Preparation method of pearlescent pigment taking flaky alpha-aluminum oxide as matrix

A pearlescent pigment and aluminum oxide technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of affecting the pearl luster of pearlescent pigments, affecting the gloss of pearlescent pigments, and the weather resistance needs to be improved, achieving remarkable results. Pearlescent effect, more cool and individual appearance, high chemical stability and mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

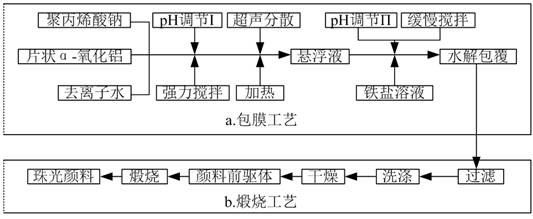

[0044] like figure 1 As shown, a method for preparing pearlescent pigments based on flaky α-alumina, which comprises the following steps:

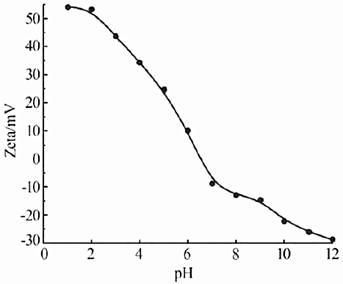

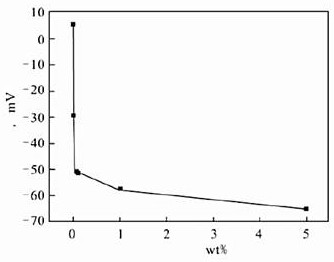

[0045] s1, in sheet α-Al 2 O 3As the base liquid, add adsorbent and acidic pH adjuster I to prepare flaky α-Al 2 O 3 Aqueous suspension solution with negative charge on the surface;

[0046] s2, adding a metal salt solution and an alkaline pH regulator II to the aqueous suspension solution to carry out a hydrolysis coating reaction to obtain a pearlescent pigment precursor;

[0047] s3, filtering, washing and drying the pearlescent pigment precursor, and calcining the dried precursor to obtain the pearlescent pigment.

[0048] specifically,

[0049] First, continuously heat the matrix solution, add adsorbent and acidic pH adjuster I, and perform ultrasonic dispersion and vigorous stirring; preferably, the continuous heating temperature is kept at 60-90 °C, and ultrasonic dispersion should be performed for 15 minutes before preparing ...

Embodiment 1

[0071] Take 5g of flake α-Al 2 O 3 , 0.03g of sodium polyacrylate was added to 100ml of deionized water, and the pH value of the solution was adjusted to 2. First, vigorously stir with a magnetic stirrer for 60 min, and then ultrasonically disperse for 15 min. During this process, the temperature of the solution is kept at 80°C. While maintaining the slow stirring of the suspension with a magnetic stirrer, slowly add 50 ml of ferric chloride with a mass fraction of 10%, and at the same time add a 10% mass fraction of sodium hydroxide solution to adjust the pH value, so that the pH value is changed from 2.0 slowly rises to 3.0. Continue to stir slowly for 5min, stop stirring, filter out the suspended solid while hot, wash with water and then dry to obtain Fe 2 O 3 / Al 2 O 3 The precursor of iron-based pearlescent pigments.

[0072] The pearlescent pigment precursor was placed in a muffle furnace for calcination at 830 °C for 60 min. The calcined product is taken out as ...

Embodiment 2

[0074] No adsorbent is added;

[0075] Take 5g of flake α-Al 2 O 3 , was added to 100 ml of deionized water, and the pH value of the solution was adjusted to 2. First, vigorously stir with a magnetic stirrer for 60 min, and then ultrasonically disperse for 15 min. During this process, the temperature of the solution is kept at 80°C. While maintaining the slow stirring of the suspension with a magnetic stirrer, slowly add 50 ml of ferric chloride with a mass fraction of 10%, and at the same time add a 10% mass fraction of sodium hydroxide solution to adjust the pH value, so that the pH value is changed from 2.0 slowly rises to 3.0. Continue to stir slowly for 5min, stop stirring, filter out the suspended solid while hot, wash with water and then dry to obtain Fe 2 O 3 / Al 2 O 3 The precursor of iron-based pearlescent pigments.

[0076] The pearlescent pigment precursor was placed in a muffle furnace for calcination at 830 °C for 60 min. The calcined product is taken ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com