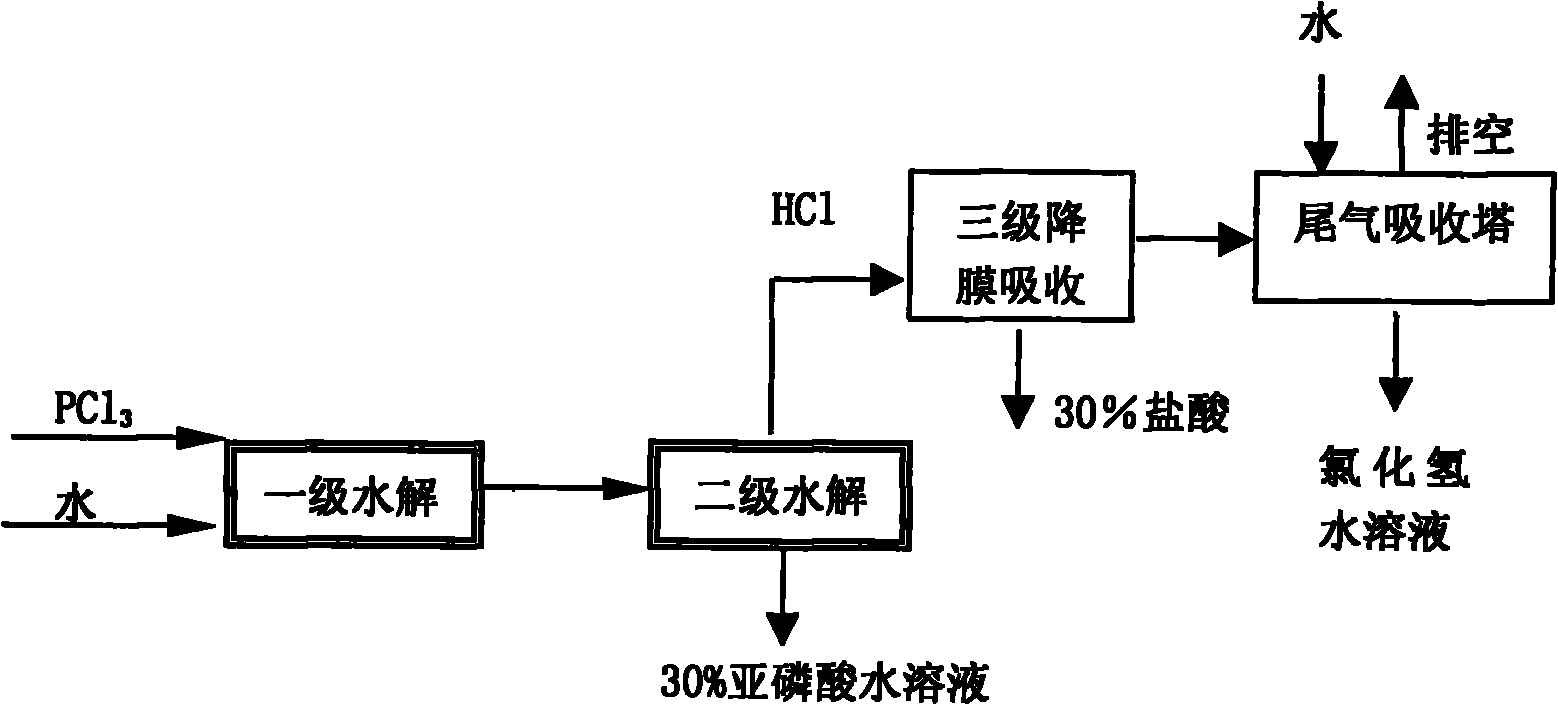

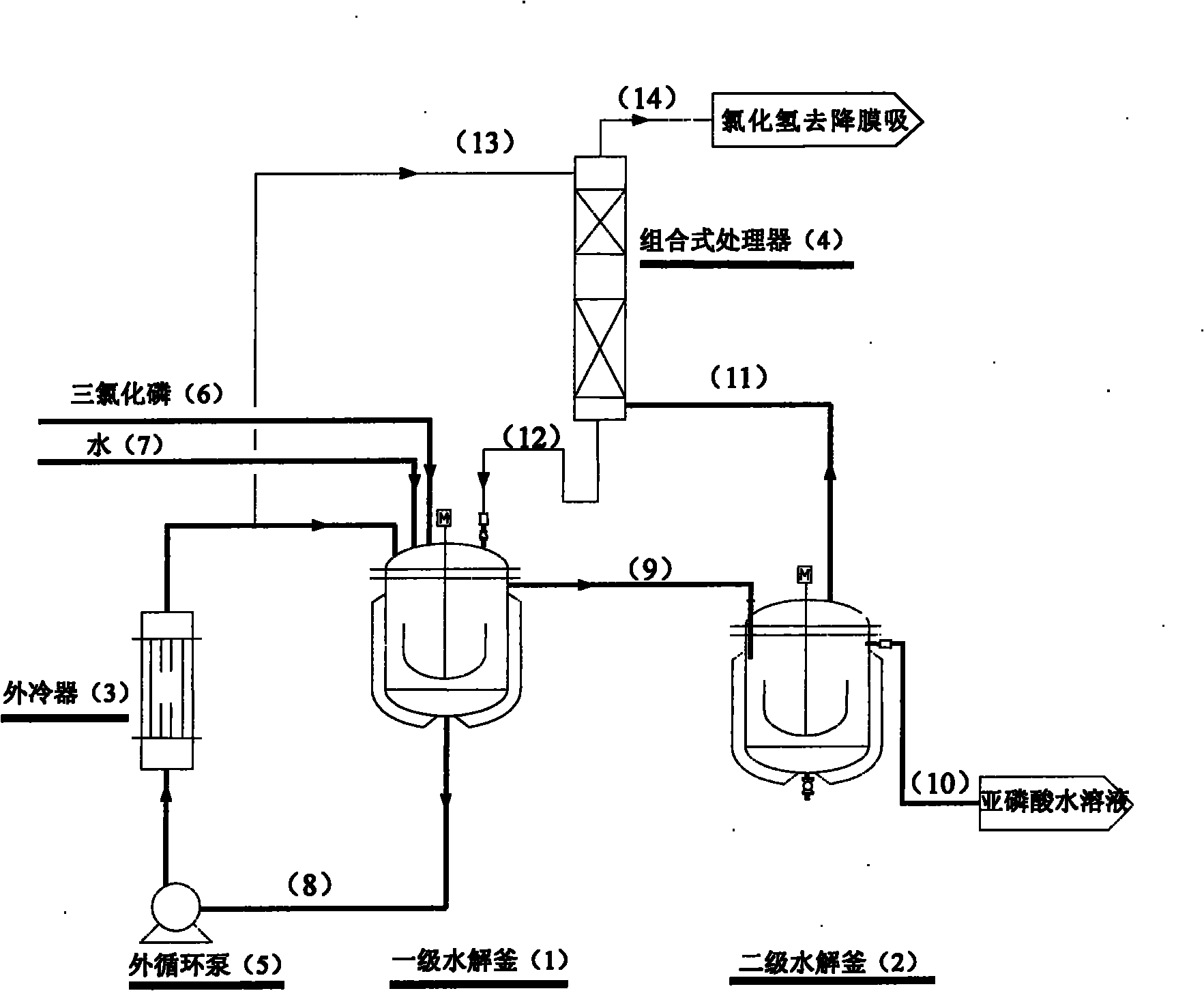

Process for preparing phosphorous acid by hydrolyzing phosphorus trichloride

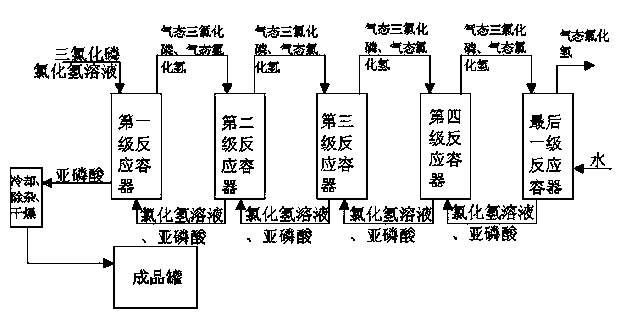

The invention relates to a process for preparing phosphorous acid by hydrolyzing phosphorus trichloride, and in particular relates to a process for preparing phosphorous acid by hydrolyzing phosphorus trichloride under a mild reaction condition. According to the process, phosphorus trichloride and a hydrogen chloride solution are subjected to hydrolysis reaction in sequence in at least four stages of cascade reaction vessels under the condition that the temperature is 65-85 DEG C and the pressure is not more than 0.1Mpa to generate a phosphorous acid solution and gaseous hydrogen chloride. In the process, the phosphorus trichloride reacts with the water in a hydrochloric acid solution, the phosphorus trichloride is subjected to an exothermic reaction, the temperature of the process can reduce the hydrolysis rate to ensure that the reaction is performed mildly, and at least four stages of cascade bubbling reactions are adopted by the process, so that the utilization ratio of raw materials is improved, the phosphorus trichloride in the reaction vessel of the previous stage can enter the reaction vessel of the next stage, the content of the phosphorus trichloride in the reaction vessel of the previous stage is reduced in other ways, the intensity of the reaction is reduced again, the production safety is improved, and the service life of equipment is prolonged.

Owner:HENAN QINGSHUIYUAN TECH

Preparation process for synthesizing phosphorous acid by hydrolyzing phosphorous trichloride

InactiveCN102249202AControl the speed of the hydrolysis reactionReaction is easy to controlChemical industryPhosphorous acidPhosphorous acidChemical industry

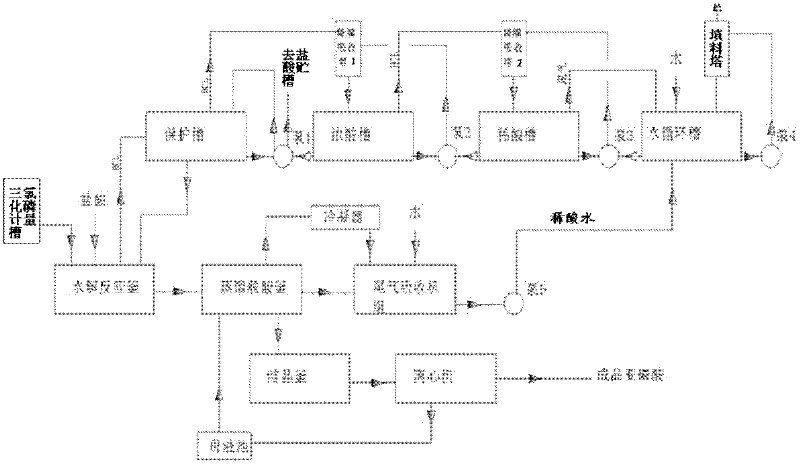

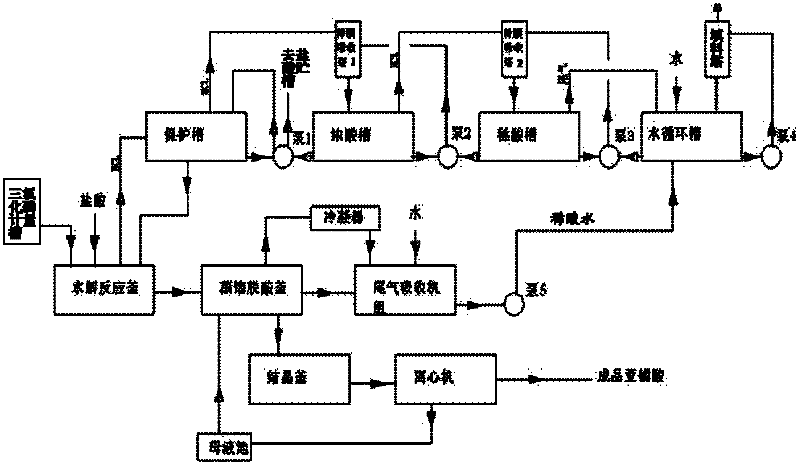

The invention belongs to the field of chemical industries, and in particular relates to a preparation process for synthesizing phosphorous acid by hydrolyzing phosphorous trichloride. The preparation process comprises the specific steps of: adding hydrochloric acid into a hydrolysis reaction kettle, dripping phosphorous trichloride into the hydrolysis reaction kettle, pumping a phosphorous acid mixture synthesized by hydrolysis reaction into a distillation and deacidification kettle with a stirrer through a pump to perform negative-pressure distillation concentration, cooling and crystallizing a concentration solution to prepare a crystallized phosphorous acid product; and absorbing an HCL gas generated through reaction through a protective trough and a hydrochloric film type absorbing system in sequence to obtain hydrochloric acid. According to the preparation process disclosed by the invention, a bubble absorbing trough (the protective trough) is additionally provided before a hydrolysis reaction film reducing hydrochloric acid absorbing system so that the HCL gas generated through reaction is more rapidly discharged, and thus the effects on the dripping quantity and the speed of the phosphorous trichloride in the hydrolysis reaction are greatly reduced. The mechanical stirrer is used in the distillation and deacidification kettle so as to implement the mechanical transmission stir, carry out the reduced-pressure distillation, enhance the heat transfer, improve the heat transfer efficiency and accelerate the deacidification speed, and thus the deacidification time is shortened and the capacity is increased.

Owner:JIANGSU DAMING TECH

Recycle of calcium phosphate

InactiveCN103264998ASimple processReduce energy consumptionPhosphorous acidPhosphorous acidCalcium biphosphate

The invention relates to a process of extracting phosphorous acid from sodium hypophosphite slag, wherein a high purity phosphorous acid product is obtained specifically by a cation exchange method through decompression, distilling and crystallization. The process comprises the following steps: extracting calcium phosphate solid from a calcium phosphate in a calcium phosphate workshop and reacting with sodium carbonate; separating and purifying to obtain a sodium phosphite liquor; decompressing, evaporating and crystallizing the sodium phosphite liquor after cation exchange through D001 resin to obtain the high purity phosphorous acid product. The process is simple in process, less in energy consumption and high in product purity, and does not cause secondary pollution at the same time.

Owner:HUBEI JIXING CHEM IND GRP

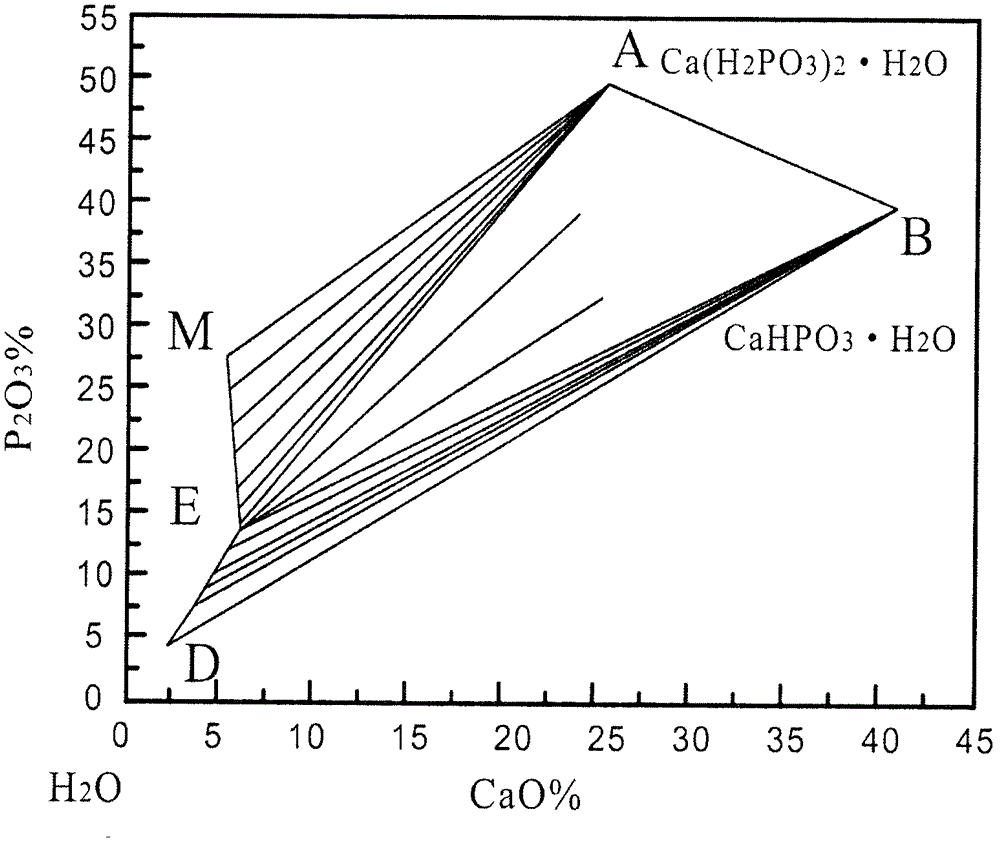

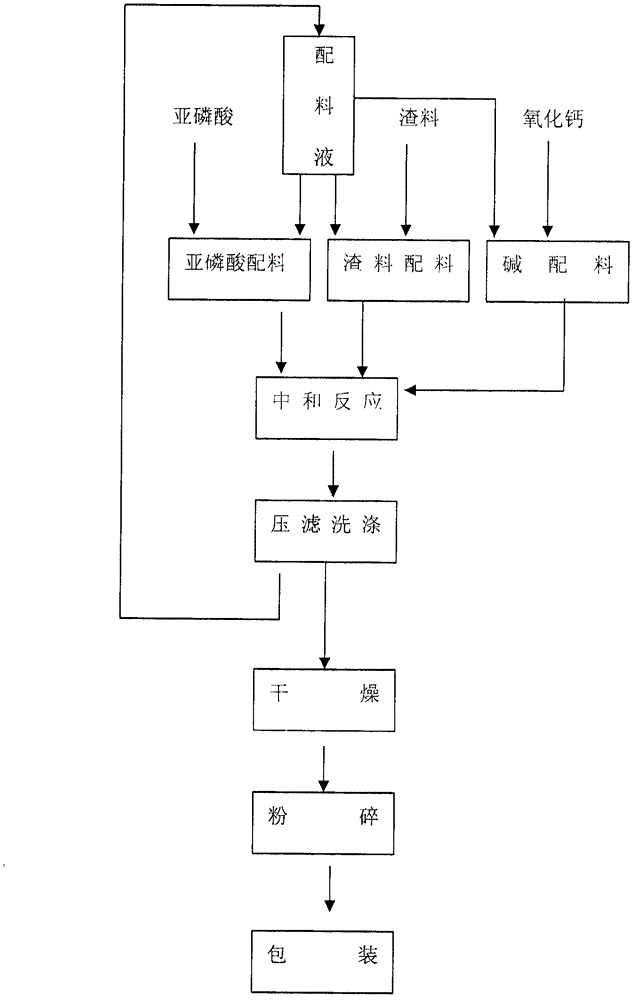

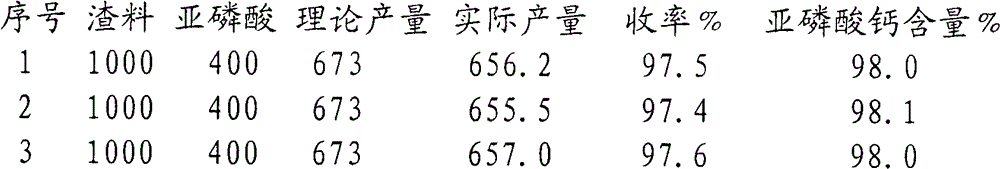

Method for preparing calcium phosphate by utilizing slag charge discharged during sodium hypophosphite preparation

ActiveCN103058156ANo pollution in the processAvoid pollutionSolid waste disposalPhosphorous acidPhosphorous acidCalcium hydroxide

The invention relates to a method for preparing calcium phosphate by utilizing slag charge discharged during sodium hypophosphite preparation. Calcium hydroxide and calcium carbonate in the slag charge react with phosphorous acid to generate calcium phosphate monohydrate, phosphorous acid is prepared according to the condition that the content of calcium hydroxide in the slag discharge is 35.48wt% and the content of calcium carbonate in the slag discharge is 10.91%, calcium phosphate is generated at a certain temperature under a stirring condition, and washing, filtering, drying and smashing are performed after the PH value is regulated, so that pure calcium phosphate is obtained. The method provided by the invention has the following prominent advantages: 1, resource utilization is reasonable, the low-end resource is extended to a high-end product; 2, the equipment investment is small, the process is simple, production is easy to control and the method is environmentally-friendly; and 3, the method provided by the invention can be used for solving the pollution of slag charge discharged by enterprise sodium hypophosphite to environment, and reducing the production cost.

Owner:王军民

Preparation method of phosphorous acid

InactiveCN101648705ASolve processing problemsCalcium/strontium/barium sulfatesPhosphorous acidPhosphorous acidPhosphate ion

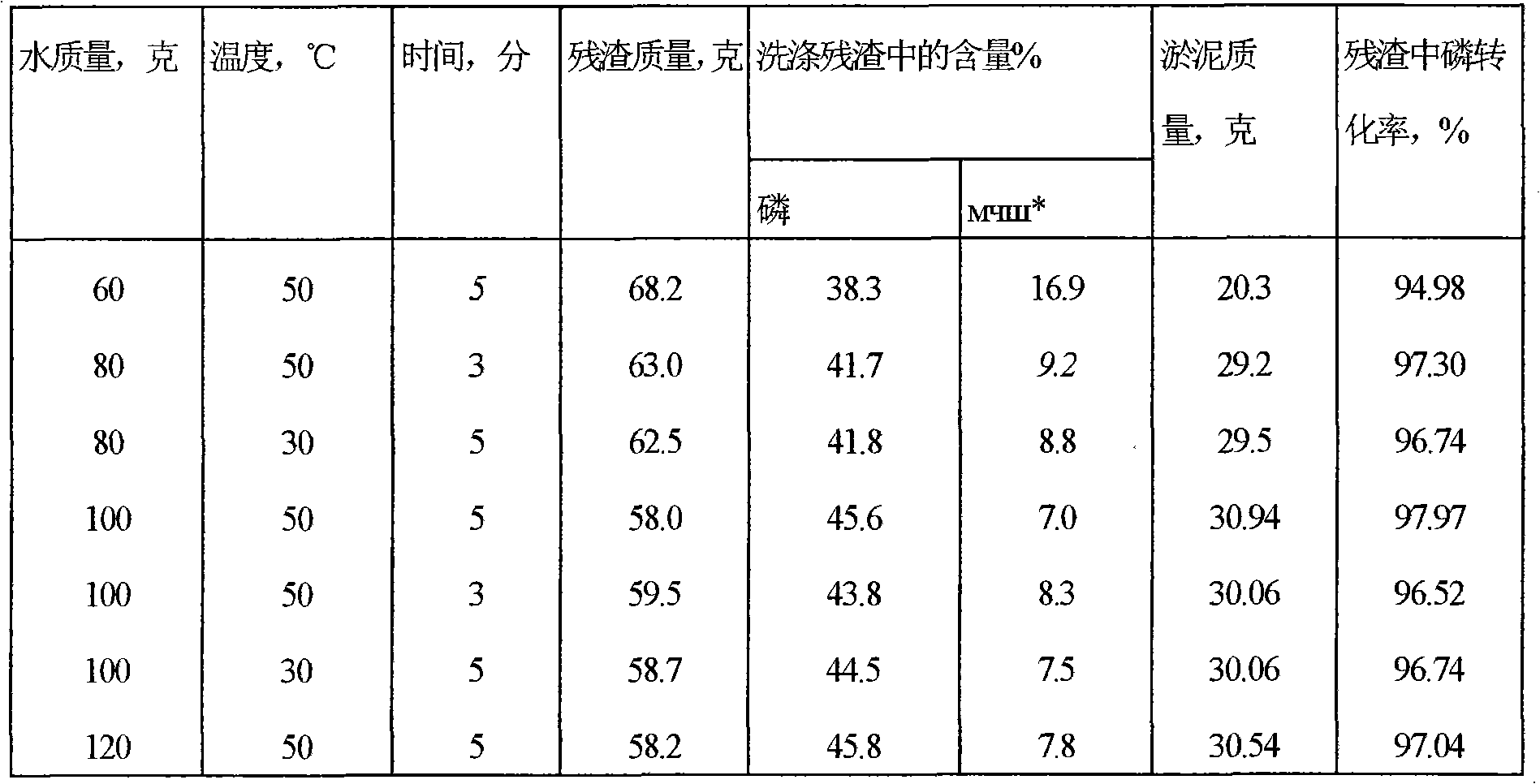

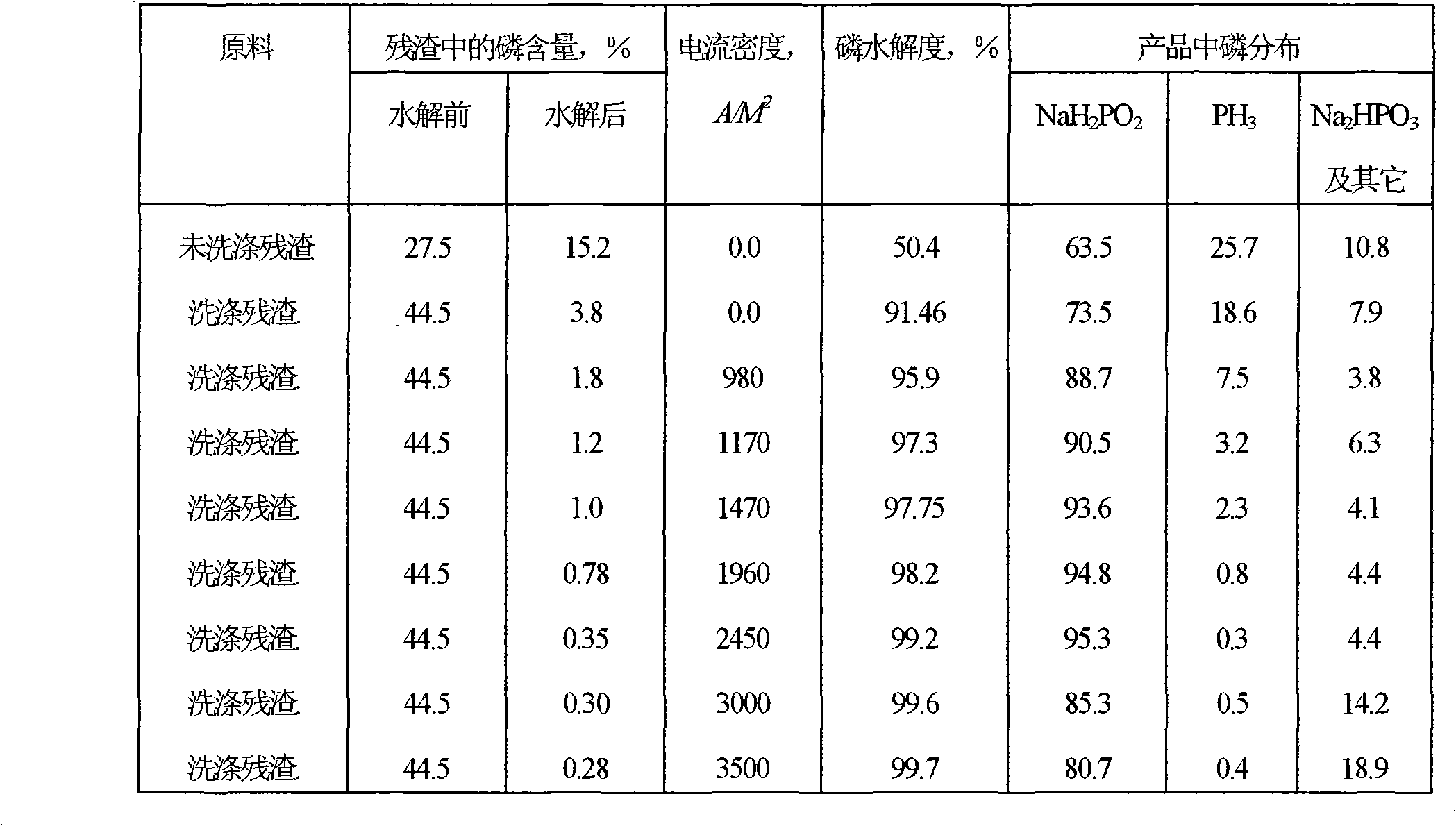

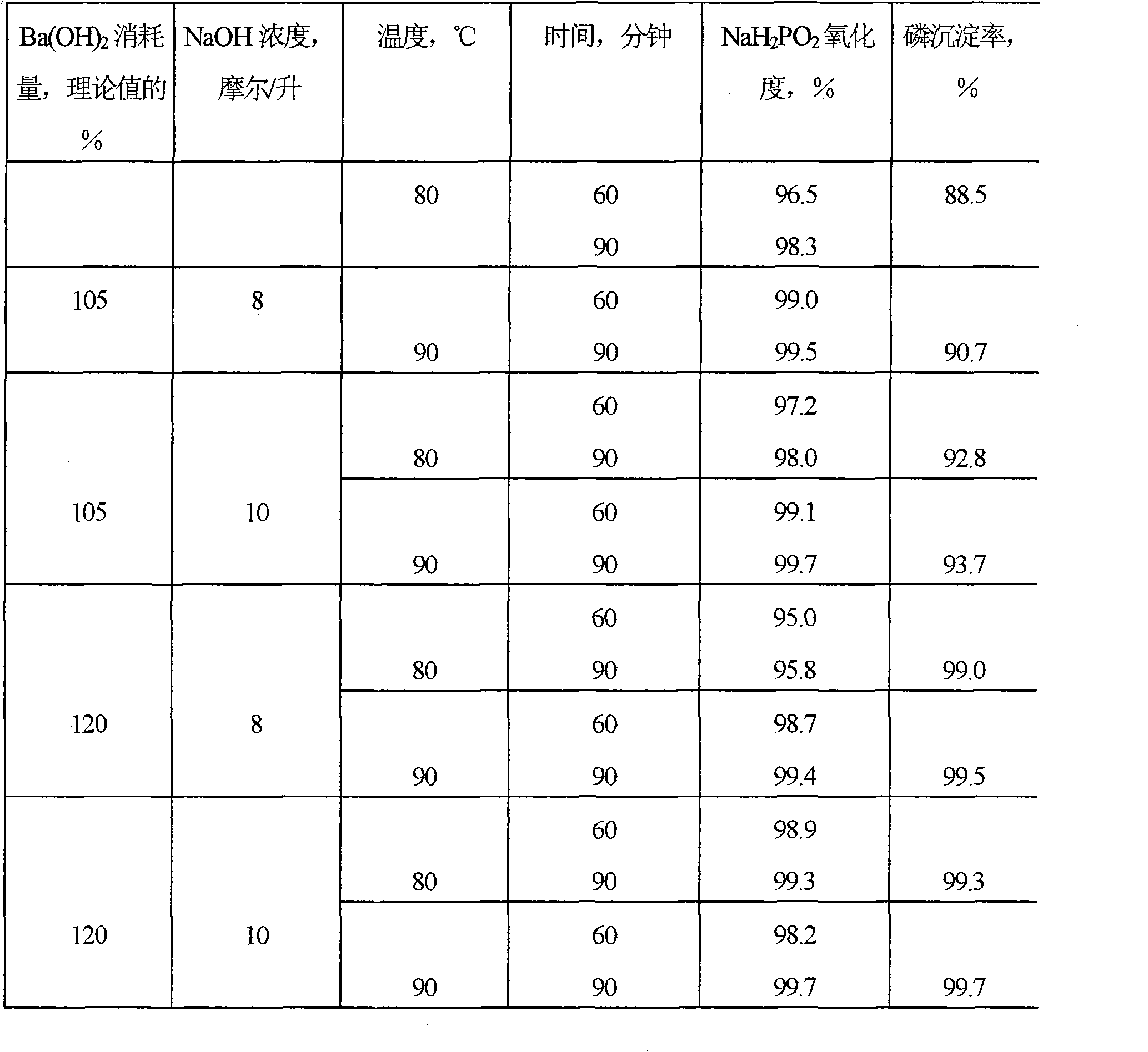

The invention relates to a preparation method of phosphorous acid. The invention relates to the inorganic acid preparation technique, namely to the phosphorous acid manufacturing technique, and can beused for further processing of phosphorus-contained residue obtained as an accessory substances during electric heating production of phosphorus. In order to reduce the time of soda treatment processof the phosphorus-contained residue, improve the phosphorous acid productivity and quality, and reduce the conversion of phosphorus into phosphine, the preparation method of phosphorous acid from phosphorus-contained raw material includes: using sodium hydrate solution to perform soda treatment; separating the aqueous alkali and precipitation; oxidizing the dissolved sodium hypophosphite into phosphate-ion, converting the phosphate-ion into the form of phosphorous acid, and proposing to take the phosphorus-contained residue as original phosphorus-contained raw material. The original residue is washed by water beforehand, processed by non-ionic emulsifier solution, the sodium hypophosphite is oxidized by sodium hydrate in the presence of barium hydroxide, the barium contained deposition isseparated from the solution, and the barium sulfate deposition and phosphorous acid solution are obtained by using sulfuric acid solution to process.

Owner:桑达-阿比克有限责任公司 +1

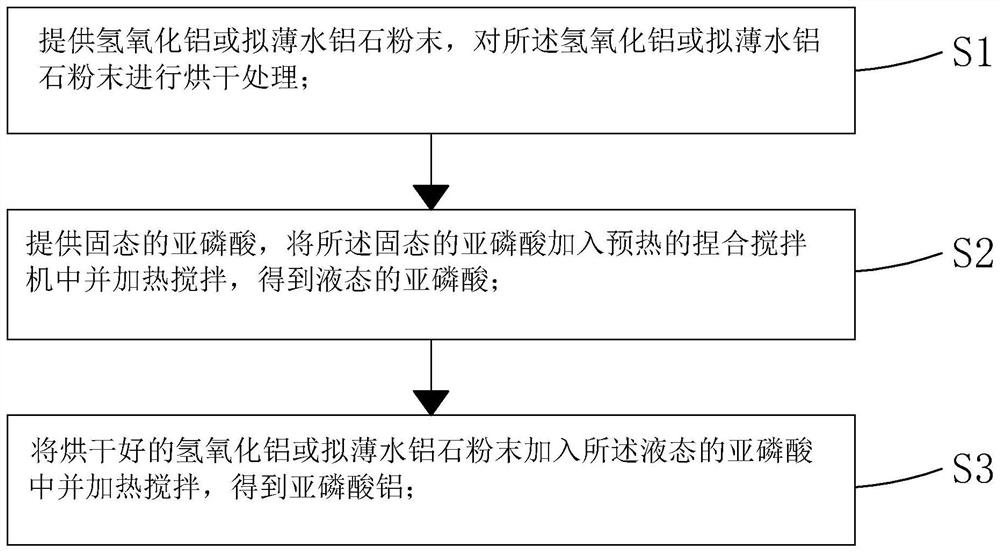

Preparation method of aluminum phosphite

InactiveCN111661830AImprove production efficiencyPromote environmental protectionPhosphorous acidPhosphorous acidAluminium hydroxide

The invention provides a preparation method of aluminum phosphite. The method comprises the following steps of: providing aluminum hydroxide or pseudo-boehmite powder, and drying the aluminum hydroxide or pseudo-boehmite powder; providing solid phosphorous acid, adding the solid phosphorous acid into a preheated kneading stirrer, heating and stirring to obtain liquid phosphorous acid; and adding the dried aluminum hydroxide or pseudo-boehmite powder into liquid phosphorous acid, heating and stirring to obtain aluminum phosphite. The method is simple in process, low in cost, high in productionefficiency and good in environmental protection performance.

Owner:SHENZHEN RUN SUN CHEM TECH

Method for continuously synthesizing phosphorous acid

The invention relates to a method for continuously synthesizing phosphorous acid, comprising the following steps of: fully filling phosphorous acid water solution in a first stage reactor, and then adding phosphorus trichloride and water for reaction at the same time; controlling the temperature to be 10-90 DEG C, and simultaneously leading the reaction material to overflow into a second stage reactor from the first stage reactor for heat preservation reaction; and controlling the temperature to be 10-90 DEG C, and then leading the finished product phosphorous acid water solution to overflow into a finished product storage tank from the second stage reactor. The method has the characteristics of simple technique, stable product quality, good yield, high safety performance, low production cost and the like.

Owner:NANTONG JIANGSHAN AGROCHEM & CHEM LIMITED LIABILITY

Modified fine antirust paint with phosphite and preparation thereof

InactiveCN1778670AImprove rust resistanceHigh yieldPigmenting treatmentPhosphorous acidPhosphorous acidPhosphoric acid

A modified phosphite fine anti-rusting pigment and its production are disclosed. The pigment consists of organic sulfonate with long straight chain as catalyst D 0.1í½1.0wt%, phosphorous acid or its solution, zinc oxide, calcium hydroxide or theirs mixture in proportion=1:1í½1:4 and with mass concentration=10í½20%. It is prepared by catalyst D surface modification or combination with catalyst D surface modification and calcium modification, which fines the pigment. It can be used for industrial production, pigment and plastic industries and is no need for grinding.

Owner:WUHAN UNIV OF TECH

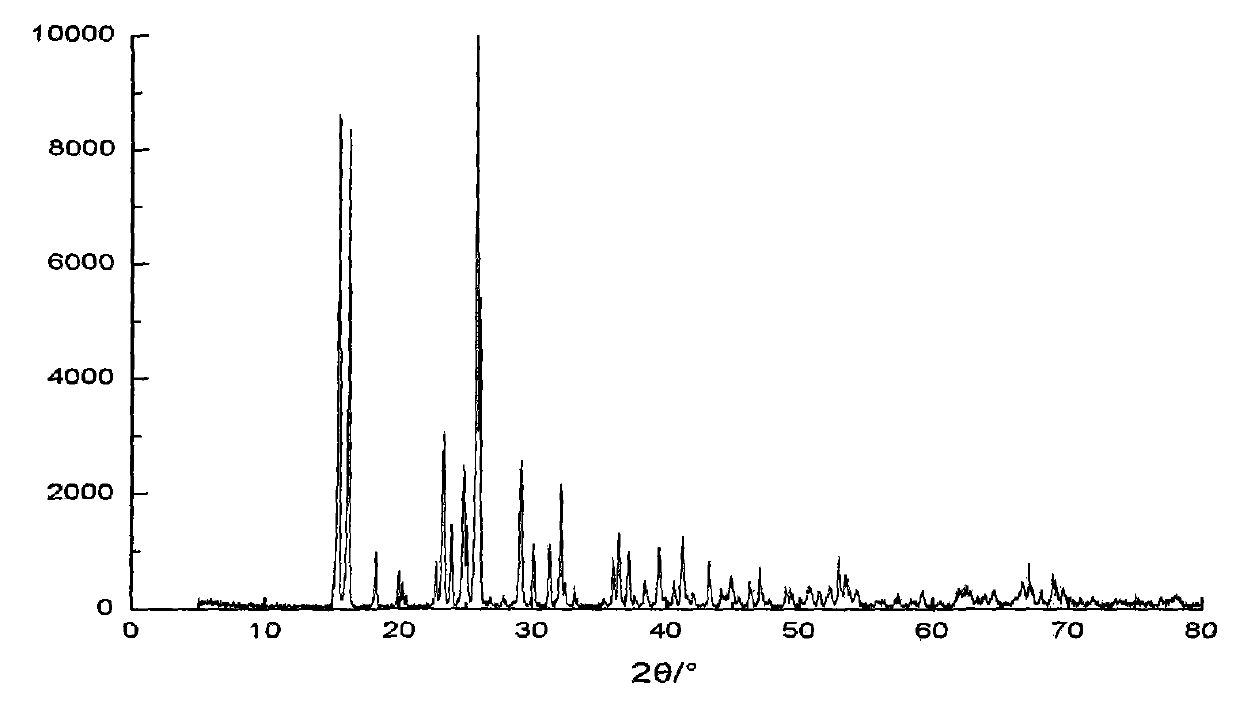

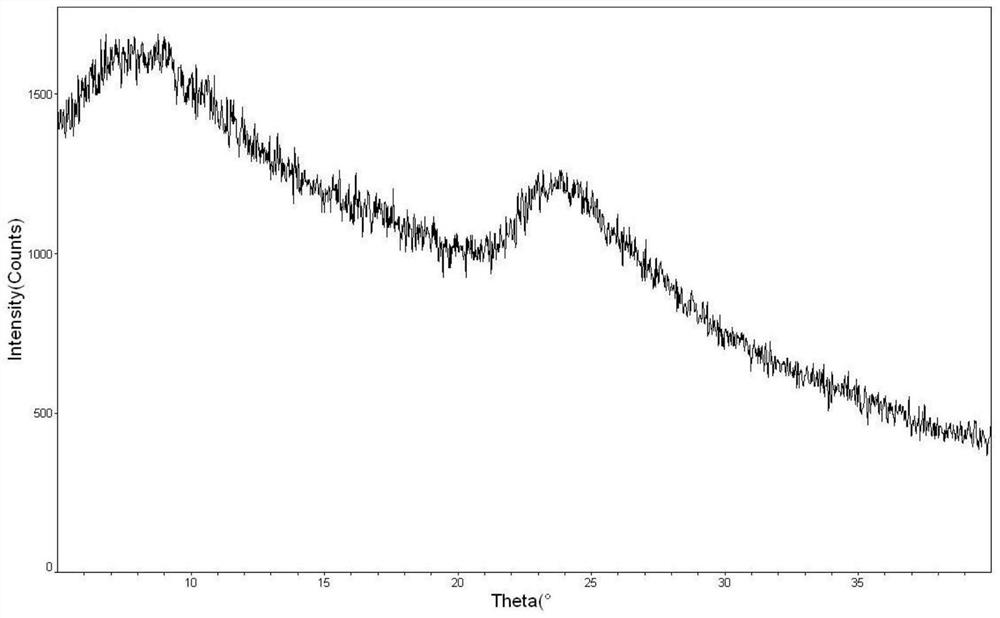

Preparation method of highly dispersed aluminum orthophosphite crystals

The invention discloses a method for synthesizing highly dispersed aluminum orthophosphite crystals from an aluminum salt and hypophosphorous acid. The method is characterized in that the method comprises the following steps: (1) using the aluminum salt to prepare an aluminum hydroxide gel, filtering and washing till a washing solution has no anions of the aluminum salt; (2) adding distilled water into the gel after washing, stirring to get an aluminum hydroxide sol, adding the sol into the hypophosphorous acid while stirring, and continuously stirring to realize full reaction after dripping; and (3) filtering and heating an obtained solution, separating out aluminum orthophosphite, filtering, and drying to get the uniform and well-dispersed aluminum orthophosphite crystals. Compared with the prior art, the method disclosed by the invention has the advantages of simple process, energy conservation, environmental protection, high product yield and purification and short production period, and is suitable for industrial production.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

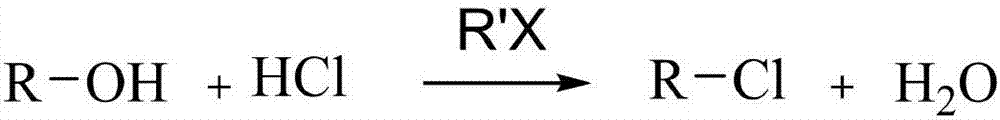

Prepn process of phosphorous acid and lower alkane halide

InactiveCN1486967AHigh recovery process requirementsIncrease contentPhosphorous acidHalogenated hydrocarbon preparationPhosphorous acidAlkane

The present invention is the production process of phosphorous acid and lower alkane halide with phosphorous trichloride and alkyl alcohol (phenol) as material. Phosphorous trichloride and alkyl alcohol (phenol) are reacted to produce phosphorous acid and lower alkane halide. The lower alkane halide is separated via proper method and the product is concentrated and crystallized to obtain phosphorous acid, with the mother liquor being circularly used. The phosphorous acid is used in producing other product. The production process is simple and low in cost.

Owner:李建兵

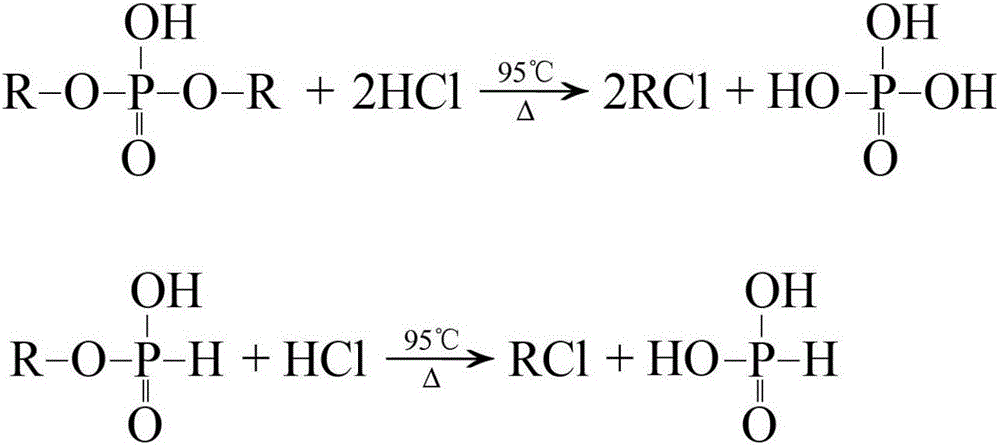

Recovery method of rectification residual liquid of dimethyl phosphite

InactiveCN105753899AHigh purityReduce generationGroup 5/15 element organic compoundsPhosphorous acidRecovery methodPhosphorous acid

The invention provides a recovery method of a rectification residual liquid of dimethyl phosphite. The preparation process comprises steps as follows: methanol and phosphorus trichloride are sprayed to an esterification reaction kettle slowly; a proper amount of ammonia is added to crude dimethyl phosphite in a neutralization tank slowly for neutralization; materials in the neutralization tank are sent to a rectifying tower to be rectified, dimethyl phosphite is completely distilled off, and a rectification residual liquid of dimethyl phosphite is left; the rectification residual liquid of dimethyl phosphite is transferred to a reaction kettle; the rectification residual liquid is subjected to activated carbon decoloration; the decolored liquid is filtered; a proper amount of hydrochloric acid is dropwise added to the filtered liquid, the mixture is sufficiently stirred until acidolysis is sufficient; tail gas generated in the acidolysis process is sent to a chloromethane recovery pipeline in a workshop; after acidolysis is finished, a phosphorous acid water solution in the kettle is concentrated and crystalized. Clean production is realized, discharge of three wastes is reduced, the recovery rate of byproducts is increased, and the production cost is reduced.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

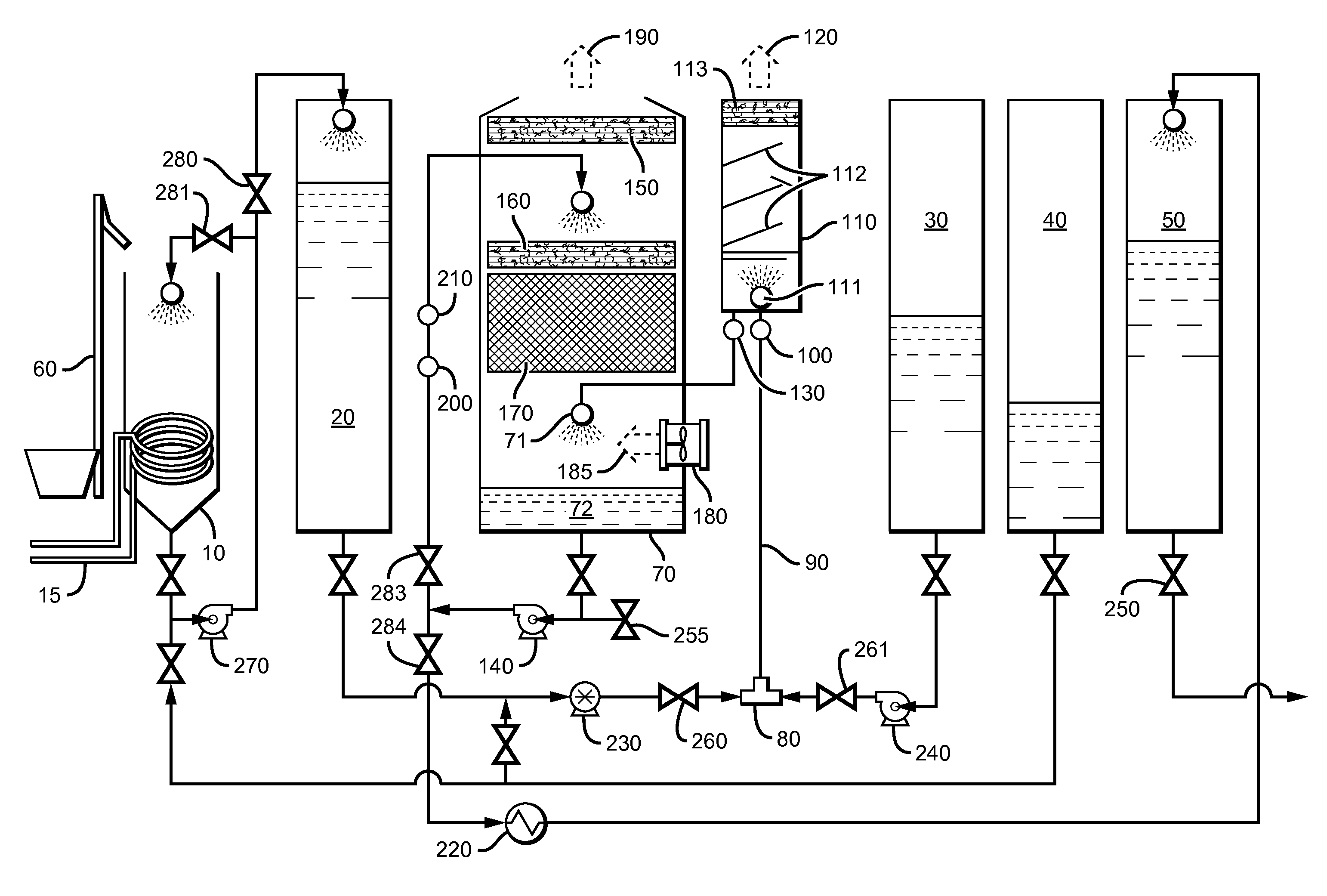

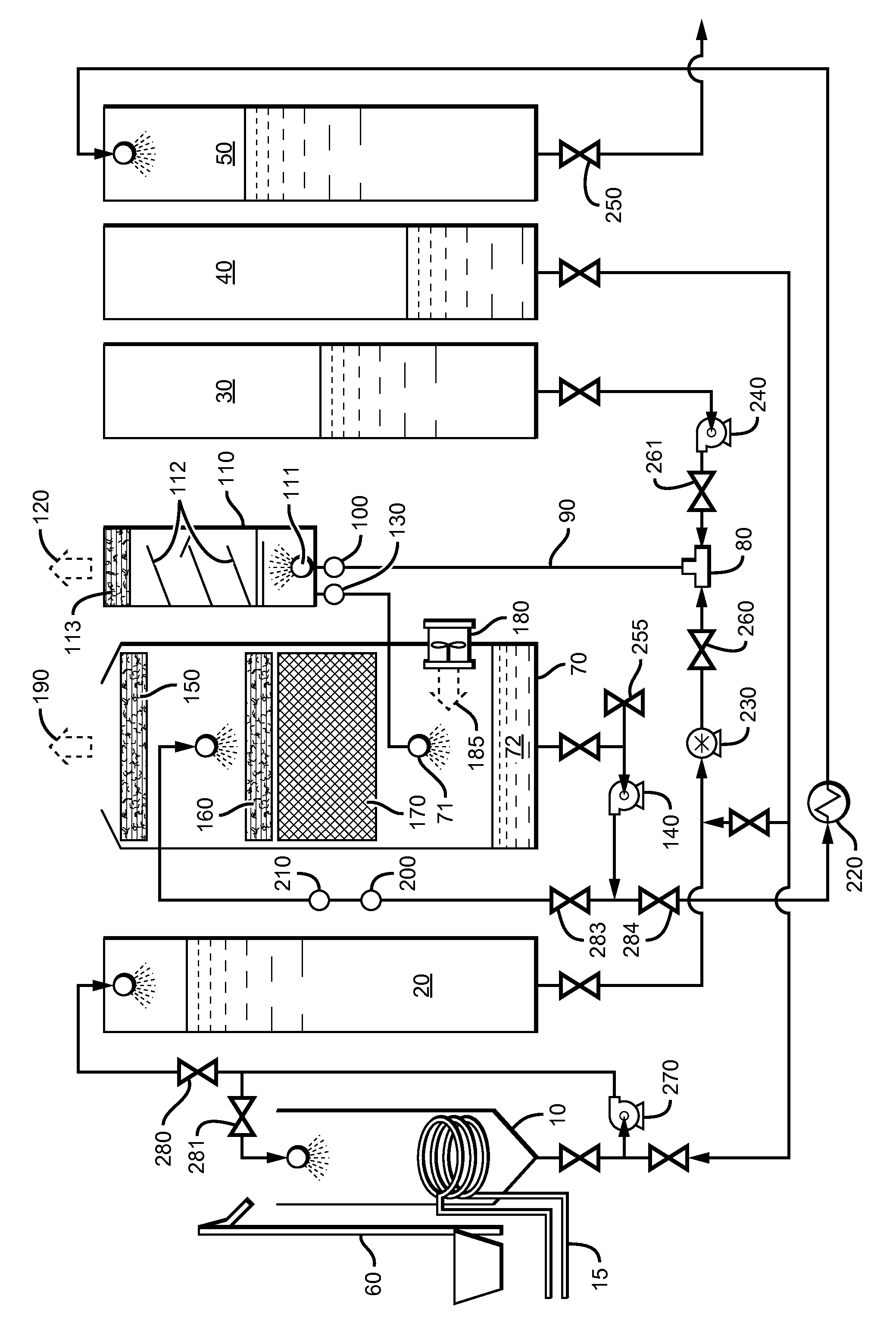

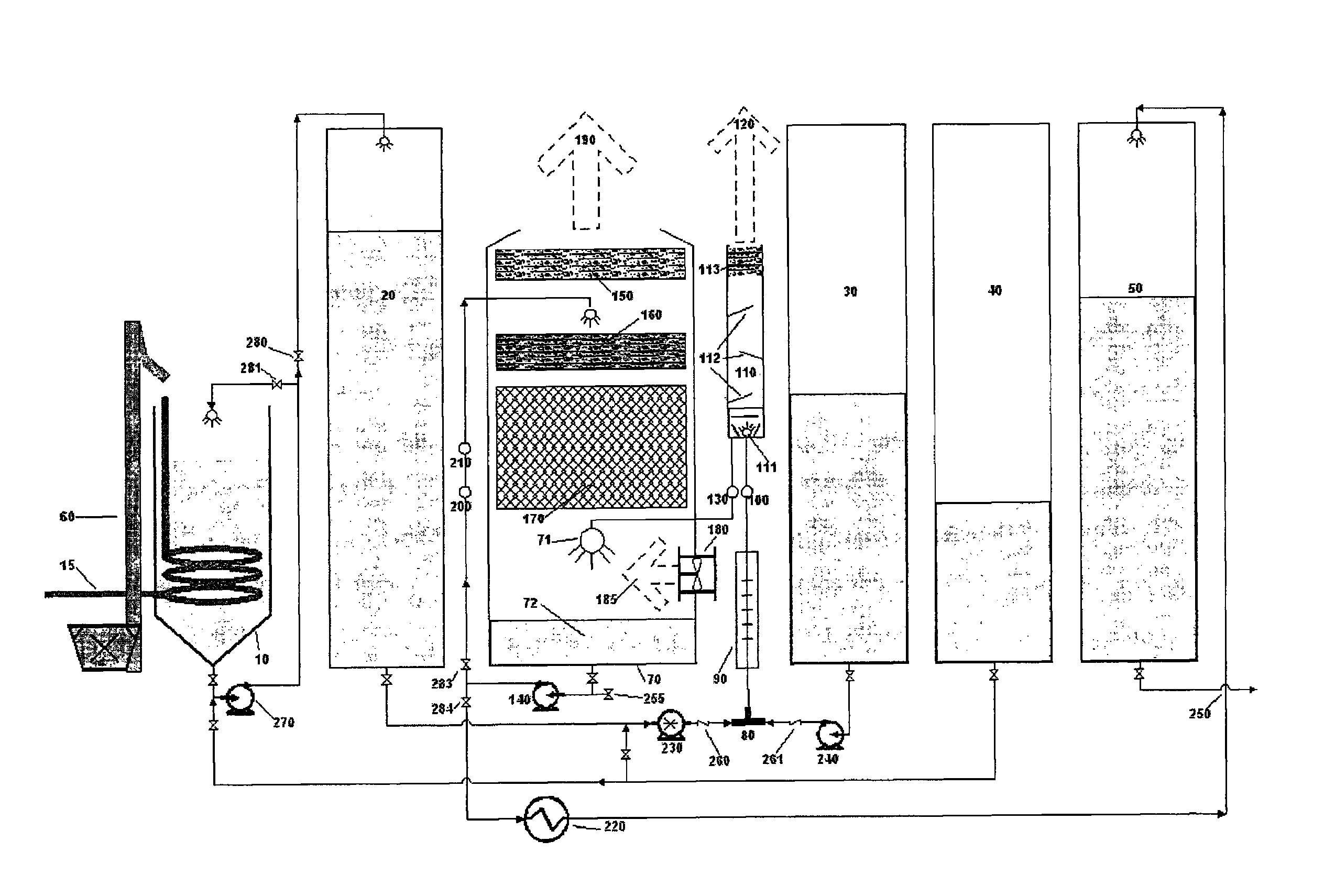

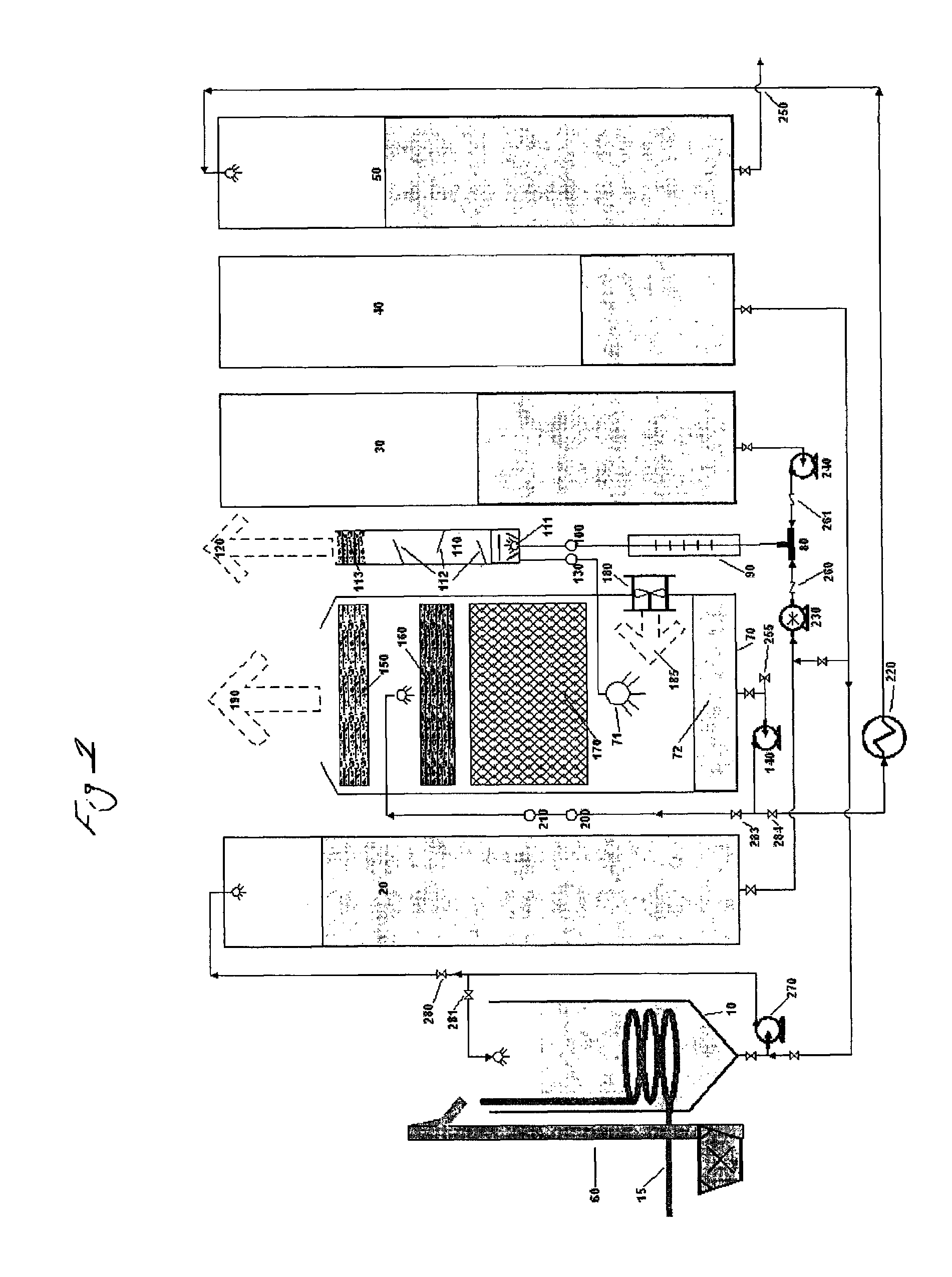

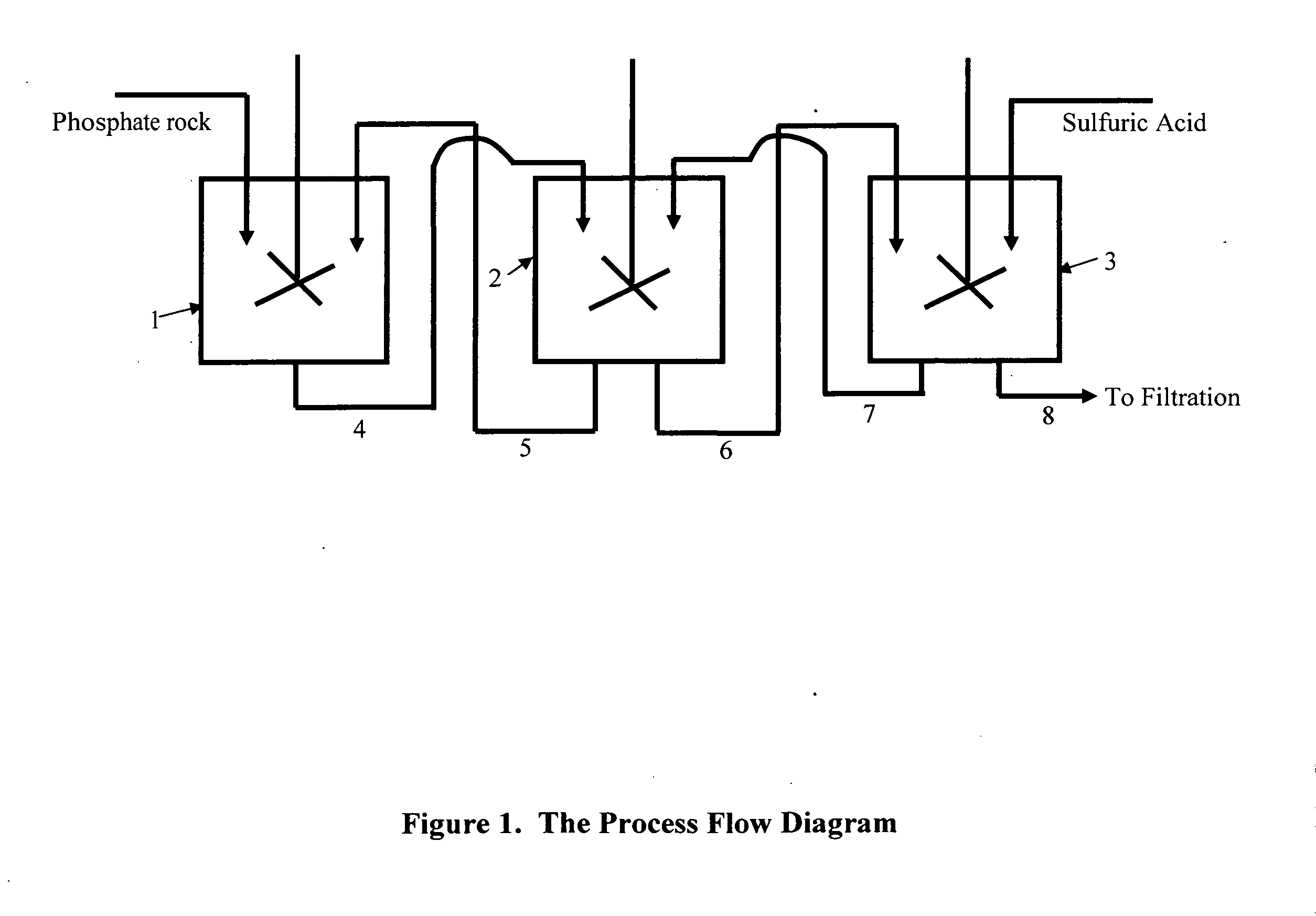

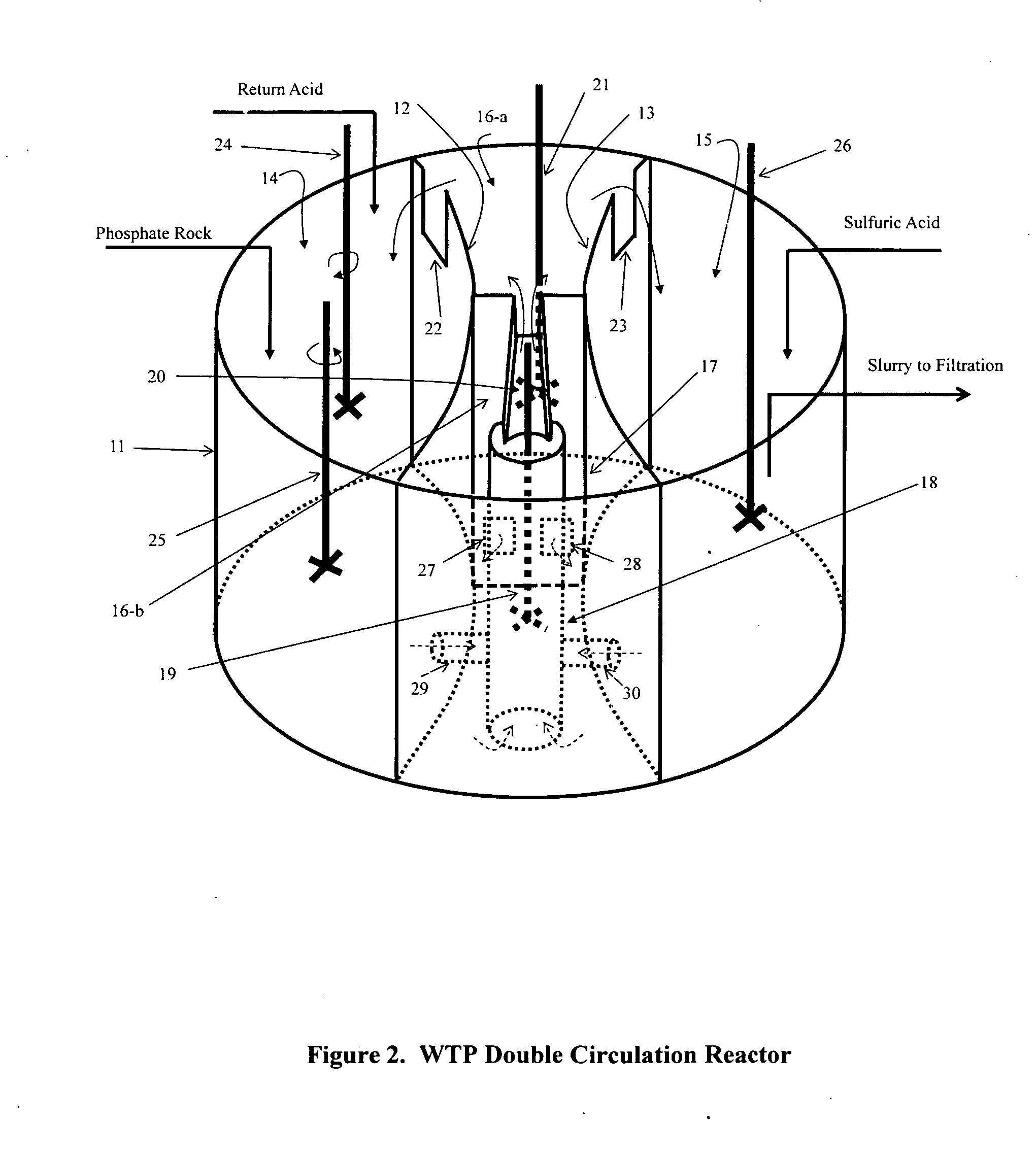

Process for Producing Products Under Very Low Supersaturation

InactiveUS20120039785A1Eliminate gypsum precipitationImprove filtering effectTransportation and packagingRotary stirring mixersSulfate levelFiltration

Disclosed is a process for any productions that involve reacting or mixing two or more substances to form one or more new substances under low supersaturation. However, the specific process used to exemplify the present invention is the “wet process” phosphoric acid production, in which this process is achieved through dissolving the phosphate ore and dispersing the sulfuric acid separately and simultaneously with the gypsum slurry that has roughly stoichiometrically balanced calcium and sulfate ions in the solution and is also at considerably low supersaturation. The slurry carried out digesting the phosphate ore and the slurry accomplished dispersing the sulfuric acid then mix together to form the said gypsum slurry that has roughly stoichiometrically balanced calcium and sulfate ions in the solution and is also at considerably low supersaturation. The slurry for filtration is drawn from the sulfuric acid dispersion compartment, and the sulfate level for this slurry is maintained suitable for the product separation.

Owner:WELLTHOUGHT PRODS

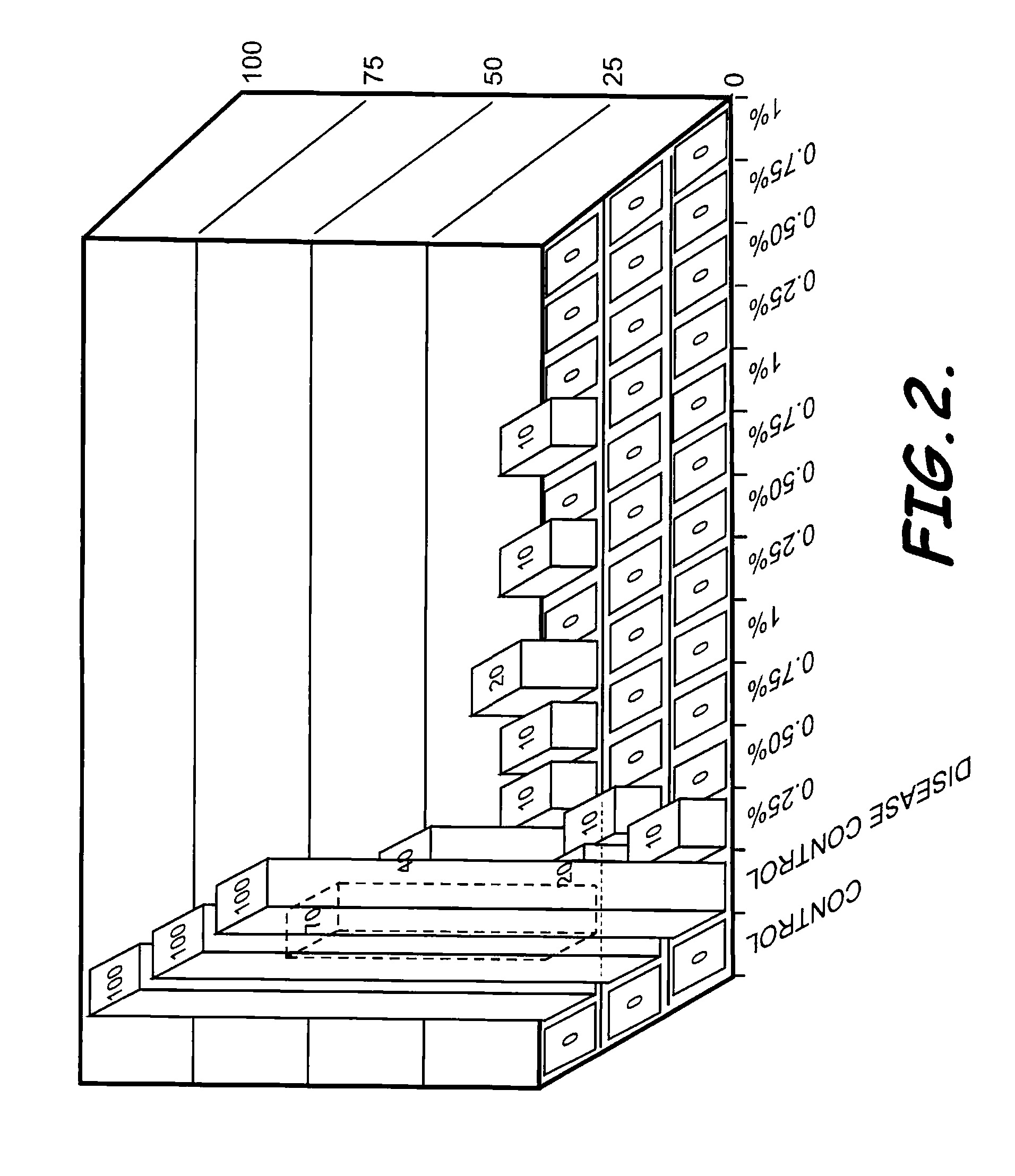

Potassium polyphosphite composition for agricultural use and associated methods

A fungicidal composition having fertilizer properties, the composition containing a high percentage of potassium polyphosphate is disclosed. The composition is useful as a fungicide and as a fertilizer for application to plants and, particularly, commercial crops. A method of making the polyphosphate composition is described, as well as methods of using same.

Owner:FABRY CARL

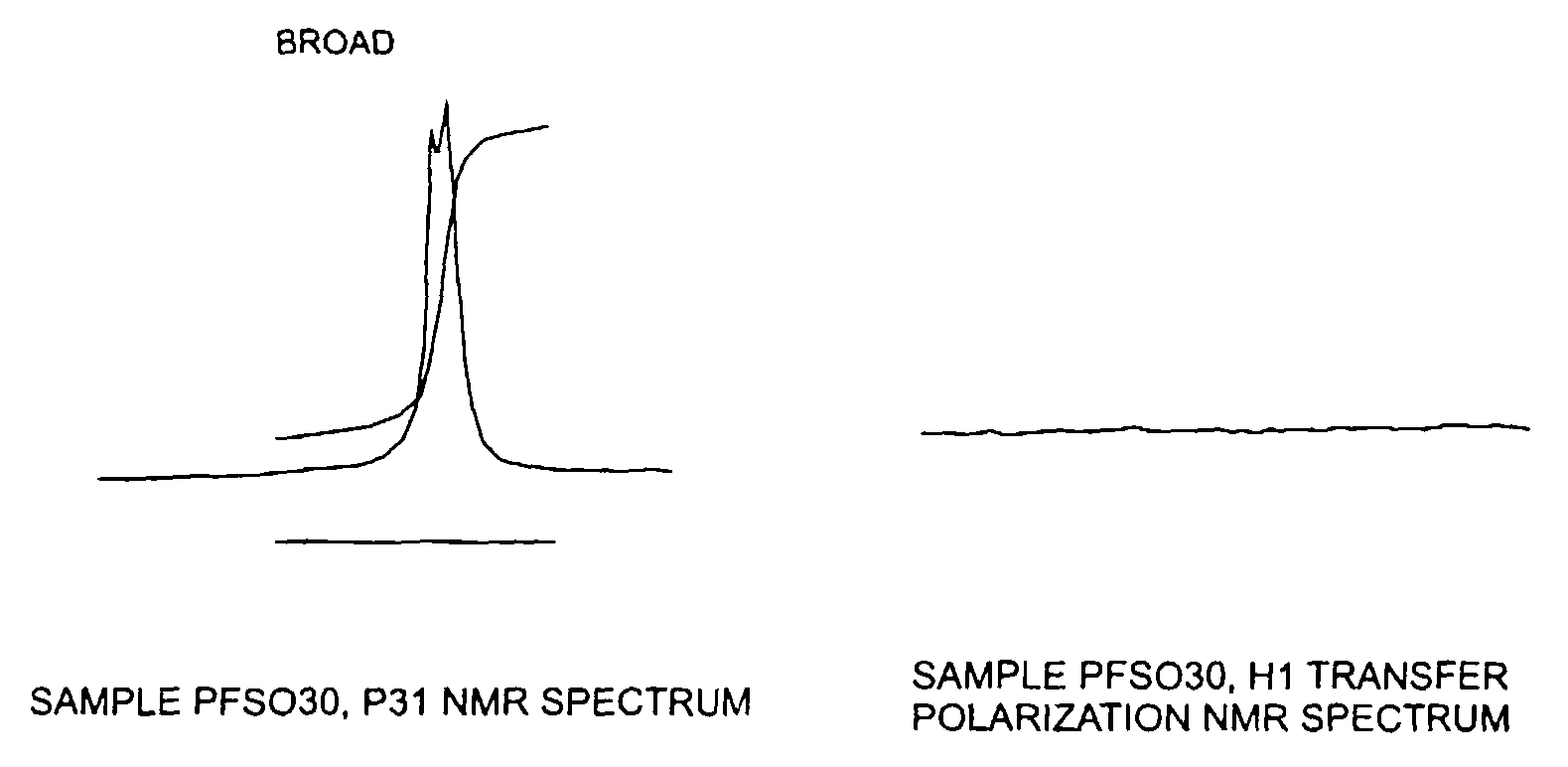

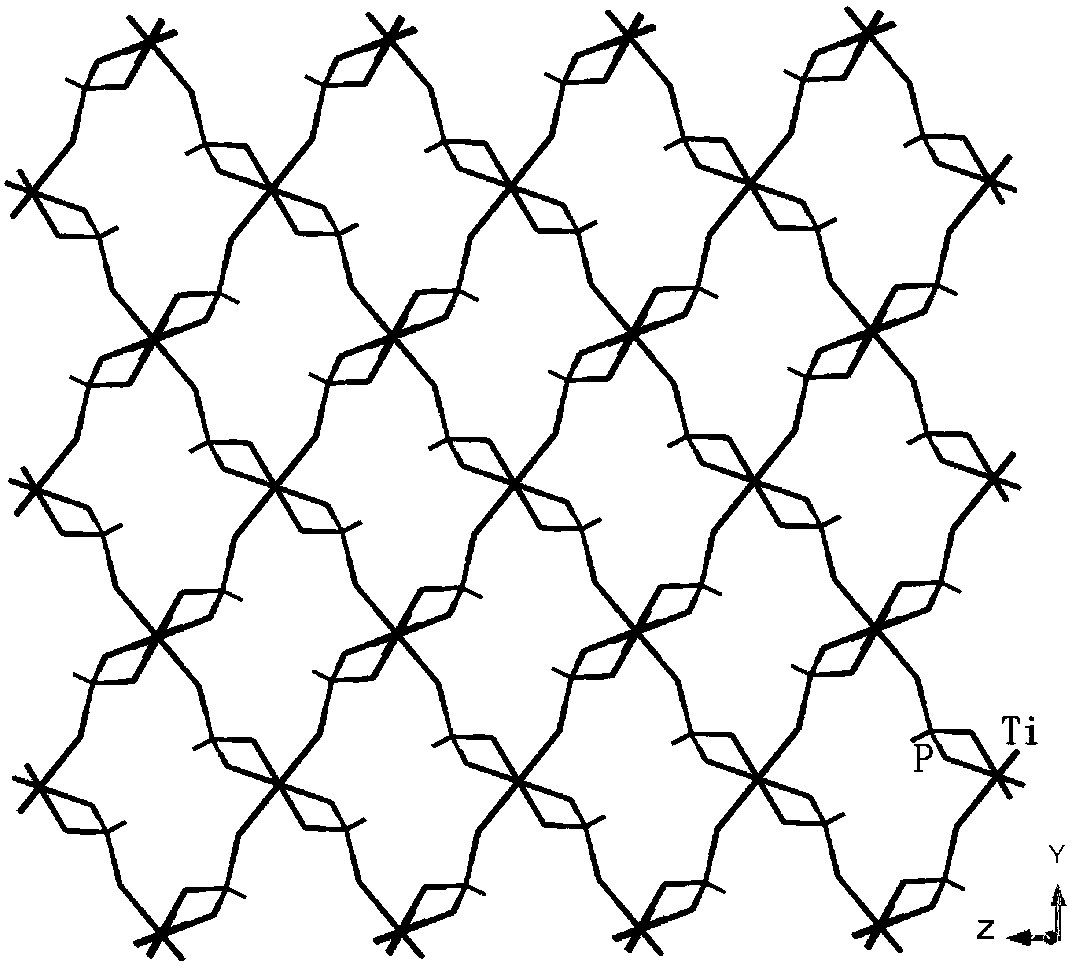

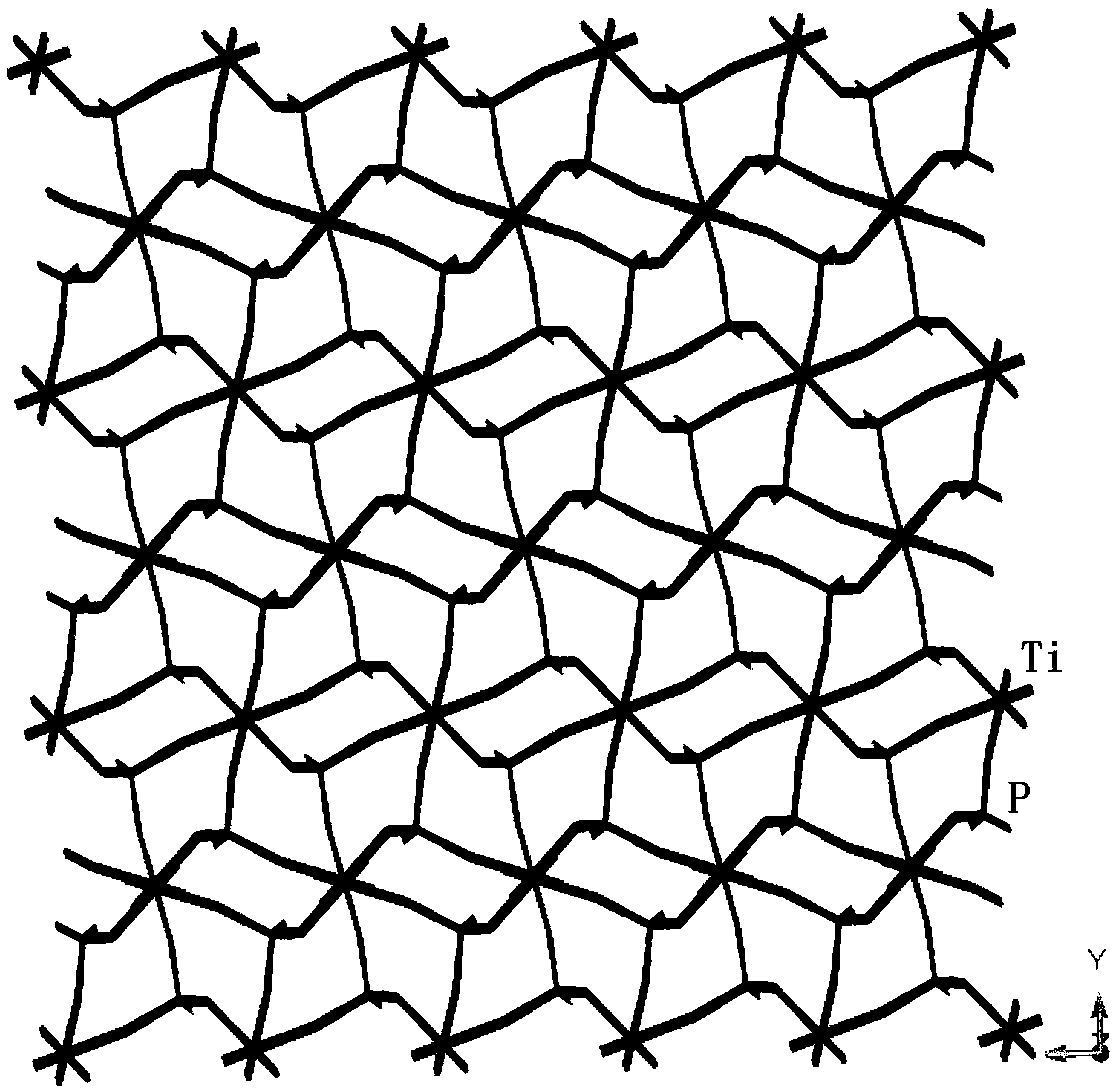

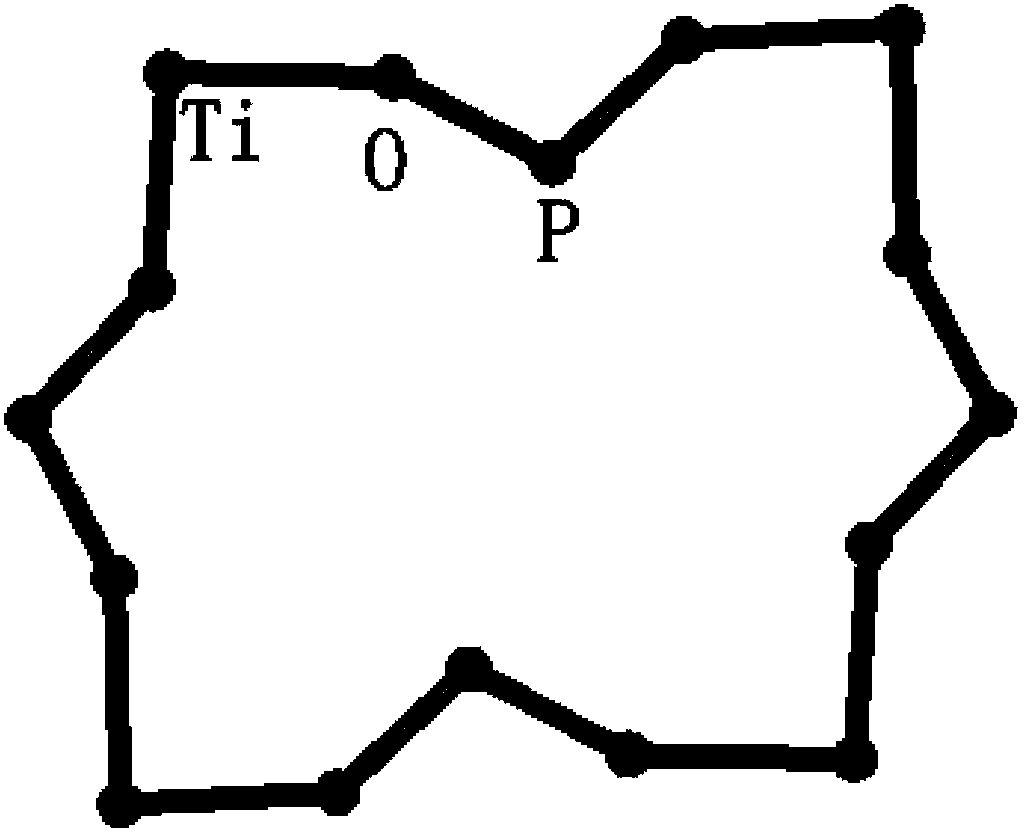

Phosphorous acid titanium with three-dimensional open-framework structure and preparation method thereof

InactiveCN103395800AEasy to prepare and effectiveImprove thermal stabilityPhosphorous acidMolecular-sieve and base-exchange phosphatesPhosphoric acidStrong acids

The invention provides phosphorous acid titanium with a three-dimensional open-framework structure and a preparation method thereof and belongs to the technical field of phosphorous acid titanium with a three-dimensional open-framework structure. The preparation method is characterized in that an open-framework crystal compound of the phosphorous acid titanium without an organic template is synthesized by adopting a strong acid method in a hydrothermal system, the morphology of a product is regulated and controlled by adjusting the quantities of phosphorous acid and hydrofluoric acid in reaction gel, and the phosphorous acid titanium compounds with the three-dimensional open-framework structure, which have the identical structure and are different in morphologies, are synthesized. The phosphorous acid titanium compound does not contain an organic template agent. Compared with other metal phosphorous acid salts, the phosphorous acid titanium compound has relatively good heat stability, thus favorable conditions are provided for the research of the property of the phosphorous acid titanium compound. The photovoltage research shows that the compound has the property of a p-type conductor. The invention has the beneficial effects of providing a simple, convenient and effective method for preparing the phosphorous acid titanium crystal material with the open-framework structure.

Owner:JILIN UNIV

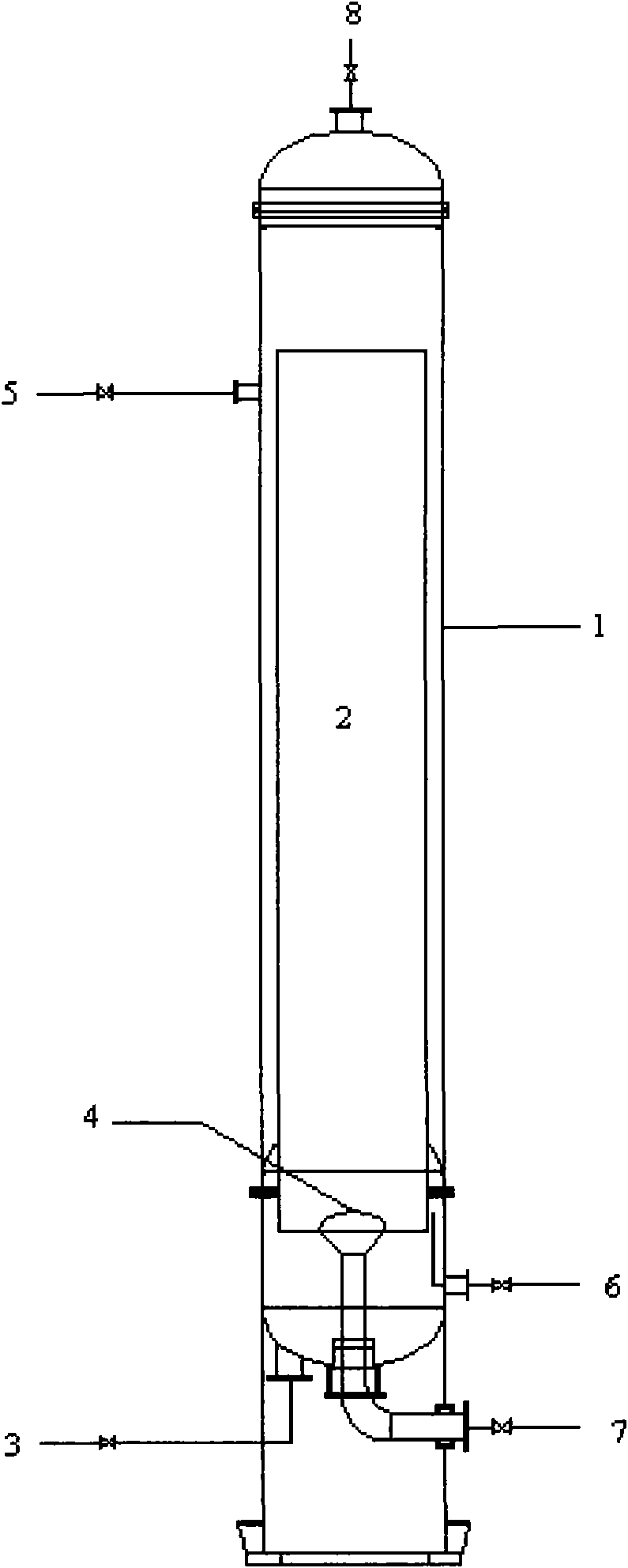

Method for preparing phosphorous acid and hydrogen chloride

The invention provides a method for preparing phosphorous acid and hydrogen chloride in an inner circulation tower by using phosphorus trichloride. The method comprises the following steps of: intermittently or continuously adding the phosphorus trichloride to the inner circulation tower, and then making the phosphorus trichloride react with a water solution in the tower to prepare a phosphorous acid water solution and a hydrogen chloride gas with large scale and high efficiency and yield and smoothly export the hydrogen chloride gas and heat. The method has the advantages of high reaction conversion rate and yield, steady reaction, high safety and the like and can be used for continuous production.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

Method for producing waste acids to prepare high-content phosphorous acid

InactiveCN107879322AImprove protectionChlorine/hydrogen-chloride purificationPhosphorous acidPhosphorous acidKerosene

The invention provides a method for producing waste acids to prepare high-content phosphorous acid. The method comprises the following steps: concentrating most of the hydrogen chloride in the waste acids by performing falling film evaporation, adsorbing metal ions by activated carbon, extracting to remove the chloride ion after tertiary amine and kerosene complexing, and performing vacuum spray drying, thereby obtaining the finished phosphorous acid. Aiming at recycling of the waste acid, the phosphorous acid and hydrochloric acid which can be directly utilized are refined from the waste acids, and synergetic development among the economy, society and environmental protection is realized.

Owner:HUNAN BIDE BIOTECH

Method for recovering phosphorous acid by acidolysis of dimethyl phosphite distillation residual liquid

The invention discloses a method for recovering phosphorous acid by acidolysis of dimethyl phosphite distillation residual liquid. Dimethyl phosphite residual liquid is subjected to the steps of filter pressing, acidolysis, secondary acidolysis concentration, crystallization, material washing and the like to obtain phosphorous acid. In the method for recovering phosphorous acid by acidolysis of dimethyl phosphite distillation residual liquid, phosphorous acid is recovered by combination of high-temperature distillation and temperature-lowering crystallization, the recovery efficiency is high, and the existing chloromethane recovering device is utilized for recovering chloromethane during the recovery process of phosphorous acid, and therefore, the recovery benefit is further enhanced.

Owner:HUBEI TAISHENG CHEM

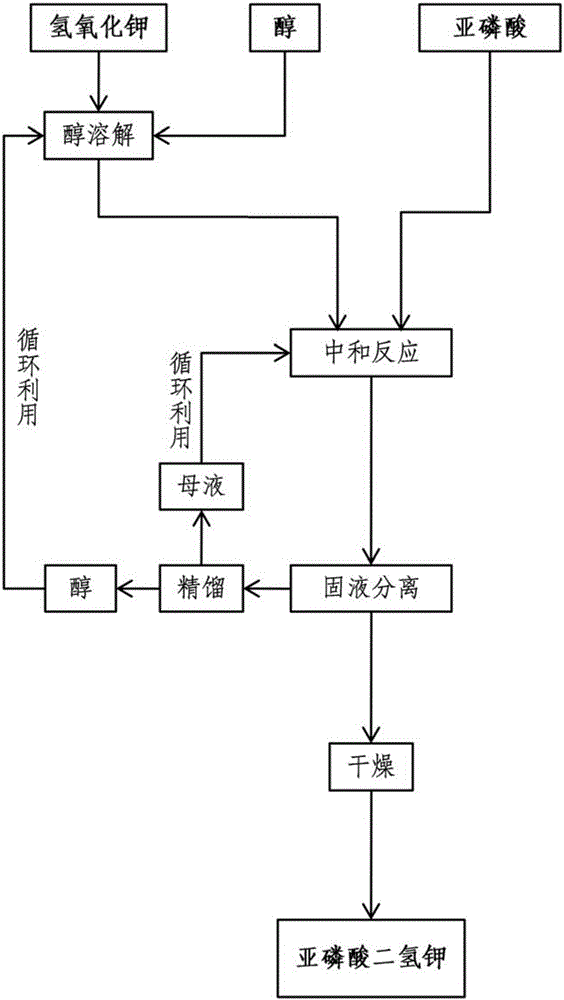

Method for preparing potassium dihydrogen phosphite

InactiveCN106672929ALow heat of vaporizationAchieve recyclingPhosphorous acidPhosphorous acidSolubility

The invention provides a method for preparing potassium dihydrogen phosphite. The method comprises the following steps: solid potassium hydroxide is dissolved in an alcohol solvent, solid phosphorous acid is added, the materials are subjected to neutralization, a product is subjected to solid-liquid separation, and high-purity potassium dihydrogen phosphite is prepared after drying, wherein alcohol is recovered from a liquid obtained after solid-liquid separation through distillation, the recovered alcohol is recycled, and distilled mother liquor returns to neutralization for recycling. Crystallization of potassium dihydrogen phosphite is omitted by means of the difference between alcohol solubility and water solubility, high-purity potassium dihydrogen phosphite can be prepared, and production procedures are simplified; no wastewater, waste gas or solid waste is discharged, alcohol recycling is realized, and the effect of circulating and clean production is realized.

Owner:四川新磷环保技术有限公司

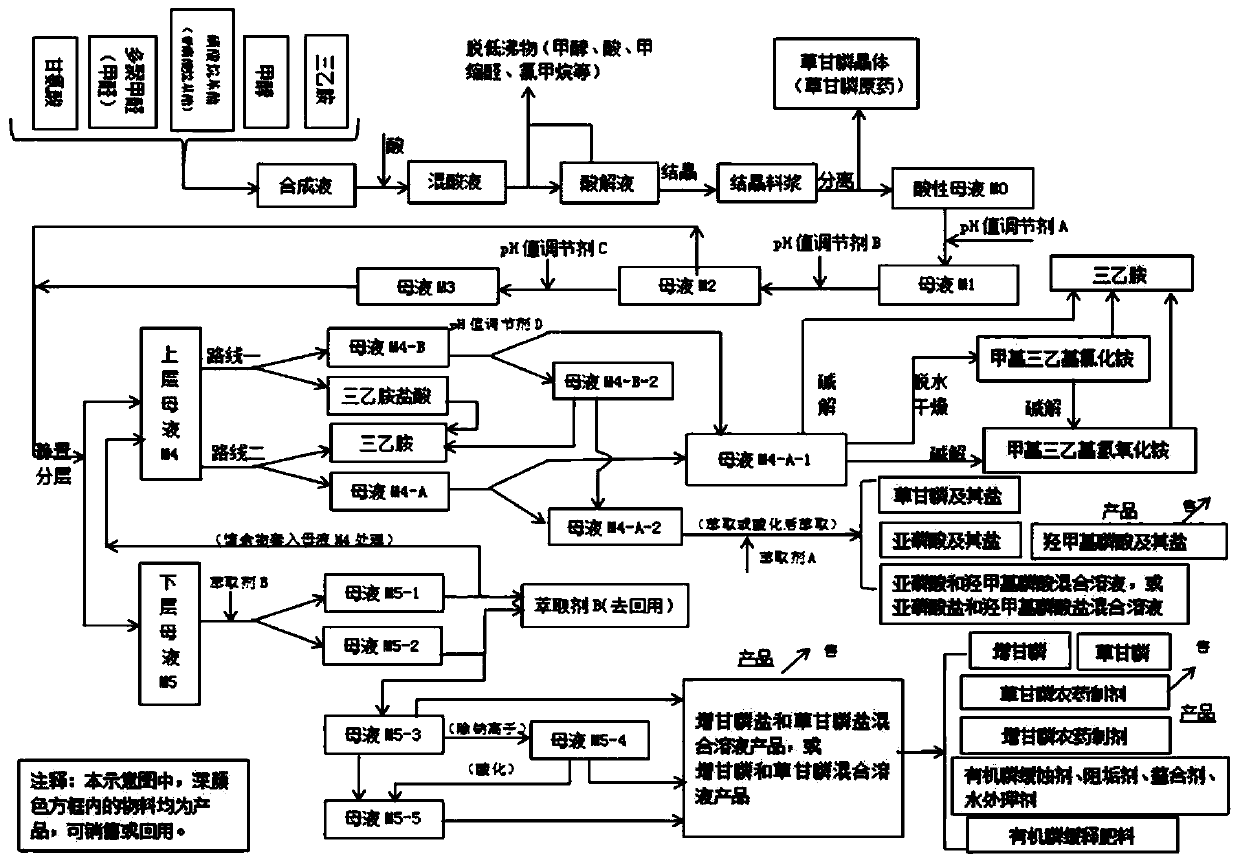

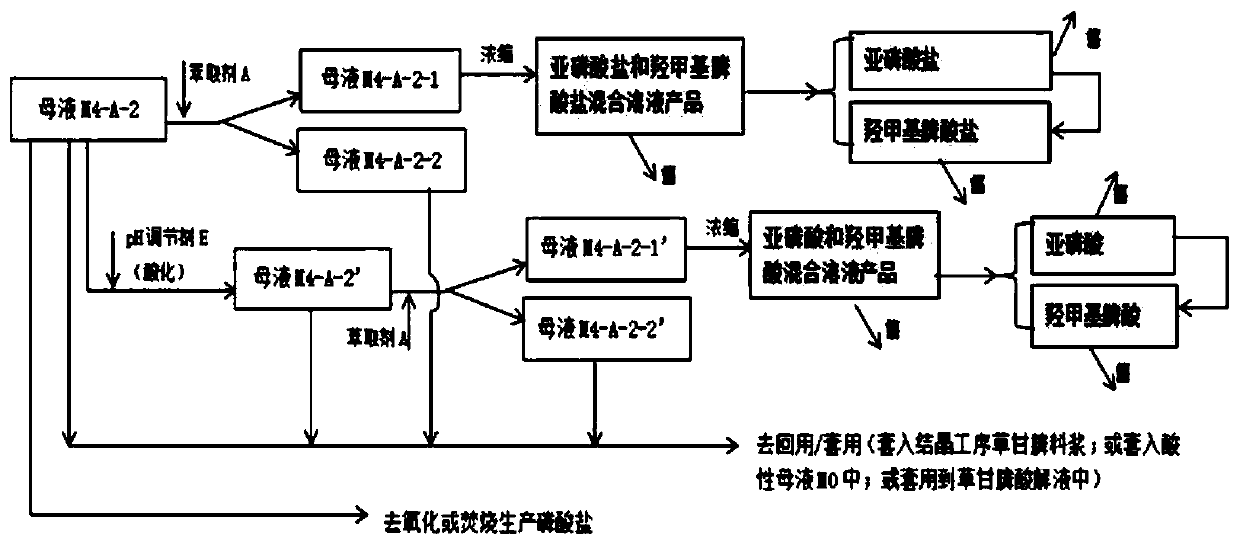

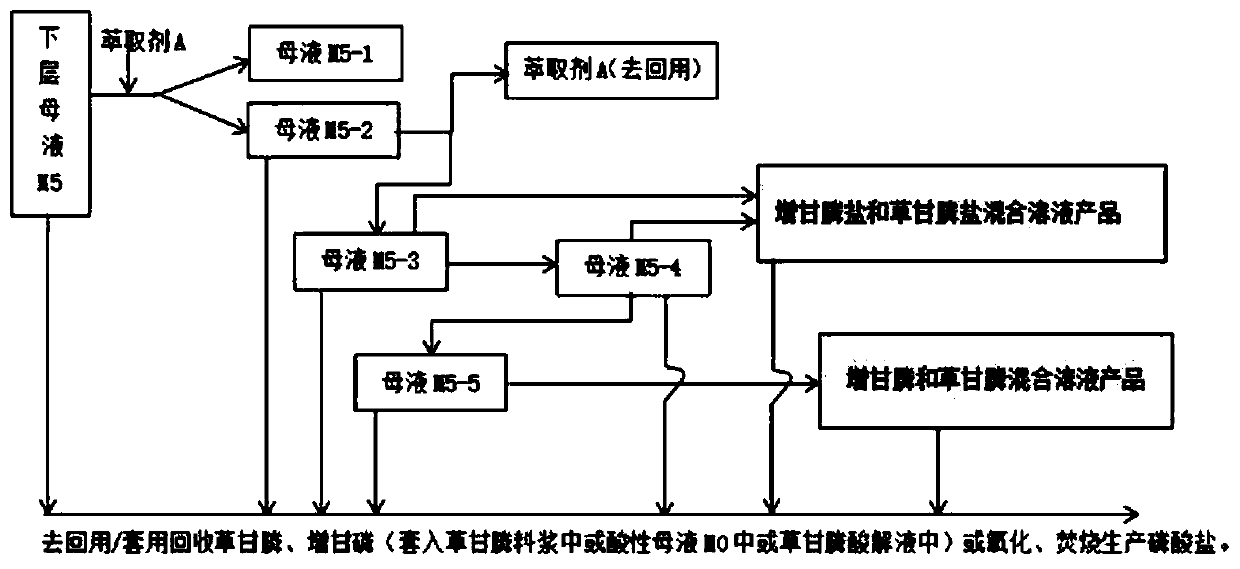

Glyphosate mother liquor comprehensive treatment and resource recycling method

PendingCN111333519AReduce volume and handling costsLess impuritiesAmino compound purification/separationGroup 5/15 element organic compoundsPhosphorous acidPulp and paper industry

The invention discloses a glyphosate mother liquor comprehensive treatment and resource recycling method which comprises the following steps: adding a pH value regulator into acidic mother liquor M0,standing for layering, and separating the solution to obtain mother liquor M4 at the upper layer and mother liquor M5 at the lower layer; the mother liquor M4 and the mother liquor M5 are treated andapplied, triethylamine hydrochloride, triethylamine, chloride salt, methyltriethylammonium chloride, phosphorous acid or salt thereof, hydroxymethylphosphonic acid or salt thereof, glyphosate or saltthereof, glyphosate or salt thereof and glyphosate or salt thereof are recovered from the mother liquor M4 and the mother liquor M5, and are respectively and correspondingly converted into products with higher additional values for utilization. The glyphosate mother liquor comprehensive treatment and resource recycling method has the advantages that the emission is reduced from the source; the method reduces the total amount and treatment load of the glyphosate mother liquor, reduces environmental pollution, realizes reasonable recycling and appreciation of resources, improves economic benefits, is environment-friendly, outstanding in economic benefits and good in technical implementation effect, and is suitable for large-scale industrial application.

Owner:陈兴华

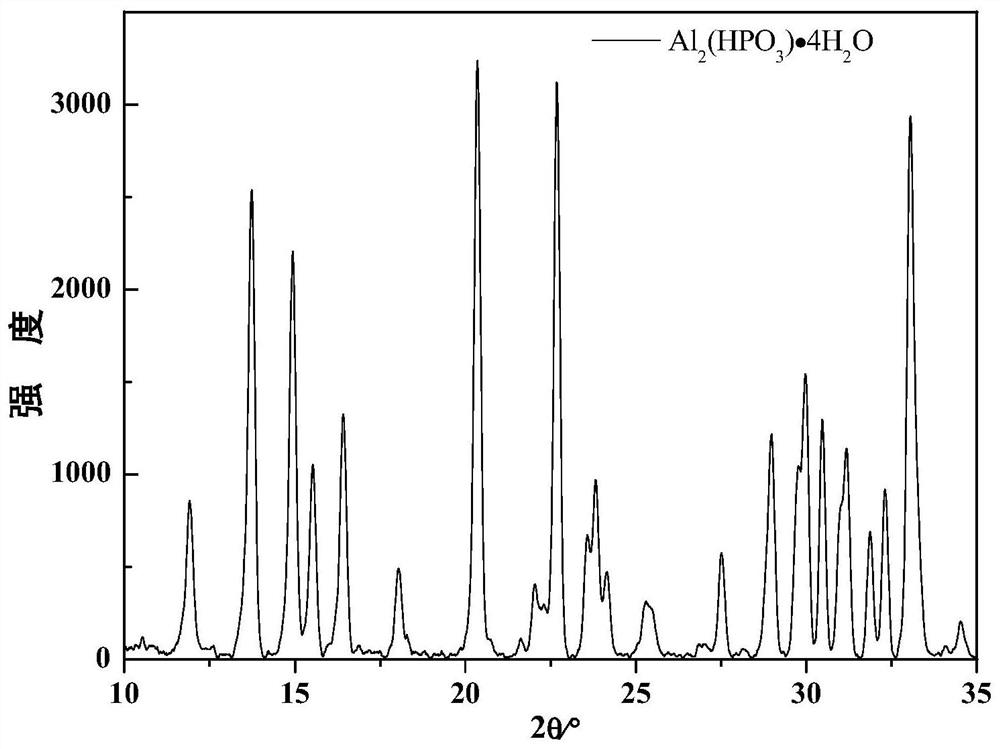

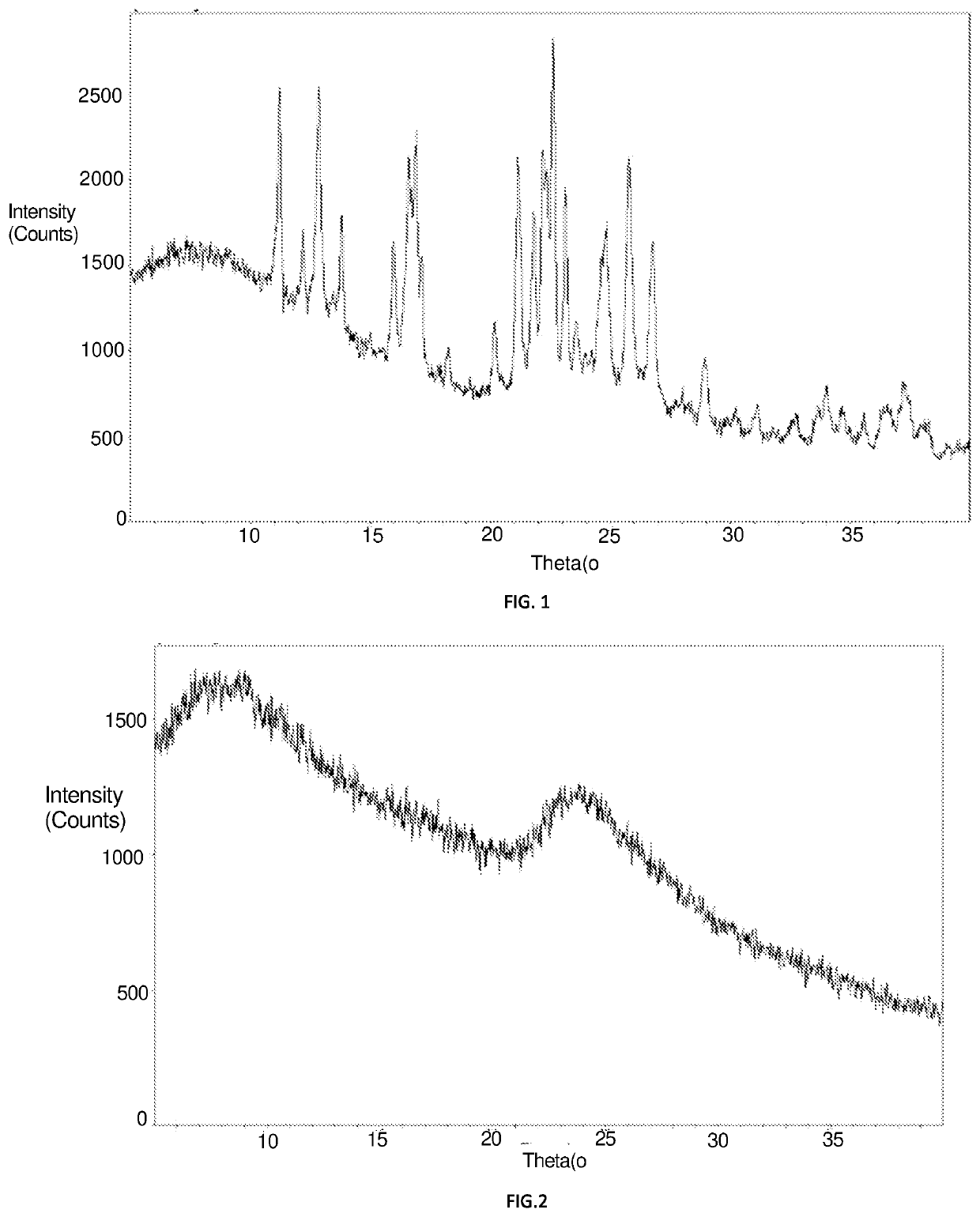

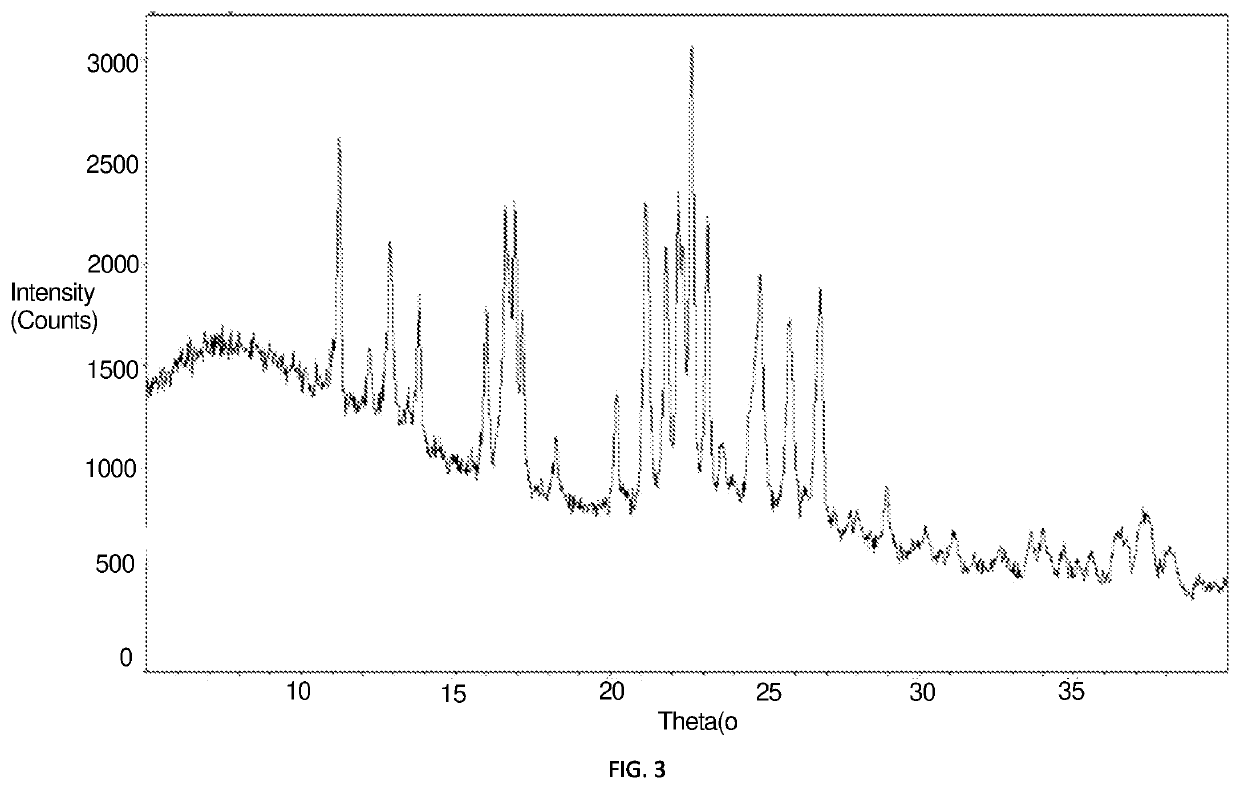

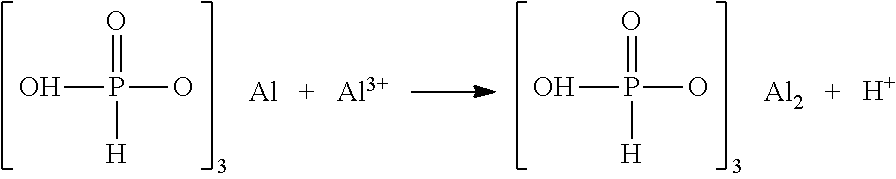

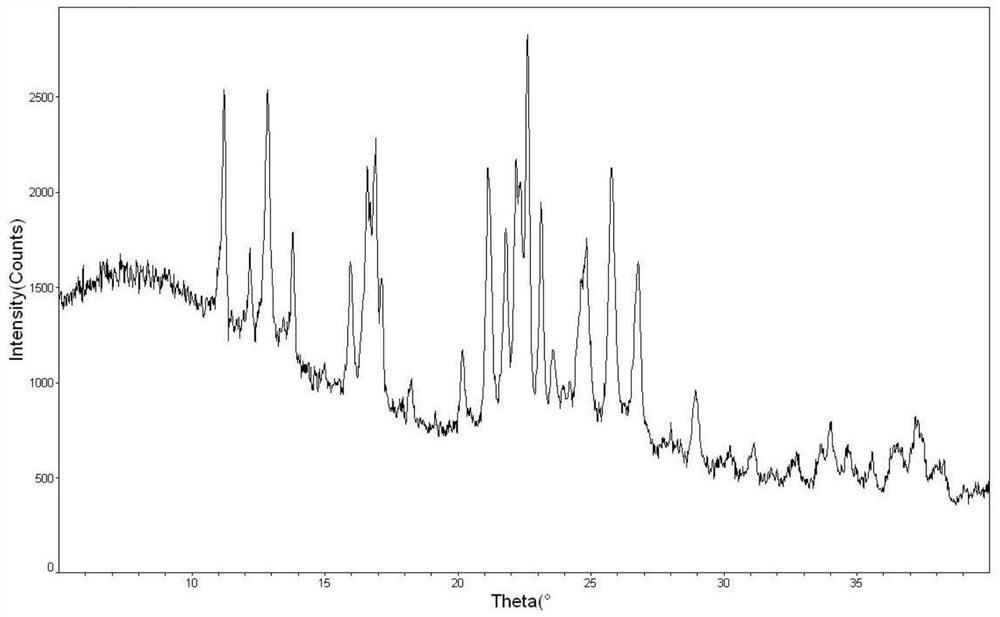

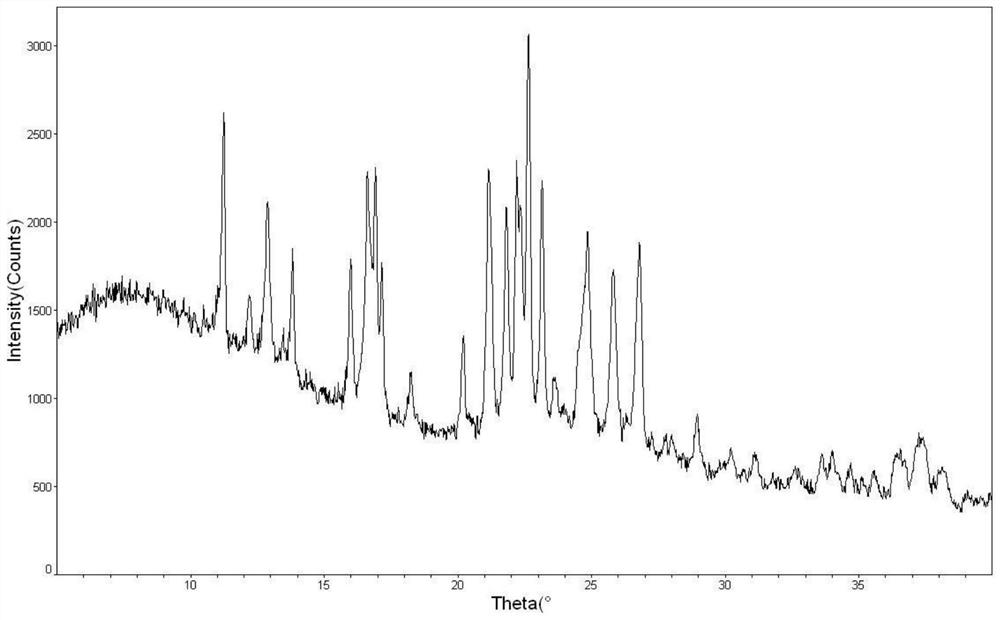

Crystalline aluminum phosphite, preparation method and application thereof

PendingUS20220127434A1High thermal decomposition temperatureLow water absorptionFireproof paintsAluminium compoundsPhosphorous acidPhosphoric acid

The present invention discloses a crystalline aluminum phosphite, a preparation method thereof and an application thereof as or for the preparation of a flame retardant or a flame retardant synergist. The preparation method has the following processes: 1, reacting aluminum hydrogen phosphite with an aluminum-containing compound in water at 80-110° C. to obtain a precipitate in the presence of no strong acid or a small amount of strong acid; 2, washing and filtering the precipitate; 3, drying the precipitate at 100-130° C.; 4, continuously heating the dried solid step by step at a low speed, where the material temperature is increased to not exceeding 350° C. from room temperature at about 5-10 h, with a temperature rise rate not exceeding 5° C. / min. Compared with amorphous aluminum hydrogen phosphite, the crystalline aluminum phosphite has a higher thermal decomposition temperature, lower water absorption and weaker acidity, and can be synergistic with diethyl aluminum hypophosphite to achieve better flame retardant property and thus, is used for a halogen-free flame retardant component of high polymer materials.

Owner:ZHEJIANG UNIV +1

Crystalline aluminum phosphite, and preparation method and application thereof

ActiveCN113460984AHigh thermal decomposition temperatureLow water absorptionFireproof paintsAluminium compoundsPhosphorous acidPhosphoric acid

The invention discloses crystalline aluminum phosphite, a preparation method thereof and application of the crystalline aluminum phosphite as or used for preparing a flame retardant or a flame-retardant synergist. The preparation method comprises the following steps: 1, reacting aluminum hydrogen phosphite and an aluminum-containing compound in water at 80-110 DEG C in the presence or absence of a small amount of strong acid to obtain a precipitate; 2, washing and filtering the precipitate; 3, drying the precipitate at the temperature of 100-130 DEG C to remove water; and 4, continuing to heat and dry the moisture solids at a low-speed gradient temperature rise speed of not more than 5 DEG C / min, and raising the temperature of the materials from normal temperature to not more than 350 DEG C within about 5-10 hours, wherein the temperature rise speed is not more than 5 DEG C / min. Compared with amorphous aluminum phosphite, the crystalline aluminum phosphite has higher thermal decomposition temperature, lower water absorption and weaker acidity, can achieve a synergistic effect with diethyl aluminum hypophosphite, has better flame retardant property, and is used as a halogen-free flame retardant component of a high polymer material.

Owner:JIANGSU LISIDE NEW MATERIAL

Method for preparing phosphorus fertilizer from liquid waste containing phosphate and phosphite ester

InactiveCN106829897ASimple production equipmentEasy to operatePhosphatesAlkali orthophosphate fertiliserLiquid wastePhosphate

The invention relates to a method for preparing phosphate fertilizer from waste liquid containing phosphoric acid ester and phosphite. The steps are as follows: S1) decompose the alkyl group in the waste liquid containing phosphoric acid ester and phosphorous acid ester under acidic conditions; S2) pass the solution obtained in S1 through alkali or carbonate neutralization; S3) evaporating the solution obtained in S2 for the first time and separating phosphate by cooling crystallization; S4) evaporating the solution obtained in S3 for the second time and separating phosphite by cooling crystallization. The invention provides a waste liquid utilization method with easy operation, safety, high phosphorus recovery rate and comprehensive waste utilization.

Owner:ZHEJIANG XINHUA CHEM

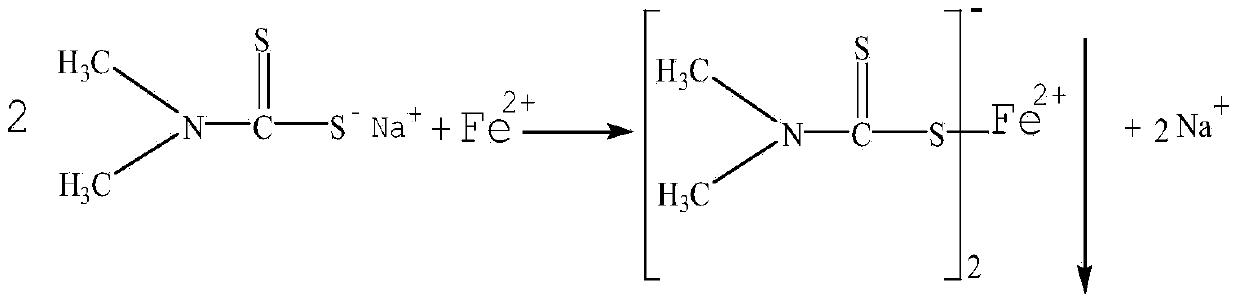

Method for reducing content of iron ions in orthophosphorous acid

The invention discloses a method for reducing the content of iron ions in orthophosphorous acid. An iron-containing orthophosphorous acid mother liquor reacts with a sodium dimethyldithiocarbamate solution to reduce the content of iron ions in order to obtain highly pure orthophosphorous acid. The method has the advantages of scientific principle, safe and environmentally friendly process, simple operation, high purity of the obtained orthophosphorous acid, and low cost of reaction raw materials.

Owner:JIANGSU DAMING TECH

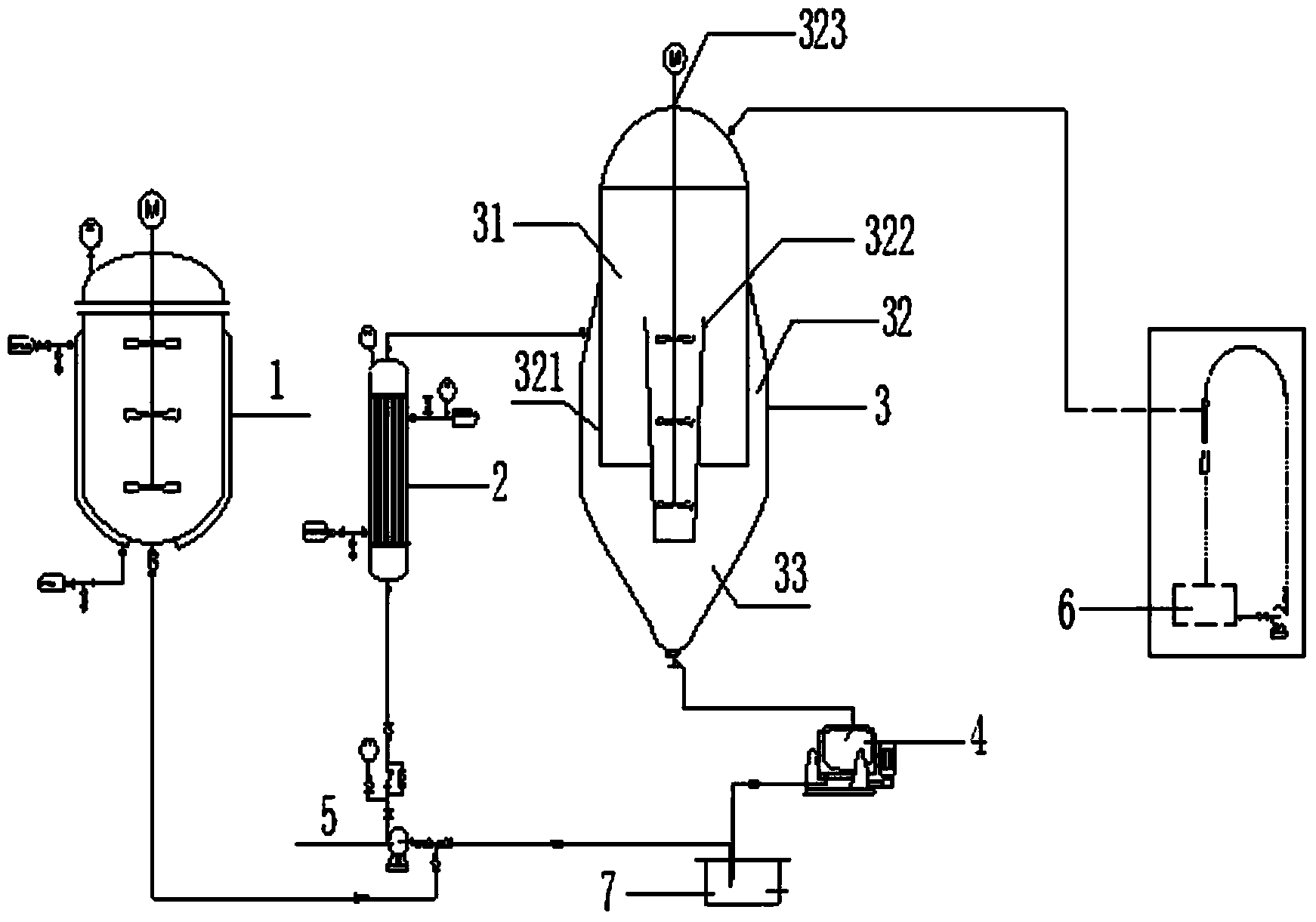

Continuous crystallizing and centrifuging system for producing phosphorous acid

InactiveCN104071761AReduce pollutionShorten crystallization timePhosphorous acidPhosphorous acidPhosphoric acid

The invention discloses a continuous crystallizing and centrifuging system for producing phosphorous acid. The system comprises a concentration kettle, a condenser, a crystallizer, a centrifugal machine and a circulating pump, and is characterized in that the concentration kettle is connected with the condenser by virtue of the circulating pump; the condenser is connected with the crystallizer by virtue of a pipeline; the crystallizer is connected with the centrifugal machine by virtue of a pipeline. According to the system, the defect of the prior art is overcome, the crystallizing time is greatly shortened, the production efficiency is improved, the energy consumption is reduced, the equipment investment is reduced, the pollution to human, equipment and environment in the operation process is reduced, and the system is safe and environment-friendly.

Owner:JIANGSU DAMING TECH

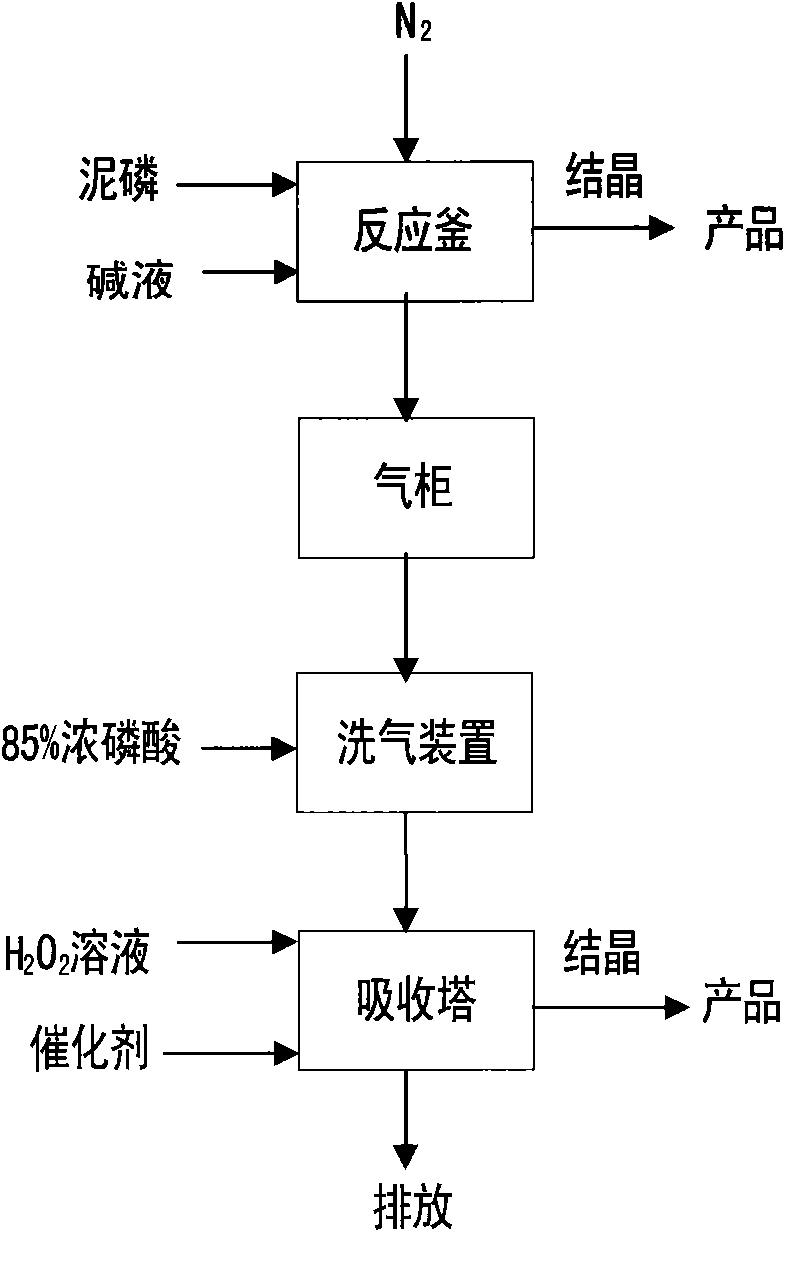

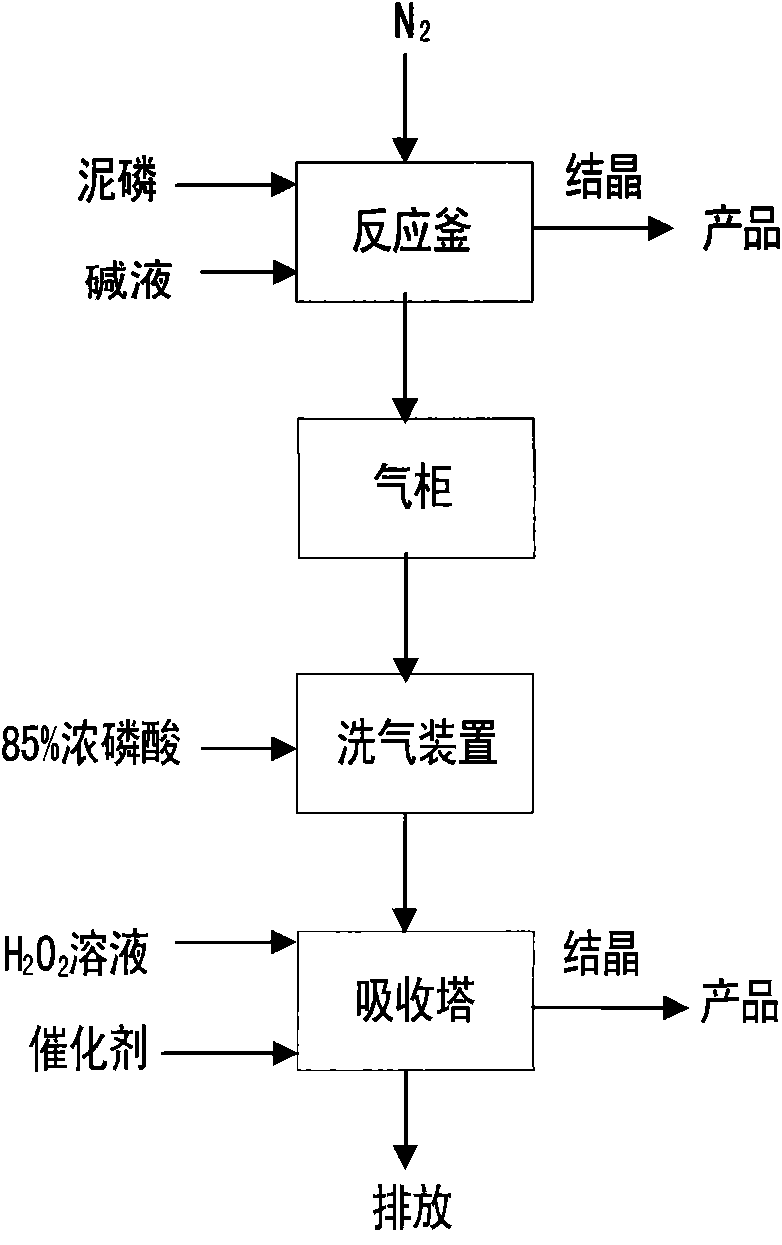

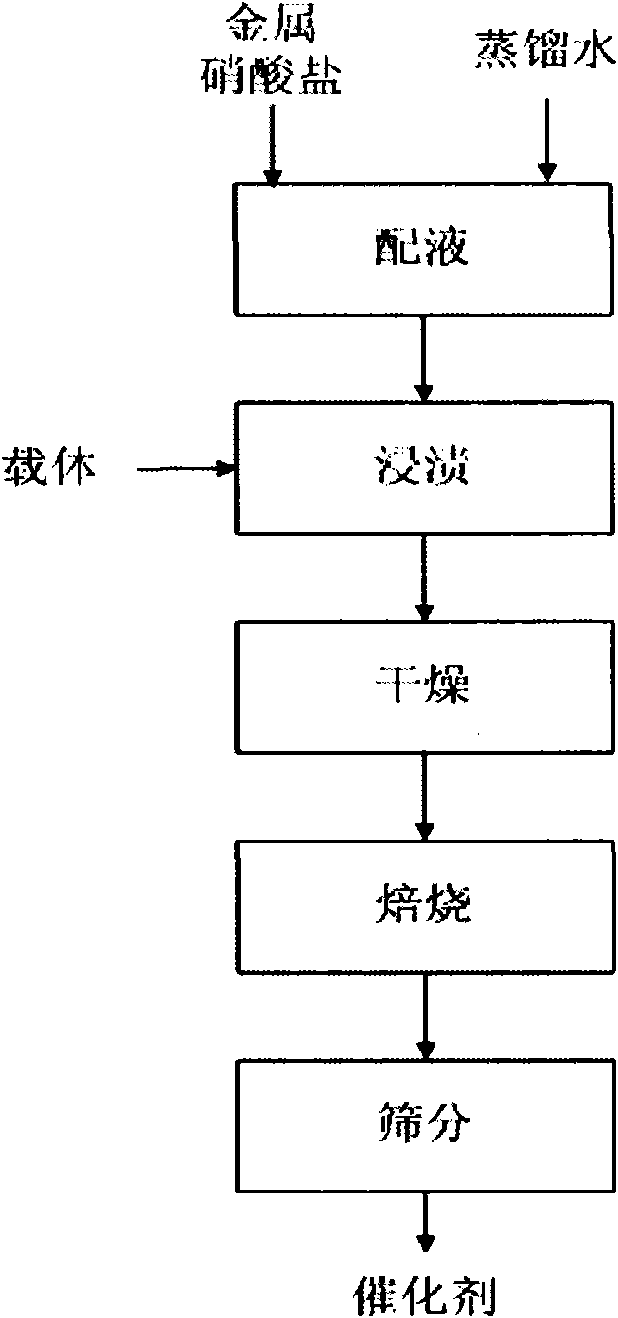

Heterogeneous catalytic oxidation method for treating tail gas generated in sodium hypophosphite preparation process from sludge phosphorus

InactiveCN101811682AImprove stabilityReduce dosageDispersed particle separationPhosphorous acidHigh concentrationHigh absorption

The invention relates to a method for treating waste slag in a yellow phosphorus production process, in particular to a heterogeneous catalytic oxidation method for treating high-concentration phosphine tail gas generated in a sodium hypophosphite preparation process from sludge phosphorus and belongs to the technical field of industrial waste gas purification treatment. The method comprises the following steps: heating the sludge phosphorus and lye in proportion to a temperature of between 75 and 95 DEG C under the condition of oxygen isolation, performing a reaction with stirring, collecting and washing the generated phosphine, absorbing the phosphine by using solution of hydrogen peroxide in the presence of a filter cake of a nitrate catalyst, wherein the mass ratio of the catalyst to the absorption liquid is 1-20 to 1,000, and reacting to form sodium hypophosphite and sodium phosphite products. The method can reduce the air pollution caused by the phosphine tail gas, have high absorption efficiency of the phosphine, and can increase the output of the sodium hypophosphite products.

Owner:KUNMING UNIV OF SCI & TECH

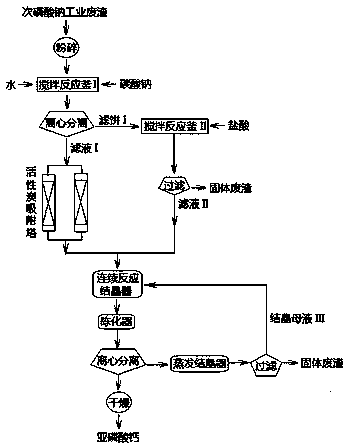

Method for preparing calcium phosphite from industrial sodium hypophosphite waste residues

InactiveCN104163410AIncrease production capacityHigh degree of automationPhosphorous acidWaste treatmentChemistry

The invention relates to a method for preparing calcium phosphite from industrial sodium hypophosphite waste residues. According to the technical scheme, the method comprises the following steps: firstly, reacting the sodium hypophosphite waste residues, water and sodium carbonate, and separating to prepare a filter cake I and filter liquor I; secondly, reacting the filter cake I with hydrochloric acid, and separating to prepare filter liquor II; thirdly, enabling the filter liquor I to pass through an active carbon adsorption system, adding the filter liquor I and the filter liquor II into a continuous reaction crystallizer, ageing, separating and drying to obtain calcium phosphite crystals with the purity of more than 99.0% and crystal mother liquor II; and finally, evaporating and crystallizing the crystal mother liquor II to obtain crude sodium chloride salt and crystal mother liquor III, and returning the crystal mother liquor III to the reaction crystallizer for circulation. According to the method, a continuous reaction crystallization process is adopted, calcium phosphite is prepared from the industrial byproducts-sodium hypophosphite waste residues used as raw materials, the sodium hypophosphite waste residues are recycled during solid waste treatment, and waste liquid is not generated in a production process; moreover, the method has the advantages that the process is simple, the operating condition is mild, the energy consumption is low, the product quality is stable, the industrialization is facilitated, and the like.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com