Method for preparing cadmium telluride or cadmium zinc telluride polycrystal material

A technology of cadmium zinc telluride and cadmium telluride, which is applied to the growth of polycrystalline materials, chemical instruments and methods, and single crystal growth, etc., can solve the problems of high cost, explosion of quartz crucible containers, and scrapping of materials due to oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Prepare 100kg of CdTe crystal material.

[0033] Preparation process:

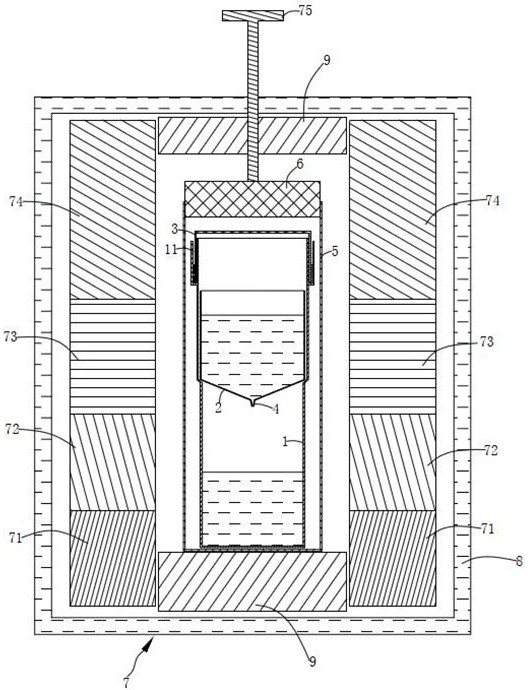

[0034] 1) The first crucible 1, the second crucible 2, and the first cover 3 are made of quartz; the first crucible 1 has an annular groove 11 along the outer peripheral wall, the inner diameter of the lower part of the first crucible 1 is 300 mm, the inner diameter of the upper part is 322 mm, and the wall thickness 5mm, length 800mm; the width of annular groove 11 is 18mm, the wall thickness is 2.5mm, and the depth is 15mm; the upper part of the second crucible 2 is cylindrical, and the lower part is funnel-shaped. 4 The total length is 100 mm, the wall thickness is 3 mm, and the inner diameter of the tail end of the thin tube 4 is 8 mm; the top of the first cover 3 is closed, the bottom is open and the side wall can be inserted into the annular groove 11, the inner diameter of the first cover 3 is 336 mm, the wall thickness is 2.5 mm, The length is 30 mm; the first crucible 1, the sec...

Embodiment 2

[0045] Embodiment 2: prepare 6kg Cd 0.96 Zn 0.04 Te crystal material.

[0046] Preparation process:

[0047] 1) The first crucible 1, the second crucible 2, and the first cover 3 are made of quartz; the first crucible 1 has an annular groove 11 along the outer peripheral wall, the inner diameter of the lower part of the first crucible 1 is 90 mm, the inner diameter of the upper part is 112 mm, and the wall thickness 3mm, length 800mm; the width of the annular groove 11 is 18mm, the wall thickness is 2.5mm, and the depth is 15mm; the upper part of the second crucible 2 is cylindrical, and the lower part is funnel-shaped. The total length of the tube 4 is 100 mm, the wall thickness is 2.5 mm, and the internal diameter of the tail end of the thin tube 4 is 1 mm; the top of the first cover 3 is closed, the bottom is open and the side wall can be inserted into the annular groove 11, the internal diameter of the first cover 3 is 336 mm, and the wall thickness is 2.5 mm. mm, lengt...

Embodiment 3

[0058] Embodiment 3: prepare 6kg Cd 0.9 Zn 0.1 Te crystal material.

[0059] Preparation process:

[0060] 1) The first crucible 1, the second crucible 2, and the first cover 3 are made of quartz; the first crucible 1 has an annular groove 11 along the outer peripheral wall, the inner diameter of the lower part of the first crucible 1 is 90 mm, the inner diameter of the upper part is 112 mm, and the wall thickness 3mm, 800mm in length, the width of the annular groove 11 is 18mm, the wall thickness is 2.5mm, and the depth is 15mm. The upper part of the second crucible 2 is cylindrical, and the lower part is funnel-shaped. The outer diameter of the cylindrical tube is 110 mm, the length is 150 mm, the total length of the funnel and the thin tube 4 is 100 mm, the wall thickness is 2.5 mm, and the inner diameter of the tail end of the thin tube 4 is 2 mm; The top of the cover 3 is closed, the bottom is open, and the side wall can be inserted into the annular groove 11. The inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com