Preparation process for synthesizing phosphorous acid by hydrolyzing phosphorous trichloride

A technology for the preparation of phosphorus trichloride, which is applied in phosphorous acid, chemical industry, phosphorus oxyacids, etc., can solve the problems of high temperature control requirements, long deacidification time, and large absorption system resistance, etc. Environmental protection requirements, the reaction is easier to control, and the effect of avoiding a large amount of heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

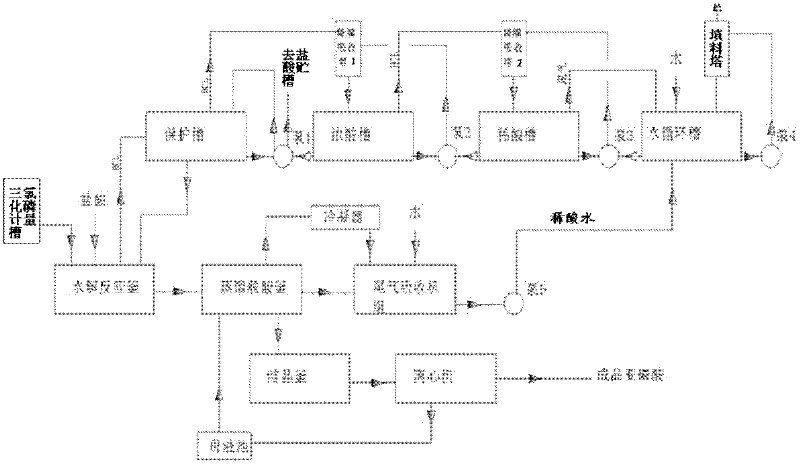

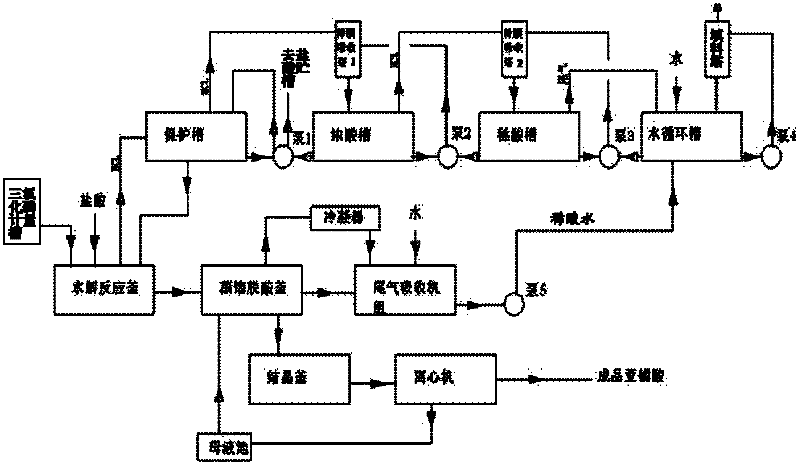

[0023] 1. Production system

[0024] The discharge port of the phosphorus trichloride high-level metering tank is connected with the phosphorus trichloride feed port of the hydrolysis reactor, the hydrochloric acid feed port of the hydrolysis reactor is connected with the hydrochloric acid supply equipment, the gas outlet is connected with the protection tank inlet, and the hydrochloric acid The feeding port is connected with the hydrochloric acid outlet 1 of the protective tank; the gas outlet of the protective tank is connected with the air inlet of the falling film absorption tower 1, and the liquid outlet of the falling film absorption tower 1 is connected with the acid inlet of the concentrated acid tank. The acid outlet 1 of the tank is connected to the feed port of the concentrated hydrochloric acid storage tank and the acid supplement port of the protection tank through the circulation pump 1, and the hydrochloric acid outlet 2 of the protection tank is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com