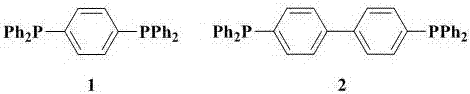

Patents

Literature

47 results about "Phosphorous chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of phosphite antioxidant 168

InactiveCN109593101AReduce consumptionReduce generationGroup 5/15 element organic compoundsFiltrationAcid value

The invention discloses a preparation method of a phosphite antioxidant 168 and belongs to the technical field of antioxidant preparation. The preparation method is as follows: adding excessive 2,4-di-tert-butylphenol and a catalyst into a reaction kettle, adding phosphorus trichloride, and carrying out a synthetic reaction to generate tri(2,4-di-tert-butyl)phosphite; then, adding an anti-hydrolytic agent, then, carrying out filtration, and evaporating the excessive 2,4-di-tert-butylphenol in filtrate to obtain a crude product of tri(2,4-di-tert-butyl)phosphite; and then, crystallizing the crude product, and carrying out centrifuging, washing and drying to obtain a final finished product. By using the preparation method of the phosphite antioxidant 168, the consumption of raw materials isreduced, a reaction solvent is reduced, the reaction time is shortened, and the generation amount of byproducts is low; and a phosphite antioxidant 168 product prepared by using the preparation methodhas the characteristics of high purity (larger than or equal to 99%, low acid value (smaller than or equal to 0.3 mgKOH / g) and good hydrolysis resistance (PH is larger than or equal to 7).

Owner:LIAONING DINGJIDE PETROCHEM

Continuous synthesis technique of hydroxyethylidenediphosphonic acid

ActiveCN102875594AIncrease productivityImprove utilization efficiencyChlorine/hydrogen-chlorideOrganic compound preparationO-Phosphoric AcidEthylic acid

The invention relates to a continuous synthesis technique of hydroxyethylidenediphosphonic acid, which comprises the following steps: 1. mixing raw materials: mixing phosphorus trichloride and acetic acid in a mol ratio of 1:(2.8-3.0) in a mixing kettle; 2. sending the mixture into a tubular reactor: pumping the mixture into the tubular reactor through a diaphragm pump; 3. carrying out esterification reaction while controlling the temperature of the tubular reactor at 70-130 DEG C; 4. separating the reaction mixture in a gas-liquid separator for recycling; 5. carrying out hydrolysis reaction to obtain the hydroxyethylidenediphosphonic acid; and 6. distilling out acetic acid under negative pressure to separate the acetic acid from the product, wherein the acetic acid enters an acetic acid storage tank as a raw material. In the invention, the hydroxyethylidenediphosphonic acid is continuously produced in a semi-closed system, thereby changing the existing intermittent production mode and enhancing the production efficiency; and the invention overcomes the defects of low product yield, too many side reactions and high contents of phosphorous acid and phosphoric acid in other preparation techniques, and implements complete cyclic utilization of acetic acids with different concentrations.

Owner:山东泰和科技股份有限公司

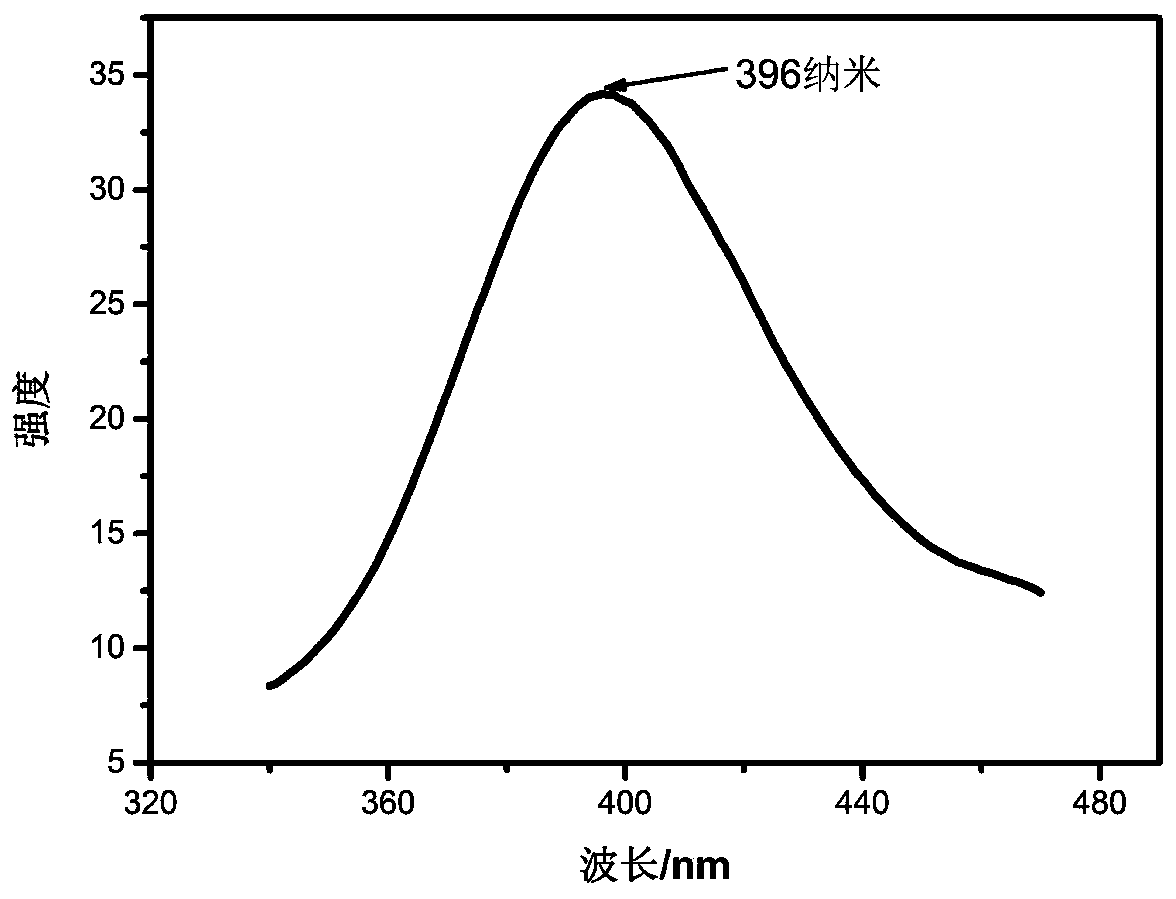

Pure organic phosphorescent material with afterglow luminescence performance and ultra-long service life, method for preparing pure organic phosphorescent material and application thereof

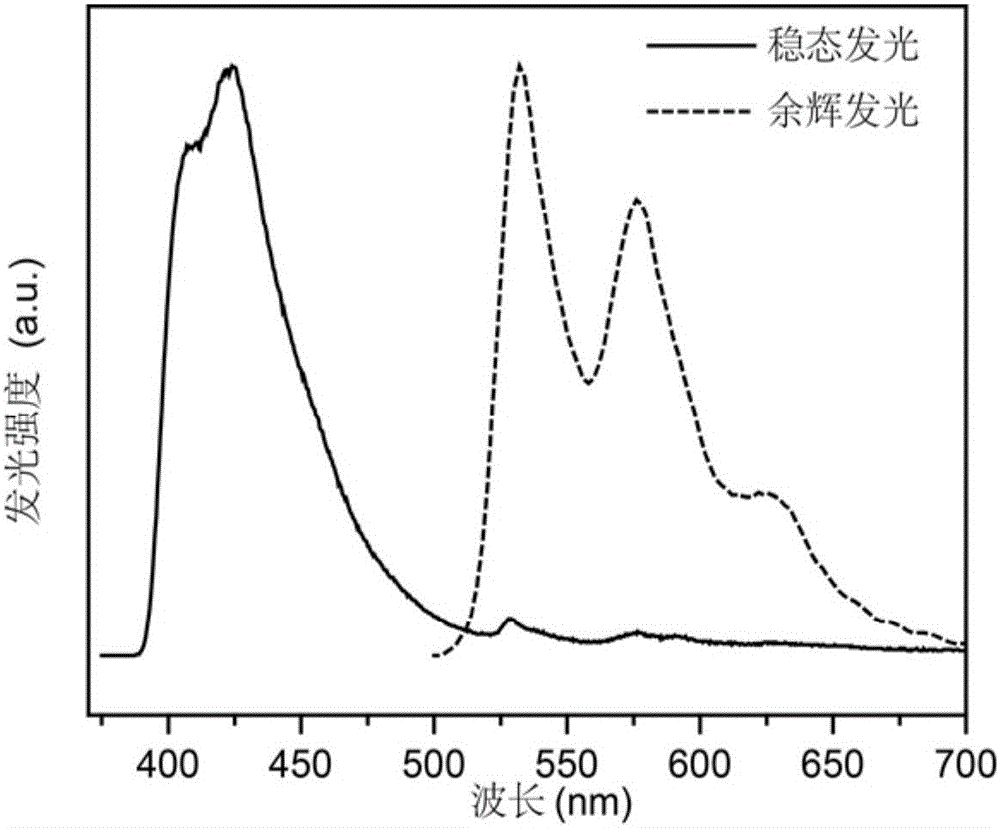

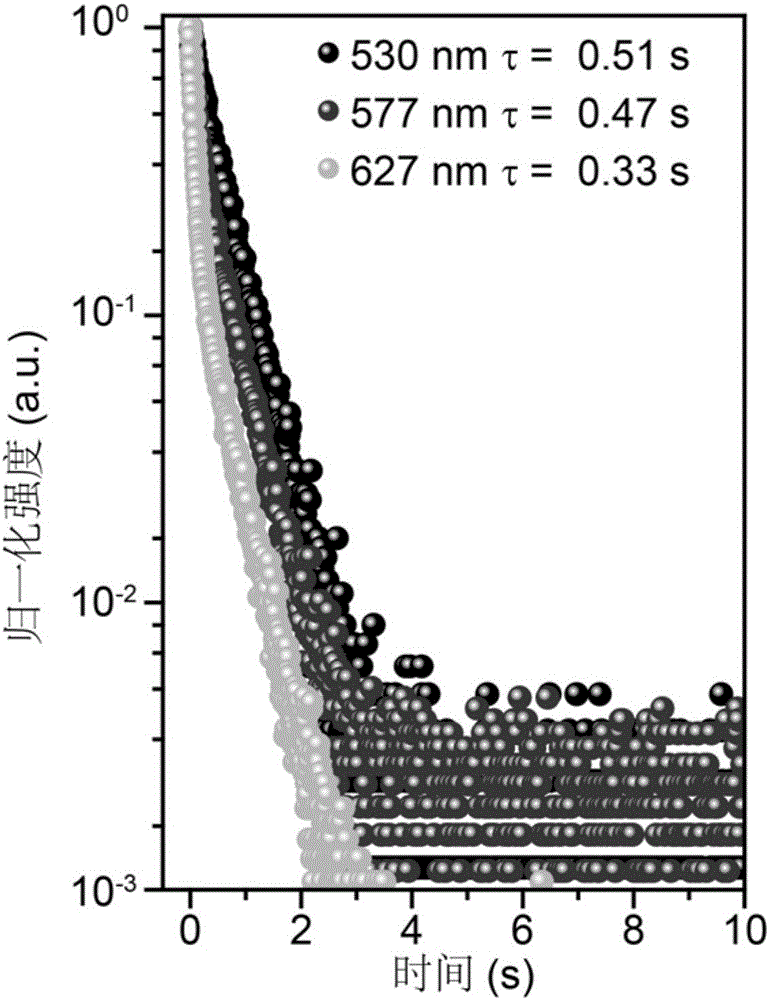

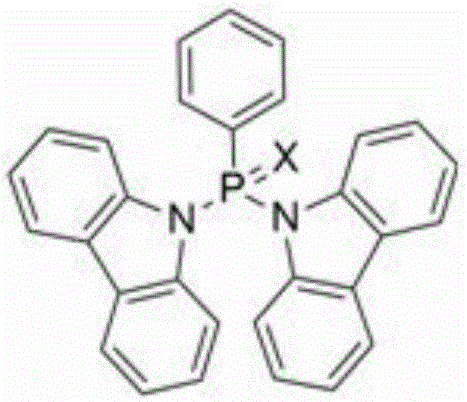

InactiveCN105859778AThe synthesis process is simpleEasy to purifyGroup 5/15 element organic compoundsLuminescent compositionsDichlorophenylphosphineCarbazole

The invention discloses an ultra-long-life pure organic phosphorescent material with afterglow luminescence performance and its preparation method and application. The pure organic phosphorescent material is composed of phenylphosphorus and carbazole structure, which is DNCzPS or DNCzPSe. The carbazole React with phenylphosphorous dichloride at low temperature to obtain the intermediate dicarbazolylphenylphosphorus; then the intermediate can be subjected to sulfidation or selenization reaction to obtain the corresponding products DNCzPS and DNCzPSe. This type of pure organic phosphorescent material has obvious afterglow luminescence properties, which greatly prolongs the luminescence lifetime of organic materials. The prepared RMB anti-counterfeiting and multi-level two-dimensional code anti-prototype device has the characteristics of high resolution and multi-level anti-counterfeiting.

Owner:NANJING UNIV OF POSTS & TELECOMM

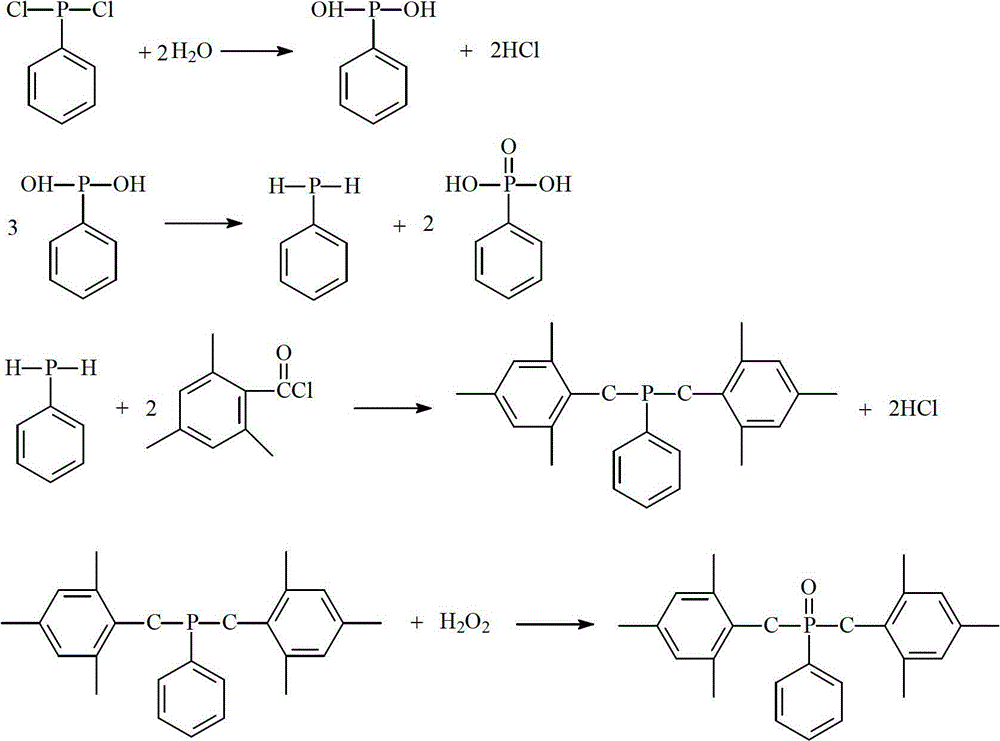

Synthetic method of photoinitiator dual (2,4,6-trimethylbenzene formyl group) phenyl phosphine oxide

ActiveCN102942593ALess prone to fireImprove securityGroup 5/15 element organic compoundsDichlorophenylphosphinePhenacyl

The invention discloses a synthetic method of photoinitiator dual (2, 4, 6-trimethylbenzene formyl group) phenyl phosphine oxide. The synthetic method comprises processes of using dichlorophenylphosphine and 2, 4, 6-trimethylbenzene acyl chloride to serve as raw materials, conducting a classification reaction under protection of nitrogen to generate dual(2, 4, 6-trimethylbenzene formyl group) phenyl phosphine, oxidizing hydrogen peroxide to obtain a target object-dual (2, 4, 6-trimethylbenzene formyl group) phenyl phosphine oxide. Compared with the existing industrial production, the process has the advantages of being safe in operation process, free of needs of dangerous metallic sodium or potassium, free of needs of using inflammable midbody phenyl phosphine, simple in reaction process, safe, easy to control, high in obtained product yield, good in quality and prone to achieve mass production and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Process for synthesis of hydroxy ethidene diphosphoric acid

InactiveCN1827625ALess investmentSimple and safe operationGroup 5/15 element organic compoundsPhosphorous acidDistillation

A method for synthesizing hydroxyl ethylidenediphosphonic acid belongs to synthesis of organo-phosphonic acid and is used in water stabilization. The phsophorus trichloride and acetic acid react at a temperature between 80 DEG C and 150 DEG C with an absolute pressure less than 760 millimeters mercury column, and the byproducts of hydrochloride and a few acetyl chlorides free of condensation are respectively retrieved and reused by combined recovery system of acetic acid and hydrochloric acid. The product of this method is obtained by hydrolyzing the acetylated hydroxyl ethylidenediphosphonic acid at a temperature between 80 DEG C and 150 DEG C with an absolute pressure no more than 760 millimeters mercury column; the collected hydrolysate of acetic acid after the distillation and the condensation is selected as raw material together with the acetic acid solution from the reclamation tower of acetic acid. The autoclave of 1000 litres daily produces products of 2500 kilograms with 60 % of solid content and less than 0.15 % of phosphorous acid; the yield rate of the products is more than 98 % calculated by phsophorus trichloride and is more than 96 % calculated by acetic acid.

Owner:傅明珠

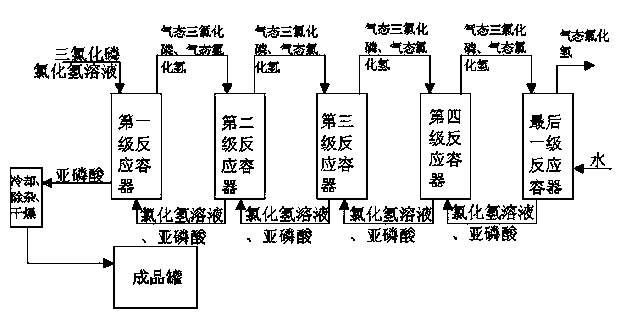

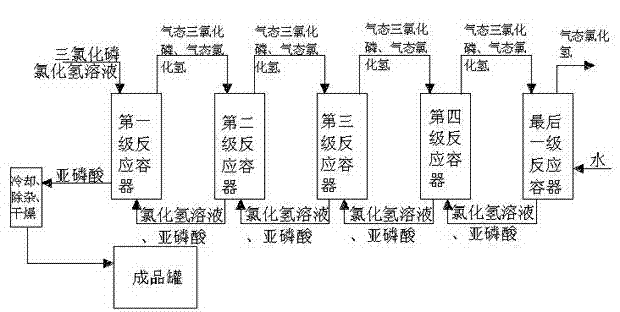

Process for preparing phosphorous acid by hydrolyzing phosphorus trichloride

The invention relates to a process for preparing phosphorous acid by hydrolyzing phosphorus trichloride, and in particular relates to a process for preparing phosphorous acid by hydrolyzing phosphorus trichloride under a mild reaction condition. According to the process, phosphorus trichloride and a hydrogen chloride solution are subjected to hydrolysis reaction in sequence in at least four stages of cascade reaction vessels under the condition that the temperature is 65-85 DEG C and the pressure is not more than 0.1Mpa to generate a phosphorous acid solution and gaseous hydrogen chloride. In the process, the phosphorus trichloride reacts with the water in a hydrochloric acid solution, the phosphorus trichloride is subjected to an exothermic reaction, the temperature of the process can reduce the hydrolysis rate to ensure that the reaction is performed mildly, and at least four stages of cascade bubbling reactions are adopted by the process, so that the utilization ratio of raw materials is improved, the phosphorus trichloride in the reaction vessel of the previous stage can enter the reaction vessel of the next stage, the content of the phosphorus trichloride in the reaction vessel of the previous stage is reduced in other ways, the intensity of the reaction is reduced again, the production safety is improved, and the service life of equipment is prolonged.

Owner:HENAN QINGSHUIYUAN TECH

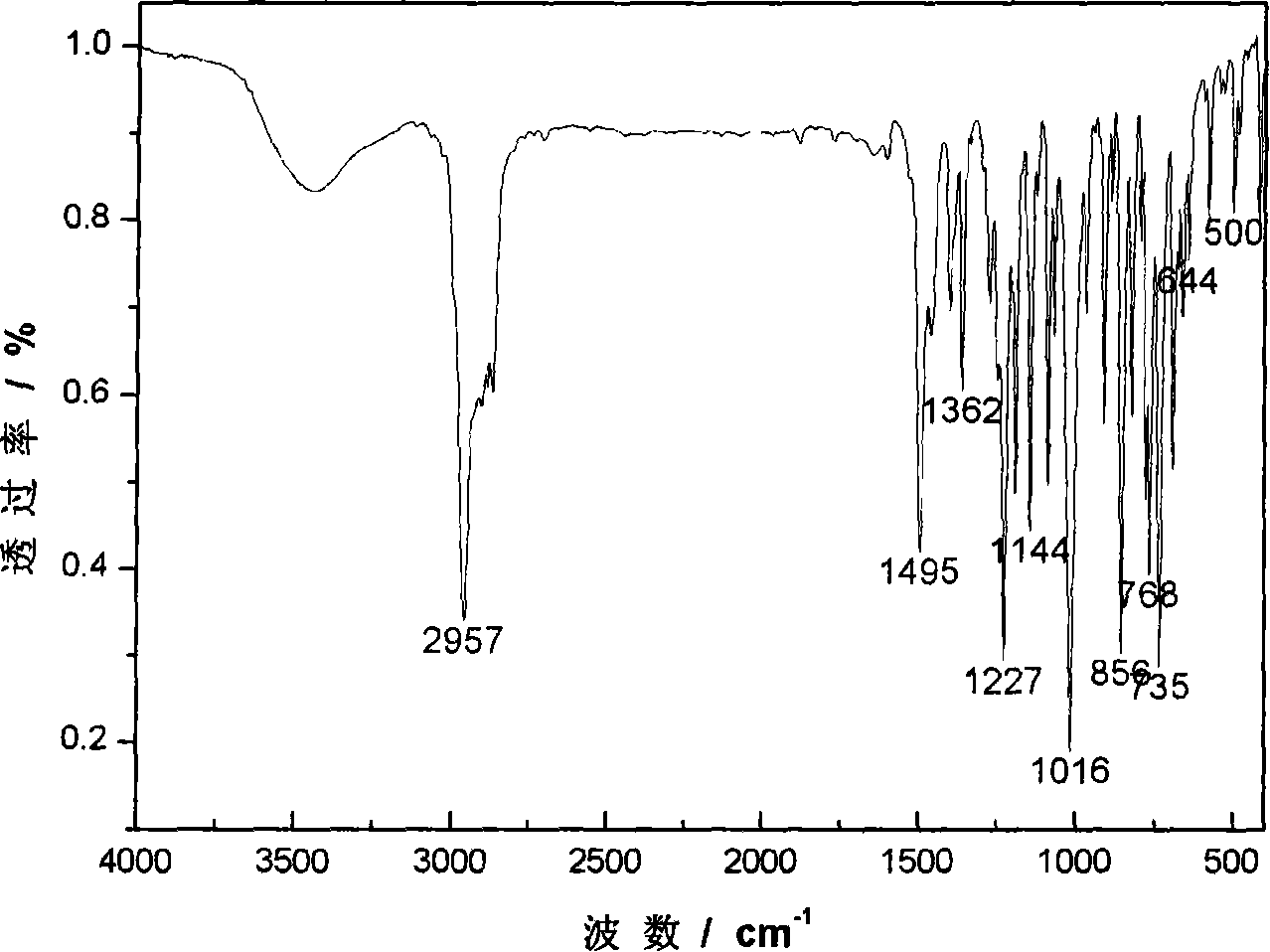

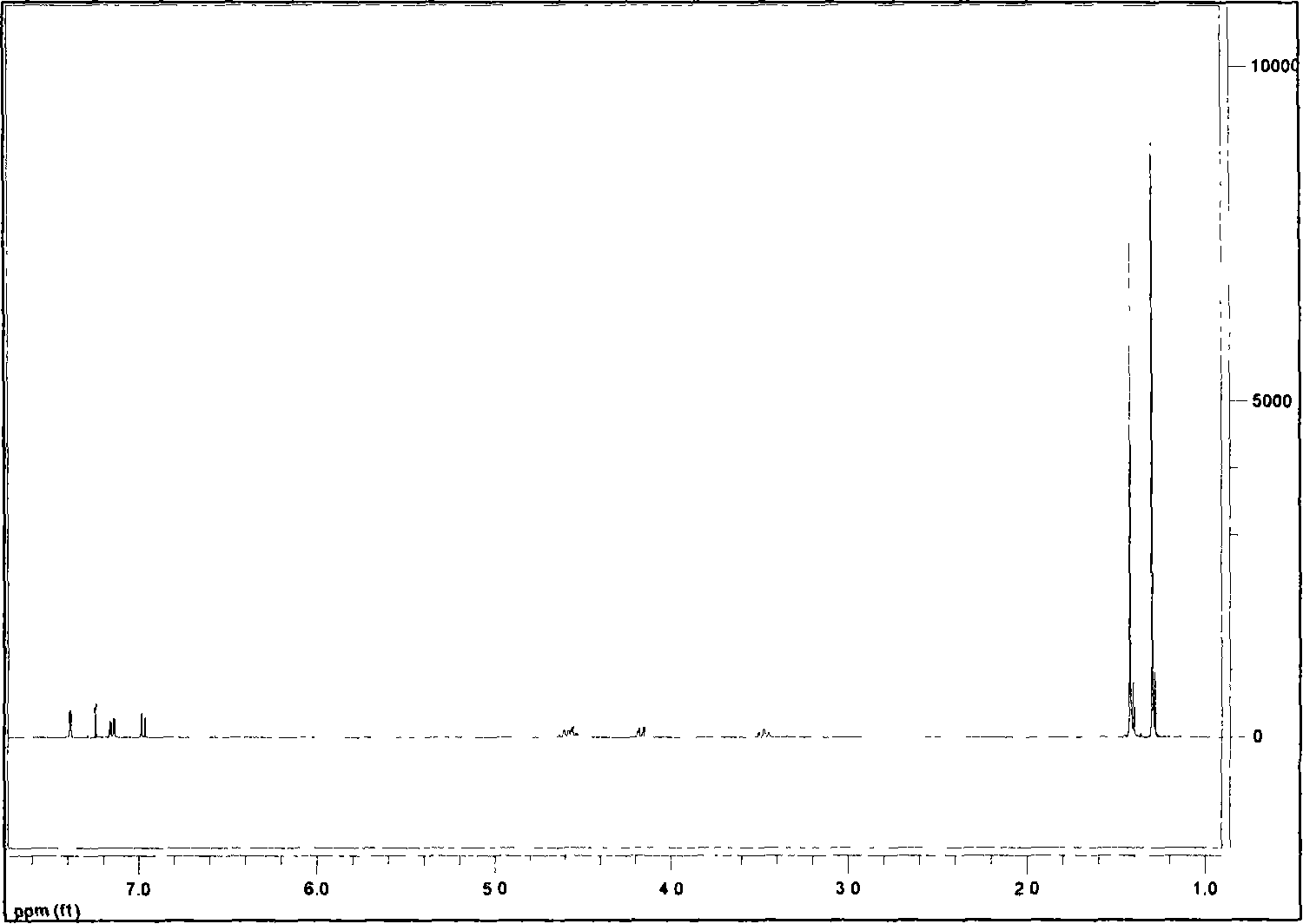

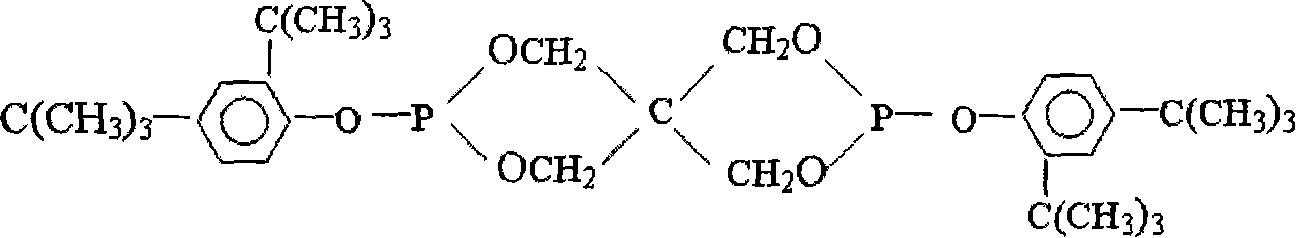

Method for synthesizing bis-(2,4-di-tert-butyl phenyl) pentaerythritol diphosphite

InactiveCN101250200ALow priceImprove responseGroup 5/15 element organic compoundsPentaerythritolSynthesis methods

The invention discloses a synthesis method of bis (2, 4-dibutylbenzene) pentaerythritol diphosphite, which comprises 1, synthesizing dichloropentaerythritol diphosphite: using xylene as solvent, adding pentaerythritol and catalyst, feeding nitrogen gas, adding phosphorous trichloride and absorbing generated hydrogen chloride gas via sodium hydroxide solution, and purifying reaction product to obtain the dichloropentaerythritol diphosphite, 2, synthesizing bis (2, 4-dibutylbenzene) pentaerythritol diphosphite: adding 2, 4-bis-tert-butylphenol into the reaction product of step 1, feeding nitrogen gas and mixing, absorbing generated hydrogen chloride gas via sodium hydroxide solution, and purifying the reaction product to obtain final product. The invention uses 2, 4-bis-tert-butylphenol, pentaerythritol and phosphorous trichloride as main materials, with low cost, easily processed reaction and high reaction yield.

Owner:SOUTH CHINA UNIV OF TECH

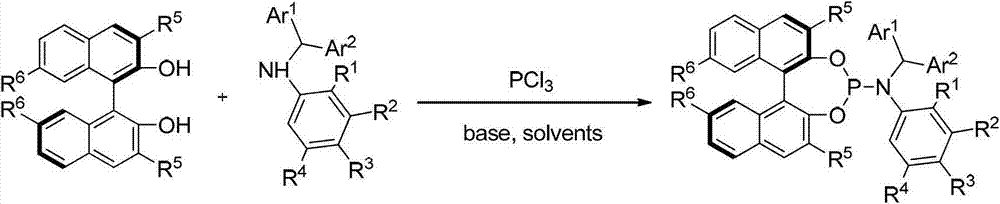

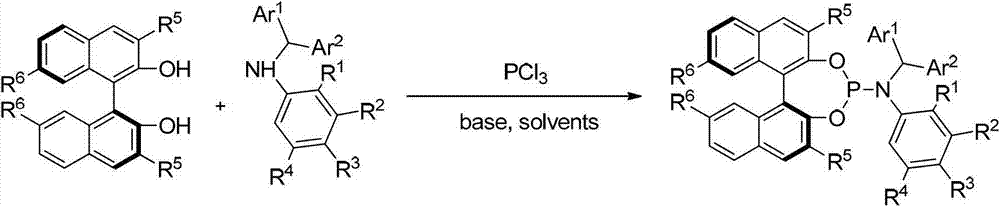

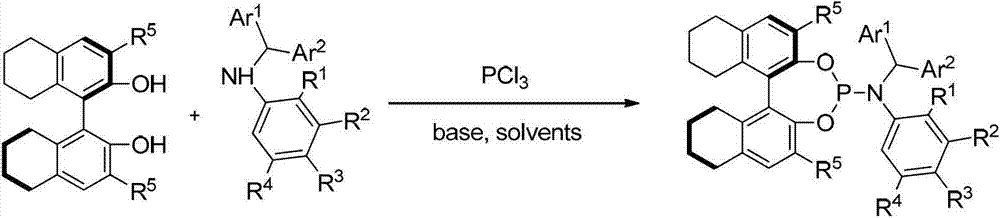

Chirality phosphine nitrogen compound containing N-aryl as well as synthetic method and application thereof

ActiveCN103087106AEfficient synthesisImprove efficiencyGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsIridiumPhosphorus trichloride

The invention provides a chirality phosphine nitrogen compound containing N-aryl as well as a synthetic method and application thereof. The phosphine nitrogen compound is based on axial chirality or comprises a helical chirality skeleton, and is synthetized by taking optically pure axial chirality or helical chirality glycols compound, phosphorus trichloride and aromatic secondary amine as raw material for reaction. The raw material used in the method is easy to obtain, the reaction condition is mild, and the products are easy to separate and purify. The N-aryl phosphine nitrogen compound base on the axial chirality or the helical chirality skeleton synthetized by the method can be effectively applied in substitution reaction of allyl catalyzed by metal iridium, so that the product can be obtained with high enantioselectivity and regioselectivity, and the substrate scope of the product is greatly widened.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

High-performance natural rubber/butadiene styrene rubber composite material

The invention discloses a high-performance natural rubber / styrene-butadiene rubber composite material. The raw materials include: natural rubber, styrene-butadiene rubber, rare-earth isoprene rubber, zinc oxide, stearic acid, sulfur, benzoyl peroxide, and an accelerator CZ, accelerator DM, accelerator NOBS, antioxidant, light calcium carbonate, magnesium oxide, calcium hydroxide, graphene oxide, bamboo charcoal powder, aluminum silicate, diatomaceous earth, sodium montmorillonite, benzyl triphenyl Phosphorous chloride, polyethylene glycol. The high-performance natural rubber / styrene-butadiene rubber composite material proposed by the invention has high strength, good heat resistance and wear resistance, can meet the use requirements of various fields, and has a long service life.

Owner:合肥市再德高分子材料有限公司

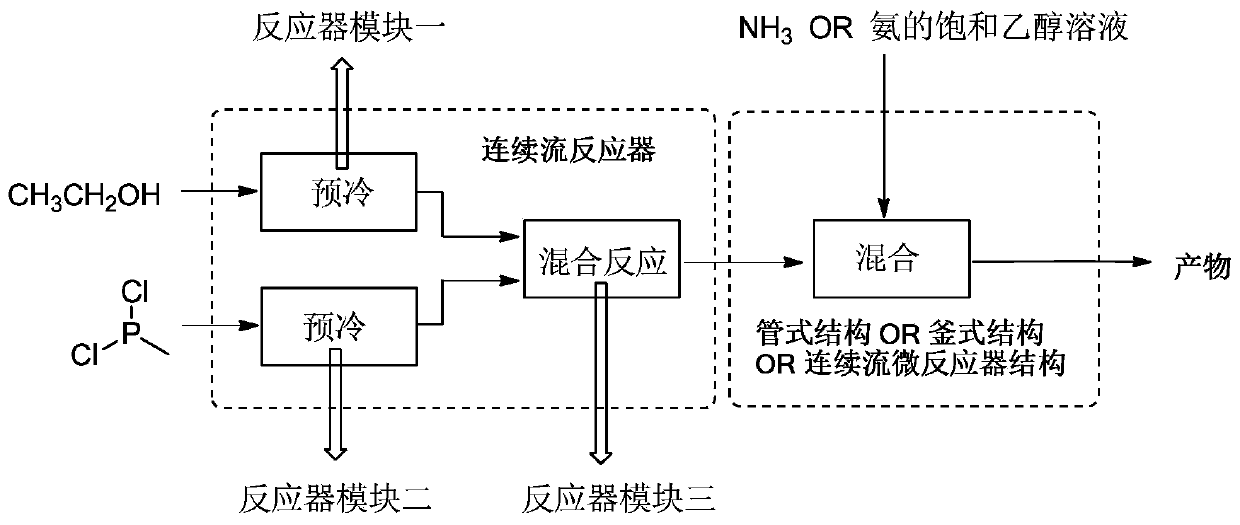

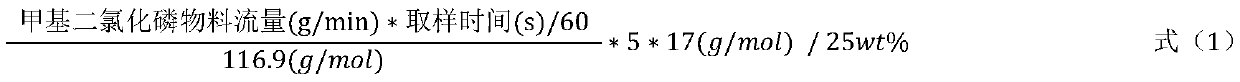

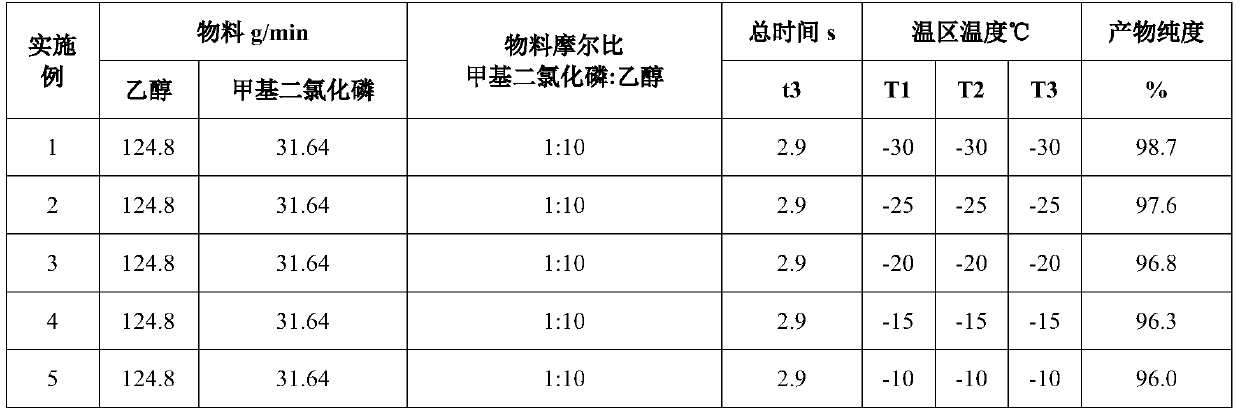

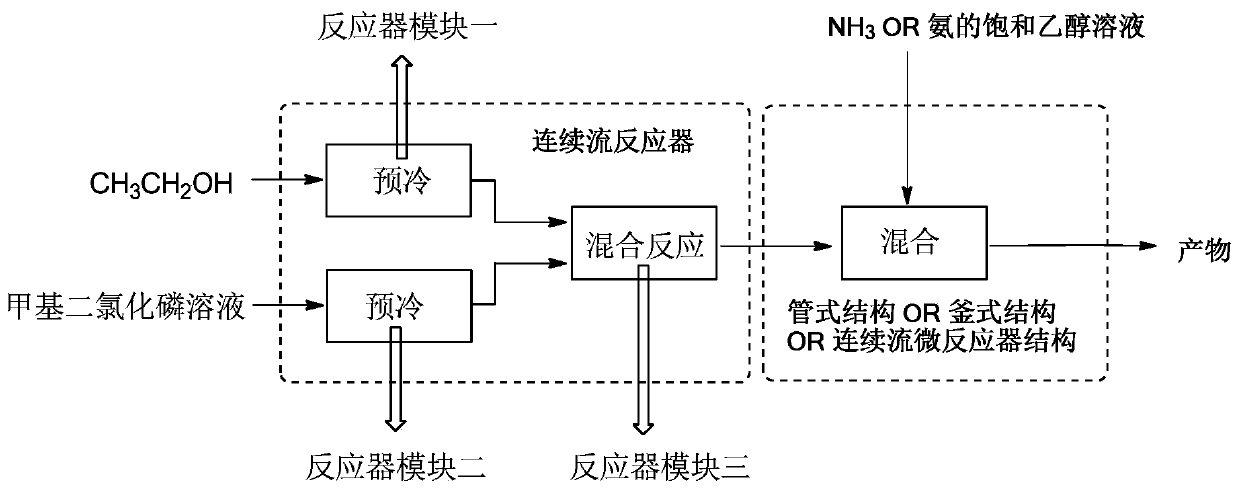

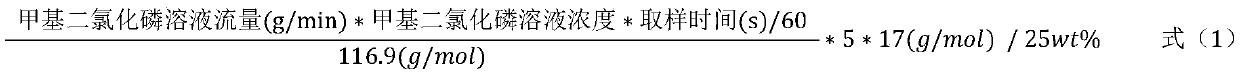

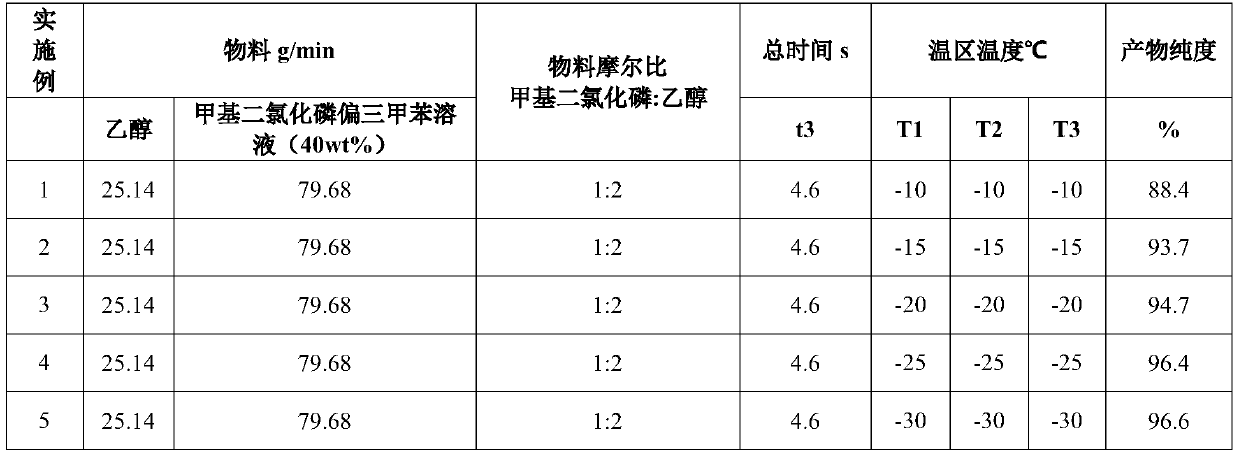

Continuous flow preparation method of diethyl methyl phosphite

PendingCN111004280ASmall liquid holding capacitySafe and efficient productionGroup 5/15 element organic compoundsChemical/physical/physico-chemical microreactorsDiethyl phosphateCombinatorial chemistry

The invention discloses a continuous flow preparation method of diethyl methyl phosphite, which comprises the following steps: continuously adding ethanol and methyl phosphorus dichloride into a feedport of a continuous flow reactor, and continuously obtaining diethyl methyl phosphite at a discharge port of the continuous flow reactor. The method has the advantages of small liquid holdup, safe and efficient production process, solving of the problems of long reaction time and low efficiency in kettle type reaction, high product yield and purity, and simple and efficient process operation.

Owner:LIER CHEM CO LTD +1

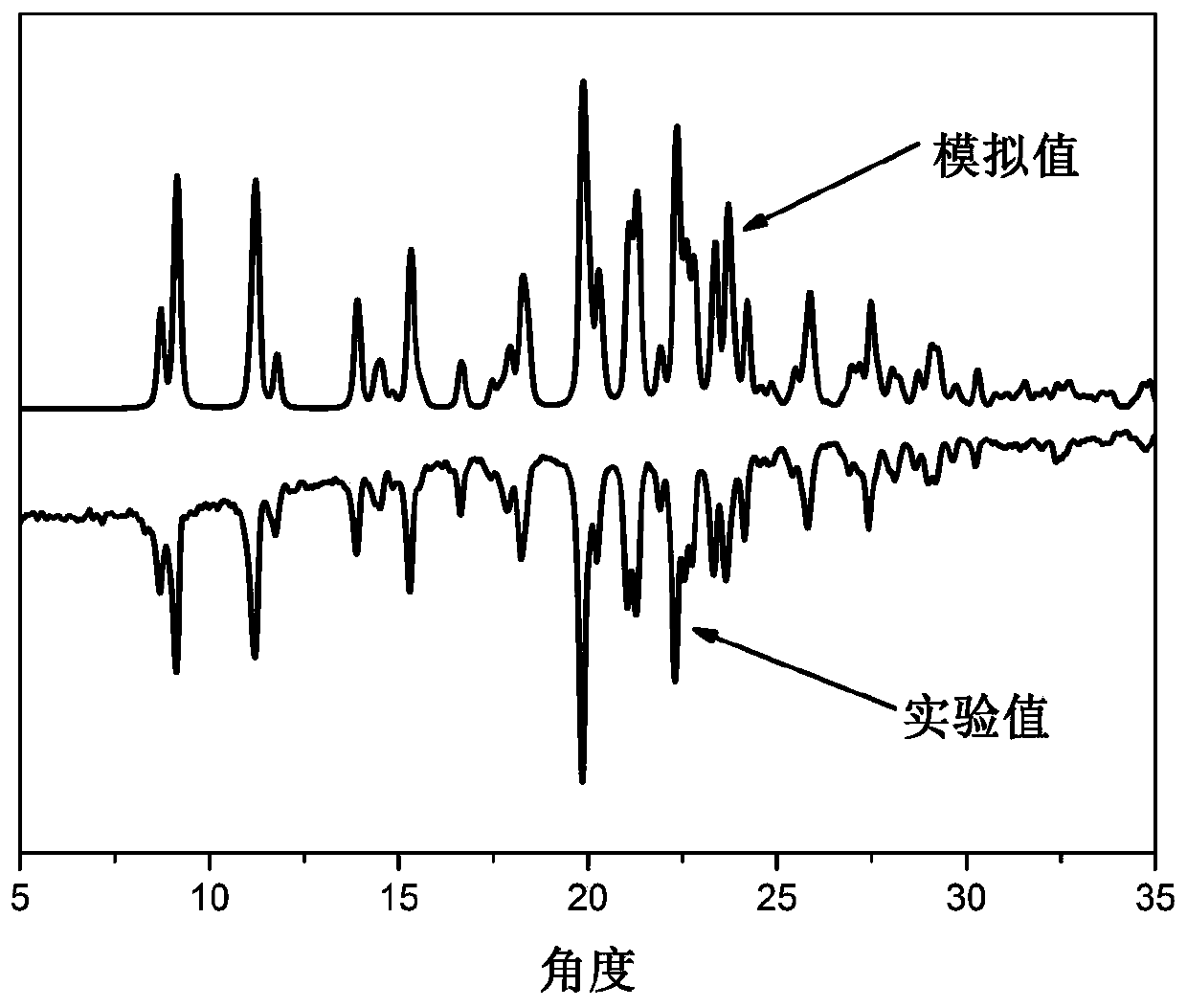

Preparation method of phosphonitrile chloride catalyst, and application of phosphonitrile chloride catalyst in preparation of alkoxy-terminated polysiloxane

ActiveCN110655049AHigh catalytic activityHigh activityNitrogen compoundsPtru catalystTetrachloroethane

The invention discloses a preparation method of a phosphonitrile chloride catalyst, and an application of the phosphonitrile chloride catalyst in the preparation of alkoxy-terminated polysiloxane. Thepreparation method comprises the following steps: purging a reaction device with nitrogen to achieve preheating treatment, opening the reaction device to remove condensate water, and sequentially infiltrating the reaction device with dichloromethane and tetrachloroethane; mixing and uniformly stirring tetrachloroethane and ammonium chloride to prepare a tetrachloroethane solution of ammonium chloride for later use; adding phosphorus pentachloride into the reaction device, slowly raising the temperature to 140-160 DEG C under the protection of nitrogen, then dropwise adding the prepared tetrachloroethane solution of ammonium chloride, carrying out a reflux reaction after the drop-by-drop addition is completed, then raising the temperature to 170-175 DEG C, continuously carrying out the reflux reaction, and cooling the reaction device to room temperature after the reaction is completed; and adding anisole into the reaction solution, and performing stirring under a vacuum condition to achieve uniform mixing in order to obtain target crystals which are the phosphonitrile chloride. The prepared phosphonitrile chloride has a high catalytic activity; and when the phosphonitrile chlorideis used for preparing alkoxy-terminated polysiloxane, a polymer with an excellent storage stability can be effectively prepared.

Owner:新纳奇材料科技江苏有限公司

Continuous flow preparation method of diethyl methyl phosphite

PendingCN111004281ASmall liquid holding capacitySafe and efficient productionGroup 5/15 element organic compoundsChemical/physical/physico-chemical microreactorsDiethyl phosphateCombinatorial chemistry

The invention discloses a continuous flow preparation method of diethyl methyl phosphite, which comprises the following steps: continuously adding ethanol and methyl phosphorus dichloride solution into a feed port of a continuous flow reactor, and continuously obtaining diethyl methyl phosphite at a discharge port of the continuous flow reactor. The method has the advantages of small liquid holdup, safe and efficient production process, solving of the problems of long reaction time and low efficiency in a kettle type reaction, high product yield and purity, and simple and efficient process operation.

Owner:LIER CHEM CO LTD +1

Highly flame-retardant aging-resistant fluorine rubber cable sheath material

ActiveCN109370117AImproves compression set performanceFast vulcanizationRubber insulatorsGroup 5/15 element organic compoundsPolymer sciencePhosphate

The invention discloses a highly flame-retardant aging-resistant fluorine rubber cable sheath material which contains the following raw materials: fluorine rubber, acrylic rubber, ethylene-propylene-diene monomer, stearic acid, magnesium oxide, dicumyl peroxide, triallyl isocyanurate, bisphenol AF, benzyl triphenyl phosphorous chloride, cerium oxide, white carbon black, fibrous sepiolite, basic magnesium sulfate whisker, zinc sulfate, desulfurized fly ash, barium sulfate, ferric oxide, a composite flame retardant and an anti-aging agent. The composite flame retardant is a mixture of caged pentaerythritol phosphate, expansible graphite, zinc borate, tea saponin and a phosphorus nitrogen flame retardant. The highly flame-retardant aging-resistant fluorine rubber cable sheath material provided by the invention is excellent in flame-retardant property, good in heat resistance and aging resistance, and small in permanent deformation.

Owner:ANHUI ZHONGHONG CABLE

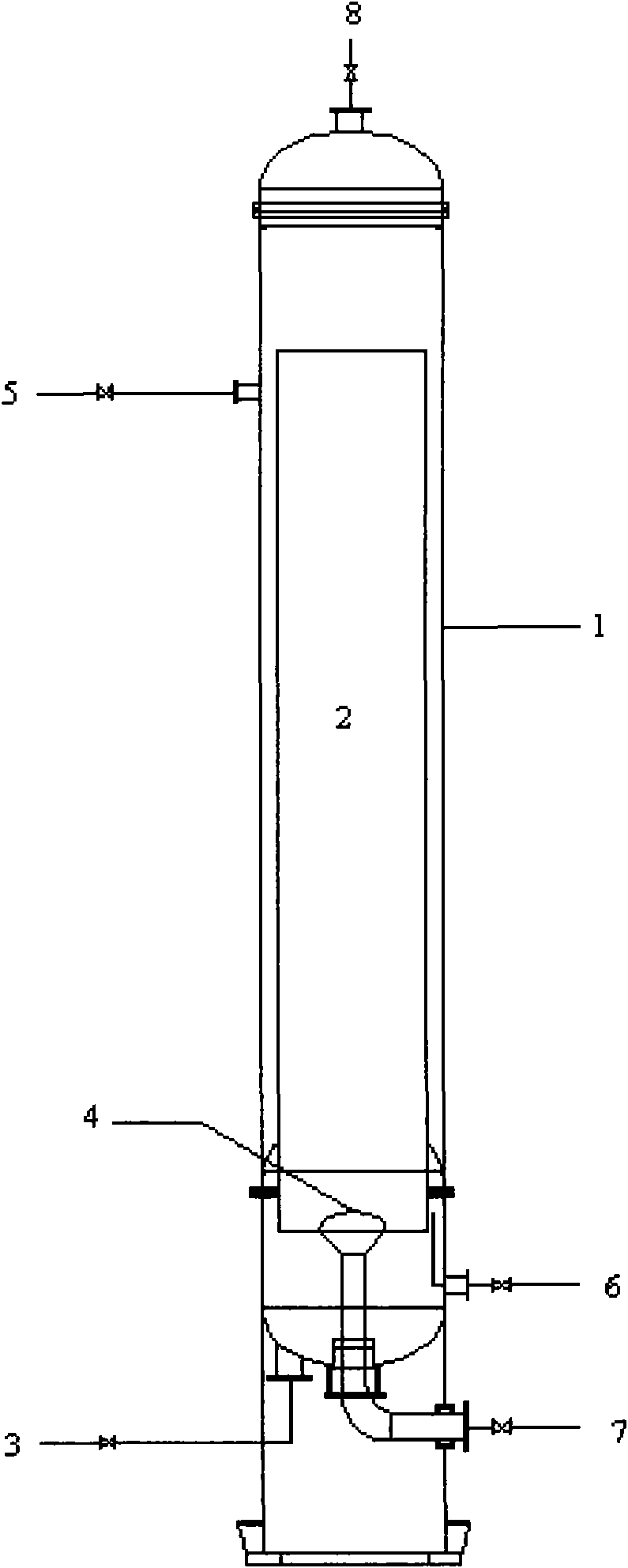

Method for preparing phosphorous acid and hydrogen chloride

The invention provides a method for preparing phosphorous acid and hydrogen chloride in an inner circulation tower by using phosphorus trichloride. The method comprises the following steps of: intermittently or continuously adding the phosphorus trichloride to the inner circulation tower, and then making the phosphorus trichloride react with a water solution in the tower to prepare a phosphorous acid water solution and a hydrogen chloride gas with large scale and high efficiency and yield and smoothly export the hydrogen chloride gas and heat. The method has the advantages of high reaction conversion rate and yield, steady reaction, high safety and the like and can be used for continuous production.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

Water-treated potassium ferrate sterilizing agent and preparation method thereof

InactiveCN104397026AGood anti-scaling effectImprove the bactericidal effectBiocideFungicidesEscherichia coliPhosphorous chloride

The application discloses a water-treated potassium ferrate sterilizing agent and a preparation method thereof. The water-treated potassium ferrate sterilizing agent is prepared by weighing and uniformly mixing potassium permanganate, concentrated hydrochloric acid, potassium hydroxide, iron nitrate nonahydrate, manganese dioxide, potassium chlorate, a polymerization inhibitor, triethylene tetramine, formaldehyde, phosphorus trichloride, a dispersing agent, sodium hydroxide, phosphorous acid, glycine and polyaspartic acid according to parts by weight. The melting point of the product is 205 DEG C; the scale inhibition rate is 96.9-98.9%; the sterilizing rate to escherichia coli, staphylococcus aureus, candida albicans, neisseria gonorrhoeae, penicillium, aspergillus, saprophytic bacteria and salmonella is 99-100%; when the water-treated potassium ferrate sterilizing agent is placed at 50-60 DEG C for a month, the sterilizing rate is 97.5-99.5%; when the water-treated potassium ferrate sterilizing agent is placed at 40-50 DEG C for half a year, the sterilizing rate is 96-99%; when the water-treated potassium ferrate sterilizing agent is placed at the room temperature for 1-2 years, the sterilizing rate is 95-97%.

Owner:SUZHOU YOUJUN ENVIRONMENTAL SCI & TECH

Bio-based macromolecular flame retardant as well as preparation method and application thereof

ActiveCN111875648AImprove thermal stabilityLittle impact on mechanical propertiesEsterified saccharide compoundsSugar derivativesEpoxyPhosphorous chloride

The invention provides a bio-based macromolecular flame retardant as well as a preparation method and application thereof. The preparation method comprises the following steps of (1) preparing tanninphosphonitrile chloride ester by a grafting method: adding 10-30g of tannin and 5-20mL of triethylamine into 50-200ml of acetonitrile to obtain a mixture, heating the mixture to 30-45 DEG C, dropwiseadding 10-40ml of phosphonitrilic chloride trimer into the mixture, and then heating the mixture at 50 DEG C for 1-3h to obtain a mixed solution containing tannin phosphonitrile chloride ester; and (2) enabling the tannin phosphonitrile chloride to react with metaphenylenediamine: adding 10-30g of the metaphenylenediamine into the mixed solution obtained in the step (1), performing heating to 60-80 DEG C, performing reacting for 2-4 hours, performing filtering, performing cleaning with the acetonitrile, and performing drying to obtain the bio-based macromolecular flame retardant. The flame retardant provided by the invention has good thermal stability and flame retardance, and solves the problem of poor thermal stability of the tannin, and besides, as a flame retardant curing agent, the reticular macromolecular structure has less influence on the mechanical properties of epoxy resins.

Owner:江苏艾泰柯新材料科技有限公司

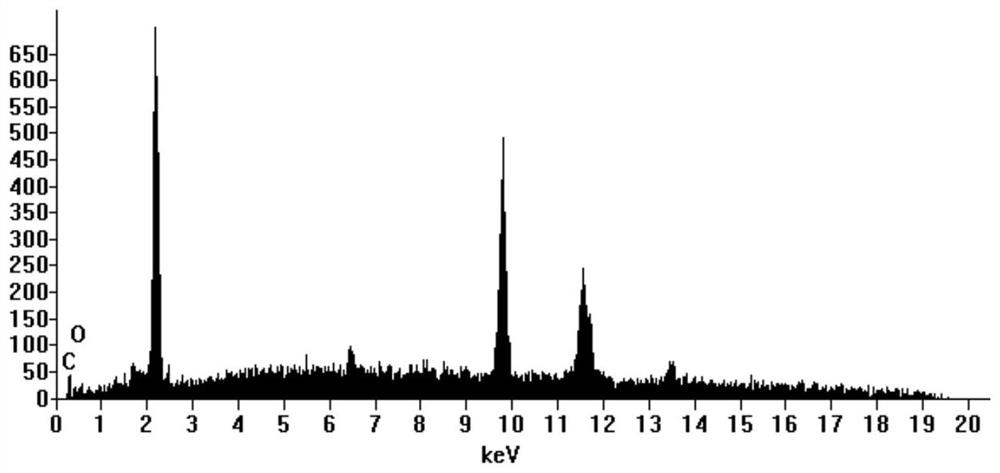

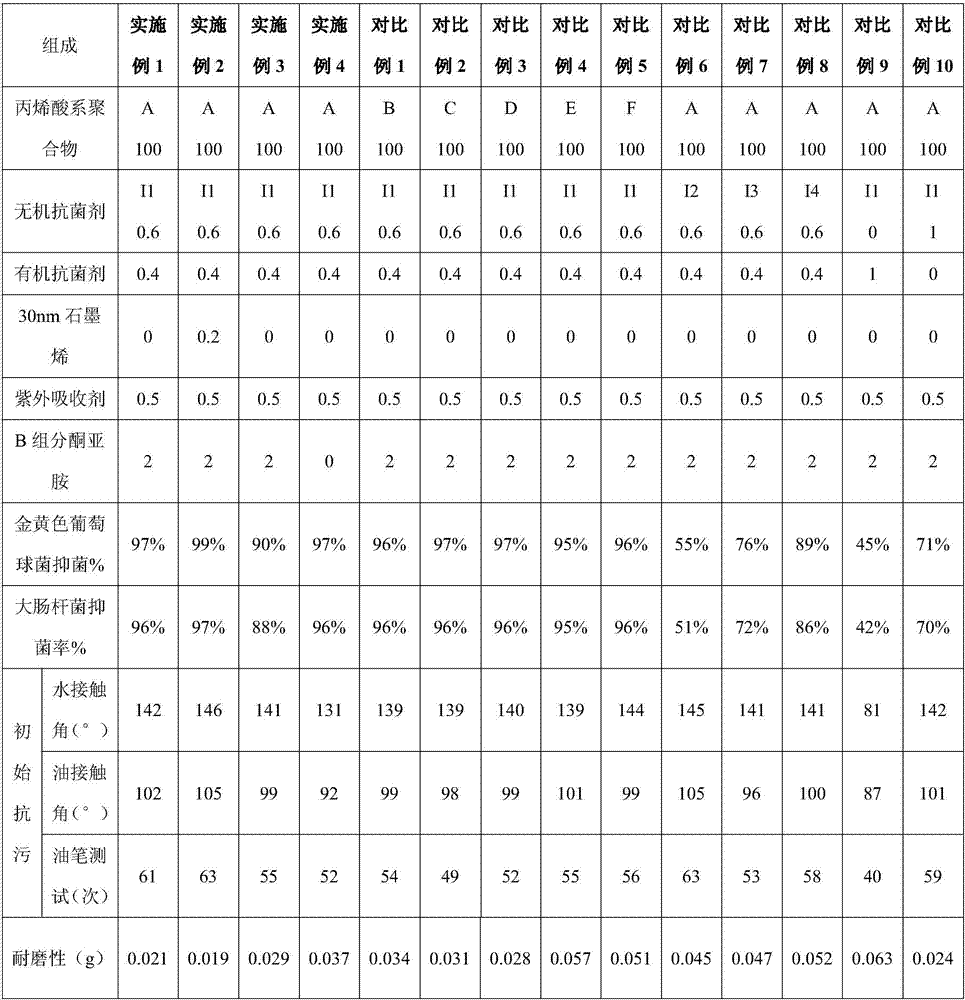

Graphene based anti-bacterial and wear-resistant double-component coating as well as preparation method, application and use method thereof

InactiveCN107955482AImprove stain resistanceImprove adhesionAntifouling/underwater paintsPaints with biocidesWear resistantAcrylic polymer

The invention provides a graphene based anti-bacterial and wear-resistant double-component coating. According to the specific scheme, the coating contains a component A and a component B, wherein thecomponent A is prepared through steps as follows: an acrylic polymer aqueous dispersion is taken as a substrate, and graphene supported titanium dioxide serving as an anti-bacterial agent, 2-acryloyloxyethyl tributylphosphonium chloride-trimethoxy vinyl silicon oligomer containing fluoroalkyl as well as other auxiliaries are added; the component B is ketimine; graphene supported titanium dioxide is prepared from 1-10 mu m graphene oxide, 10-15 nm titanium dioxide particles and a silane coupling agent through uniform dispersion in water, reduction and drying. Acrylic polymers are subjected to monomer selection, glass beads are introduced, so that wear resistance is improved, a final product has excellent anti-bacterial performance, wear resistance, stain resistance and adhesive force, and the coating with the excellent anti-bacterial performance and wear resistance is suitable for being used in hospitals and schools with large volume of people.

Owner:马晓洁

Preparation method of metharcylic acid, 2-isocyanatoethyl ester

InactiveCN103113261AReduce generationNo pollution in the processPreparation from carbamatesPtru catalystOrganosolv

The invention discloses a preparation method of a binder, namely, metharcylic acid, 2-isocyanatoethyl ester. The preparation method comprises the following steps of: (1) adding ethanol amine and an organic solvent into a reactor with a stirrer, a thermometer and a condensing tube, slowly dropping methylclhlorofonmate at 50-60 DEG C, and after dropping, continuously reacting for 2-4 hours; (2) adding a catalyst into the reactor, slowly dropping methylacryloyl at 80-100 DEG C, and after dropping, continuously reacting for 3-8 hours; (3) adding phosphorus pentachloride into the reactor to react at 50-100 DEG C and reacting for 48-72 hours; and (4) carrying out solid-liquid separation on the reactant obtained in step (3), depressurizing and distilling the filtrate, and collecting the fraction so as to obtain the metharcylic acid, 2-isocyanatoethyl ester. By utilizing the method, the generation of toxic phosgene in the production process is greatly reduced, so that potential safety hazard is reduced; the total yield is over 85%; and the whole process is generally free of environmental pollution.

Owner:ZHANGJIAGANG HICOMER CHEM CO LTD

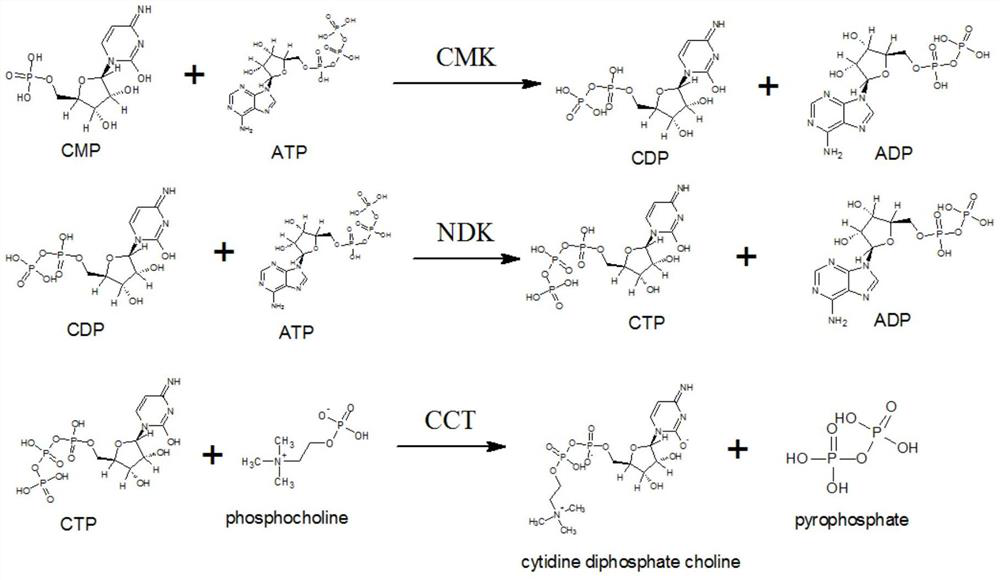

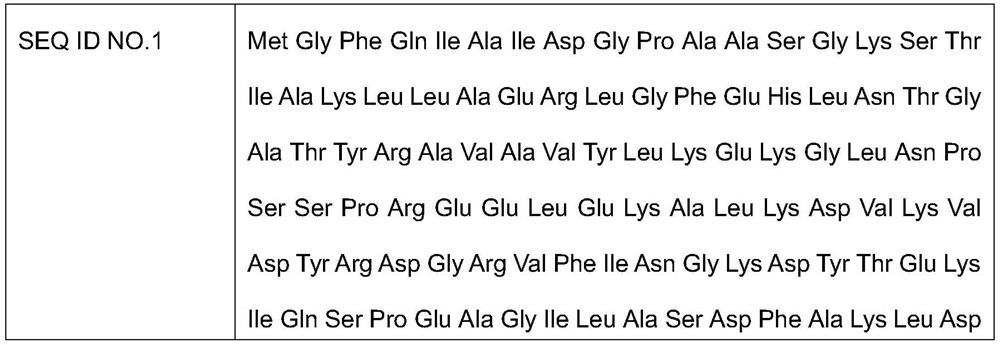

Synthetic method of citicoline sodium

InactiveCN111808899AAvoid disadvantages that need to be dealt withEnzyme source stabilityTransferasesFermentationCholine PhosphateCiticoline sodium

The invention discloses a synthetic method of citicoline sodium. The synthetic method comprises the following steps: adding 5'-cytidylic acid, calcium phosphorylcholine chloride, ATP, an aqueous magnesium chloride solution and a Tris-HCl buffer solution into a reaction vessel, and carrying out uniform mixing; then, adjusting a pH value to 6.0-8.0, adding CMP phosphokinase, nucleoside diphosphate kinase and choline phosphate-cytidyltransferase, and carrying out a stirring reaction for 4-10 hours at a temperature of 25-50 DEG C; and conducting high-speed centrifugation, and taking a supernatantto obtain citicoline sodium. Compared with the traditional citicoline sodium synthesis process, the synthetic method provided by the invention is environment-friendly in a synthesis route, stable in yield and is beneficial for reducing energy consumption and protecting the environment, so the synthetic method is suitable for large-scale industrial production.

Owner:ENZYMASTER NINGBO BIO ENG CO LTD

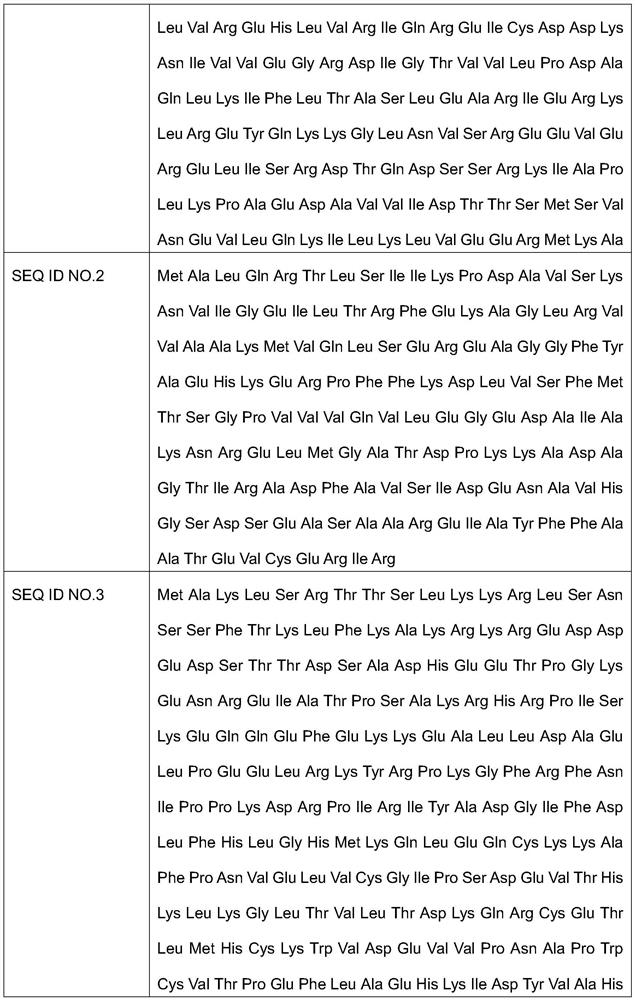

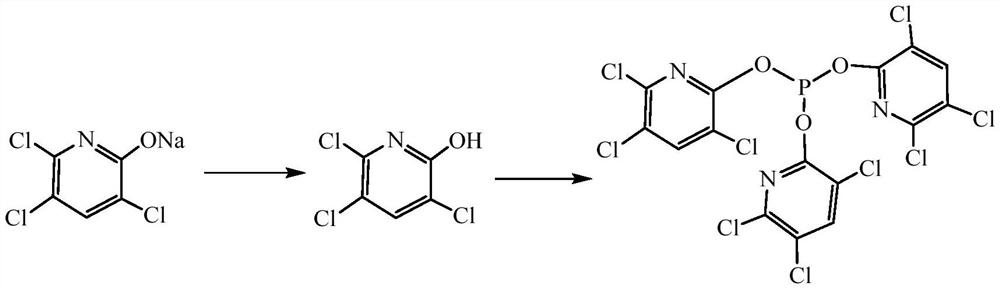

Synthesis method of tri(3,5,6-trichloropyridinyl)phosphite

ActiveCN112110956AReduce generationHigh purityGroup 5/15 element organic compoundsChemical recyclingPtru catalystOrganic base

The invention relates to a method for synthesizing tri(3,5,6-trichloropyridinyl)phosphite, which comprises the following steps of: synthesizing 2-hydroxy-3,5,6-trichloropyridine under an acidic condition by using sodium 3,5,6-trichloropyridin-2-olate as a raw material, conducting drying and dehydrating, and controlling the reaction temperature of the product, a catalyst and phosphorus trichlorideto be 70-93 DEG C on the premise of micro-negative pressure to obtain the tri(3,5,6-trichloropyridinyl)phosphite. The specific synthetic route is shown in the specification. Micro negative pressure and the catalyst are introduced in the reaction process, so that the generation of diester and other side reactions is reduced, the reaction speed is increased, the reaction time is shortened, the purity and yield of a target product are improved, meanwhile, an organic alkali or organic ammonia acid-binding agent is not used, the production cost is reduced, and three wastes are reduced.

Owner:赵东源 +1

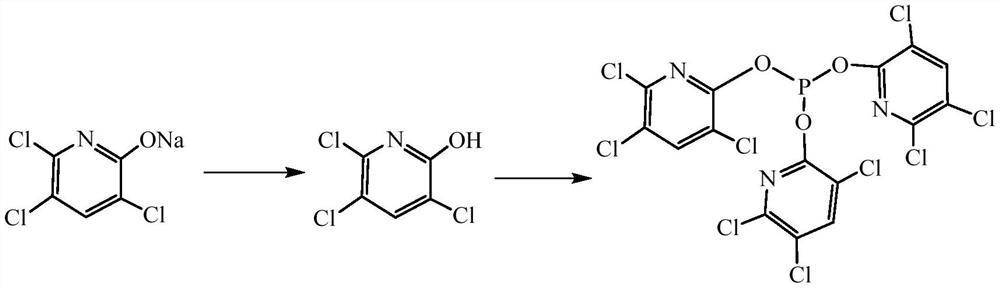

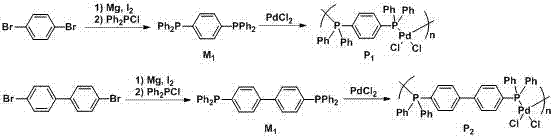

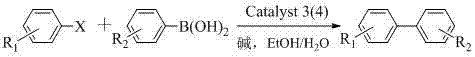

Self-loading diphosphine-palladium catalyst and preparation method and application thereof

ActiveCN107090008AImprove thermal stabilitySolve the problem of recycling and reuseOrganic compound preparationGroup 8/9/10/18 element organic compoundsGrignard reagentPalladium catalyst

The invention relates to a self-loading diphosphine-palladium catalyst and a preparation method and application thereof. According to the preparation method, diphenyl phosphorous chloride is used as a raw material, and after the chloride is replaced by a Grignard reagent, the raw material is coordinated with palladium bichloride to form the catalyst. The catalyst has the advantages that (1), the catalyst has higher thermal stability; (2), the catalyst can be used for catalyzing a Suzuki-Miyaura coupling reaction under a mild condition and acquires an excellent catalyzing effect; (3), after a catalyzing reaction is completed, the catalyst can be reused through simple centrifugal filtration, and the difficult problem of recycling and reutilization of a homogeneous catalyst is solved. The preparation method is simple and feasible in reaction routes, and the catalyst can be used as an efficient catalyst to be applied to the synthesis of medicines, spices, pesticides and functional materials.

Owner:HUBEI UNIV

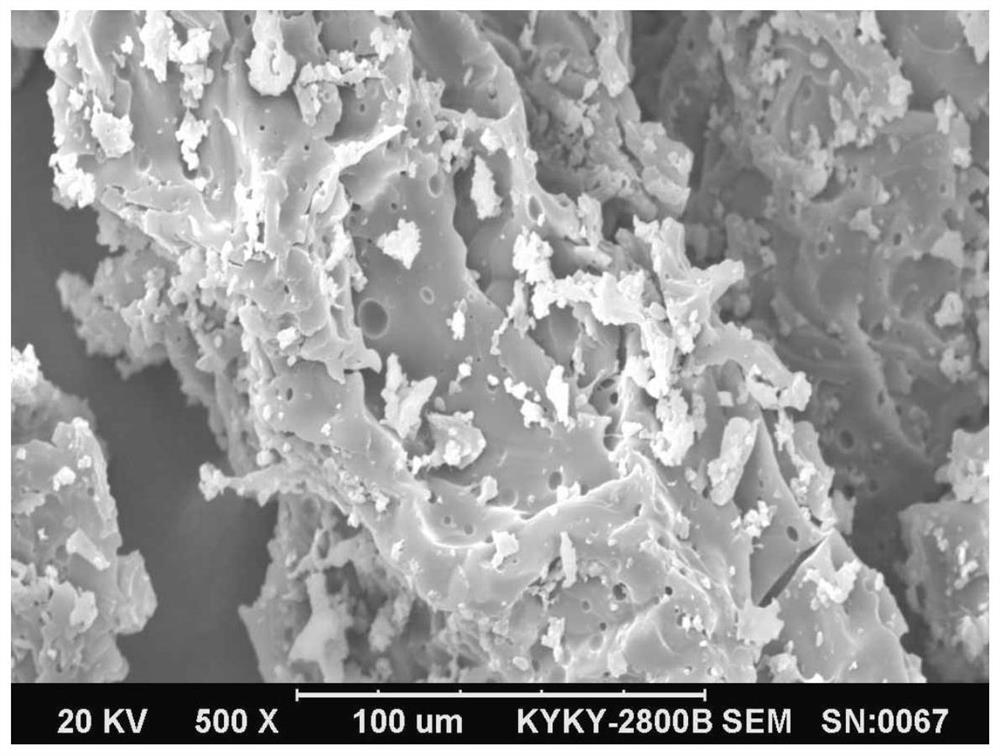

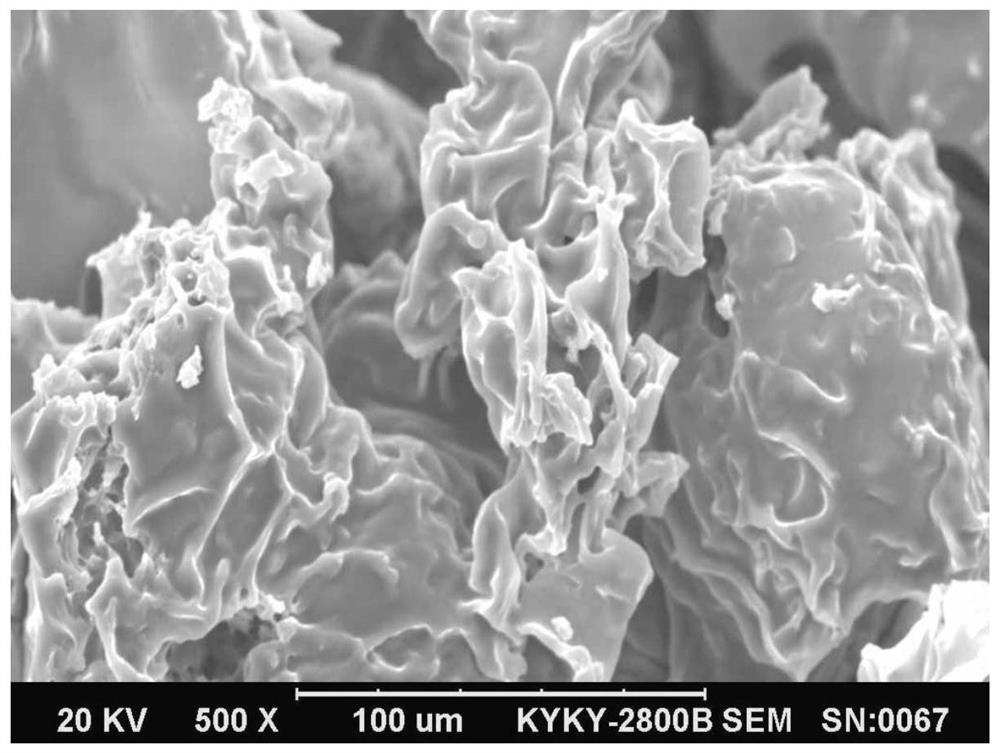

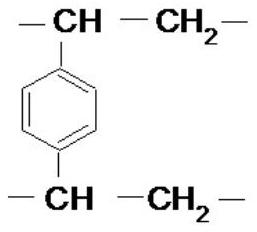

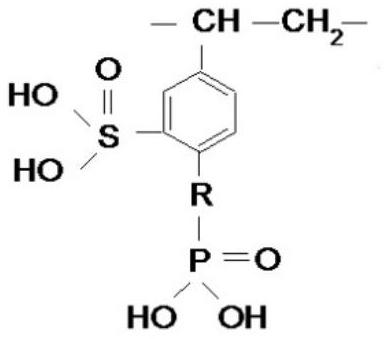

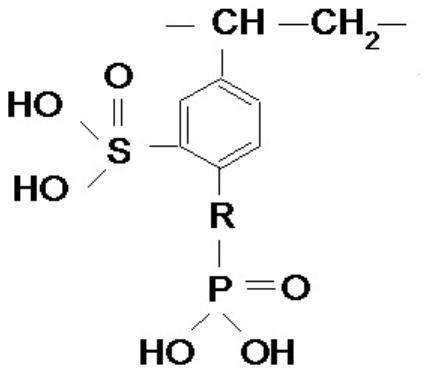

Iron ion adsorption resin, preparation method and application thereof in removal of iron ions in solution

PendingCN111686700AHigh adsorption selectivityGood removal effectIon-exchange process apparatusOther chemical processesO-Phosphoric AcidPhosphorous chloride

The invention discloses iron ion adsorption resin, a preparation method thereof and an application of the iron ion adsorption resin in removal of iron ions in a solution. The preparation method comprises the following steps: preparing resin with a styrene skeleton by using a suspension polymerization method, and then preparing sulfonic acid resin with different phosphoric acid structures through the processes of chlorination, phosphorylation and sulfonation. The sulfonic acid resin prepared in the invention has strong binding capacity to iron, and has the advantages of high iron ion removal precision, complete analysis and the like, and can be used in a complex environment.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

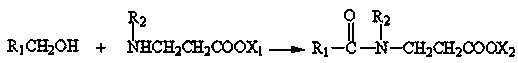

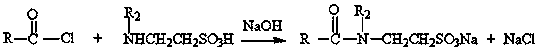

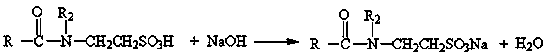

Synthesis method of surfactant

PendingCN111004142AReduce selectionEmission reductionOrganic compound preparationTransportation and packagingActive agentWater chlorination

The invention discloses a synthetic method of a surfactant. The synthetic method comprises the following steps: (1) adding fatty alcohol, a catalyst and amino acid ester into a reactor; (2) closing the reactor, and slowly heating to 200-300 DEG C; (3) carrying out a heat preservation reaction for 2-10 hours; (4) degassing; and (5) treating to obtain a finished product. According to the invention,fatty alcohol is directly selected as an acylation reagent to perform a reaction, so that the step of fatty acid acylation is omitted, the selection of dangerous substance acylation reagents such as phosgene, thionyl chloride, trichloromethyl chloroformate, phosphorus trichloride, phosphorus pentachloride and phosphorus oxychloride is reduced, the emission of byproducts such as phosphorous acid and the like is reduced, and the method is feasible from the aspect of reaction mechanism; and fatty alcohol and amino acid ester are selected to be subjected to a direct reaction, so that impurities such as chlorine ions and the like are not introduced in the process, and the target product is obtained through the direct reaction so as to eliminate the steps of acidification, salification or waterwashing desalination and reduce the use and discharge of salt-containing wastewater or an organic solvent.

Owner:ZHANGJIAGANG GREAT CHEM

Continuous synthesis technique of hydroxyethylidenediphosphonic acid

ActiveCN102875594BIncrease productivityImprove utilization efficiencyChlorine/hydrogen-chlorideOrganic compound preparationO-Phosphoric AcidEthylic acid

The invention relates to a continuous synthesis technique of hydroxyethylidenediphosphonic acid, which comprises the following steps: 1. mixing raw materials: mixing phosphorus trichloride and acetic acid in a mol ratio of 1:(2.8-3.0) in a mixing kettle; 2. sending the mixture into a tubular reactor: pumping the mixture into the tubular reactor through a diaphragm pump; 3. carrying out esterification reaction while controlling the temperature of the tubular reactor at 70-130 DEG C; 4. separating the reaction mixture in a gas-liquid separator for recycling; 5. carrying out hydrolysis reaction to obtain the hydroxyethylidenediphosphonic acid; and 6. distilling out acetic acid under negative pressure to separate the acetic acid from the product, wherein the acetic acid enters an acetic acid storage tank as a raw material. In the invention, the hydroxyethylidenediphosphonic acid is continuously produced in a semi-closed system, thereby changing the existing intermittent production mode and enhancing the production efficiency; and the invention overcomes the defects of low product yield, too many side reactions and high contents of phosphorous acid and phosphoric acid in other preparation techniques, and implements complete cyclic utilization of acetic acids with different concentrations.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

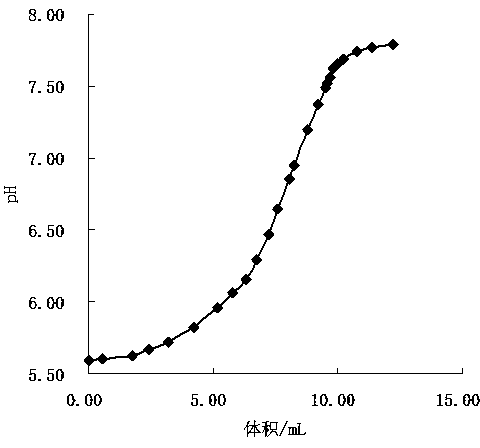

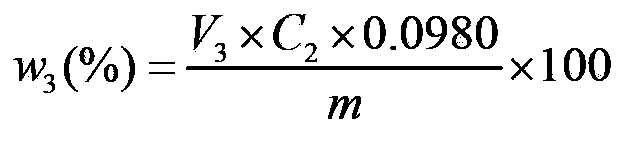

Method for determination of the content of main components of phosphorus trichloride hydrolysis solution

InactiveCN103364524AAccurate measurementSimple and fast operationChemical analysis using titrationPhosphorous acidPhosphoric acid

The invention relates to a method for determination of the content of main components of a phosphorus trichloride hydrolysis solution. The method is carried out according to the following steps: 1) accurately weighing a phosphorus trichloride hydrolysis solution sample, adding water, in the condition of stirring, titrating the solution to the pH of 4.5 with a sodium hydroxide standard titration solution, and recording consumption volume V1 of the sodium hydroxide standard titration solution; 2) continuing to titrate the solution to the pH of 9.5 with the sodium hydroxide standard titration solution, and recording consumption volume V2 of the sodium hydroxide standard titration solution; 3) further adding an excess neutral calcium chloride solution, titrating the solution to the pH of 7.53 with the sodium hydroxide standard titration solution, and recording consumption volume V3 of the sodium hydroxide standard titration solution; and 4) calculating results. Through use of the method, fast and real-time detection of the content of hydrochloric acid, phosphorous acid and phosphoric acid in the phosphorus trichloride hydrolysis solution can be realized, and the method has the advantages of simple operation, high accuracy, good precision, good reproducibility and the like. But if a conventional acid-base indicator method is adopted, the phosphorus trichloride hydrolysis solution sample cannot be accurately determined because of low phosphoric acid content in the phosphorus trichloride hydrolysis solution sample.

Owner:CHONGQING UNISPLENDOUR CHEM

Disinfection powder of landscape fish pond water and preparation method of disinfection powder

InactiveCN106342961AReasonable formulaSimple preparation processBiocideWaste water treatment from animal husbandryChlorine dioxideBud

The invention provides disinfection powder of landscape fish pond water, and relates to the technical field of aquaculture. The disinfection powder is prepared from the following raw materials: 30 to 40 parts of a chlorine dioxide solution, 15 to 25 parts of a hydrogen peroxide solution, 10 to 20 parts of dodecyl dimethyl benzyl ammonium chloride, 8 to 10 parts of polyhydroxypropyl polyethylene-polyamine, 2 to 4 parts of dodecyl triphenyl phosphorous chloride, 3 to 5 parts of salviae miltiorrhizae radix et rhizoma, 2 to 4 parts of radix angelicae pubescentis, 3 to 5 parts of herba junci setchuensis, 2 to 4 parts of fructus gleditsiae, 3 to 5 parts of folium artemisiae argyi, 2 to 4 parts of radix angelicae dahurioae, 2 to 4 parts of herba pogostemonis, 1 to 3 parts of rhizoma kaempferiae, 1 to 3 parts of Chinese angelica, 2 to 4 parts of fortune loosestrife herb, 1 to 3 parts of shrubalthea bark, 1 to 3 parts of cuckoo-bud and 2 to 4 parts of carpesium herb. The disinfection powder of the landscape fish pond water has the beneficial effects that the prepared disinfection powder has a reasonable formula and a simple preparation process, has a very great sterilization effect on fish culture water; the content of toxic substances in a water body is small; normal survive of landscape fishes is guaranteed; the fish water does not need to be frequently replaced, and the disinfection powder is convenient and simple to use.

Owner:安徽省淮王渔业科技有限公司

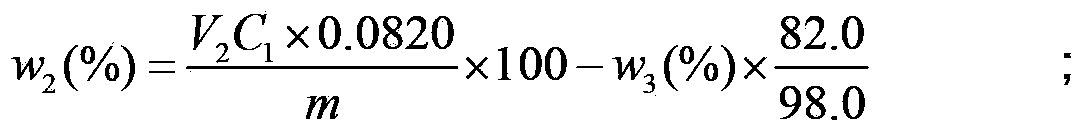

Method for preparing Alendronic acid

InactiveCN1660860AControl reaction temperatureTemperature controlGroup 5/15 element organic compoundsPhosphorous acidBoiling point

A process for preparing Alunphosphonic acid includes such steps as reflux reaction between gamma-aminobutanoic acid, PCl3, and phosphorous acid in the inertial solvent whose boiling point is 50-90 deg.C, and post-treating. Its reaction temp can be controlled well.

Owner:ZHEJIANG UNIV OF TECH

Benzyltriphenylphosphine tetranuclear manganese (II) complex

ActiveCN111171074AStrong fluorescenceGroup 5/15 element organic compoundsLuminescent compositionsMetal chlorideNonlinear optics

The invention discloses a benzyltriphenylphosphine tetranuclear manganese (II) complex, and the molecular formula of the complex is as follows: metal chloride, benzyltriphenylphosphonium chloride andpotassium thiocyanate are used as raw materials to synthesize a hybrid material at room temperature. The material has excellent fluorescence property and important value in the aspects of nonlinear optical property and information storage.

Owner:JIANGXI UNIV OF SCI & TECH

Process for preparing phosphorous acid by hydrolyzing phosphorus trichloride

Owner:HENAN QINGSHUIYUAN TECH

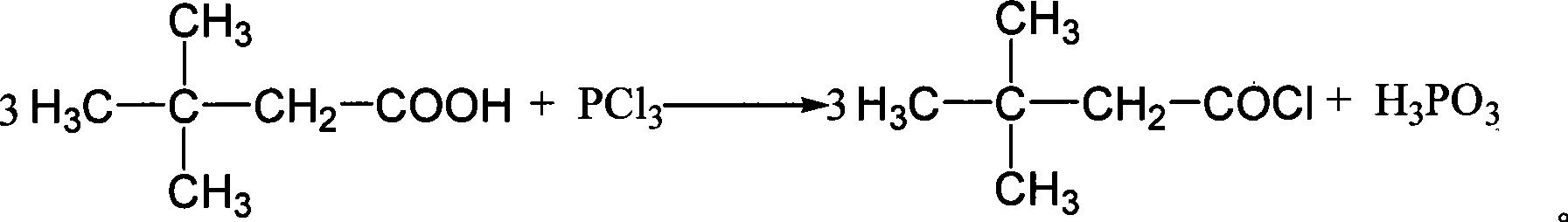

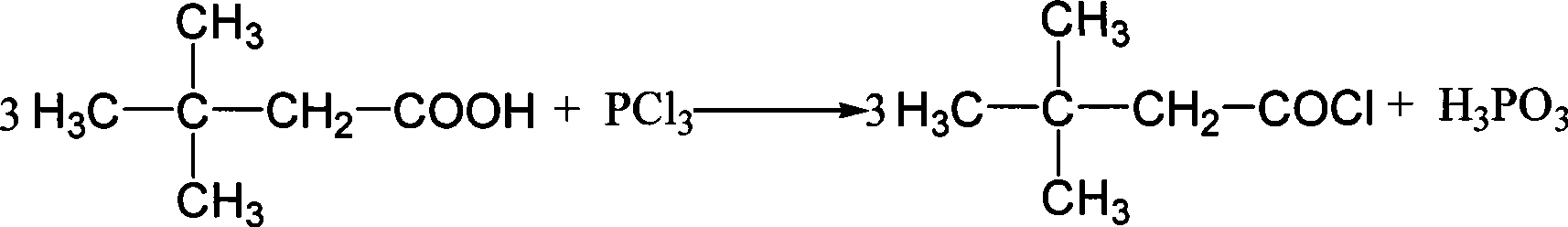

Synthetic method of 3,3-dimethyl butyladehyde

InactiveCN101391947ALow priceReduce dosageOrganic compound preparationCarboxylic compound preparationEnvironment effectOrganic synthesis

The invention provides a synthesizing method of 3, 3-dimethyl butyraldehyde, relates to an organic synthesis intermediate, particularly a method for preparing 3, 3-dimethyl butyraldehyde by the reaction of 3, 3-dimethylbutyric acid and phosphorus trichloride. A synthesizing method of 3, 3-dimethyl butyraldehyde with simple process, simple and convenient operation, high safety, low production cost and small influence to environment is provided. The method comprises the steps: the 3, 3-dimethylbutyric acid is added in a reactor and stirred, the phosphorus trichloride is added, then reaction is carried out after the temperature is raised to reaction temperature, after reaction, the reaction system is cooled to room temperature and stands for layering; and the lower layer of orthophosphorous acid divided after standing is taken as byproduct, the crude product of acyl chloride is adopted to carry out vacuum distillation under the absolute pressure of 20KPa and the distillate at 79 to 81 DEG C is collected, therefore the 3, 3-dimethyl butyraldehyde product is obtained.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com