Process for preparing phosphorous acid by hydrolyzing phosphorus trichloride

A technology of phosphorus trichloride and phosphorous acid, which is applied in the direction of phosphorous acid, phosphorus oxyacid, etc., can solve the problems of high equipment maintenance cost, large equipment investment, complicated process, etc., to reduce the initial equipment investment, reduce material requirements, The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

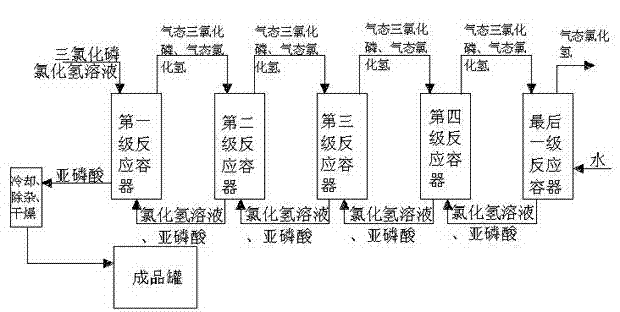

[0024] The first-stage reaction vessel is filled with 37% hydrogen chloride solution by mass, and the second, third and fourth reaction vessels are filled with hydrogen chloride solution with a mass percentage lower than 37%, and the mass percentages decrease successively. Phosphorus trichloride is added dropwise into the first-stage reaction vessel, and the phosphorus trichloride reacts with the water in the hydrogen chloride solution to generate phosphorous acid and gaseous hydrogen chloride with heat release. A part of phosphorus trichloride absorbs heat and becomes gaseous, enters the second-stage reaction vessel with gaseous hydrogen chloride, and takes away part of the heat generated by the hydrolysis reaction; the phosphorous acid in the first reaction kettle is exported, cooled, removed, and dried After that, it enters the finished product tank.

[0025] The gaseous hydrogen chloride and gaseous phosphorus trichloride entering the second-stage reaction vessel are fu...

Embodiment 2

[0030] The specific process is with reference to embodiment 1, and in the present embodiment, the reaction vessel of series connection is six grades, and wherein each grade of reaction vessel is made up of 6 parallel reaction kettles, and the temperature in each grade of reaction vessel is controlled at 85 ℃, and pressure is 0.1MPa. The liquid replenishing method is: water → sixth reaction vessel → fifth reaction vessel → fourth reaction vessel → third reaction vessel → second reaction vessel → first reaction vessel.

Embodiment 3

[0032] Concrete process is with reference to embodiment 1, and in the present embodiment, the reaction vessel of series connection is five grades, and wherein each grade of reaction vessel is made up of 5 parallel reaction kettles, and the temperature in each grade of reaction vessel is controlled at 75 ℃, and pressure is 0.05MPa. The way of replenishing liquid is: water→fifth-stage reaction container→fourth-stage reaction container→third-stage reaction container→second-stage reaction container→first-stage reaction container.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com