Synthetic method of 3,3-dimethyl butyladehyde

A technology of dimethyl butyraldehyde and a synthesis method, which are applied in 3 fields of preparation, can solve the problems of large consumption of thionyl chloride, serious equipment corrosion, and large environmental impact, and achieve short reaction time, low production cost, and small environmental impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

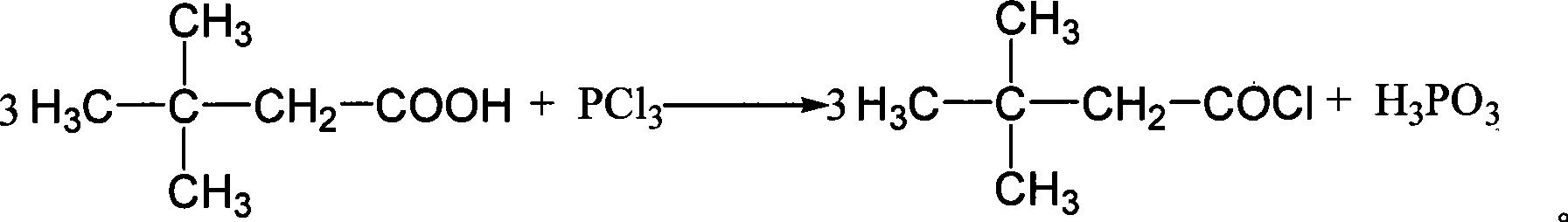

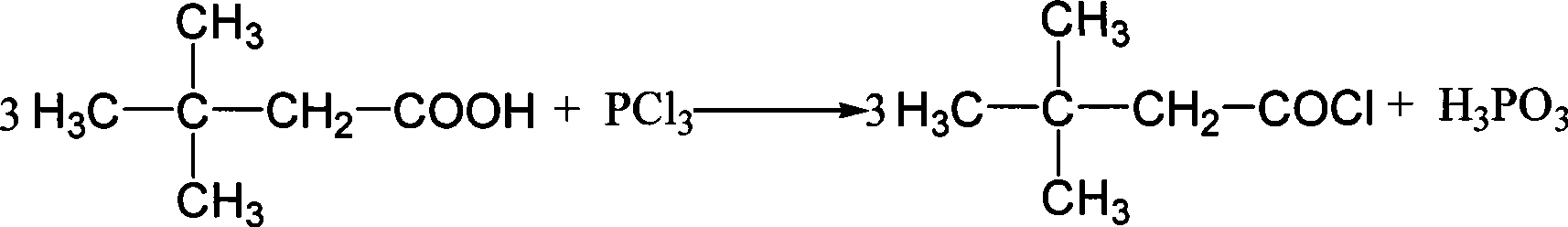

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: In a 500ml four-necked flask with an electric stirrer, a thermometer and a reflux condenser, add 3,3-dimethylbutanoic acid 46.4g (0.4mol), start stirring, dropwise at room temperature After the dropwise addition of 27.47g (0.2mol) of phosphorus trichloride was completed, the temperature was raised to 60°C for 2 hours. After the reaction was completed, it was cooled to room temperature, and placed in a separatory funnel to separate layers. Take the upper layer and collect the fraction at 79-81°C by vacuum distillation under the absolute pressure of 20KPa to obtain 46.91g of 3,3-dimethylbutyraldehyde product with a yield of 87.12%.

Embodiment 2

[0015] Embodiment 2: reaction device and operation method are the same as embodiment 1. The difference is that the amount of phosphorus trichloride added is 18.26g (0.133mol). As a result, 42.54 g of 3,3-dimethylbutyraldehyde was obtained with a yield of 79.01%.

Embodiment 3

[0016] Embodiment 3: reaction apparatus and operation method are the same as embodiment 1. The difference is that the amount of phosphorus trichloride added is 36.67g (0.267mol). As a result, 48.94 g of 3,3-dimethylbutanal was obtained with a yield of 90.89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com