Preparation method of highly dispersed aluminum orthophosphite crystals

A technology of aluminum phosphite and high dispersibility, which is applied in the field of materials, can solve the problems of by-products and other problems, and achieve the effects of energy saving, simple operation and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

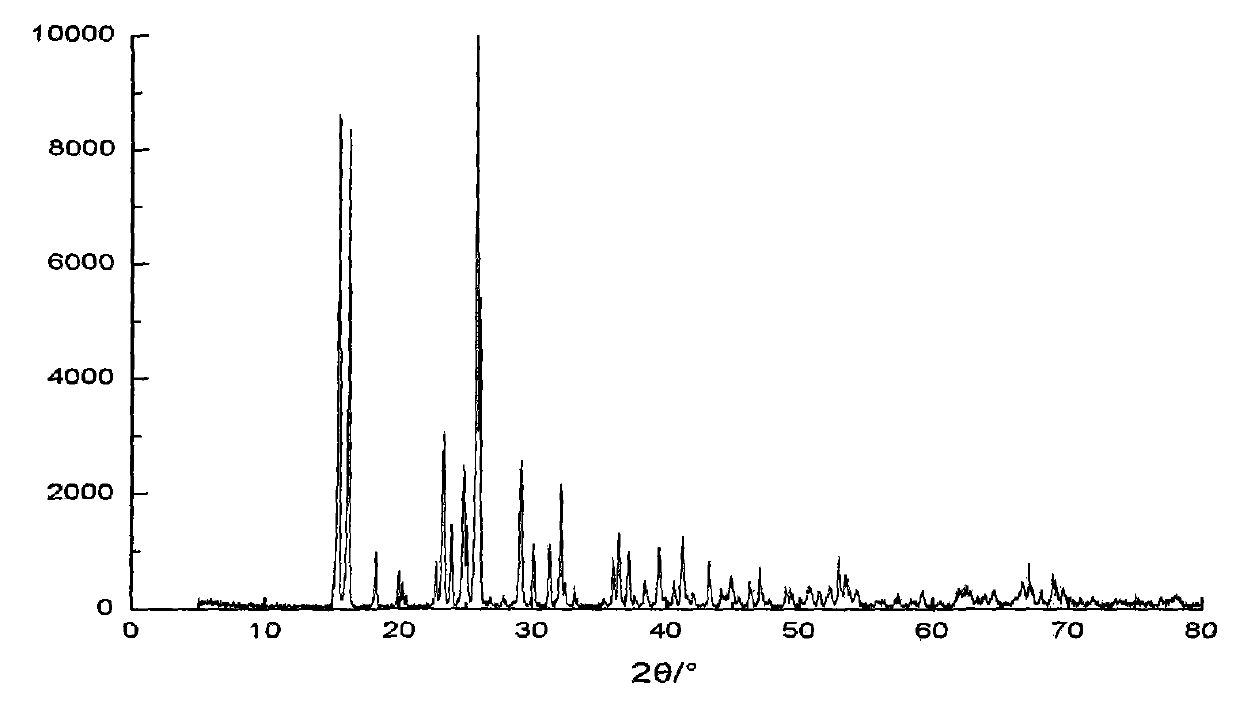

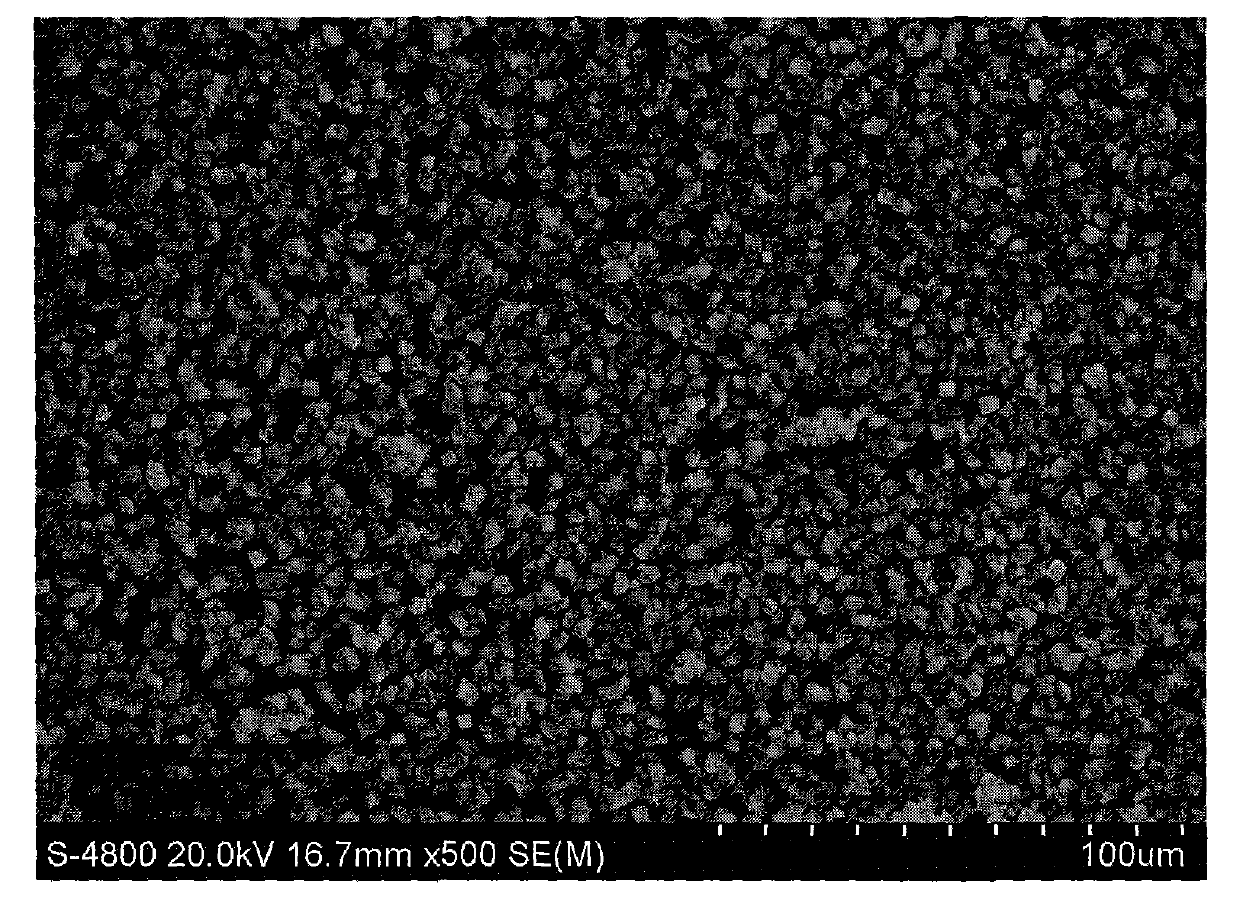

Image

Examples

Embodiment 1

[0023] Weigh AlCl 3 ·6H 2 Dissolve 4.1 g of O2 in 200 mL of distilled water, add 15% ammonia water to AlCl drop by drop 3 solution to a slight excess of ammonia water, filter the resulting precipitate, and wash with distilled water several times until there is no Cl in the washing liquid. - . Add 50mL of distilled water to the washed gel and stir to obtain aluminum hydroxide sol, add aluminum hydroxide sol to 25% hypophosphorous acid, stir while adding, stop adding when the pH of the solution is 3-4, continue stirring to complete the reaction. The obtained solution was filtered, and the filtrate was heated to 85° C., and aluminum phosphite was precipitated. After filtering and drying, 25.2 grams of well-dispersed aluminum phosphite crystals were obtained.

Embodiment 2

[0025] Weigh Al 2 (SO 4 ) 3 18H 2 O3 3.3 g was dissolved in 200 mL of distilled water, and 15% ammonia water was added dropwise to Al 2 SO 4 A slight excess of ammonia water in the solution, filtered to form a precipitate, washed with distilled water several times, until there is no SO in the washing liquid 4 2- . Add 80 mL of distilled water to the washed gel and stir to obtain aluminum hydroxide sol, add aluminum hydroxide sol to 50% hypophosphorous acid, stir while adding, stop adding when the pH of the solution is 4-5, and continue stirring to complete the reaction. The obtained solution was filtered, and the filtrate was heated to 90° C., and aluminum phosphite was precipitated. After filtering and drying, 25.8 grams of well-dispersed aluminum phosphite crystals were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com