A b-pillar upper end joint structure

A joint structure, B-pillar technology, applied in the superstructure, superstructure sub-assembly, transportation and packaging, etc., can solve the problems of cracking risk, stress concentration, virtual welding of solder joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

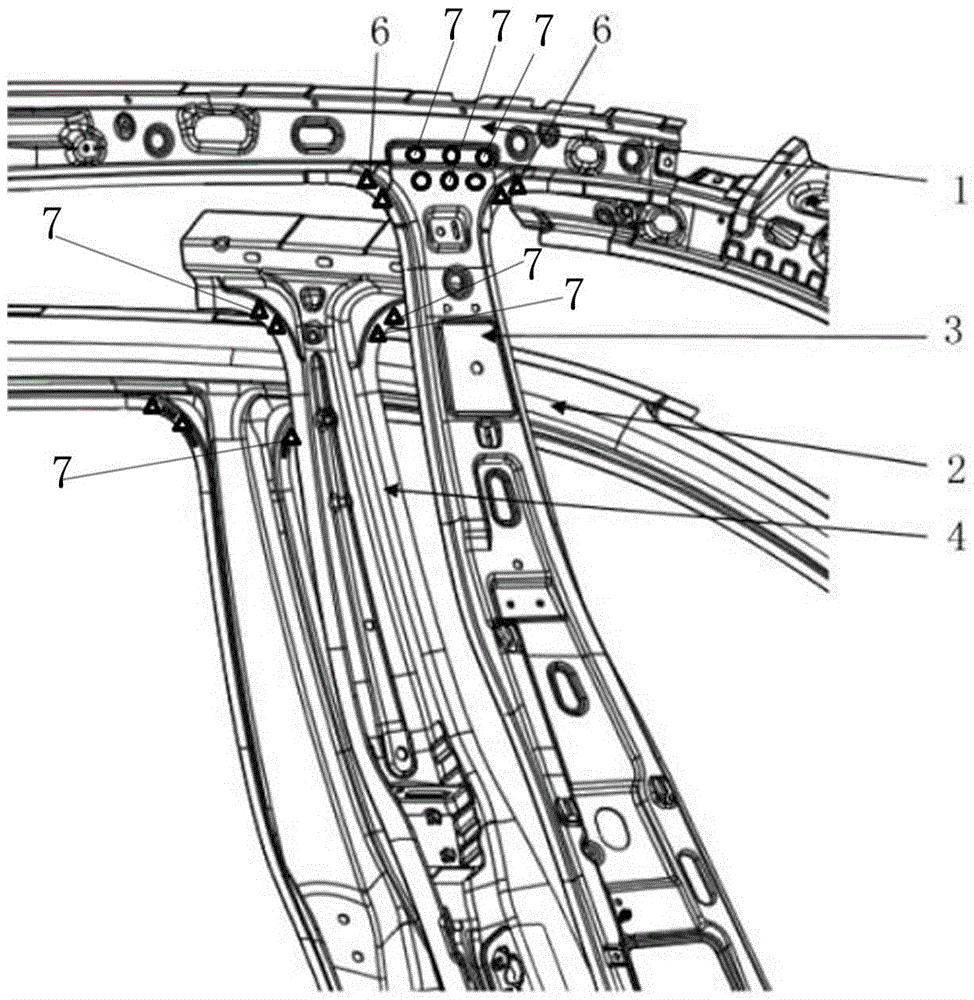

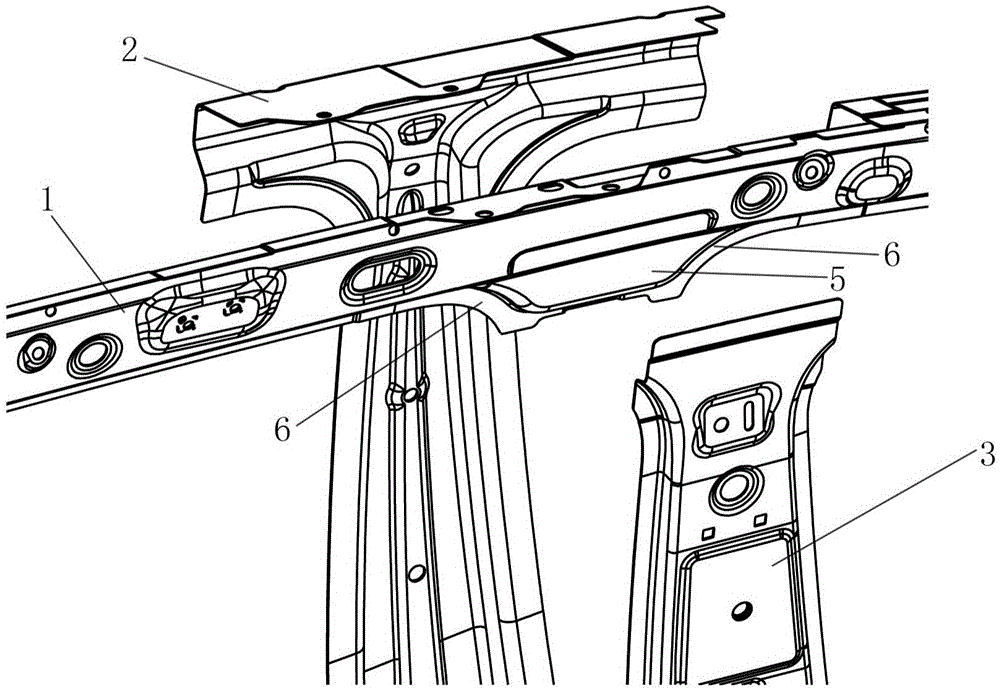

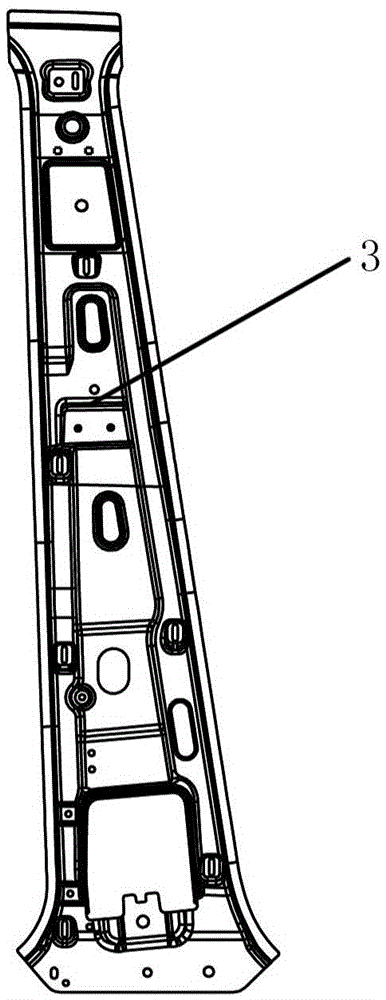

[0020] The following with attached Figure 1 to Figure 4 A B-pillar upper end joint structure of the present invention will be further described in detail.

[0021] A B-pillar upper end joint structure of the present invention, please refer to Figure 1 to Figure 4 , comprising a roof sill inner panel 1, a side wall outer panel 2, a B-pillar inner panel 3 and a B-pillar reinforcement plate 4, the upper part of the B-pillar inner panel 3 is fixedly connected to the roof sill inner panel 1, and the side wall outer panel Panel 2, the upper side sill inner panel 1 and the B-pillar reinforcement panel 4 are fixedly connected, the side wall outer panel 2, B-pillar inner panel 3 and B-pillar reinforcement panel 4 are fixedly connected, and the B-pillar inner panel 3 It is I-shaped, and the side sill inner panel 1 and the B-pillar inner panel 3 are separately fixed. An arc-shaped transition section 6 is provided, and the upper part of the B-pillar inner panel 3 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com