Patents

Literature

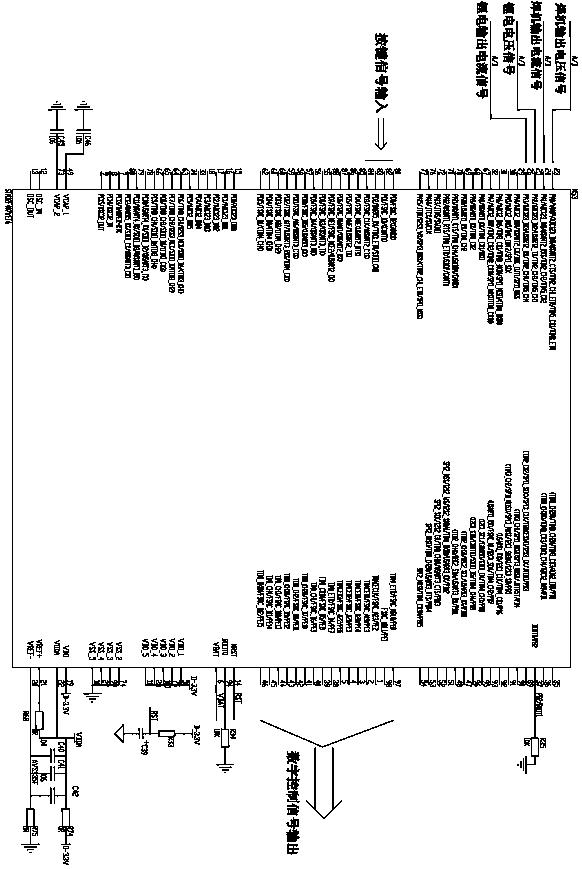

42results about How to "Improve welding processability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum-magnesium alloy welding wire for gas shield welding of aluminum-alloy car body and preparation method thereof

InactiveCN103451496ASimple compositionImprove welding processabilityWelding/cutting media/materialsSoldering mediaMaterials scienceMagnesium alloy

The invention discloses an aluminum-magnesium alloy welding wire for the gas shield welding of an aluminum-alloy car body and a preparation method thereof. The preparation method of the aluminum-magnesium alloy welding wire comprises the following steps: smelting and refining, continuously casting and rolling, drawing the wire and carrying out surface polishing treatment on the welding wire. The aluminum-magnesium alloy welding wire disclosed by the invention has the advantages of high performance and stable and good joint performance.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

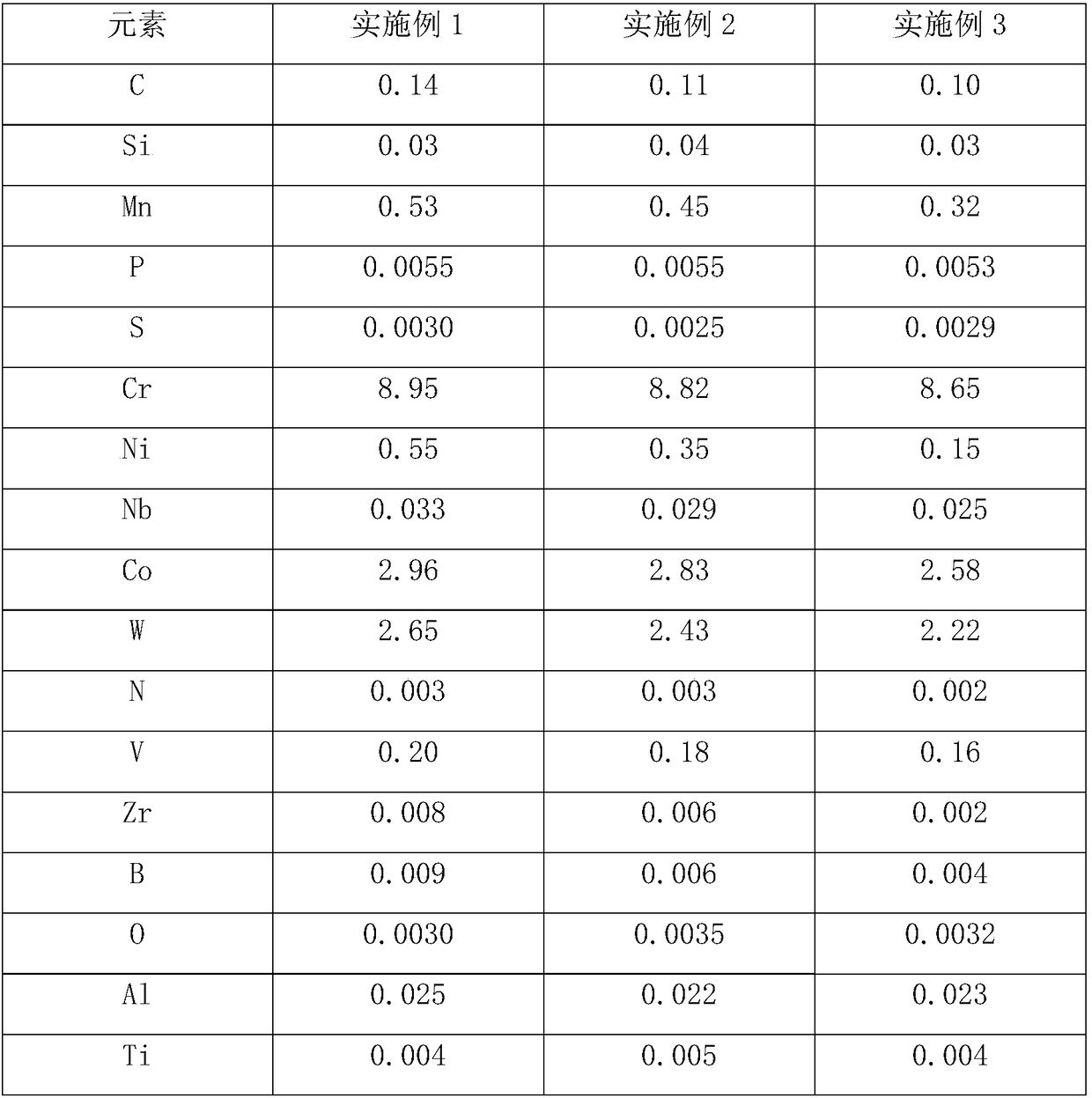

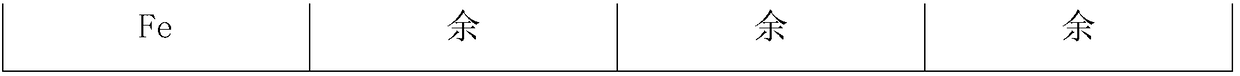

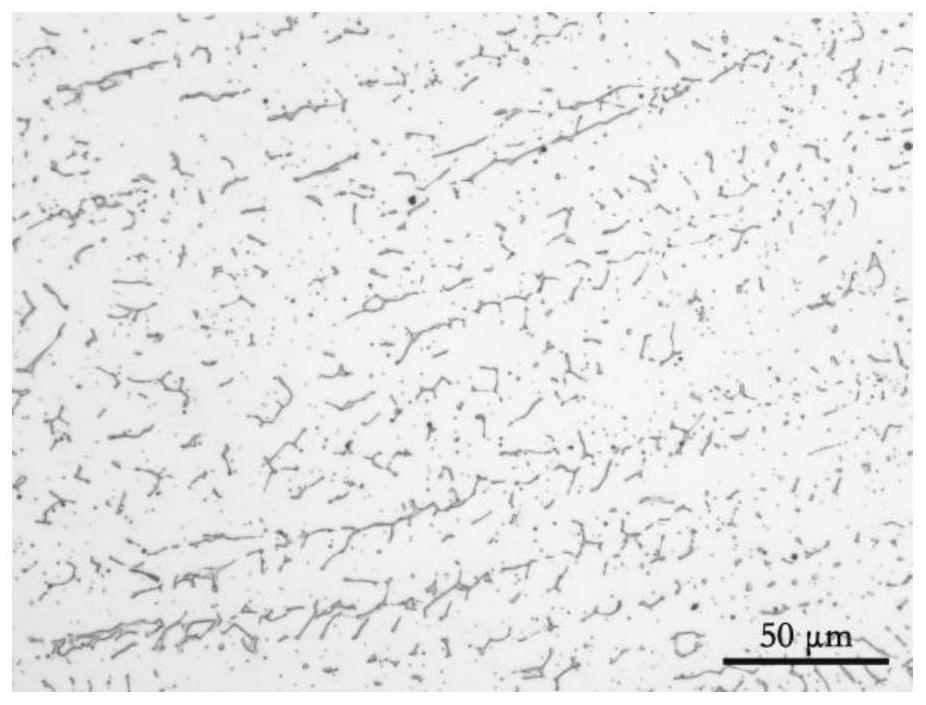

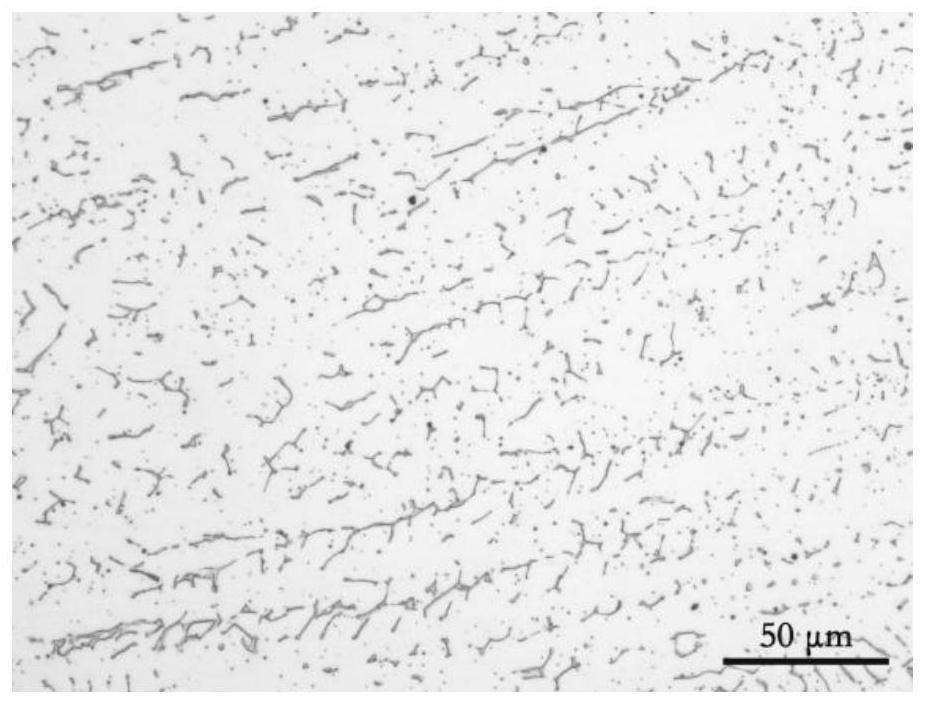

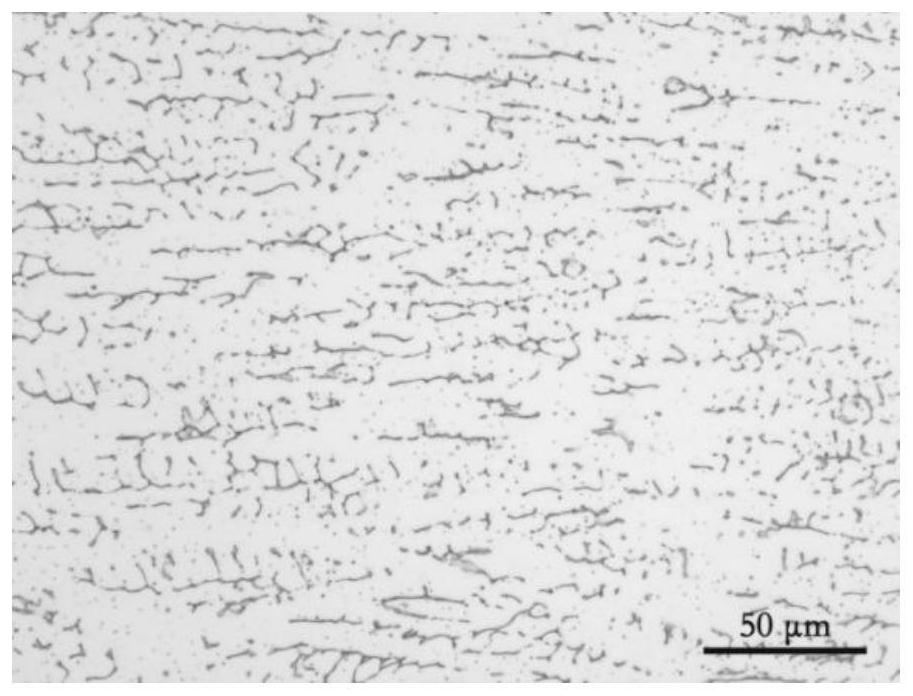

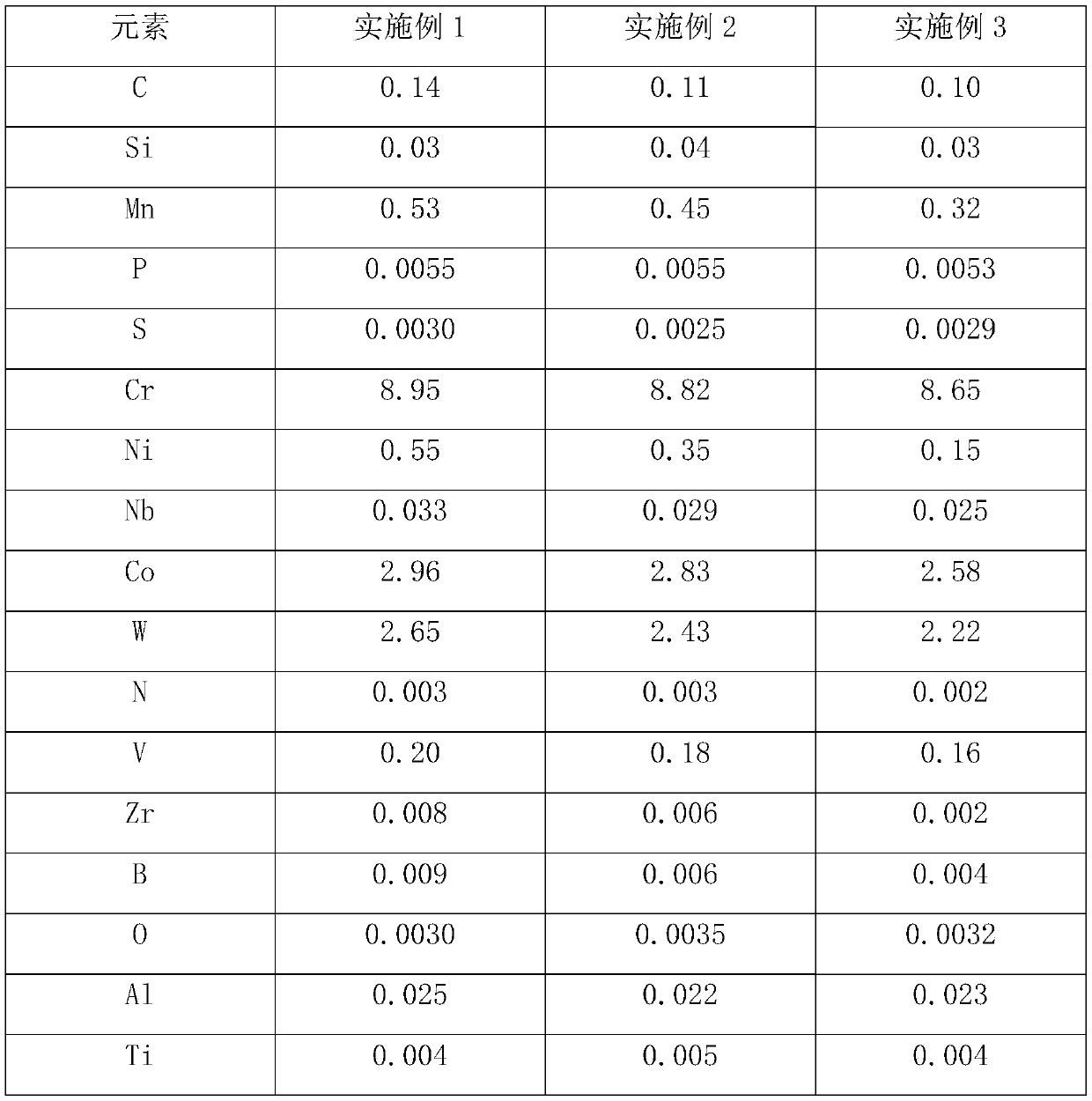

Bright welding wire for heat-resistant steel for ultra-supercritical coal-fired power station

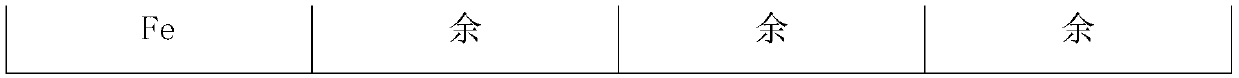

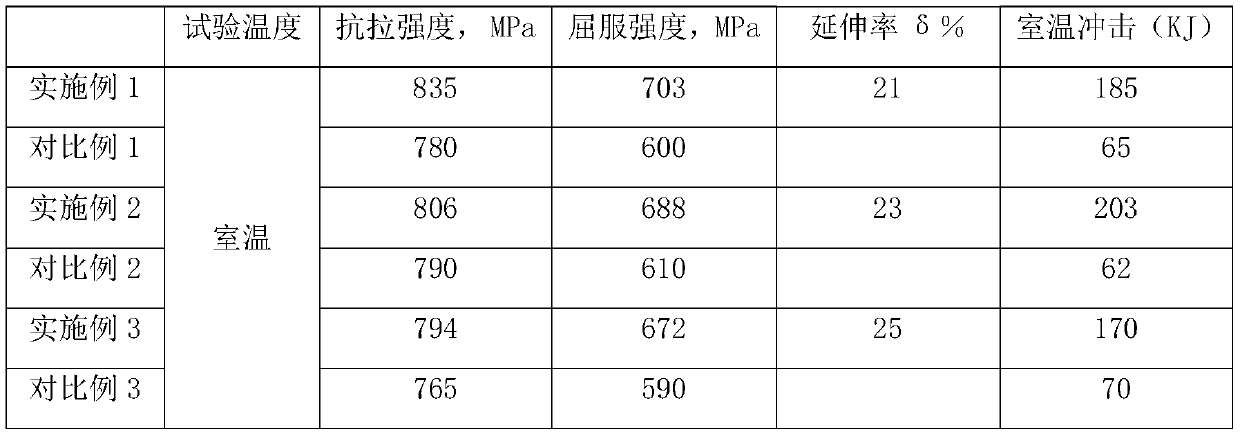

ActiveCN108838579AImprove welding processabilityImprove surface cleanlinessWelding/cutting media/materialsSoldering mediaRoom temperatureMechanical property

The invention discloses a bright welding wire for heat-resistant steel for an ultra-supercritical coal-fired power station and belongs to the technical field of welding materials. The welding wire comprises, by weight, 0.10-0.15% of C, 8.5-9.0% of Cr, 0.1-0.6% of Ni, 0.3-0.6% of Mn, 2.5-3.0% of Co, 2.0-2.7% of W, 0.020-0.035% of Nb, 0.001-0.010% of Zr, less than or equal to 0.006% of N, 0.16-0.20%of V, 0.003-0.010% of B, less than or equal to 0.20% of Si, less than or equal to 0.006% of P, less than or equal to 0.006% of S, less than or equal to 0.010% of O, less than or equal to 0.03% of Al,less than or equal to 0.01% of Ti and the balance Fe and inevitable impurity elements. The bright welding wire has the advantages that the welding wire has good welding process performance and excellent deposited metal flowability and formability, and the deposited metal after welding has excellent mechanical properties and good room temperature impact toughness.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

Alkaline welding rod coating capable of improving welding process property

InactiveCN1586798AFine splash particlesReduce manufacturing costWelding/cutting media/materialsSoldering mediaIron powderManganese

The alkaline welding rod coating with raised welding performance consists of: marble 39-45 wt%, silica mud 3-10 wt%, fluorite 16-25 wt%, metal Mn 2-4 wt%, Si-Fe alloy 0.5-3 wt%, Ti-Fe alloy 8-12 wt%, cellulose 0.5-1.0 wt%, titania 3-9 wt%, atomized iron powder 6-15 wt% and graphite+Na2CO3 1-2.5 wt%. The said components are mixed, and the mixture is then coated with sodium water glass as adhesive onto low alloy steel welding core to produce alkaline low alloy steel welding rod or onto carbon steel welding core to produce alkaline carbon steel welding rod. The alkaline welding rod with the welding rod coating has excellent welding performance.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

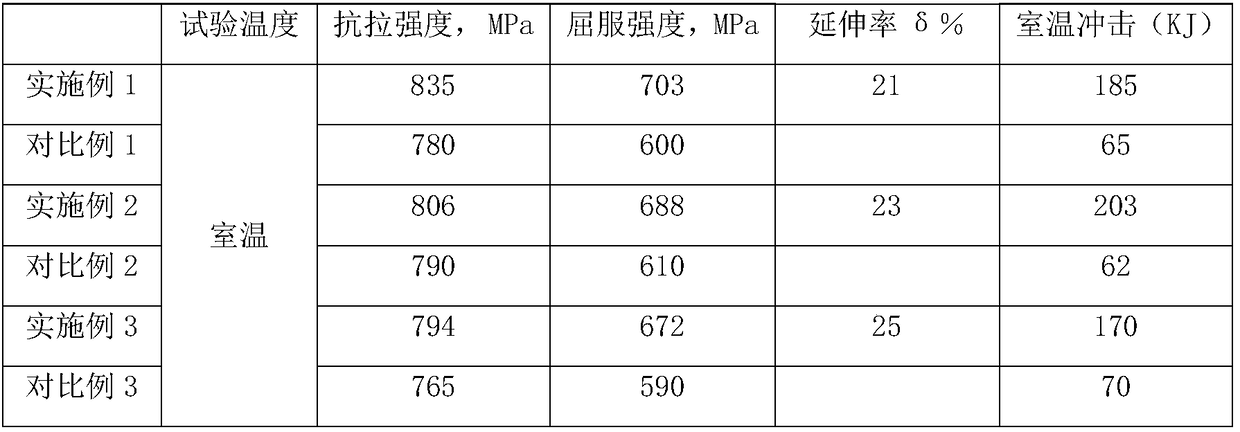

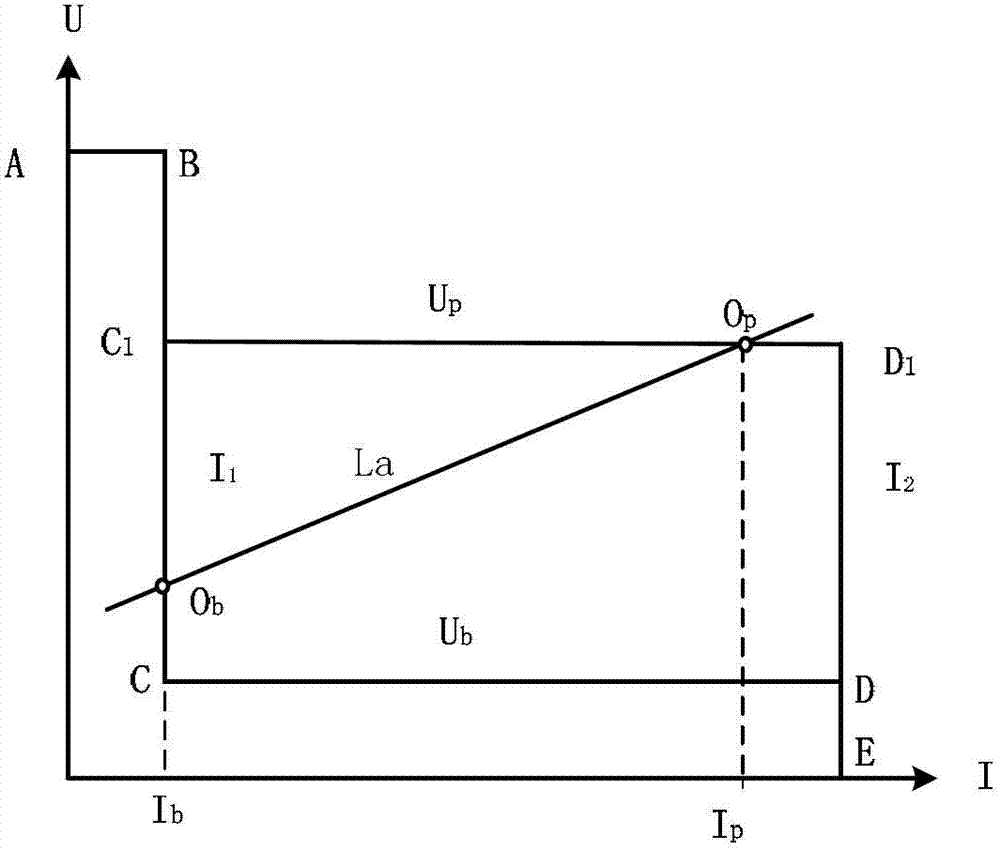

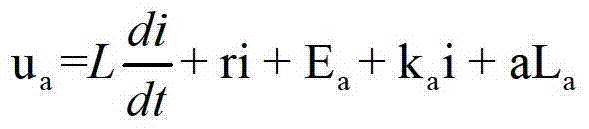

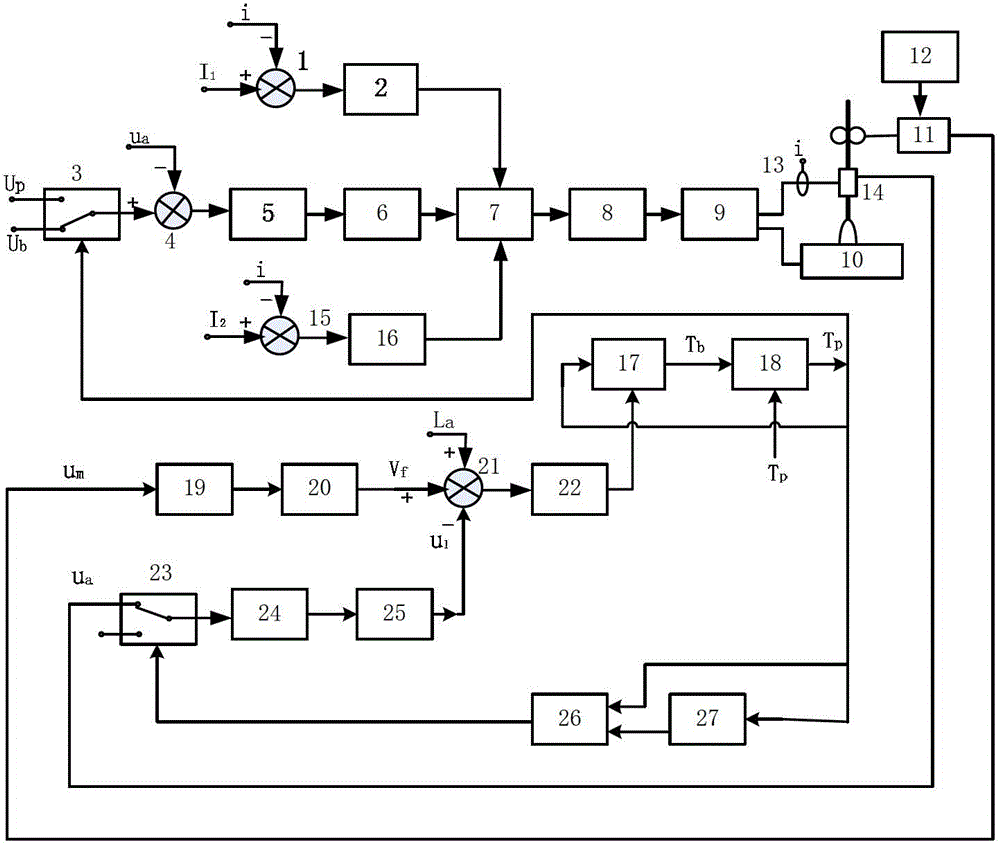

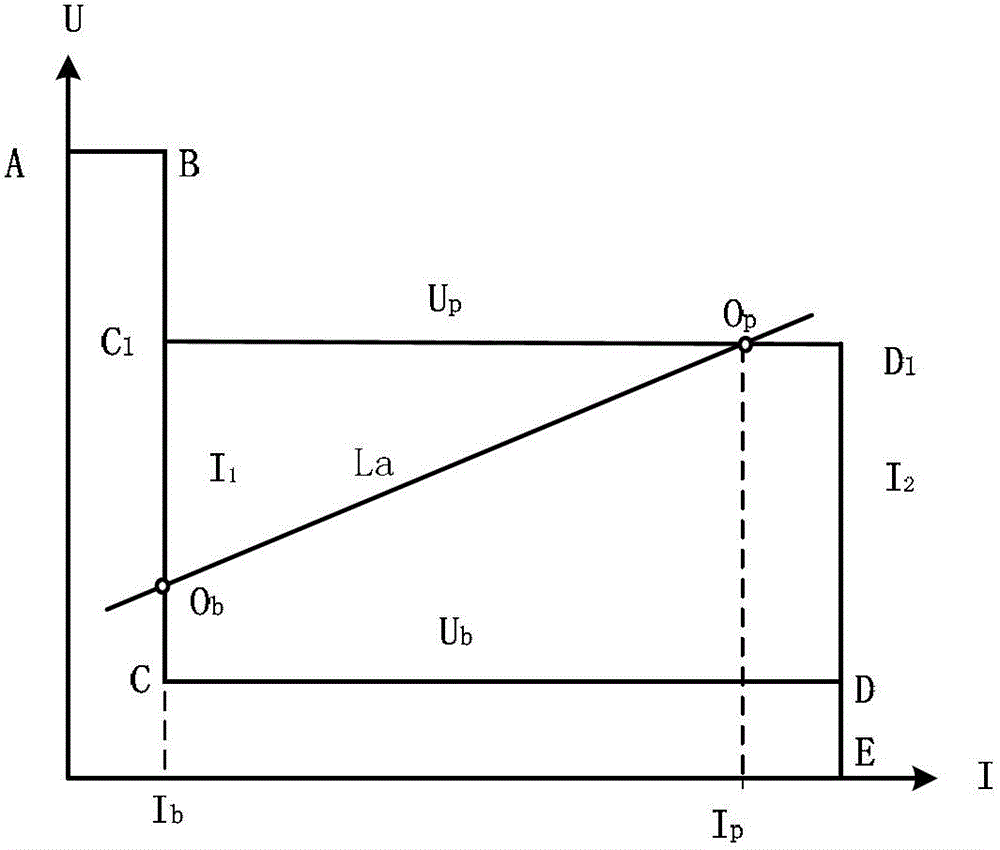

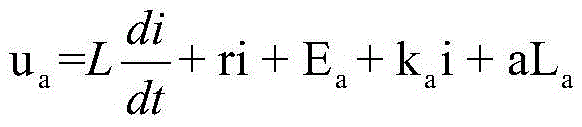

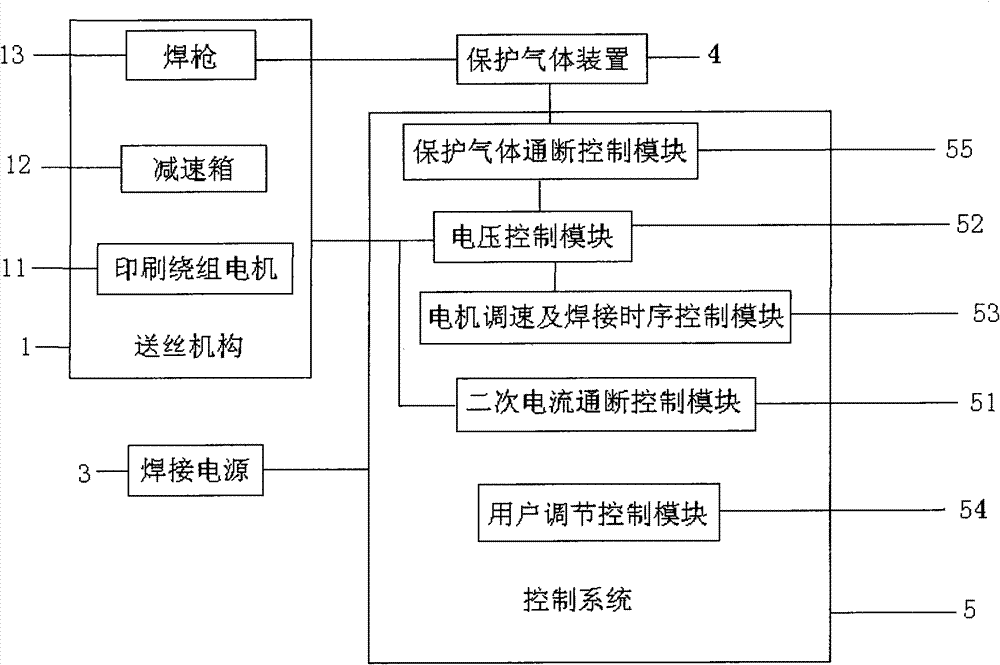

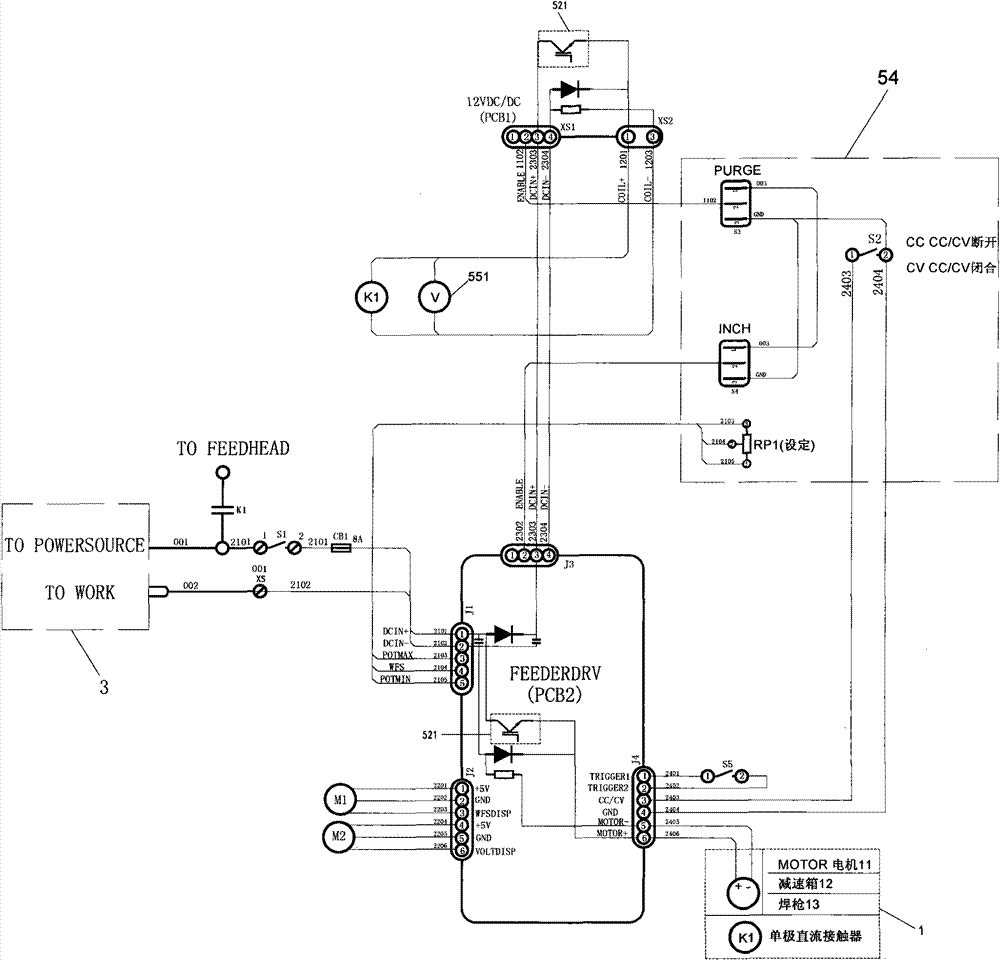

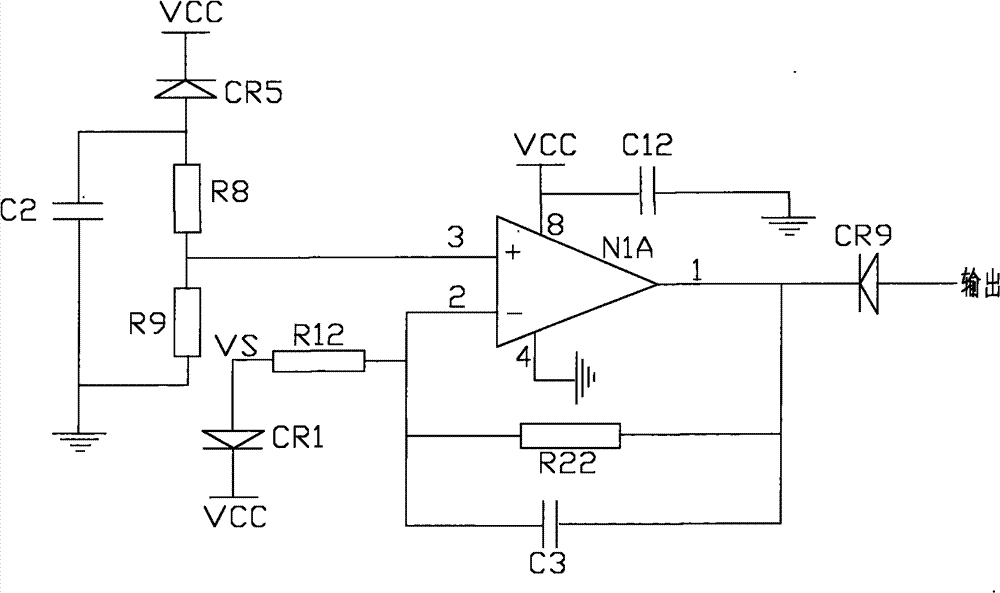

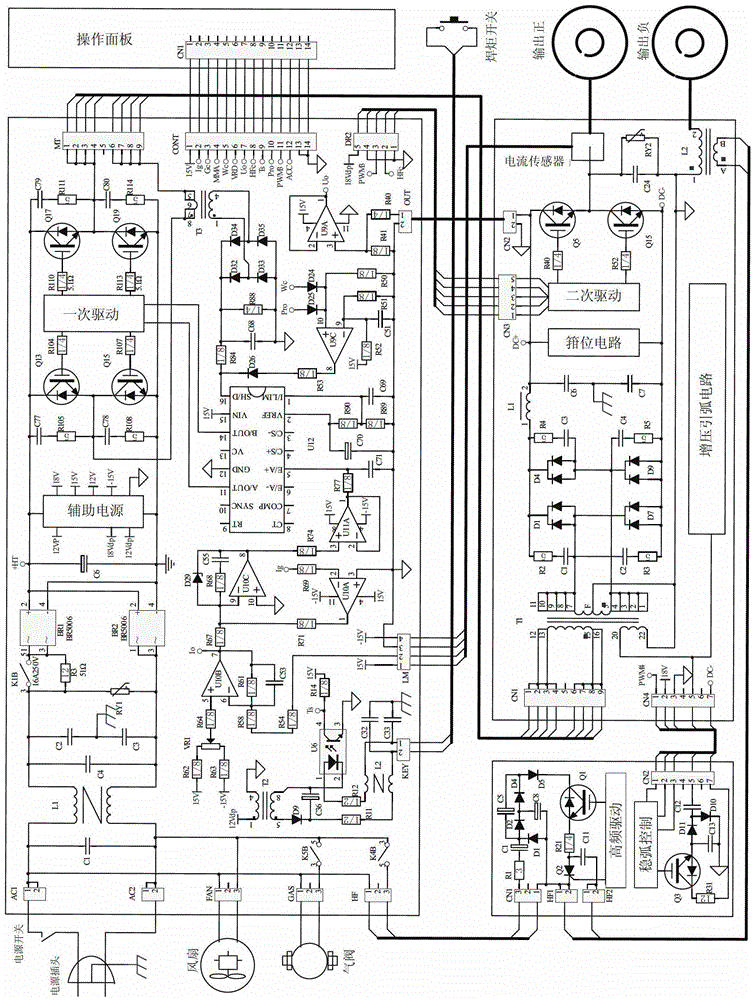

Control method and system for pulse MIG (Metal-Inert Gas) welding electric arc

ActiveCN103203530AThe arc length is constantConstant pulse widthArc welding apparatusNegative feedbackLoop closing

The invention discloses a control method and system for a pulse MIG (Metal-Inert Gas) welding electric arc. The method and the system disclosed by the invention has the advantages that the pilot-arc width or the pulse frequency of the pulse MIG electric arc is commonly controlled in a loop-opened feed-forward control mode of a welding-wire feeding speed signal and a loop-closed negative-feedback control mode of an electric arc length signal so as to maintain dynamic balance of the feeding speed and the fusion speed of welding wires and maintain constant electric arc length of the system and a constant jet transient mode of molten drops when welding current adjustment (by adjusting the wire-feeding speed), wire-feeding speed disturbance or arc length disturbance occurs. In addition, the invention also discloses a new process which adopts the method and the system and is used for controlling the fusion depth and the forming of welding seams by adopting a pulsating feeding mode for welding.

Owner:广州焊王电气科技有限公司

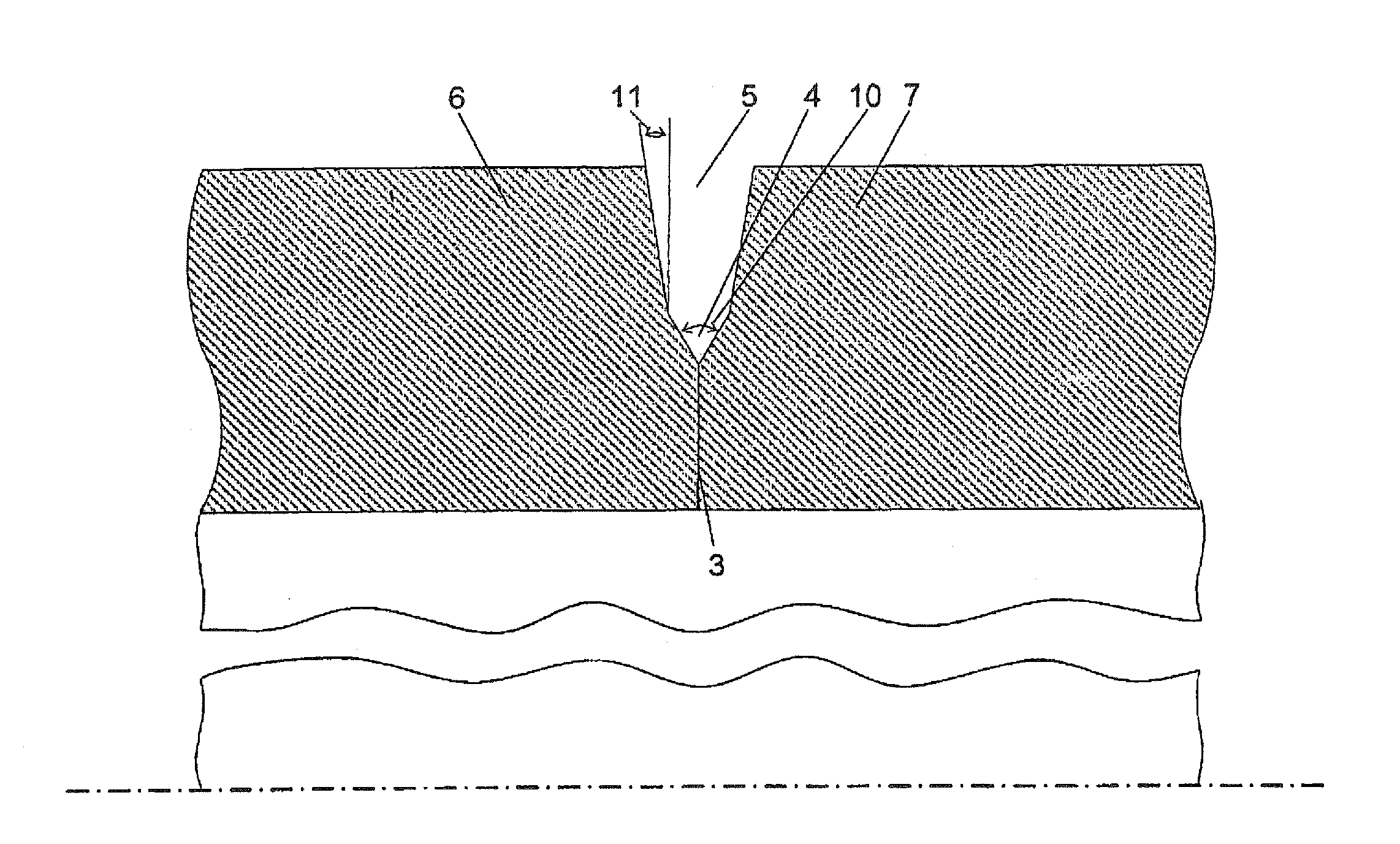

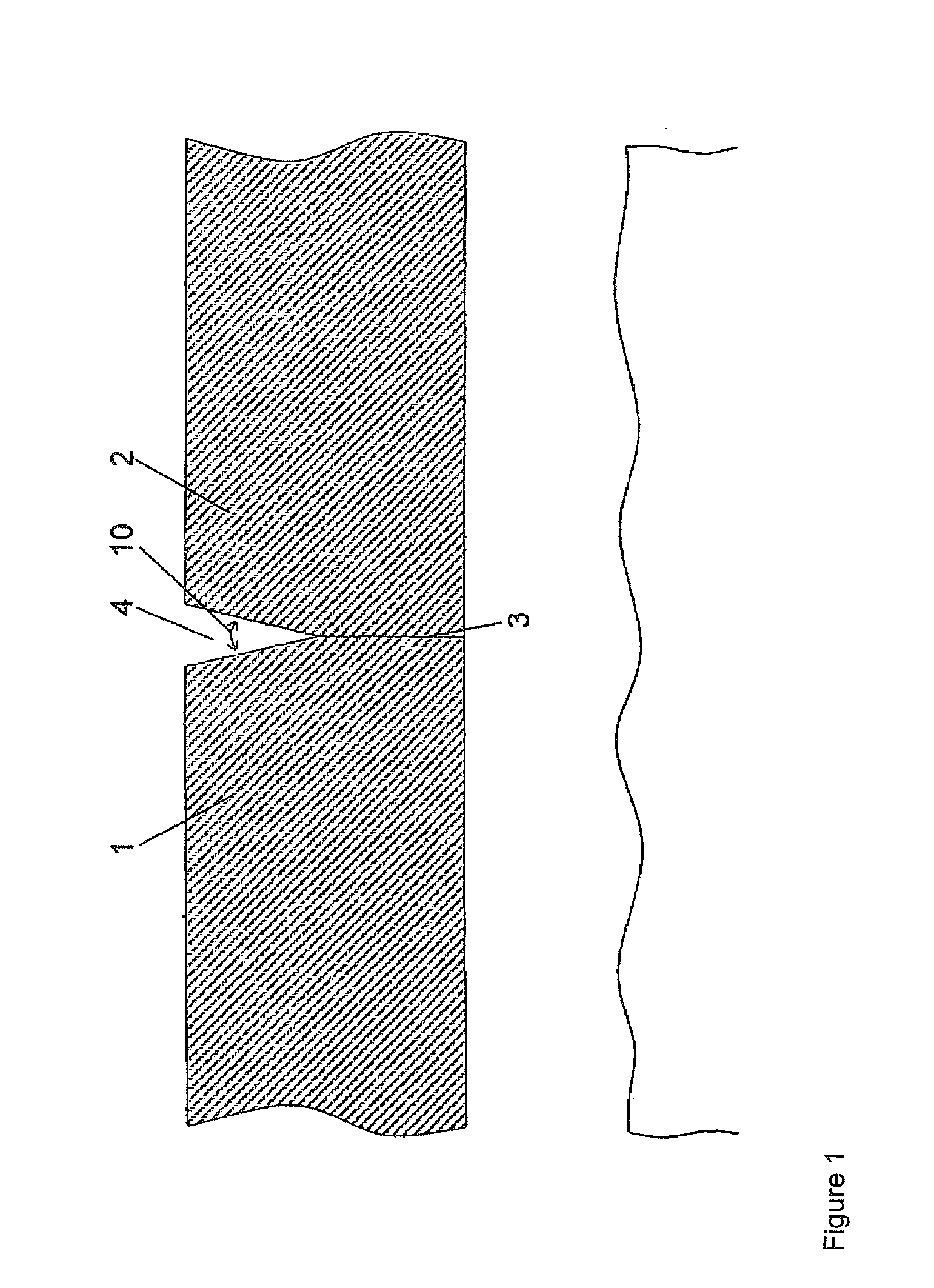

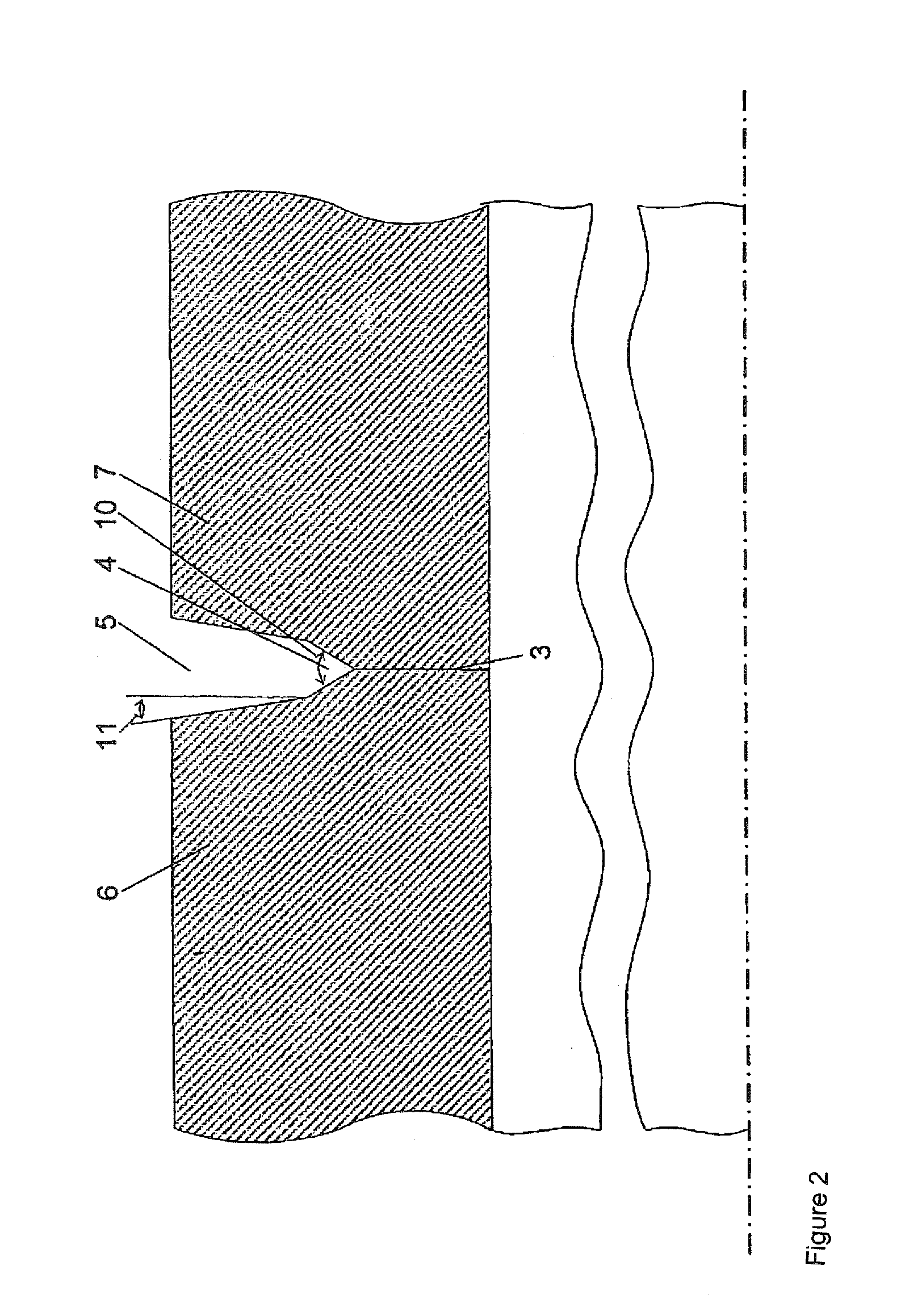

Method for connecting thick-walled metal workpieces by welding

ActiveUS8373083B2Improve welding processabilityEasy to optimizeWelding/cutting media/materialsWelding electrode featuresEngineeringArc welding

The invention relates to a method for connecting thick-walled metal workpieces by welding. In order to create the weld joint, the cross-sections are provided with a maximum of three weld regions according to wall thickness, the welding being carried out by a combined use of welding methods: the first weld region (root) is welded by means of laser beam welding or hybrid laser-arc welding, the second weld region is welded by means of hybrid laser-arc welding, and the third weld region required occasionally depending on the thickness of the sheet metal is welded by means of hybrid laser-arc welding or simply arc welding. The invention also relates to a seam preparation corresponding to the respective welding method used.

Owner:V&M DEUT GMBH

Welding electrode coating

ActiveCN105057924AAbundant raw ore reservesRich reservesWelding/cutting media/materialsSoldering mediaIron powderSlag

The invention discloses a welding electrode coating. The welding electrode coating comprises components of, by mass, 15-65 parts of attapulgite of medium-low grades, 0-10 parts of quartz sand, 15-20 parts of dolomite, 19-50 parts of magnesia and 1-5 parts of iron powder. According to the welding electrode coating, used attapulgite raw ore is rich in reserve and low in price and provides a stable raw material source for coating welding, and welding electrodes obtained on the basis are low in cost, stable in arc and small in spattering particle during welding, prone to slag removal after welding, smooth and attractive in formed weld joint, low in welding dust generating rate, safe and non-toxic, good in economic and environment benefit and broad in application prospect.

Owner:盱眙凹土能源环保材料研发中心 +1

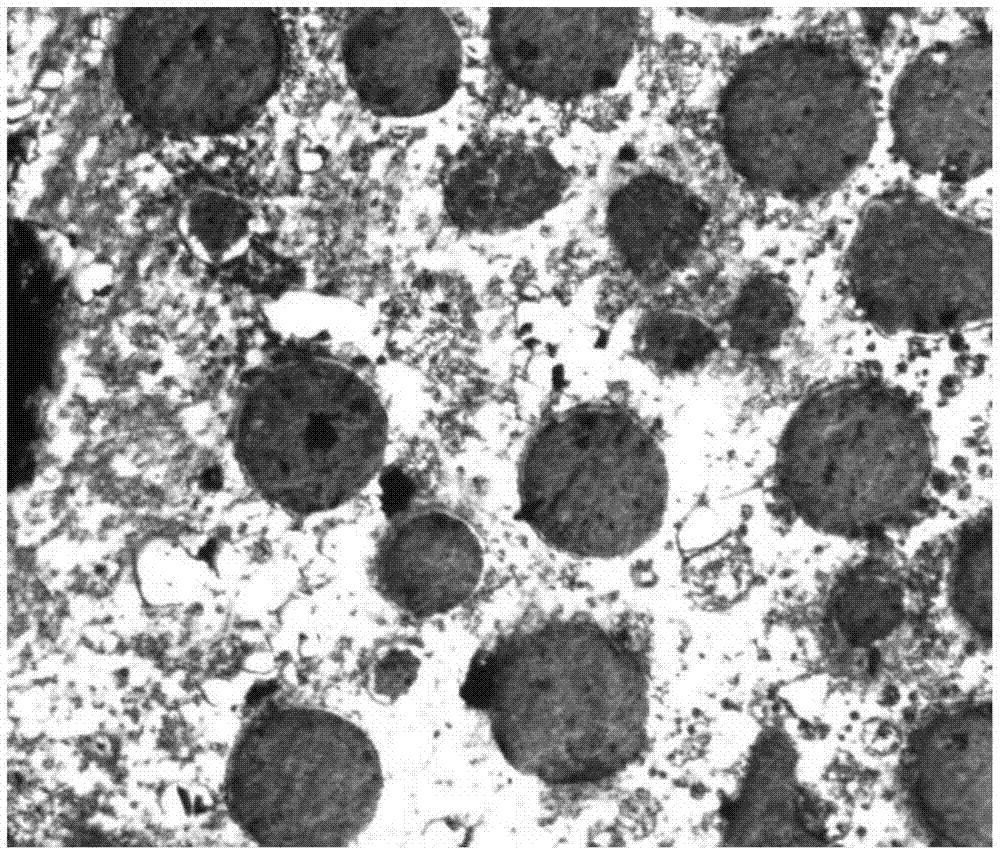

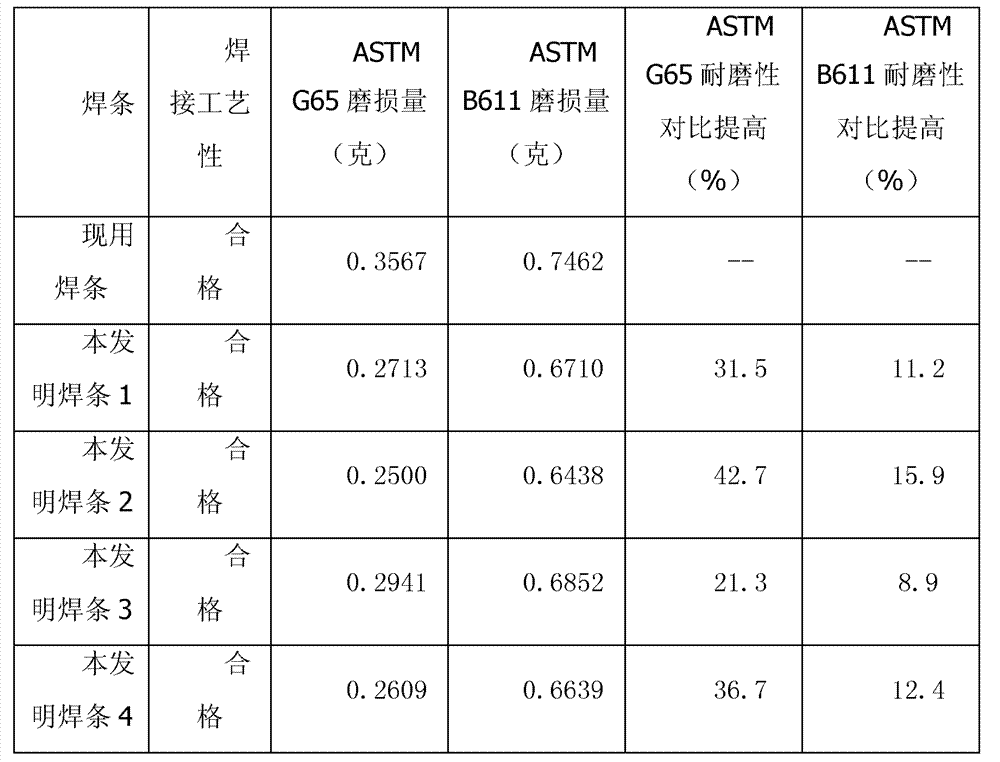

A pipe welding rod with low stress wear resistance

ActiveCN103228402BImprove welding processabilityAdvanced technologyDrill bitsWelding/cutting media/materialsMacrocrystallineAlloy

Owner:KINGDREAM PLC CO +1

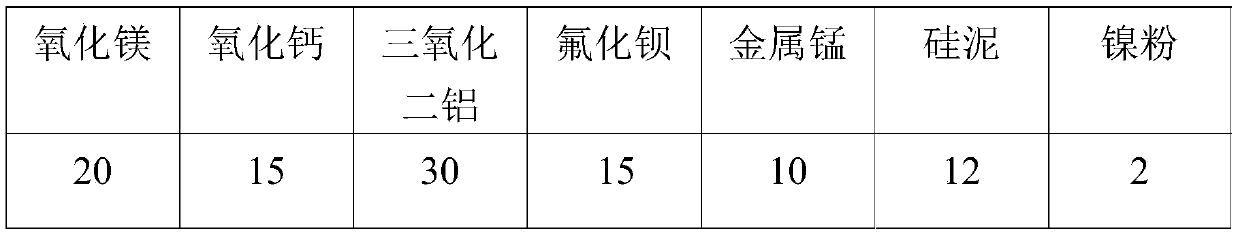

Seamless self-protection flux-cored wire for low-nitrogen non-magnetic naval vessel steel welding

ActiveCN112404795AFast solidificationEasily ionizedWelding/cutting media/materialsSoldering mediaSilica fumeNitriding

The invention relates to a seamless self-protection flux-cored wire for low-nitrogen non-magnetic naval vessel steel welding. According to the technical scheme, the seamless self-protection flux-coredwire is composed of 70 wt%-80 wt% of a stainless steel strip and 20 wt%-30 wt% of flux-cored powder, and the stainless steel strip is filled with the flux-cored powder. The stainless steel strip comprises the following chemical components of, in percentage by weight, 0.03-0.08 wt% of C, less than or equal to 1wt% of Si, less than or equal to 2 wt% of Mn, 18-20 wt% of Cr, 8-11 wt% of Ni, less thanor equal to 0.03 wt% of S, less than or equal to 0.03 wt% of P and the balance Fe and inevitable impurities. The flux-cored powder comprises the following chemical components of, in percentage by weight, 40-43 wt% of barium fluoride, 5-8 wt% of marble, 8-10 wt% of aluminum powder, 2-4 wt% of silicon powder, 7-10 wt% of manganese powder, 2-5 wt% of manganese nitride, 10-13 wt% of nickel powder, 5-7 wt% of chromium powder and the balance iron powder. According to the seamless self-protection flux-cored wire, weld metal formed by welding the low-nitrogen non-magnetic naval vessel steel is high in strength, good in ductility and toughness, non-magnetic and excellent in seawater corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Welding wire flux core, welding wire, preparation method of welding wire and welding method

ActiveCN112388202ASimple production processImprove plasticityArc welding apparatusWelding/cutting media/materialsFluorideMetal

The invention provides a welding wire flux core, a welding wire, a preparation method of the welding wire and a welding method, and relates to the technical field of welding materials. The flux core is formed by following chemical components including, by mass percent, 1-6% of Mn, 0.1-5% of Si, 0.1-2% of Mg, 35-50% of Cr, 15-25% of Ni; 1-10% of Na2O and K2O, 0.1-2% of fluoride, 15-30% of TiO2, 3-10% of SiO2 and the balance Fe and inevitable impurities. After the welding wire is adopted for surfacing, the tensile strength of a surfacing layer of the welding wire is 527-547 MPa, the elongation is 38%, the welding wire is used as a backing welding material of an alloy steel flux-cored wire for surface surfacing, it is guaranteed that no open cracks exist in side bending (d=4t, and alpha=180 degrees) after heat preservation of 690 DEG C and heat treatment of 32 hours, and surfacing layer metal has no intergranular corrosion tendency; the welding process performance is good, electric arcs are stable, splashing is small, weld joint forming is attractive, and vertical downward welding can be achieved through short-circuit transition; and the welding wire is simple in production process, reasonable in alloy system design and low in comprehensive cost.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

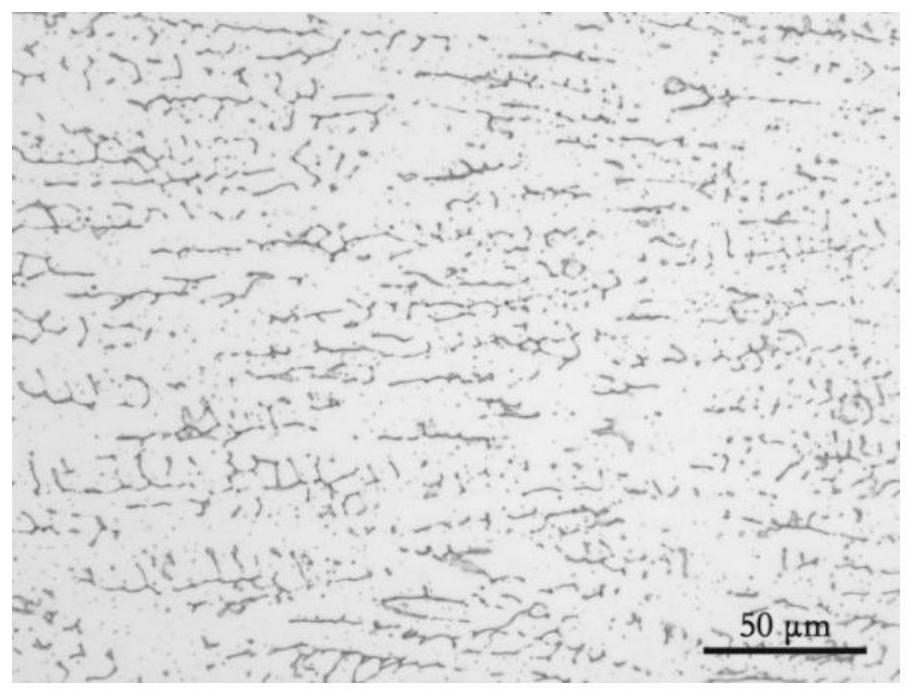

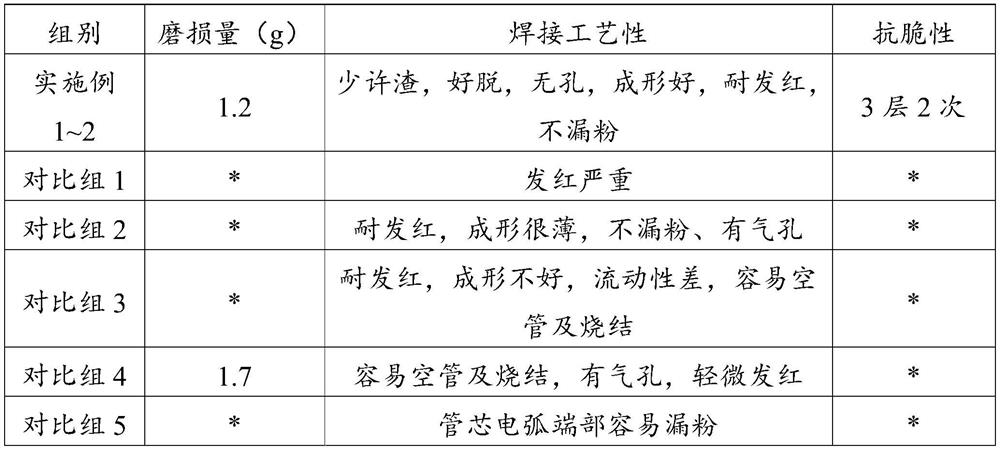

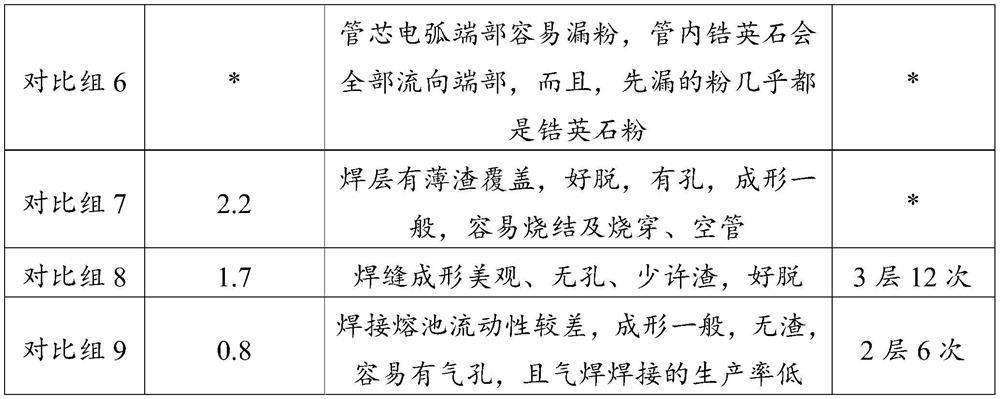

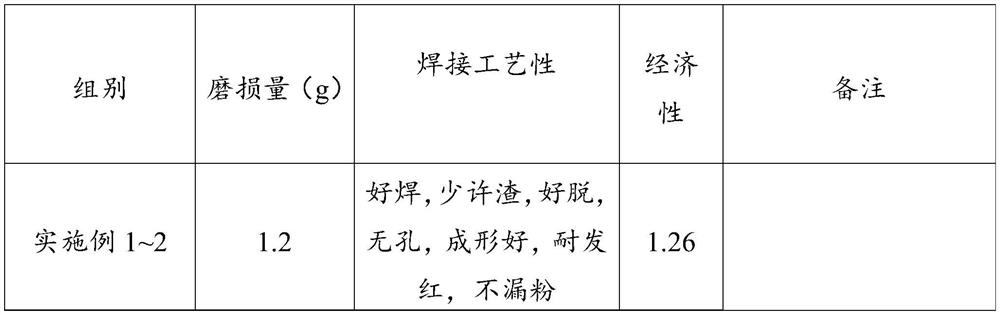

High-wear-resistance flux-cored electrode and preparation method thereof

ActiveCN112222670AHigh hardnessEfficient removalWelding/cutting media/materialsSoldering mediaChromiumTungsten carbide

The invention discloses a high-wear-resistance flux-cored electrode and a preparation method thereof. The electrode comprises a pipe body, a flux core and a coating; the pipe body is filled with the flux core; the coating wraps the pipe body; the flux core is prepared from the components including tungsten carbide and boron carbide, and the weight ratio of the tungsten carbide to the boron carbidein the flux core is 1:1; and the coating is prepared from the components including, by weight, 40.0%-45.0% of tungsten carbide, 3.0%-7.0% of graphite powder, 21.0%-26.0% of chromium equivalent, 13.0%-21.0% of high-potassium feldspar powder and 1.0%-23.0% of nominal iron powder. According to the electrode, the problems that powder leaks from the end of a welding arc, a pipe coating and a coating become red, a flux core is prone to oxidation or serious sintering and the like can be avoided, meanwhile, the relatively high stripping resistance, welding process and economical efficiency are achieved, the coating and the pipe core are resistant to reddening, the porosity resistance, the stripping resistance, the cost performance and the like are superior to those of existing similar electrodesor gas welding tubular tungsten carbide rods, the welding seam metal hardness is high, and the wear resistance is excellent.

Owner:广州鑫钻新材料科技开发有限公司

Gas metal arc welding flux-cored wire used for ultralow-temperature high-manganese steel

InactiveCN112894199AAchieve strength requirementsExcellent ultra-low temperature toughnessWelding/cutting media/materialsSoldering mediaIron powderManganese

The invention relates to a gas metal arc welding flux-cored wire used for ultralow-temperature high-manganese steel. According to the technical scheme, the gas metal arc welding flux-cored wire used for the ultralow-temperature high-manganese steel is composed of 65-70 wt% of a steel strip and 30-35 wt% of flux core powder; the steel strip comprises the following chemical components: 0.10-0.20 wt% of C, 0.01-0.05 wt% of Si, 3-7 wt% of Mn, less than or equal to 0.002 wt% of P, less than or equal to 0.001 wt% of S, and the balance Fe and inevitable impurities; and the flux core powder comprises the following chemical components: 28-34 wt% of rutile, 2-4 wt% of zircon sand, 2-4 wt% of potassium titanate, 20-25 wt% of electrolytic manganese, 8-15 wt% of nickel powder, 8-12 wt% of high-carbon ferro-chrome, and the balance iron powder. According to the gas metal arc welding flux-cored wire used for the ultralow-temperature high-manganese steel, all-position welding can be achieved, and the welding efficiency is high; and formed weld metal is good in forming, low in pore sensitivity and excellent in low-temperature toughness, and the strength matches that of the ultralow-temperature high-manganese steel.

Owner:浙江鸿途焊接科技有限公司 +2

Welding method for gas shielded welding of aluminium-alloy vehicle body

InactiveCN103447664AHigh strengthSmall splashArc welding apparatusWelding/cutting media/materialsSurface oxidationEngineering

The invention discloses a welding method for gas shielded welding of an aluminium-alloy vehicle body. The welding method comprises the following specific steps of: in welding, spraying a layer of pasty welding agent on an assembled welding seam base material in advance, wherein the pasty welding agent is 10-15mm in width and 50-200mum in thickness; when the welding agent entering a low-temperature area at the periphery of the temperature field of the arc reaches the melting temperature (560 DEG C) along with the movement of welding arc along the direction of a welding seam, immediately melting the welding agent into a liquid film, quickly wetting the surface of the base material, removing an oxidation film on the surface of the base material, and then covering the surface of the base material and the surface of metal in a molten pool. The welding method disclosed by the invention has the advantages that the welding process can be finished only by using the heat inputted in arc welding to melt the base material with the melting point of being 570-640 DEG C and welding wires as electrodes; aluminium-alloy MIG gas shielded welding connection of the high-strength vehicle body can be realized only by inputting low heat, the process is excellent, and the performance of joints is stable and good.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

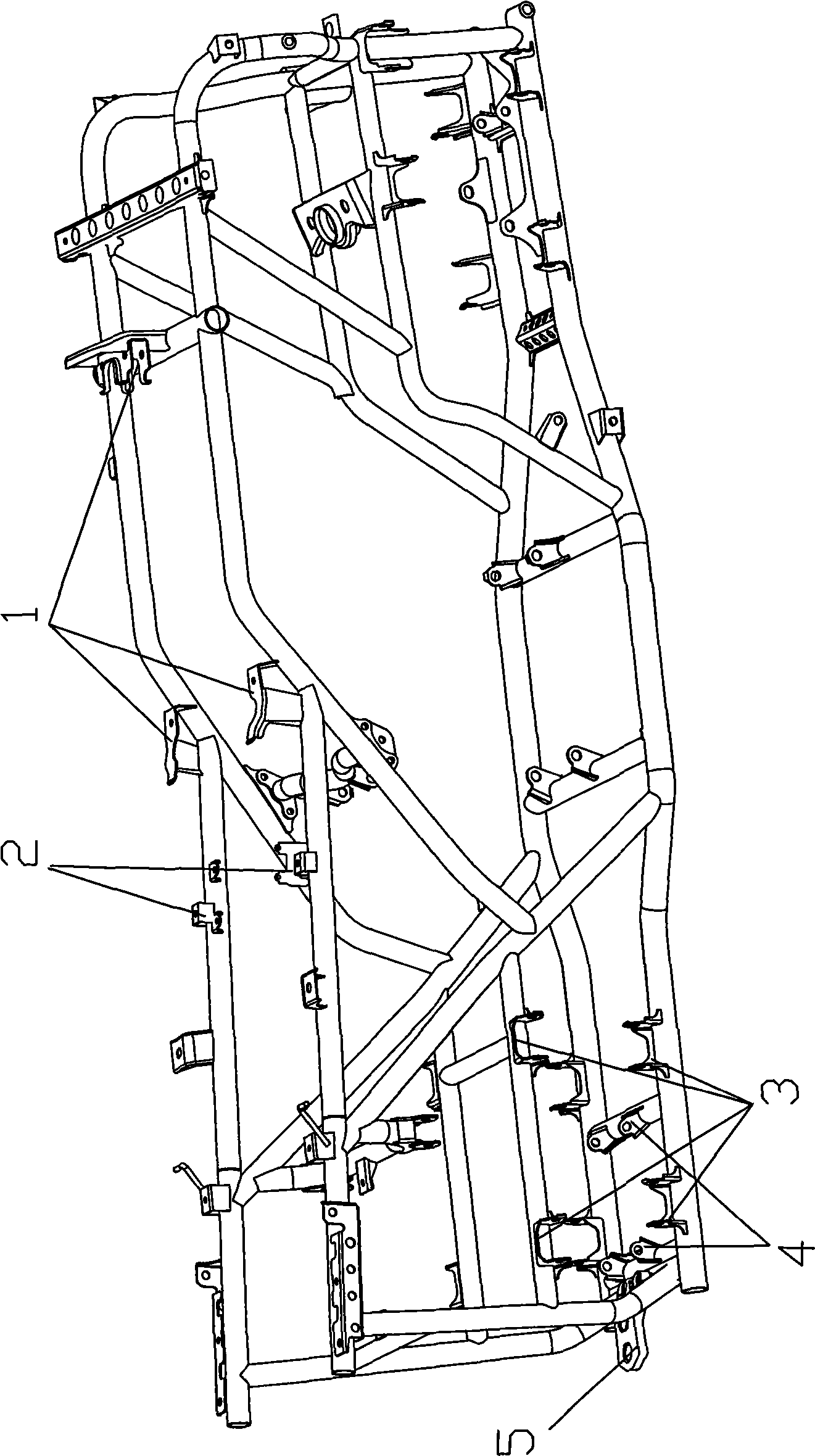

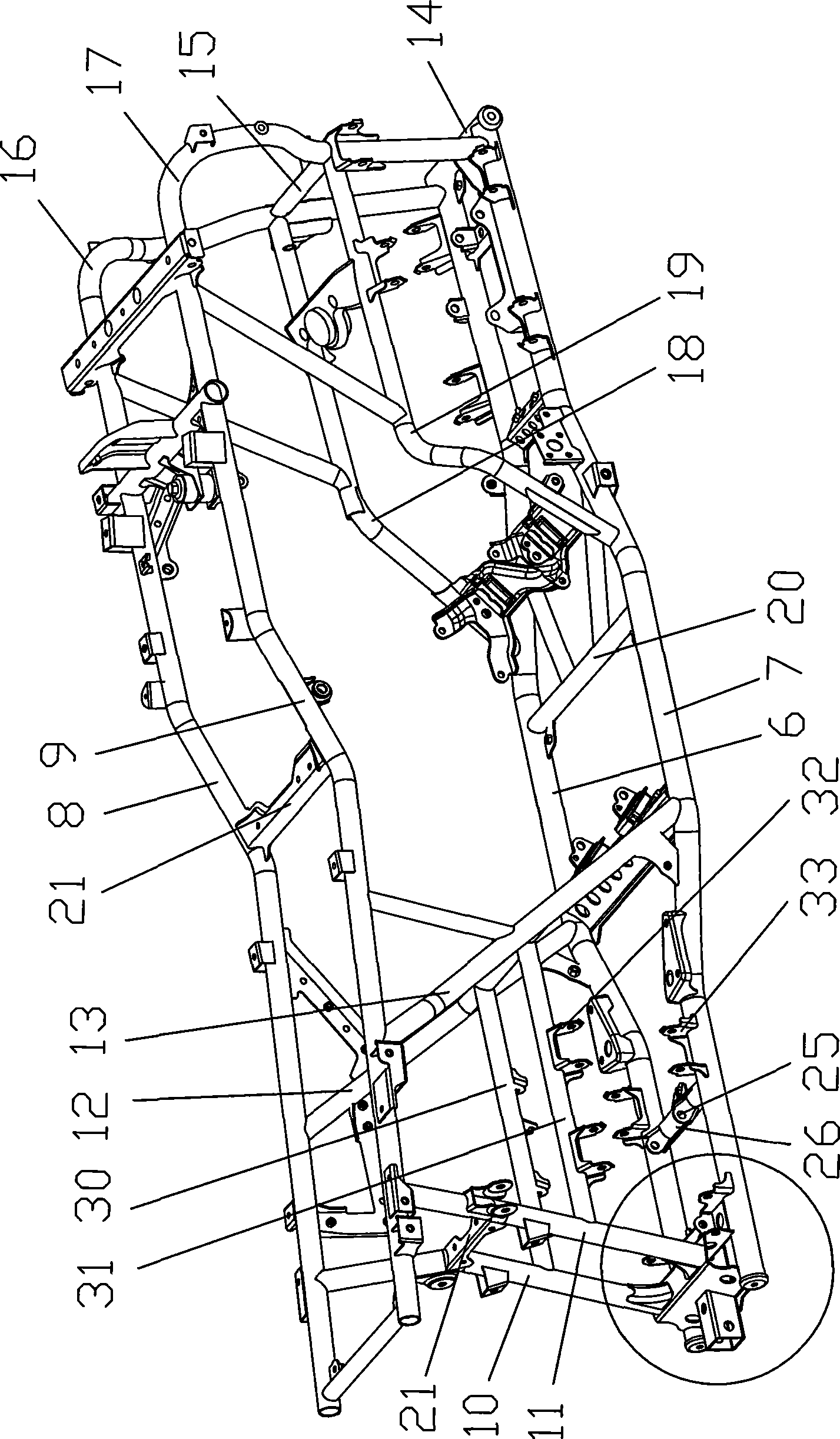

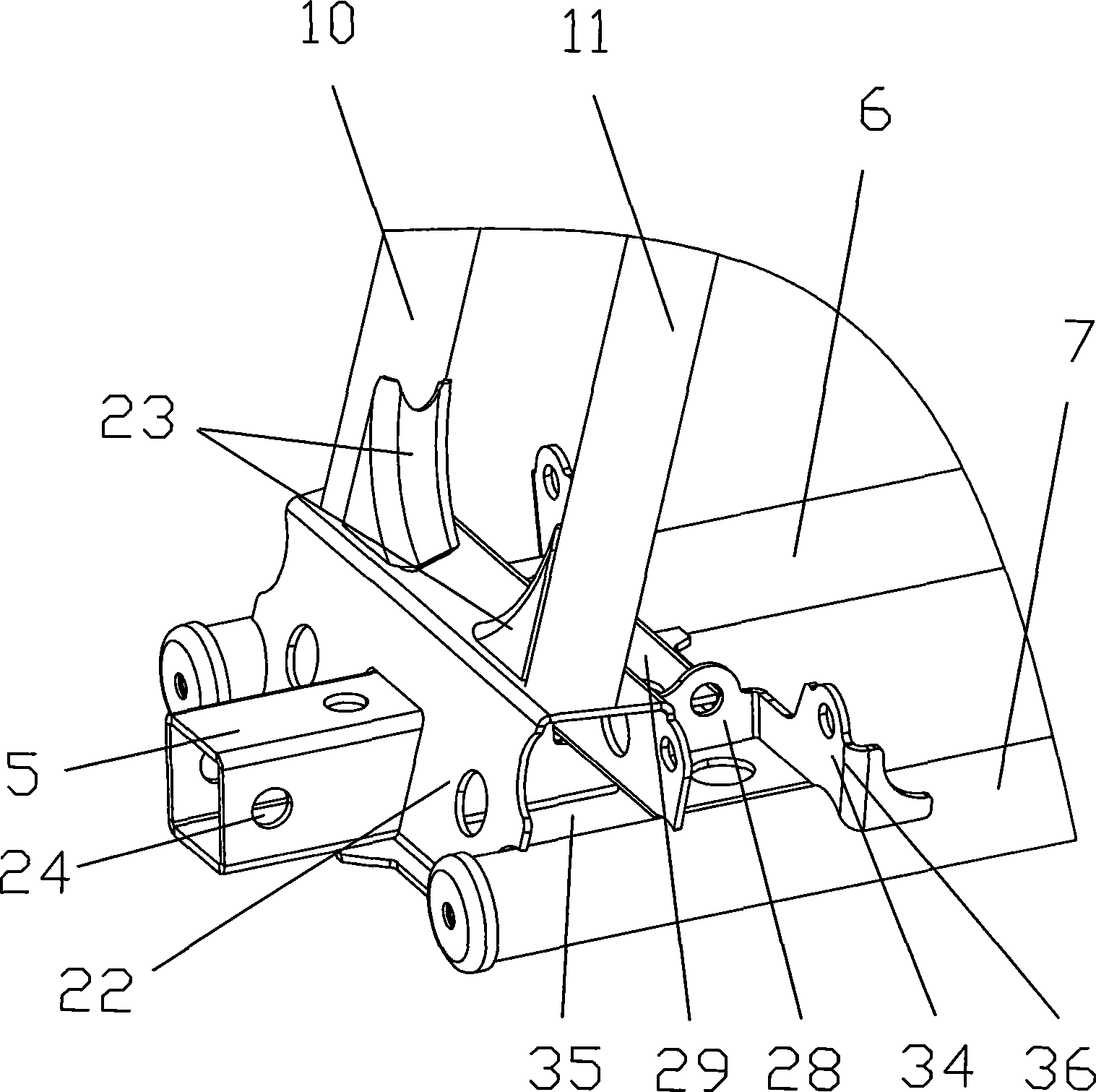

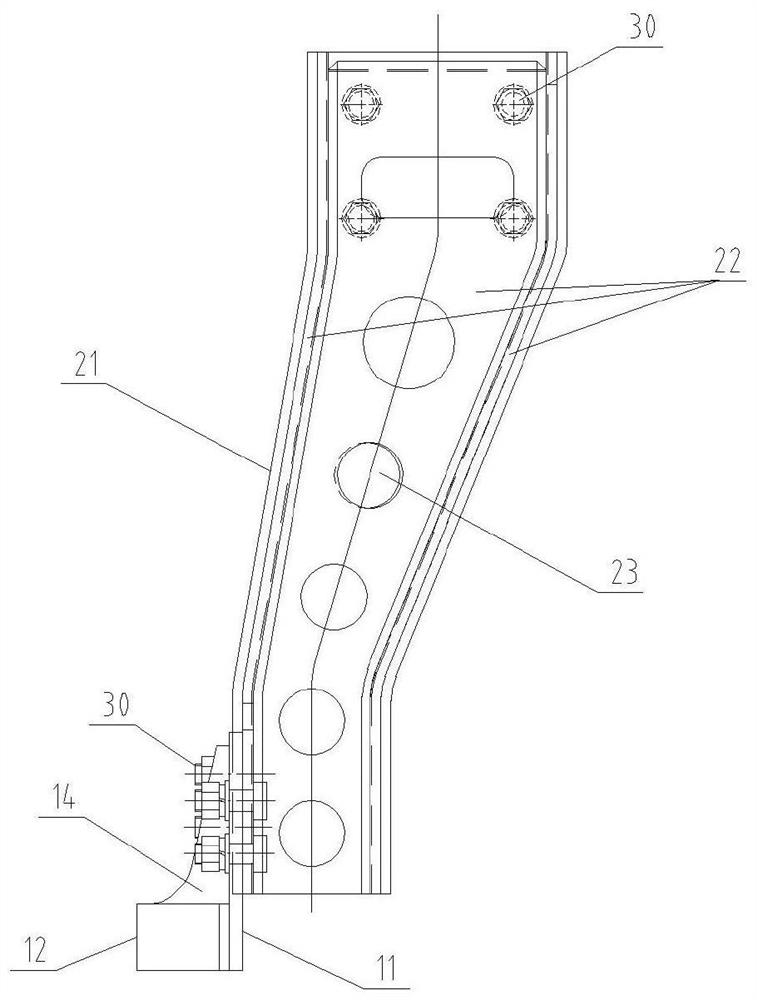

Frame assembly of all-terrain vehicle

InactiveCN101544256AConsolidate connection strengthReasonable structureMotorcyclesManufacturing cost reductionVehicle frame

The invention discloses a frame assembly of an all-terrain vehicle. The rear of a main reducing gear which is provided with a lug, and a rocker part which is provided with a lug and towing are combined into a whole through a bottom tube rear composition board, and the towing, a rear rocker and the main reducing gear are mounted, positioned and combined into a sheet metal component as possible; and simultaneously, an air filter provided with a lug is arranged on the front of a frame, and an oil tank mounting plate is arranged on the rear of the frame, so that an oil tank is positioned on the rear of the frame and the air filter is positioned on the front of the frame. The frame assembly has compact structure, optimized spacial arrangement, light weight and more reasonable mass distribution of a whole vehicle, improves welding manufacturability and reduces welding frock to reduce manufacturing cost, and well guarantees strength and rigidity of the whole vehicle through reinforcing members.

Owner:CHONGQING LONCIN MOTOR

Alkaline welding rod coating capable of improving welding process property

InactiveCN1295056CFine splash particlesReduce manufacturing costWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

The alkaline welding rod coating with raised welding performance consists of: marble 39-45 wt%, silica mud 3-10 wt%, fluorite 16-25 wt%, metal Mn 2-4 wt%, Si-Fe alloy 0.5-3 wt%, Ti-Fe alloy 8-12 wt%, cellulose 0.5-1.0 wt%, titania 3-9 wt%, atomized iron powder 6-15 wt% and graphite+Na2CO3 1-2.5 wt%. The said components are mixed, and the mixture is then coated with sodium water glass as adhesive onto low alloy steel welding core to produce alkaline low alloy steel welding rod or onto carbon steel welding core to produce alkaline carbon steel welding rod. The alkaline welding rod with the welding rod coating has excellent welding performance.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

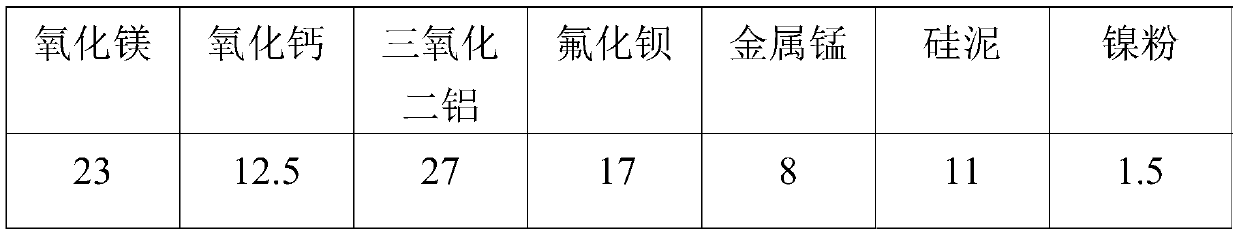

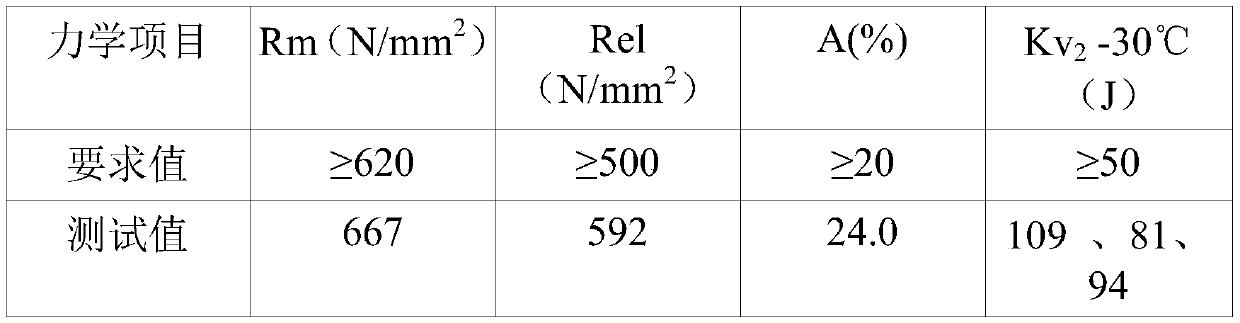

High-strength and high-toughness submerged arc horizontal welding agent and preparing method and application thereof

ActiveCN110052739AImprove welding processabilityHigh strengthArc welding apparatusWelding/cutting media/materialsElectrolysisManganese

The invention provides a high-strength and high-toughness submerged arc horizontal welding agent and a preparing method and application thereof. The high-strength and high-toughness submerged arc horizontal welding agent comprises welding agent powder and a bonding agent. The welding agent powder comprises following components including, by weight, 20-25 parts of magnesium oxide, 9-15 parts of calcium oxide, 25-30 parts of aluminum oxide, 15-20 parts of barium fluoride, 5-10 parts of electrolytic manganese metal, 8-12 parts of silicon mud and 1.5-2.5 parts of nickel powder. According to the high-strength and high-toughness submerged arc horizontal welding agent, the submerged arc welding agent is adopted, the deposited metal tensile strength reaches 620 MPa, the low-temperature ballistic work is high, the high-strength and high-toughness submerged arc horizontal welding agent is specially used for horizontal welding, deslagging is easy, forming is attractive, and the welding quality can be guaranteed.

Owner:TIANJIN YONGCHANG WELDING WIRES

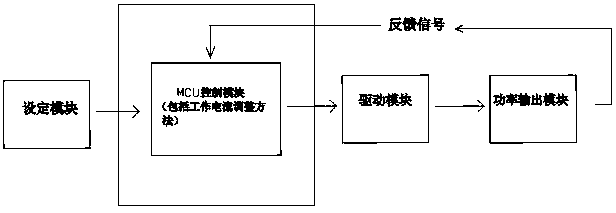

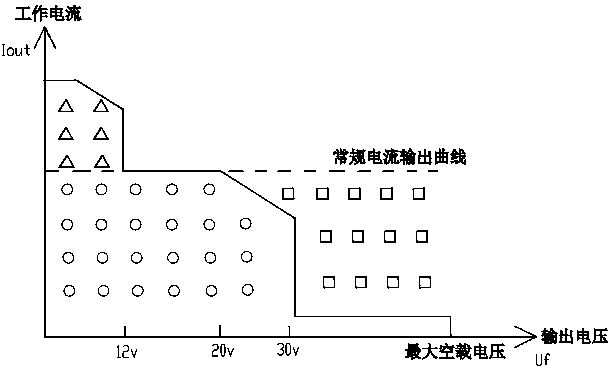

Method for adjusting working current of lithium electric welding machine

ActiveCN111390346AImprove welding processabilityImprove welding work efficiencyArc welding apparatusProcess engineeringElectric current flow

The invention discloses a method for adjusting working current of a lithium electric welding machine. The method comprises the following steps of 1, sampling welding voltage and current and sampling power supply voltage and current of a lithium battery; 2, according to a current-limiting / boundary current formula Iout = Ubat * Ibatmax * eta / Uf, calculating and judging an electric arc welding stateof the welding machine in a working process, and dynamically adjusting a welding current; and 3, outputting the adjusted welding current. Peak discharge and continuous discharge performance of a lithium battery system are fully utilized, a current-limiting / boundary current formula Iout = Ubat * Ibatmax * eta / Uf is suitable for a normal welding state, a short-circuit state and a long-arc state in the welding process, the welding current of a welding machine is not limited to a traditional cross-flow design mode, and the output current in a wider range can be obtained, so that the welding process performance is improved, the welding operation efficiency is improved, and the endurance is increased.

Owner:NANJING LEGENDALE ENERGY STORAGE CO LTD

Nickel-saving austenitic stainless steel welding rod for surfacing of Cr-Mo steel flange forge piece and preparation method of nickel-saving austenitic stainless steel welding rod

ActiveCN112846568AImprove crack resistanceAccelerated corrosionWelding/cutting media/materialsSoldering mediaCrack resistanceElectrolysis

The invention discloses a nickel-saving austenitic stainless steel electrode for surfacing of a Cr-Mo steel flange forge piece and a preparation method of the nickel-saving austenitic stainless steel electrode, and belongs to the technical field of welding materials. The nickel-saving economical austenitic stainless steel surfacing electrode is smooth and attractive in weld joint formation and has excellent crack resistance and intergranular corrosion resistance. The nickel-saving austenitic stainless steel electrode for surfacing of the Cr-Mo steel flange forge piece is composed of a welding core and a coating, wherein the coating is prepared from rutile, mica powder, potassium titanate, electrolytic manganese metal, fluorite, potassium feldspar, marble, cryolite, alkali, metal chromium powder and niobium powder according to the mass fraction. The preparation method comprises the following steps that firstly, the materials are mixed to obtain the coating, then the coating is uniformly mixed with pure sodium water glass, the welding core is coated with the coating, and baking is carried out at low temperature and high temperature to obtain the electrode. According to the electrode, manganese and nitrogen are combined to replace an alloy element nickel to obtain an austenite structure, the manufacturing cost is low, and the crack resistance and corrosion resistance of a material can be improved.

Owner:HARBIN WELDING INST LTD

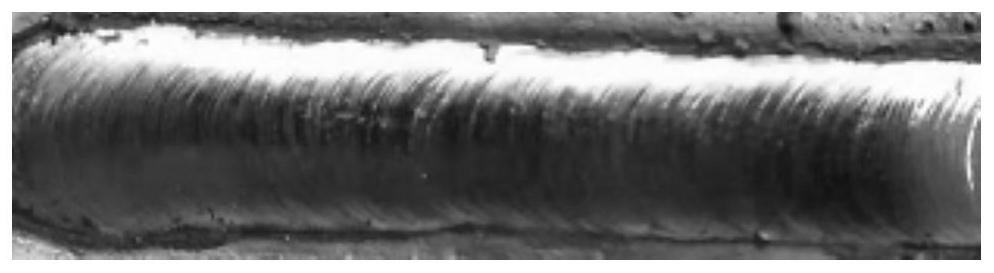

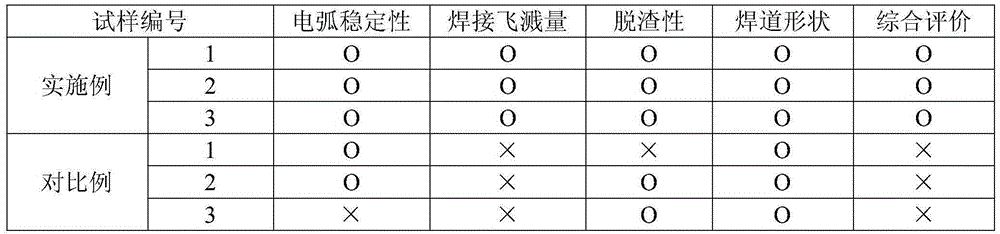

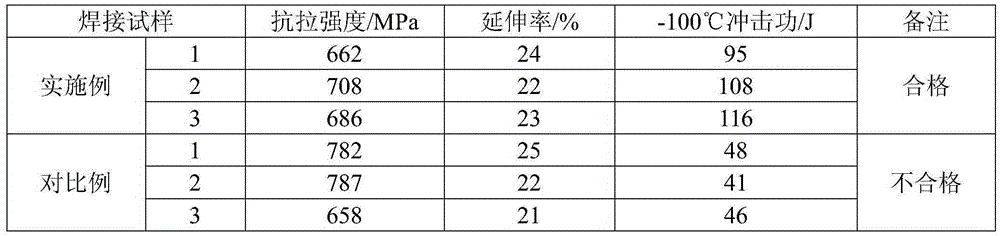

Low-spatter ultralow-hydrogen welding rod excellent in minus 100 DEG C impact toughness

InactiveCN106825997AReduce contentTackle splashWelding/cutting media/materialsSoldering mediaZirconCoating

The invention discloses a low-spatter ultralow-hydrogen welding rod excellent in minus 100 DEG C impact toughness. The low-spatter ultralow-hydrogen welding rod excellent in minus 100 DEG C impact toughness comprises a coating and a core wire, and is characterized in that the coating is composed of, by weight, 5-20% of marble, 1-5% of fluorite, 5-20% of cryolite, 1-5% of strontium carbonate, 0.1-3% of zircon, 0.1-0.5% of ferroboron, a proper amount of binder and the like; and the core wire is low-sulfur low-phosphorous low-alloy steel composed of, by weight, 0-0.1% of C, 0-0.004% of S and 0-0.005% of P. The welding rod is low in spatter, ultralow in weld metal hydrogen, excellent in low-temperature toughness and adaptive to all-position welding.

Owner:HAINING RUIAO METAL TECH CO LTD

Low hydrogen type electrode and preparation method thereof

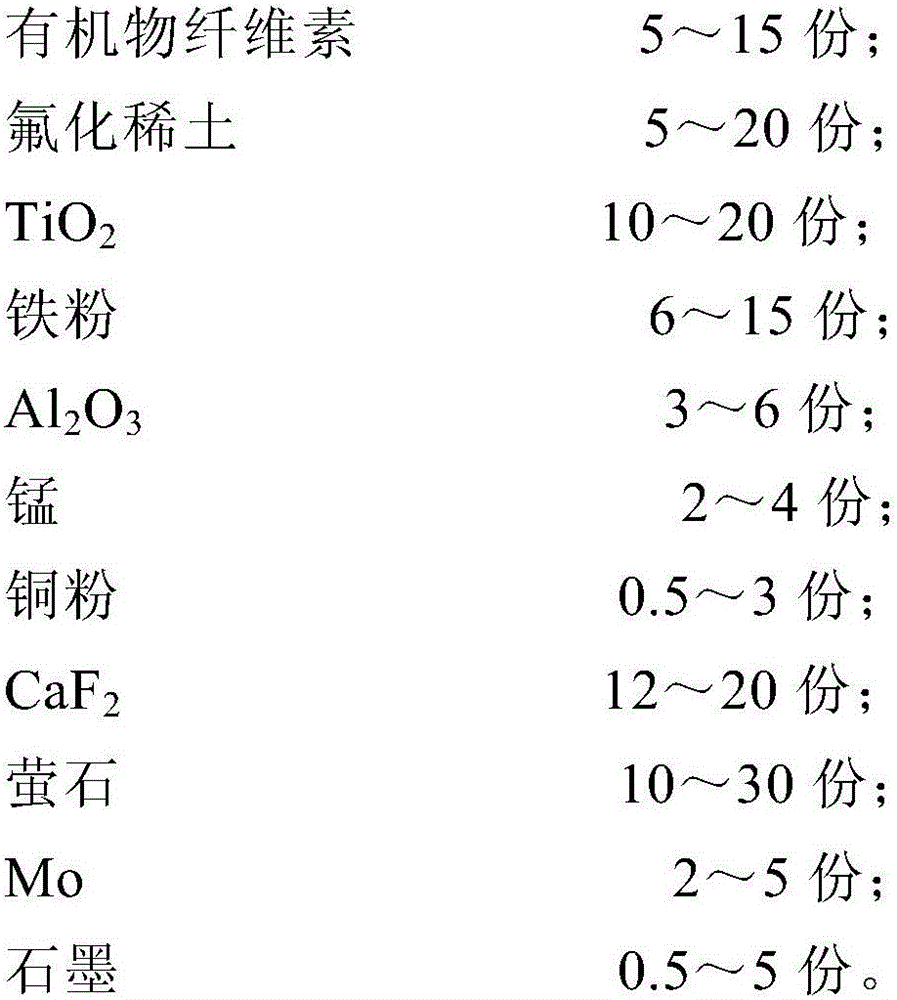

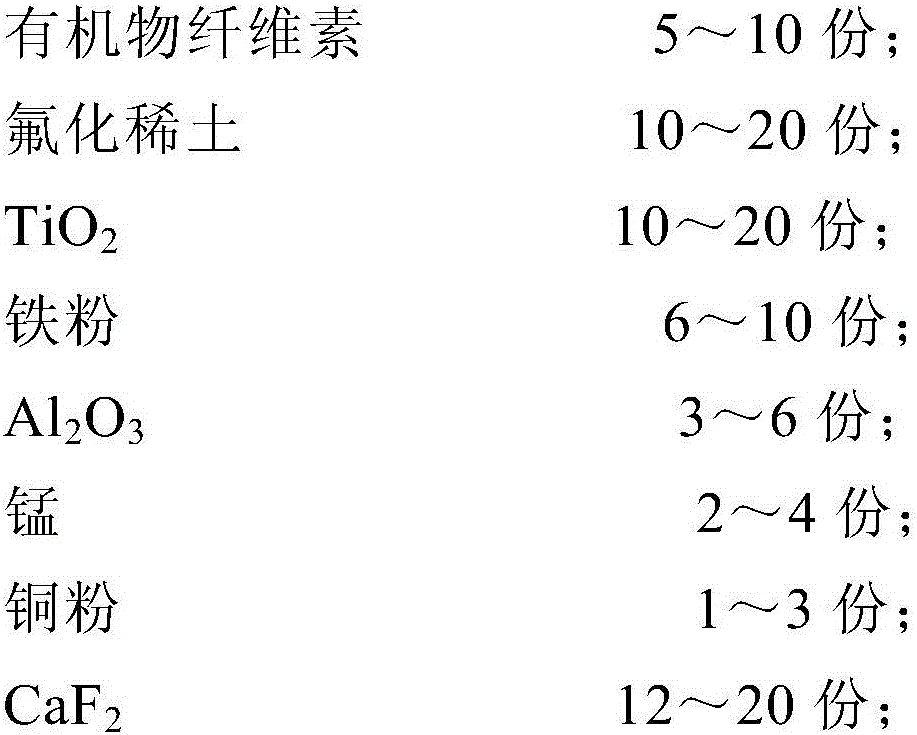

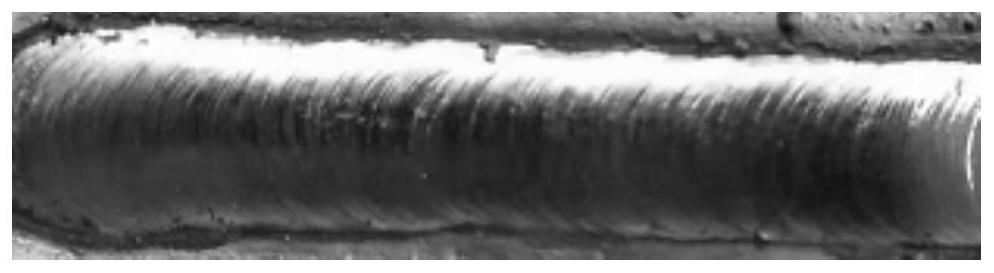

InactiveCN106624454ALower oxidation potentialForming small ripplesWelding/cutting media/materialsSoldering mediaCelluloseRare earth

The invention provides a low hydrogen type electrode and a preparation method thereof. The low hydrogen type electrode comprises a coating and a core wire. The core wire is a low-alloy steel. The coating is prepared from, by weight ratio, 5-15 parts of organic cellulose, 5-20 parts of rare earth fluoride, 10-20 parts of TiO2, 6-15 parts of iron powder, 3-6 parts of Al2O3, 2-4 parts of manganese, 0.5-3 parts of copper powder, 12-20 parts of CaF2, 10-30 parts of fluorite, 2-5 parts of Mo and 0.5-5 parts of graphite. The invention further discloses a preparation method of the low hydrogen type electrode. The low hydrogen type electrode is good in spreadability, small in splashed particles, excellent in fire resistant performance and good in technological operation performance.

Owner:DALIAN ZINTELLIGENCE TECH

Electrode coating

ActiveCN105057924BAbundant raw ore reservesRich reservesWelding/cutting media/materialsSoldering mediaIron powderSlag

The invention discloses a welding electrode coating. The welding electrode coating comprises components of, by mass, 15-65 parts of attapulgite of medium-low grades, 0-10 parts of quartz sand, 15-20 parts of dolomite, 19-50 parts of magnesia and 1-5 parts of iron powder. According to the welding electrode coating, used attapulgite raw ore is rich in reserve and low in price and provides a stable raw material source for coating welding, and welding electrodes obtained on the basis are low in cost, stable in arc and small in spattering particle during welding, prone to slag removal after welding, smooth and attractive in formed weld joint, low in welding dust generating rate, safe and non-toxic, good in economic and environment benefit and broad in application prospect.

Owner:盱眙凹土能源环保材料研发中心 +1

A nickel-saving austenitic stainless steel welding rod for overlay welding of cr-mo steel flange forgings and preparation method thereof

ActiveCN112846568BImprove crack resistanceAccelerated corrosionWelding/cutting media/materialsSoldering mediaElectrolysisCrack resistance

A nickel-saving austenitic stainless steel electrode for surfacing welding of Cr-Mo steel flange forgings and a preparation method thereof. The invention belongs to the technical field of welding materials. The purpose of the invention is to develop a nickel-saving economical austenitic stainless steel surfacing welding electrode with smooth and beautiful weld seam, excellent crack resistance and intergranular corrosion resistance. A nickel-saving type austenitic stainless steel electrode for surfacing welding of Cr-Mo steel flange forgings of the present invention is composed of a welding core and a coating, and the coating is composed of rutile, mica powder, potassium titanate, electrolytic metal according to the mass fraction Manganese, fluorite, potassium feldspar, marble, cryolite, alkali, metallic chromium powder and niobium powder. Method: first mix the materials to obtain the coating, then mix the coating with pure sodium water glass evenly, then coat the welding core, and obtain the welding rod after low-temperature and high-temperature baking. The welding rod of the invention uses manganese and nitrogen to replace the alloy element nickel to obtain an austenite structure, has low manufacturing cost, and can improve the crack resistance and corrosion resistance of the material.

Owner:HARBIN WELDING INST LTD

A kind of pulse mig welding arc control method

ActiveCN103203530BControl heat inputImprove performanceArc welding apparatusLoop closingControl manner

Owner:广州焊王电气科技有限公司

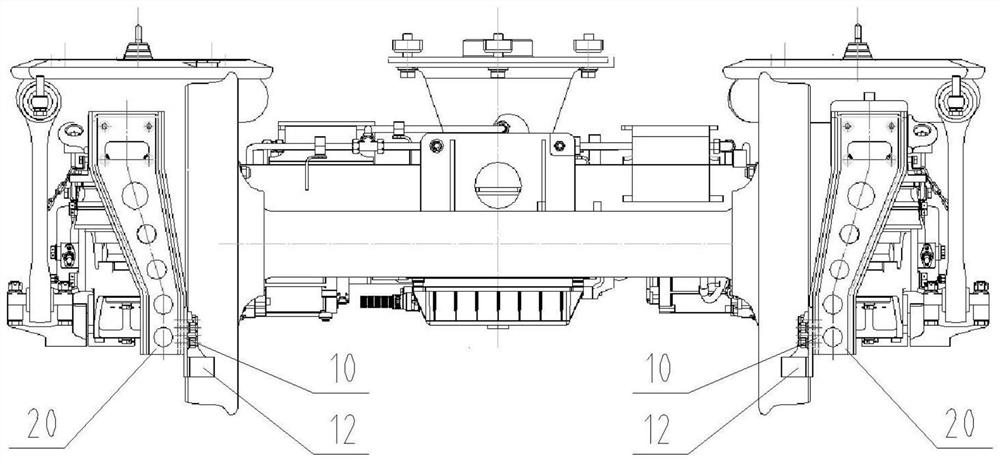

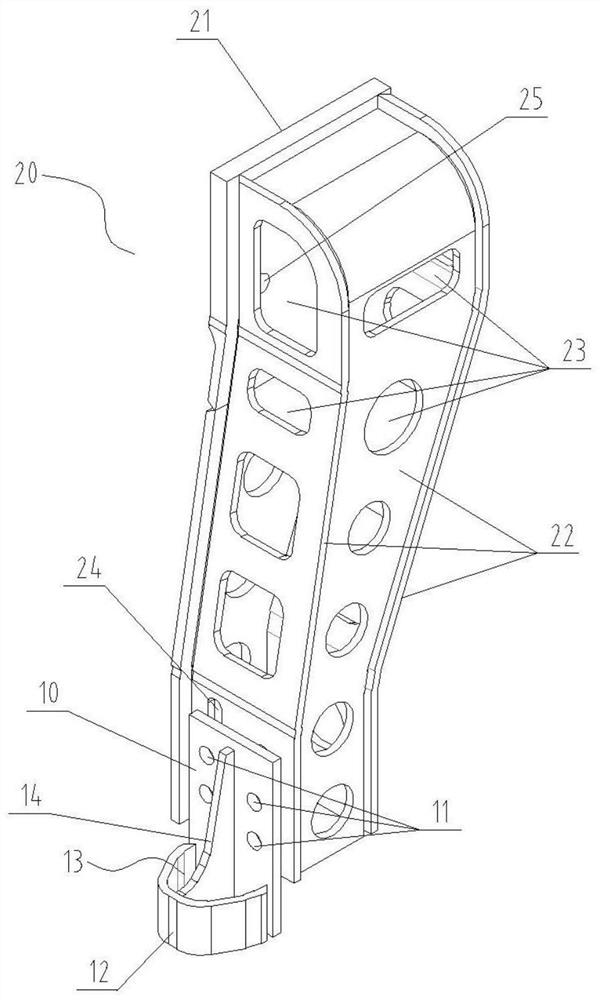

Cowcatcher, device and bogie

PendingCN114044018ASimple structureIncrease spaceRailway wheel guards/bumpersBogieStructural reliability

The invention discloses a cowcatcher, a device and a bogie, and belongs to the technical field of railway vehicle body parts, the cowcatcher is provided with a cowcatcher body part capable of being arranged on one side of a running rail, and the upper portion of the cowcatcher body part is provided with a mounting structure used for fixing the position of the cowcatcher body part. The lower portion of the cowcatcher body part is provided with a cowcatcher part which is used for being close to the rail face of a running rail and can protrude towards the central axis of the center in the running direction of a vehicle, and the two ends of the cowcatcher part are fixedly connected with the cowcatcher body part through a welding technology. The cowcatcher of the invention has a novel structure, the welding operation space and the observation space are increased, so that the welding manufacturability is improved, the structural reliability is high, and the service life is long.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Welding wire flux core and welding wire, method for preparing welding wire and welding method

ActiveCN112388202BSimple production processImprove plasticityArc welding apparatusWelding/cutting media/materialsMass fractionMetal

The invention provides a welding wire flux core, a welding wire, a preparation method and a welding method of the welding wire, and relates to the technical field of welding materials. The flux core is composed of the following chemical components in mass fractions: Mn: 1-6%; Si: 0.1-6% 5%; Mg: 0.1‑2%, Cr: 35‑50%; Ni: 15‑25%; Na 2 O and K 2 The sum of the mass fractions of O is 1‑10%; fluoride: 0.1‑2%; TiO 2 : 15‑30%; SiO 2 : 3‑10%; the balance is Fe and unavoidable impurities. After the welding wire provided by the present invention is used for surfacing, the tensile strength of the surfacing layer is 527-547 MPa, and the elongation is 38%. As the backing welding material of alloy steel flux-cored welding wire for surface surfacing, it can ensure heat preservation at 690 ° C. After 32 hours of heat treatment, the side bend (d=4t, α=180°) has no open cracks, and the surfacing layer metal has no intergranular corrosion tendency; and the welding process performance is good, the arc is stable, the spatter is small, the weld shape is beautiful, and the short-circuit transition is adopted Vertical downward welding can be realized; and the production process of the welding wire is simple, the design of the alloy system is reasonable, and the overall cost of the welding wire is low.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

A bright welding wire for ultra-supercritical coal-fired power station heat-resistant steel

ActiveCN108838579BImprove welding processabilityImprove surface cleanlinessWelding/cutting media/materialsSoldering mediaPower stationMetal

The invention discloses a bright welding wire for heat-resistant steel for an ultra-supercritical coal-fired power station and belongs to the technical field of welding materials. The welding wire comprises, by weight, 0.10-0.15% of C, 8.5-9.0% of Cr, 0.1-0.6% of Ni, 0.3-0.6% of Mn, 2.5-3.0% of Co, 2.0-2.7% of W, 0.020-0.035% of Nb, 0.001-0.010% of Zr, less than or equal to 0.006% of N, 0.16-0.20%of V, 0.003-0.010% of B, less than or equal to 0.20% of Si, less than or equal to 0.006% of P, less than or equal to 0.006% of S, less than or equal to 0.010% of O, less than or equal to 0.03% of Al,less than or equal to 0.01% of Ti and the balance Fe and inevitable impurity elements. The bright welding wire has the advantages that the welding wire has good welding process performance and excellent deposited metal flowability and formability, and the deposited metal after welding has excellent mechanical properties and good room temperature impact toughness.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

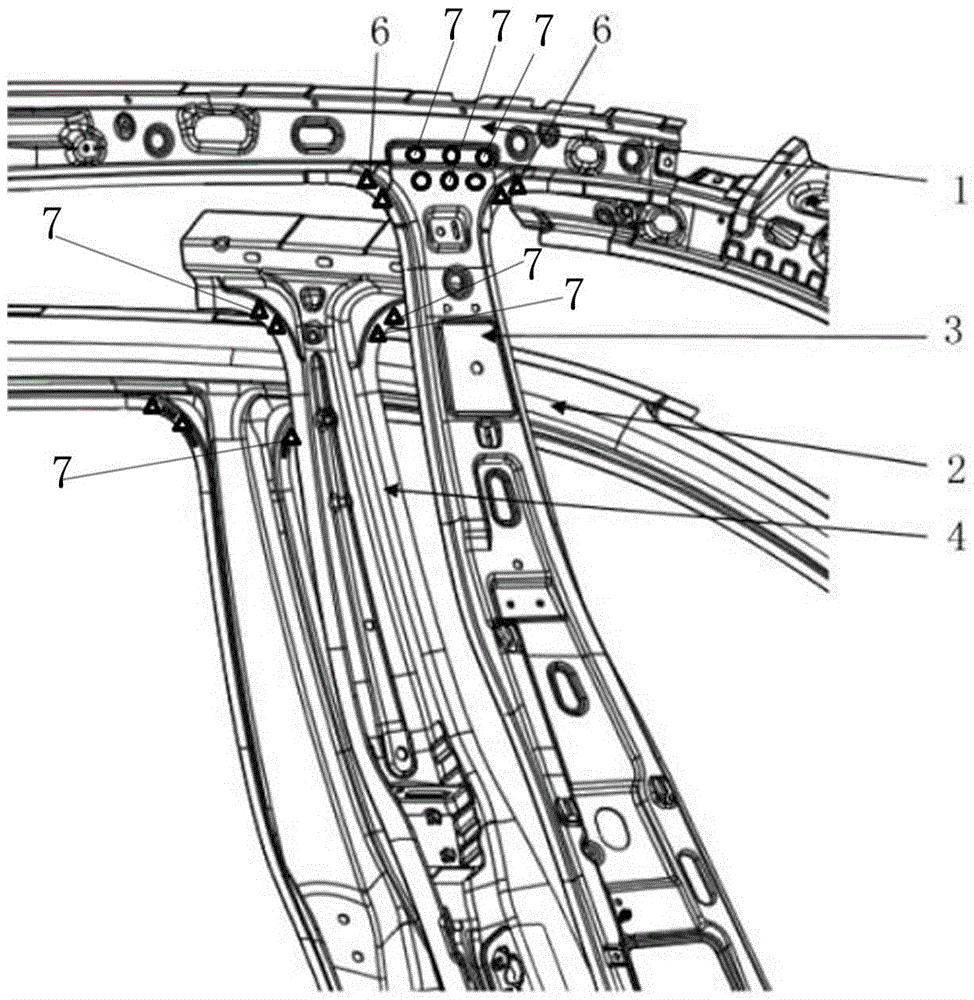

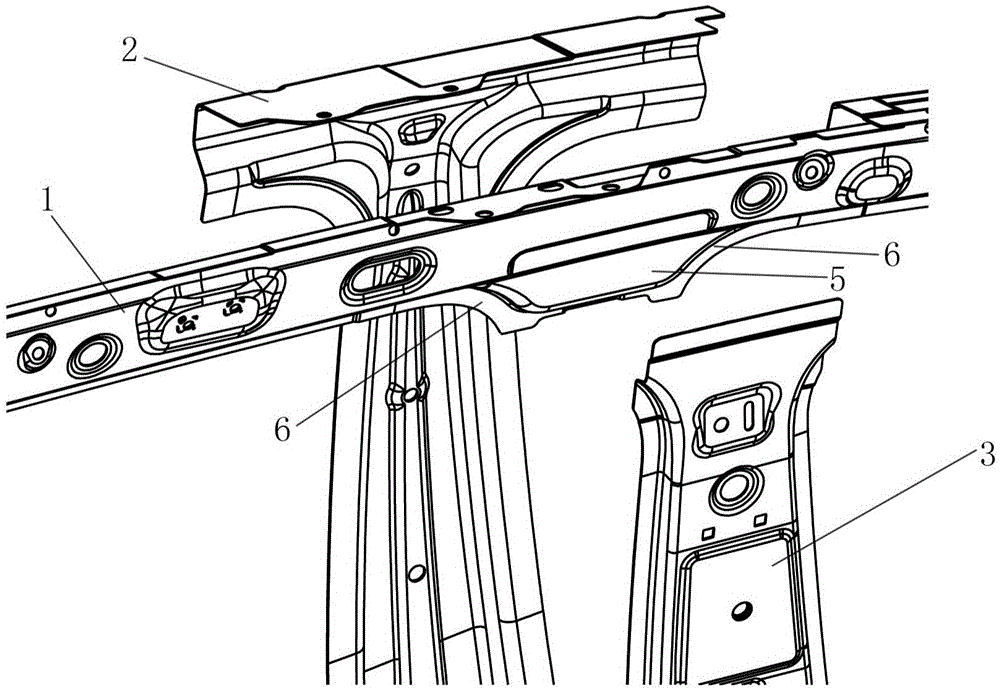

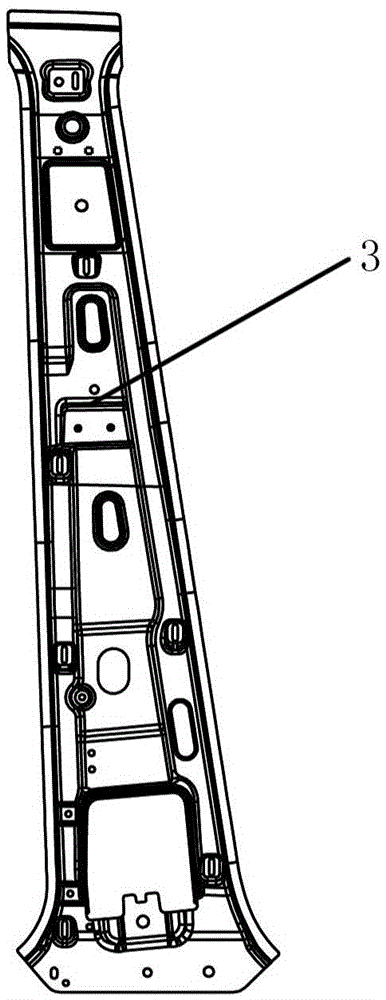

A b-pillar upper end joint structure

ActiveCN103538635BGuaranteed firmnessImprove securitySuperstructure subunitsStress concentrationBiomedical engineering

The invention discloses a B-pillar upper end connector structure. The B-pillar upper end connector structure comprises a cantrail inner panel, a body side outer panel, a B-pillar inner panel and a B-pillar reinforced panel. The upper portion of the B-pillar inner panel is fixedly connected with the cantrail inner panel, the body side outer panel, the cantrail inner panel and the B-pillar reinforced panel are fixedly connected, the body side outer panel, the B-pillar inner panel, and the B-pillar reinforced panel are fixedly connected, the B-pillar inner panel is in the shape of an I, the position of the cantrail inner panel, which is separately fixed onto the B-pillar inner panel, is provided with an outwards-protruding stepped surface, an arc-shaped transition section is arranged between the stepped surface and the cantrail inner panel, and the upper portion of the B-pillar inner panel is fixedly connected with the stepped surface. The B-pillar upper end connector structure is simple, the fillet portion of the B-pillar upper end can avoid four-layer welding, the manufacturability of welding can be improved, gaps can be avoided, the stress value can be reduced, stress concentration can be avoided, costs can be reduced, and performance can be improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

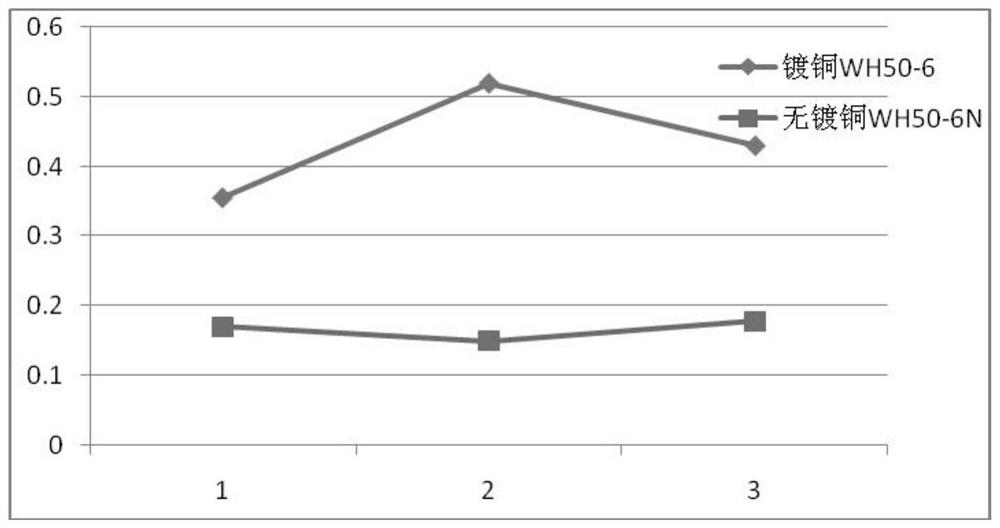

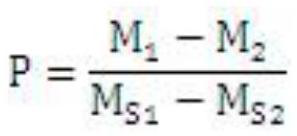

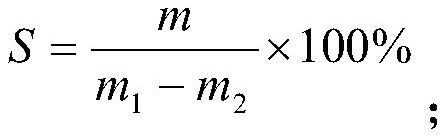

A surface coating material for copper-free welding wire, its preparation method and application

ActiveCN111644778BImproved arc stabilityReduce wear rateWelding/cutting media/materialsSoldering mediaArc stabilityCopper plating

The invention provides a surface coating material for copper-free welding wire and its preparation method and application. The surface coating material includes the following components in mass percentage: 85-90% of base oil, polytetrafluoroethylene 4-10%, nano-titanium dioxide 1-2%, tin oxide 0.6-1.3%, nano-antimony powder 0.2-0.6%, arc stabilizer 1.5-2.5%. The invention improves the wire feeding performance by adding nano-titanium dioxide, nano-antimony powder and other components, reduces the wear rate of the contact tip, and takes into account excellent electrical conductivity. At the same time, the addition of arc stabilizers such as potassium borate and sodium carbonate improves the arc of copper-free welding wire. Stability, reducing spatter, so that the welding process has been greatly improved. The coefficient of variation of current and voltage is reduced by 5-10% and the spatter rate is reduced by 10-15% through Hannover quantitative measurement.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Arc voltage induction wire feeder

Owner:北京坤和兴业科技有限公司

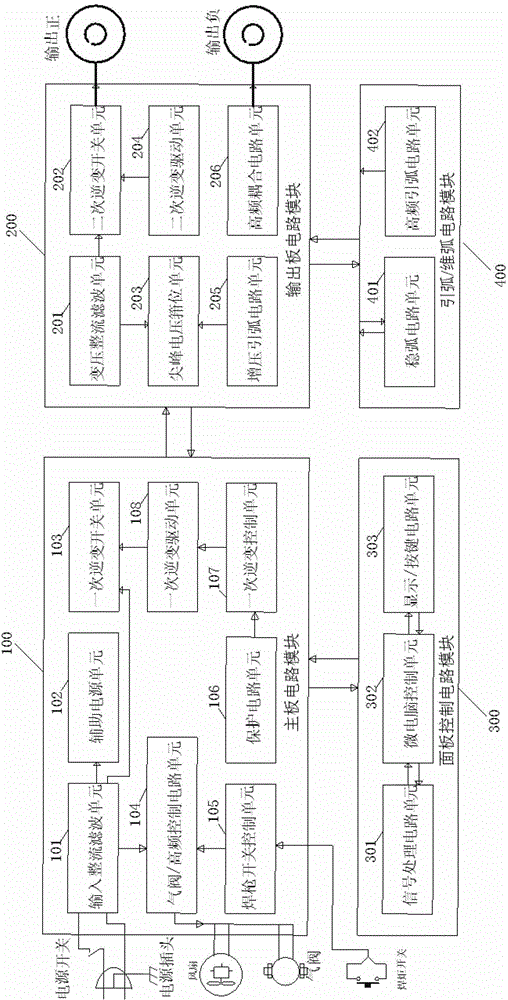

Double-contravariant alternating square wave argon tungsten-arc welder and control method thereof

ActiveCN103084711BIntuitive displayEasy to operateArc welding apparatusCoupling inductorElectric cables

The invention discloses a double-contravariant alternating square wave argon tungsten-arc welder which comprises a main board circuit module, an output board circuit module, a panel control circuit module and a striking arc / pilot arc circuit module. An input end of the main board circuit module is connected with an external alternating input power plug through a power switch. An output end of the main board circuit module is connected with an input end of the output board circuit module through multi-core range cables. A positive output connector and a negative output connector of the welder are respectively connected with an output end of the output board circuit module through copper bar cables. The panel control circuit module is connected with a control end mouth of the main circuit module through multi-core range cables. An input end of the striking arc / pilot arc circuit module is connected with a control end mouth of the output board circuit module through multi-core range cables. An output end of the striking arc / pilot arc circuit module is connected with an output end mouth of the output board circuit module through a high frequency coupling inductor. The double-contravariant alternating square wave argon tungsten-arc welder is used for reducing power consumptions of a power supply, saving material costs, volume of compressing whole machine and weights of the whole machine, increasing portability of the welder, and improving duty cycle.

Owner:SHANGHAI GREATWAY WELDING EQUIP

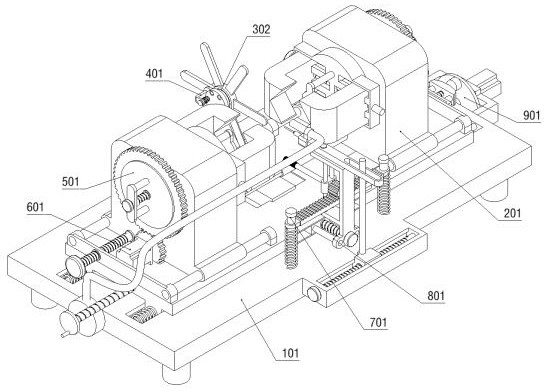

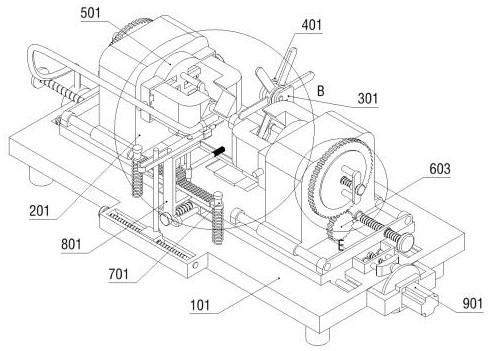

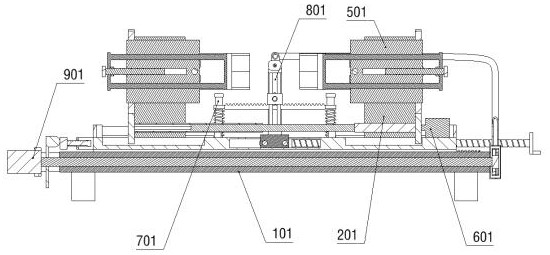

Outer edge welding device for hydraulic cylinder manufacturing

ActiveCN114589439AWeld firmlyLow costWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderStructural engineering

The invention provides an outer edge welding device for hydraulic cylinder manufacturing, and relates to the technical field of hydraulic cylinder welding. Two sliding adjusting parts are mounted on the mounting supporting part; the structures on the two sliding adjusting parts are the same; a movable seam clamping device is connected to the mounting supporting part in a sliding manner; the movable seam clamping device is fixedly connected with an elastic positioning device; the two sliding adjusting parts are rotationally connected with rotating mounting parts correspondingly. Arc-shaped swing welding can be achieved, welding is firmer, the overall linkage performance is higher, and auxiliary smoke removal and cleaning work can be achieved; the problems that an existing outer edge welding device for hydraulic cylinder manufacturing is low in overall installation precision, meanwhile, welding is not stable enough, simultaneous rotating welding cannot be achieved, meanwhile, flexible welding line adjustment cannot be achieved, the welding quality is affected, meanwhile, arc swing welding cannot be achieved, and swing adjustment is not convenient and fast enough are solved.

Owner:江苏力速达液压有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com