Method for preparing phosphorus fertilizer from liquid waste containing phosphate and phosphite ester

A phosphite and phosphate-containing technology, which is applied in the direction of phosphorous acid, ammonium orthophosphate fertilizer, chemical instruments and methods, etc., can solve the problem of waste liquid containing phosphite and orthophosphate, and the method of utilization has not been reported, phosphoric acid Difficult to recycle ester phosphite waste liquid, difficulty in phosphate ester and phosphite waste liquid, etc., to achieve the effect of high added value, good economical practicability, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

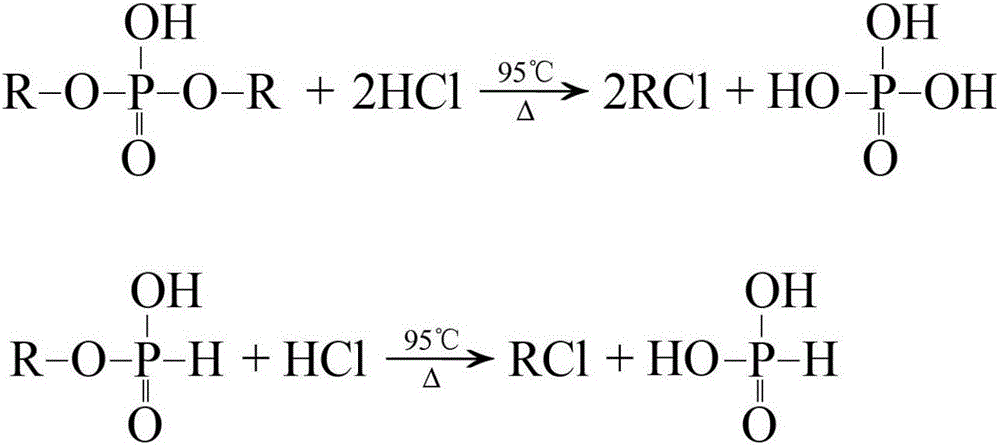

[0025] Add 400 grams of waste liquid containing 24.55% of phosphoric acid ester and 25.62% of phosphite ester into the beaker. After the temperature is raised to 95°C, add 400 grams of concentrated hydrochloric acid to adjust the pH value to 1.5. Speed 300rpm, phosphoric acid ester and phosphite ester decompose alkyl to generate phosphoric acid and phosphorous acid respectively, the reaction is as follows:

[0026]

[0027] After the reaction, cool down and vacuum filter after standing for 16 hours. The evaporated hydrogen chloride and alcohol are treated by water spraying and absorption. When the filtrate is warmed up to 85°C, neutralize with potassium hydroxide solution and adjust the pH value of the solution to 4 under stirring conditions, and continue to stir and react for 1.0h under this condition, phosphoric acid and phosphorous acid will further produce potassium dihydrogen phosphate and diphosphorous acid The hydrogen potassium reaction is as follows:

[0028] h ...

Embodiment 2

[0032] Add 400 grams of waste liquid containing 24.55% of phosphoric acid ester and 25.62% of phosphite ester into the beaker. After heating up to 95°C, add 400 grams of concentrated hydrochloric acid to adjust the pH value to 2. Stir and react at a constant temperature of 95°C for 4.0 hours, then cool , vacuum filtration after standing for 18h. When the filtrate is heated up to 85°C, neutralize with sodium carbonate solution under stirring conditions and adjust the pH value of the solution to 5, continue stirring and reacting for 1.0h under this condition, after the reaction is completed, the solution is concentrated by vacuum evaporation to a solution volume of After 180 grams, cool and crystallize, separate, and dry to 425 grams of disodium hydrogen phosphate product. The separated mother liquor was concentrated by vacuum evaporation twice, crystallized by cooling, and dried to 328 grams of disodium hydrogen phosphite product. After analyzing the product, the disodium hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com