Crystalline aluminum phosphite, and preparation method and application thereof

A technology of aluminum phosphite and aluminum hydrogen phosphite, applied in the field of materials, can solve the problems of easy discoloration, negative impact, easy moisture absorption of flame retardants, etc., and achieve the effects of low water absorption, acidity, and high thermal decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

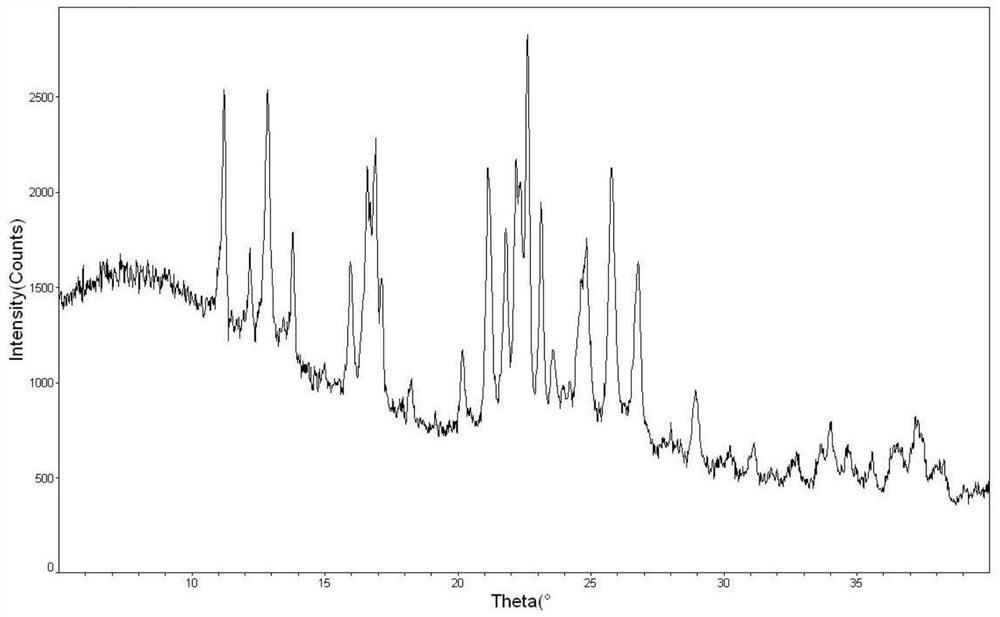

[0074] The preparation of embodiment 1 crystalline aluminum phosphite

[0075] The preparation process is: add 270g (1mol) aluminum hydrogen phosphite ((H 2 PO 3 ) 3 Al) and the water of 630g, fully stirring and dissolving, obtain aluminum hydrogen phosphite solution. In a 500mL beaker, 75g of aluminum sulfate is dissolved in 175g of water, and then 8.1g of concentrated phosphoric acid (H 3 PO 4 ) fully stirred and mixed evenly, and transferred to the dropping funnel. Heat the reaction kettle to 90°C, start to add phosphoric acid-containing aluminum sulfate solution dropwise, and the dropwise addition is completed in 2 hours, add alkali to adjust the pH value to 2.2, and keep warm for 1 hour to continue the reaction. Filter while hot, and wash the precipitate several times until the conductivity of the washed water is less than 50 μs / cm, then stop washing. Transfer the material to the oven, heat up to 120°C, dry for 60min, the moisture content of the solids is 0.1wt%, th...

Embodiment 2

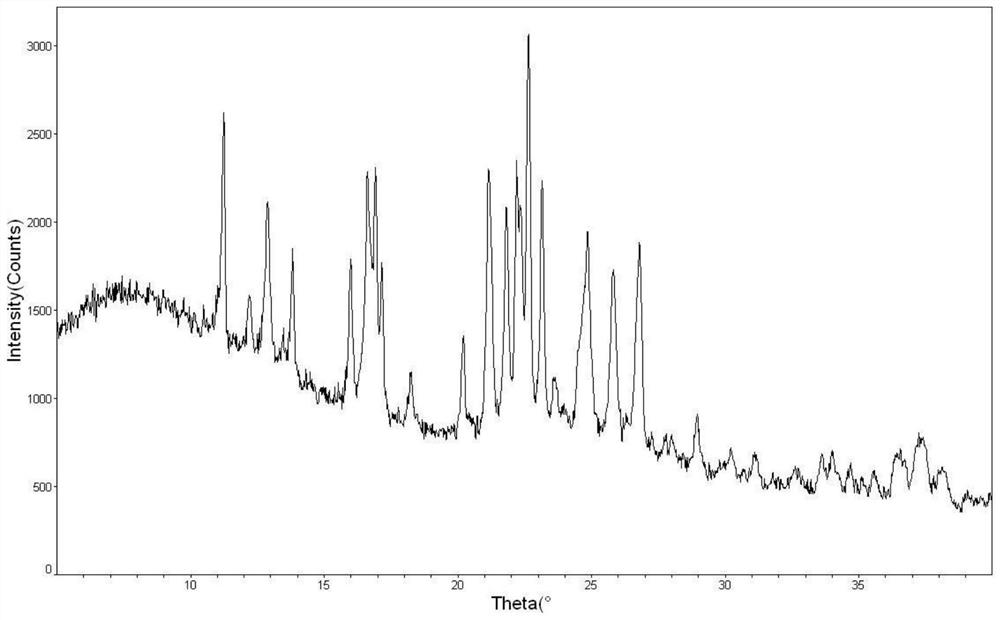

[0083] The preparation of embodiment 2 crystalline aluminum phosphites

[0084] The preparation process is: add 270g (1mol) aluminum hydrogen phosphite ((H 2 PO 3 ) 3 Al) and the water of 630g, fully stirring and dissolving, obtain aluminum hydrogen phosphite solution. Disperse 78g of aluminum hydroxide in 200g of water in a 500mL beaker and transfer to the dropping funnel. Heat the reaction kettle to 90°C, start dropwise adding the aluminum hydroxide suspension, and complete the dropwise addition in 2 hours, adjust the pH value to 2.6 through the aluminum hydroxide solid, and keep warm for 1 hour to continue the reaction. Filter while hot, and wash the precipitate several times until the conductivity of the washed water is less than 50 μs / cm, then stop washing. Transfer the material to the oven, heat up to 120°C, dry for 60min, the moisture content of the solids is 0.1wt%, then raise the temperature to 180°C at a rate of 2°C / min, keep it for 60min, then raise the temperat...

Embodiment 3

[0096]Adopt the nylon 66 of 52wt%, the glass fiber of 30wt%, the crystalline aluminum phosphite of embodiment 1 of 3.4wt% and 14.6wt% diethylaluminum hypophosphite (LFR8003, Jiangsu Liside New Material Co., Ltd.), according to The general procedure is to prepare flame-retardant glass fiber reinforced nylon 66, and prepare samples to test the flame-retardant performance. The flame-retardant material reaches UL94 V0 (0.8mm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com