Method for preparing phosphorous acid and hydrogen chloride

A technology of hydrogen chloride and phosphorous acid, applied in the direction of phosphorous acid, chlorine/hydrogen chloride, phosphorus oxyacid, etc., can solve the problems of reaction exotherm, gas entrainment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

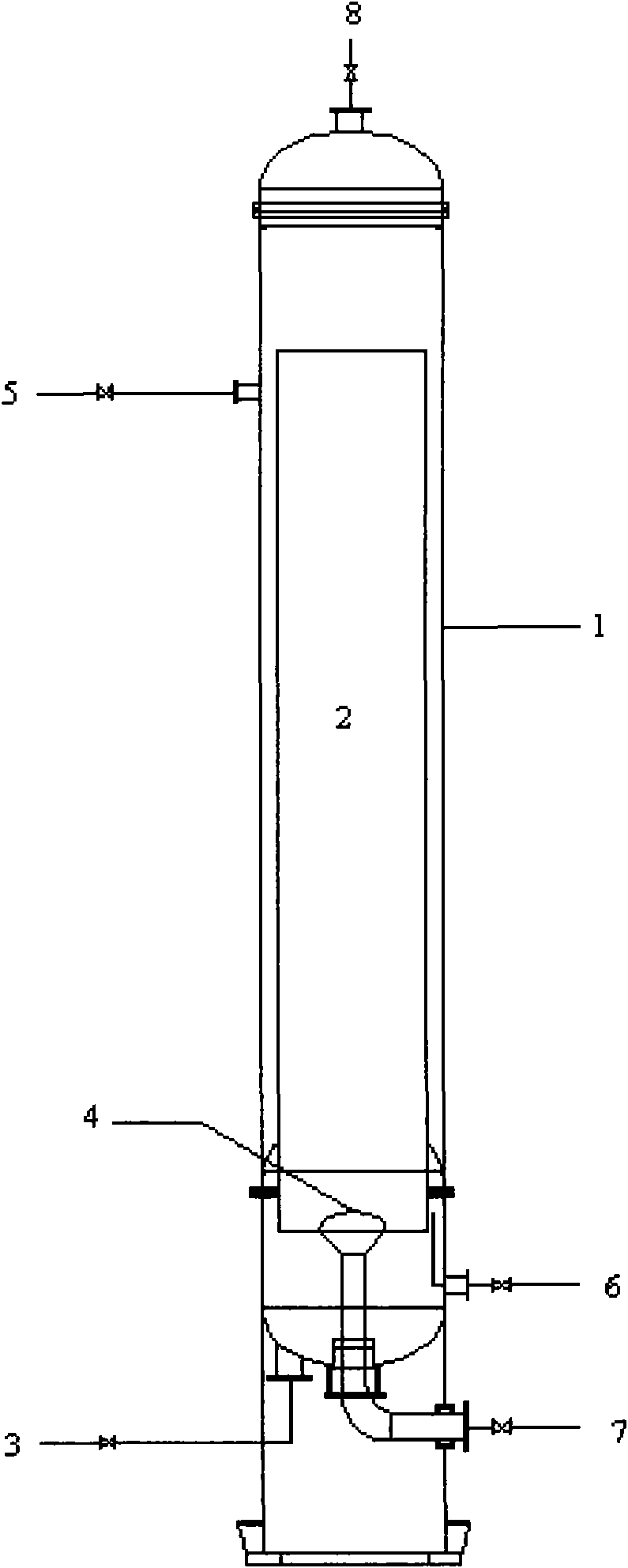

[0047] according to figure 1 Shown is a central airlift internal loop reactor. The volume of the reactor is 5L. First, 2.5L of aqueous solution containing 30% hydrogen chloride is injected into the reactor. 10mol of 98% phosphorus trichloride enters the axial center of the system through the pump at a flow rate of 10mol / h from the bottom 7 of the reactor, and the reactor is controlled. The temperature is 50-80°C, the system pressure is -0.02-0.10MPa, the reaction feed liquid circulates from the outside of the inner sleeve of the reactor, and the hydrogen chloride gas overflows from the top 8 of the reactor and then enters the water system for absorption. After phosphorus trichloride added, continue to insulate for 0.5 hour, final hydrogen chloride yield 99.4% (calculated in phosphorus trichloride), phosphorous acid concentration is 26.51%, phosphorous acid total yield>99% (calculated in phosphorus trichloride ).

Embodiment 2

[0049] Using the same reactor as in Example 1, the volume of the reactor is 5L, first inject 2.0L of 30% hydrogen chloride aqueous solution into the reactor, and heat the aqueous solution to 70-75°C. 98% phosphorus trichloride enters the axial center of the system through a pump at a flow rate of 10 mol / h from the bottom of the reactor, and at the same time, 6.5 mol / h aqueous solution containing 30% hydrogen chloride enters from the top 5 of the reactor through a pump in the form of spraying system, the temperature inside the reactor is controlled at 50-80°C, the system pressure is -0.02-0.15MPa, the reaction feed liquid circulates from the outside of the inner sleeve of the reactor, and flows out continuously at the lower part 6 of the reactor; after the hydrogen chloride gas overflows from the top 8 of the reactor Enter the water system to absorb. The final yield of hydrogen chloride is 99.7% (calculated by phosphorus trichloride), the concentration of phosphorous acid in th...

Embodiment 3

[0051] according to figure 1 Shown is a central airlift internal loop reactor. The volume of the reactor is 5L. Firstly, 2.5L of bisglyphosate condensation mother liquor containing 10% hydrogen chloride is injected into the reactor, and then 10mol of 98% phosphorus trichloride enters the system axial direction through the pump at a flow rate of 2mol / h from the bottom 7 of the reactor. In the center, the feed liquid enters and exits the heat exchanger through 3 and 5 to cool the reaction liquid, and the temperature in the reactor is controlled at 30-50°C, and the system pressure is -0.05-0.1MPa. The reaction feed liquid circulates from the outside of the inner sleeve of the reactor, and the hydrogen chloride gas overflows from the top 8 of the reactor and then enters the water system for absorption. After the reaction temperature begins to drop, turn off the cooling water, adjust the flow rate of phosphorus trichloride to be 10mol / h, and enter the axial center of the system th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com