Preparation method of cyclosiloxane

A technology of cyclosiloxane and alkoxysilane, which is applied in the field of preparation of cyclosiloxane, can solve the problems of reduced purity of cyclosiloxane, high reaction temperature, fast hydrolysis speed, etc., and achieve the reduction of linear polysilicon The production of oxane, the promotion of cyclization reaction, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

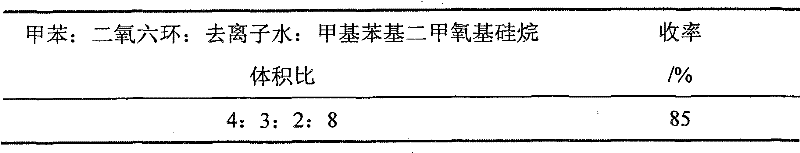

[0027] In a 1000ml three-necked flask equipped with a stirring, thermometer and dropping funnel, add 40ml of dioxane, 200ml of toluene, 200ml of deionized water, and 4g of NaOH, stir evenly, and control the temperature of the system at 60°C. A mixture of 200ml of methylphenyldimethoxysilane and 200ml of toluene was slowly added dropwise, and after the dropwise addition was completed, the reaction was continued for 2h. Then gradually raise the temperature to 80°C to distill off the methanol generated by the reaction. Stop the reaction, let stand to separate the water layer, wash the oil layer with water until neutral, dry, and evaporate the solvent to obtain 134.6 g of hydrolyzate with a yield of 90%.

Embodiment 2

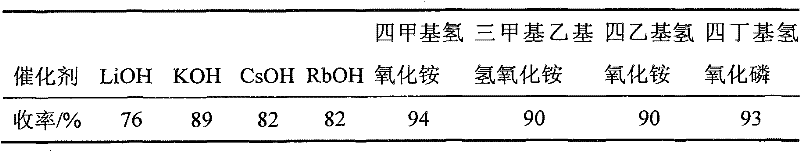

[0029] According to the same method as in Example 1, the catalyst type was changed, and the amount was fixed at 2% of the mass of the alkoxysilane. The results obtained are shown in Table 1 below.

[0030] Table 1

[0031]

Embodiment 3

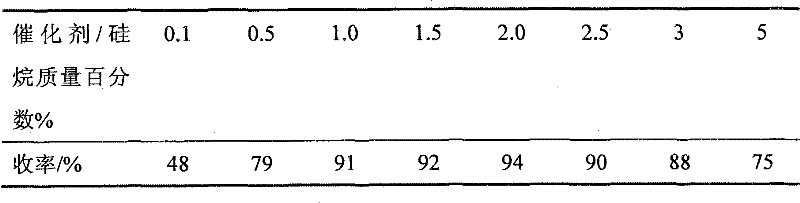

[0033] By the same method as in Example 1, tetramethylammonium hydroxide was selected as the catalyst to change the catalyst consumption, and the obtained results are shown in Table 2 below.

[0034] Table 2

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com