Preparation method of phosphorous acid

A technology of phosphorous acid and phosphite, which is applied in the direction of phosphorous acid, phosphorus oxyacid, calcium/strontium/barium sulfate, etc., can solve the problems of low efficiency, low phosphorus yield, multi-stage processing, etc., and achieve The effect of shortening time and increasing productivity

Inactive Publication Date: 2010-02-17

桑达-阿比克有限责任公司 +1

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of this method is that phosphorus is lost due to the generation of phosphine when the yellow phosphorus is hydrolyzed, so the phosphorus yield in the final product is low (no more than 50-55%), and the process is multi-stage and efficient.

The use of expensive catalysts complicates the process and helps to oxidize some of the phosphite-ions to phosphate-ions, contaminating the phosphorous acid

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0029] The method of this application tests the phosphorus-containing residue sample of electrothermal production phosphorus under laboratory conditions, and its composition is as follows, mass %: phosphorus-27.5, residue inorganic part-34.6, water-37.9.

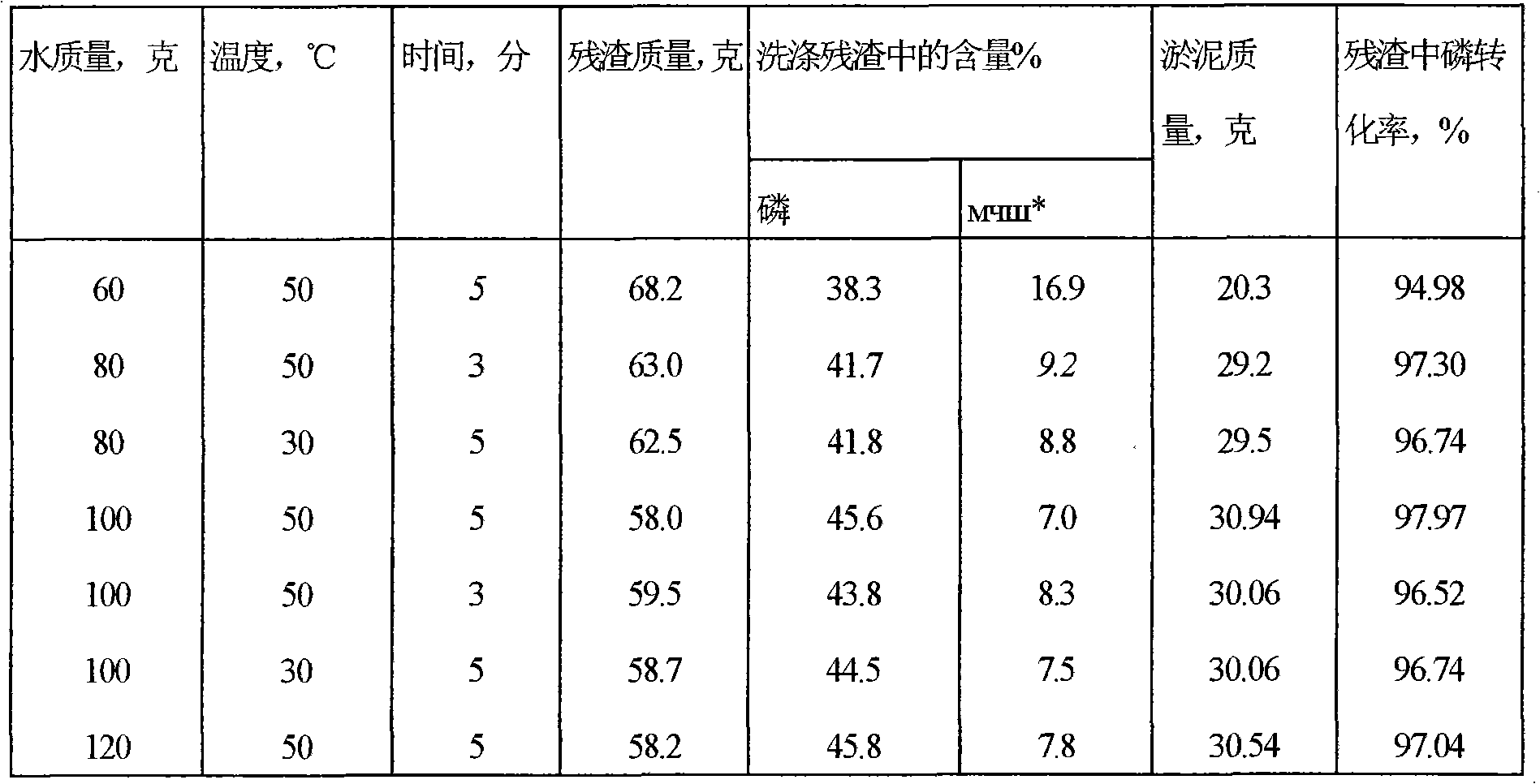

[0030] Experiments were carried out in which the residue was washed with water in a reactor under mechanical agitation. The original residue mass for each experiment was 100 g.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

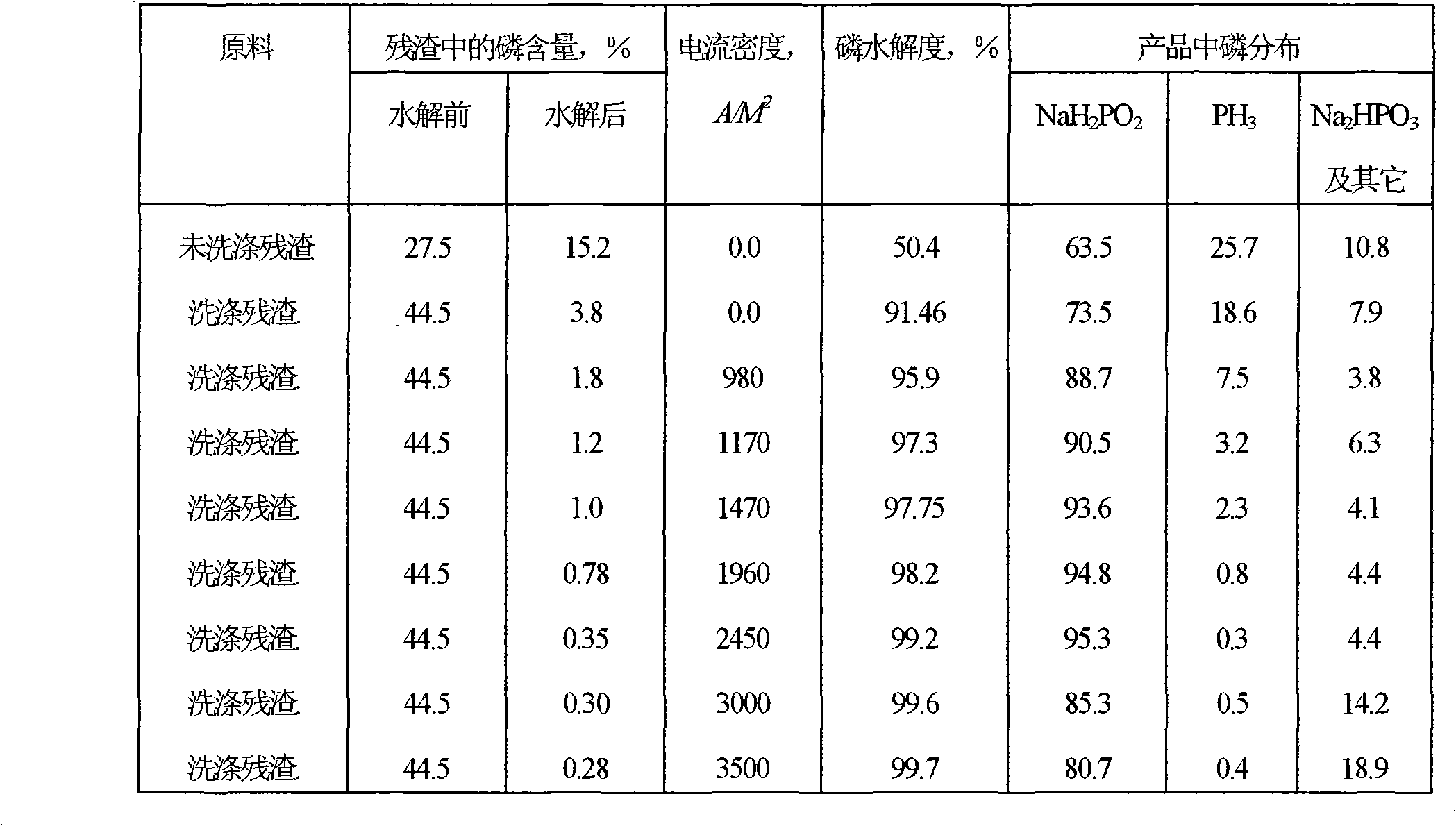

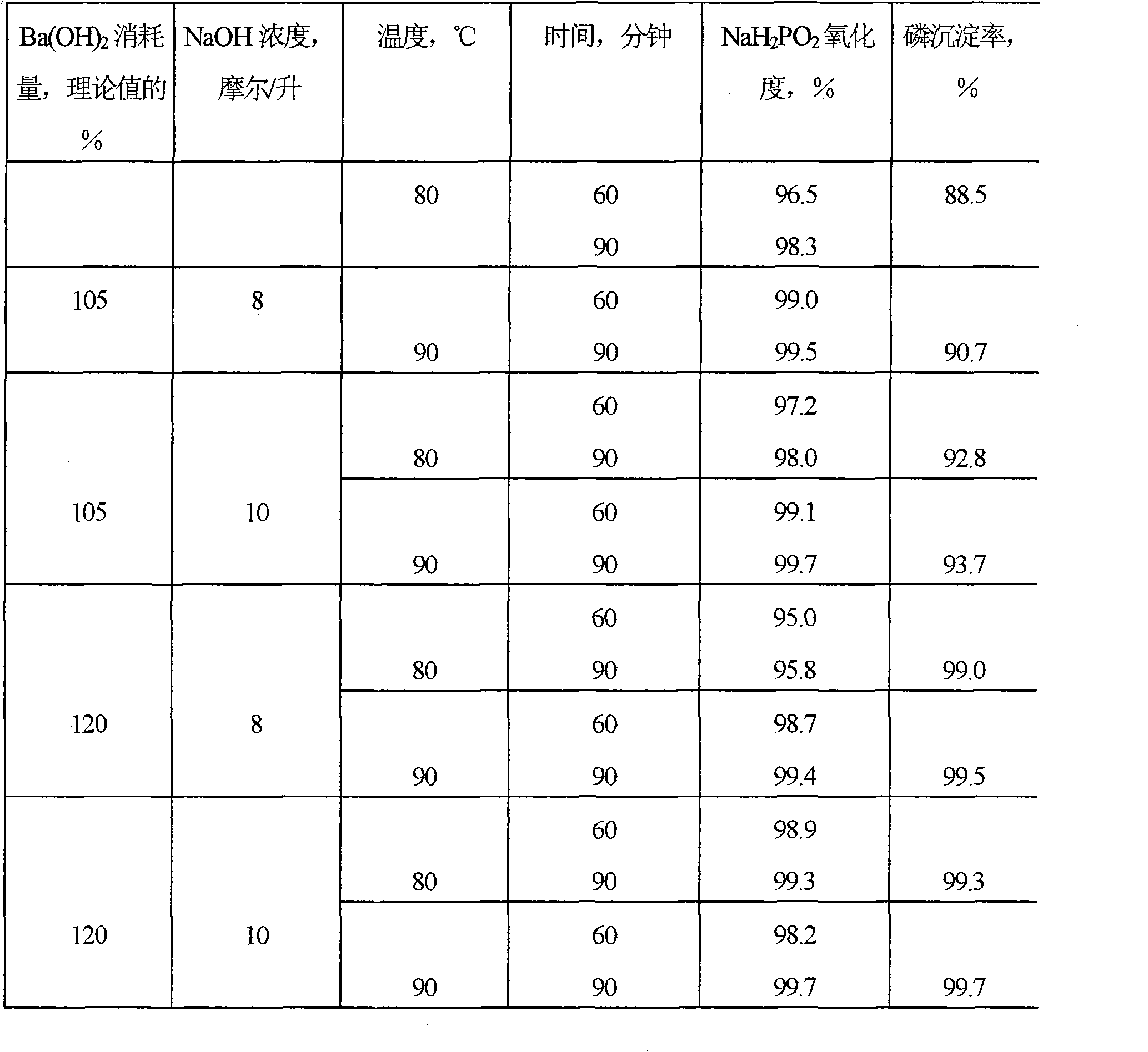

The invention relates to a preparation method of phosphorous acid. The invention relates to the inorganic acid preparation technique, namely to the phosphorous acid manufacturing technique, and can beused for further processing of phosphorus-contained residue obtained as an accessory substances during electric heating production of phosphorus. In order to reduce the time of soda treatment processof the phosphorus-contained residue, improve the phosphorous acid productivity and quality, and reduce the conversion of phosphorus into phosphine, the preparation method of phosphorous acid from phosphorus-contained raw material includes: using sodium hydrate solution to perform soda treatment; separating the aqueous alkali and precipitation; oxidizing the dissolved sodium hypophosphite into phosphate-ion, converting the phosphate-ion into the form of phosphorous acid, and proposing to take the phosphorus-contained residue as original phosphorus-contained raw material. The original residue is washed by water beforehand, processed by non-ionic emulsifier solution, the sodium hypophosphite is oxidized by sodium hydrate in the presence of barium hydroxide, the barium contained deposition isseparated from the solution, and the barium sulfate deposition and phosphorous acid solution are obtained by using sulfuric acid solution to process.

Description

technical field [0001] The present invention relates to a process for the preparation of mineral acids, ie phosphorous acid, which can be used for the treatment of phosphorus-containing residues obtained as by-products in the electrothermal production of phosphorus. Background technique [0002] It is known to oxidize elemental phosphorus to phosphorus trioxide, which is then dissolved in cold water to prepare phosphorous acid. The phosphorous acid that obtains according to this method mixes many phosphoric acids, and its purification is a very complicated work (French patent № 2125587, C01D25 / 16, 1972). [0003] Phosphorous acid can be prepared by oxidizing phosphorus with chlorine under the water layer, or by mixing concentrated hydrochloric acid with 5-15% in PCl 3 PCl in an inert organic solvent 3 Solution interactions are prepared. The defect of this method is complex equipment structure, poor working conditions, phosphorous acid mixed with chlorine, organic compound...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B25/163C01F11/46

Inventor Y·巴格诺夫

Owner 桑达-阿比克有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com