A pearlescent printing material

A technology of printing materials and pearlescent pigments, which is applied in printing, protein coating, coating, etc., can solve the problems of particle aggregation and pearlescent effect not obvious, product appearance performance is difficult to control, and pearlescent powder distribution is uneven, etc., to achieve image High color reproduction, good printing fastness, and obvious pearlescent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

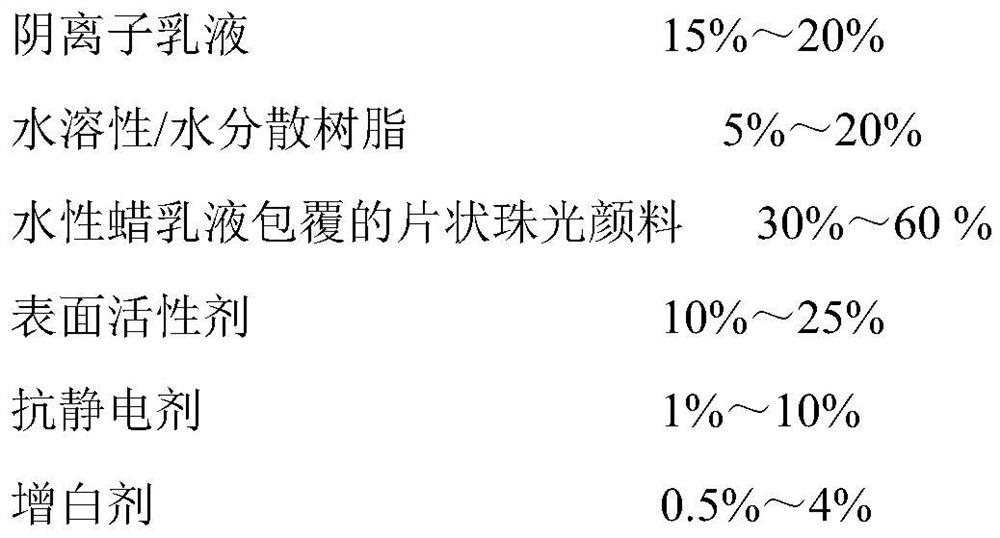

[0039] The preparation steps of the pearlescent printing material of the present invention are as follows:

[0040] a) According to the weight ratio of water-based wax emulsion and flake pearlescent pigment is 1:5~1:20, add flake pearlescent pigment into water-based wax emulsion, add deionized water to obtain the mixture, stir at low speed and normal temperature, and take samples for centrifugal drying Finally, the surface energy of flake pearlescent pigments is tested by Washburn ≤ 45mJ / m 2 , the reaction is terminated. The mixture is centrifuged at a rotational speed of 800r / min to 1000r / min to obtain a precipitate, which is taken out and washed with deionized water, then centrifuged and dried to obtain a flaky pearlescent pigment coated with an aqueous wax emulsion.

[0041] b) According to the formula of the coating solution, add the flaky pearlescent pigment emulsion coated with the anionic emulsion, water-soluble resin and water-based wax emulsion into the container, an...

Embodiment 1

[0046] (1) Take 66.7g of paraffin wax emulsion (solid content 30%) and put it into a container, add 100g of silver pearl powder (particle size 5μm~20μm) while stirring, add deionized water to make the total amount of the mixture reach 400g, and put it under normal temperature Stir for 3 hours at a rotating speed, centrifuge at a rotating speed of 800r / min to 1000r / min for 20 minutes to obtain a precipitate, take out the precipitate and wash it with deionized water, then continue to centrifuge for 5 minutes, take it out and dry it, and obtain a sheet-shaped wax coated with water-based wax emulsion Pearlescent pigment, the surface energy is tested by the Washburn indirect method, and the test surface energy is 40mJ / m 2 .

[0047] (2) Amino-modified silicone anionic emulsion 30g (solid content 50%), polyvinyl alcohol (polymerization degree 1700, hydrolysis degree 88% concentration 10%) 50g and paraffin emulsion coated pearl powder particles 60g are added in the container, Stir e...

Embodiment 2

[0050] (1) Get 18g polyethylene wax emulsion (solid content 40%) and put into container, add 72.8g golden pearlescent powder (particle diameter 10 μm~60 μm) while stirring, add deionized water to make the total amount of mixture reach 400g, in Stir at room temperature and low speed for 2 hours, centrifuge at a speed of 800r / min to 1000r / min for 20 minutes to obtain a precipitate, take out the precipitate and wash it with deionized water, then continue to centrifuge for 5 minutes, take it out and dry it, and get a water-based wax emulsion coating The flaky pearlescent pigment, with the Washburn indirect method to test the surface energy, the test surface energy is 45mJ / m 2 .

[0051] (2) Add 20 g of amino-modified silicone anionic emulsion (solid content 50%), 40 g of gelatin solution with a concentration of 50% and 40 g of pearl powder particles coated with polyethylene wax emulsion into the container, stir evenly, and then add surface active Add 18.5g of antistatic agent, 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com