Low-spatter-rate ER50-6 gas-protection solid welding wire

A solid welding wire, spatter rate technology, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems of welding spatter slag inclusion, welding shielding airflow blockage, hindering the normal wire discharge of welding wire, etc., to reduce welding spatter rate, ensure Stability, the effect of realizing welding process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A low spatter rate ER50-6 gas-shielded solid welding wire, the measured chemical composition (%) of the welding wire is as follows in Table 1:

[0028] Table 1 Example 1 Welding Wire Measured Chemical Composition (%)

[0029] element

C

S

mn

Si

P

Cr

Ni

measured value

0.071

0.012

1.51

0.87

0.012

0.004

0.007

element

Mo

V

Cu

Al

O

N

Ca

measured value

0.003

0.002

0.13

0.04

0.005

0.004

0.001

[0030] The balance is Fe, and the total is 100%. Wherein: the weight ratio of Mn+Si is: 2.38%; the weight ratio of Mn:Si is: 1.736.

[0031] Copper plating layer thickness: HQT-IA microcomputer multifunctional electrolytic thickness gauge is used, and the measured thickness value is 0.29 μm.

[0032] The welding wire is wound around its own diameter without delamination and peeling.

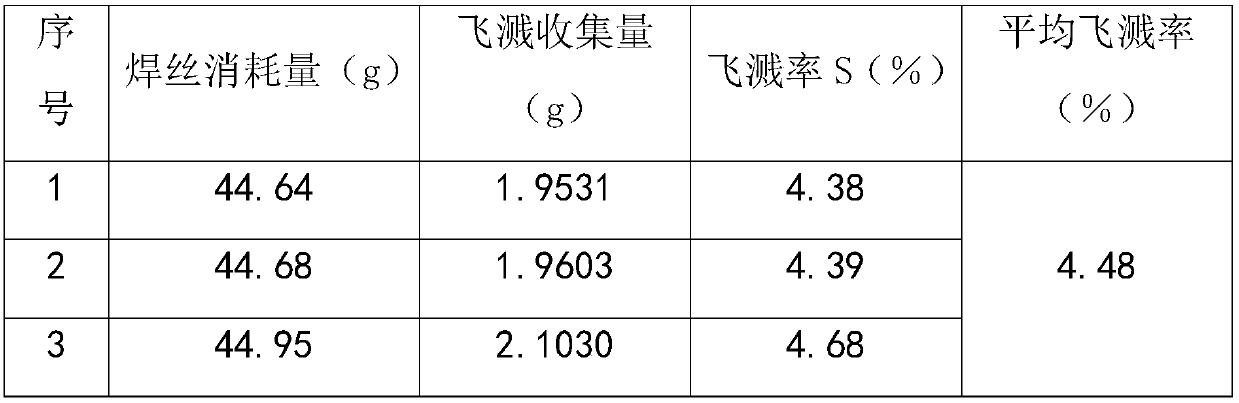

[0033] The welding spatter rate test was carried out on the welding wire in Ex...

Embodiment 2

[0038] A low spatter rate ER50-6 gas-shielded solid welding wire, the measured chemical composition (%) of the welding wire is as follows in Table 3:

[0039] Table 3 Example 1 Welding Wire Measured Chemical Composition (%)

[0040] element

C

S

mn

Si

P

Cr

Ni

measured value

0.074

0.004

1.54

0.89

0.016

0.06

0.0021

element

Mo

V

Cu

Al

O

N

Ca

measured value

0.009

0.001

0.12

0.03

0.0052

0.0063

0.001

[0041] The balance is Fe, and the total is 100%. Wherein: the weight ratio of Mn+Si is: 2.43%; the weight ratio of Mn:Si is: 1.73.

[0042] Copper plating layer thickness: HQT-IA microcomputer multifunctional electrolytic thickness gauge is used, and the measured thickness value is 0.32 μm.

[0043] The welding wire is wound around its own diameter without delamination and peeling.

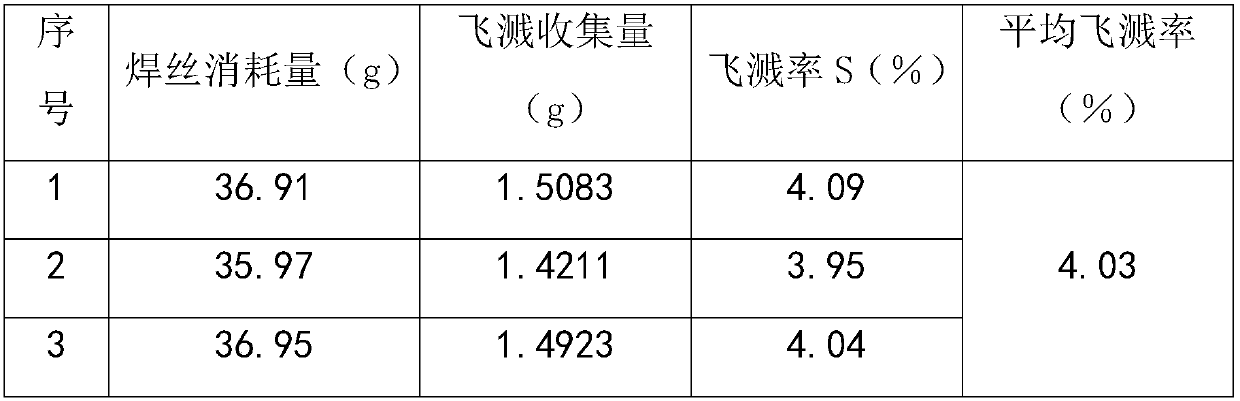

[0044] The welding spatter rate test was carried out on the welding wire in E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com