Bright welding wire for heat-resistant steel for ultra-supercritical coal-fired power station

A coal-fired power station, ultra-supercritical technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of poor durability and high addition amount, and achieve the effect of improving welding manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

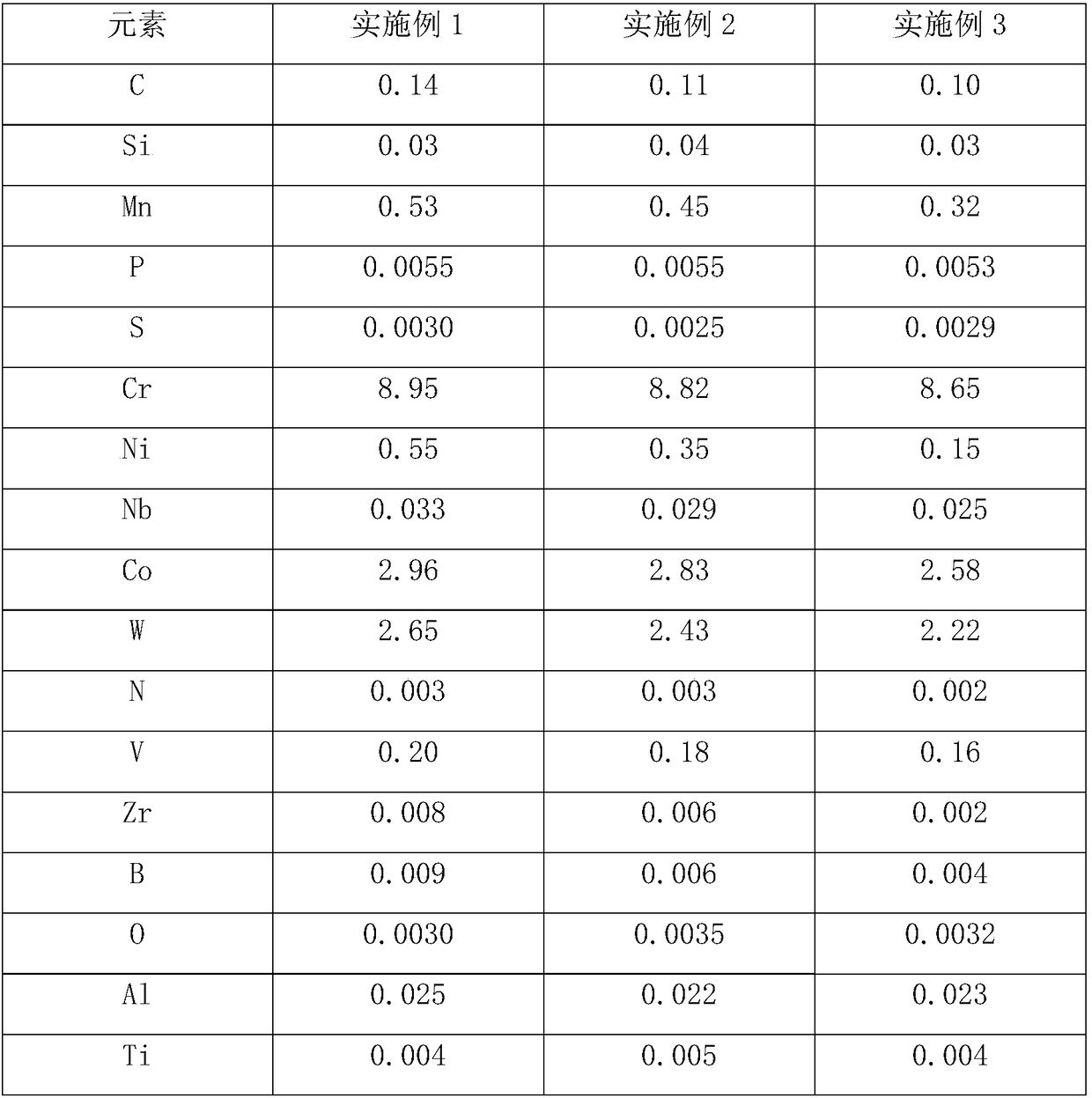

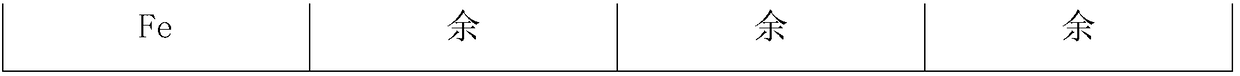

[0026] A bright welding wire for ultra-supercritical coal-fired power station heat-resistant steel, including C, Cr, Co, Mn, W, Nb, Zr, Ni, B, Fe elements, strictly controlled O, N, Al, Si, Ti content and P, S and other unavoidable impurity elements, the weight percent of each component obtained by actual measurement is shown in Table 1. The finished welding wire was welded by non-melting inert gas tungsten shielded welding and the corresponding data were tested. The performance test results of the deposited metal are shown in Table 2.

Embodiment 2

[0028] A bright welding wire (BYH15) for ultra-supercritical coal-fired power station heat-resistant steel and its preparation method, including C, Cr, Co, Mn, W, Nb, Zr, Ni, B, Fe elements, strict control of O, N , Al, Si, Ti content and P, S and other unavoidable impurity elements, the weight percentage of each component obtained by actual measurement is shown in Table 1. The finished welding wire was welded by non-melting inert gas tungsten shielded welding and the corresponding data were tested. The performance test results of the deposited metal are shown in Table 2.

Embodiment 3

[0030] A bright welding wire (BYH15) for ultra-supercritical coal-fired power station heat-resistant steel and its preparation method, including C, Cr, Co, Mn, W, Nb, Zr, Ni, B, Fe elements, strict control of O, N , Al, Si, Ti content and P, S and other unavoidable impurity elements, the weight percentage of each component obtained by actual measurement is shown in Table 1. The finished welding wire was welded by non-melting inert gas tungsten shielded welding and the corresponding data were tested. The performance test results of the deposited metal are shown in Table 2.

[0031] Chemical composition wt.% of welding wire of table 1 embodiment

[0032]

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com