Modularization solar selective coat continuous coating device

A technology of coating equipment and solar energy, applied in the direction of coating, gaseous chemical plating, metal material coating process, etc., can solve the problems of no solution, waste, idle equipment, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described below in conjunction with accompanying drawing:

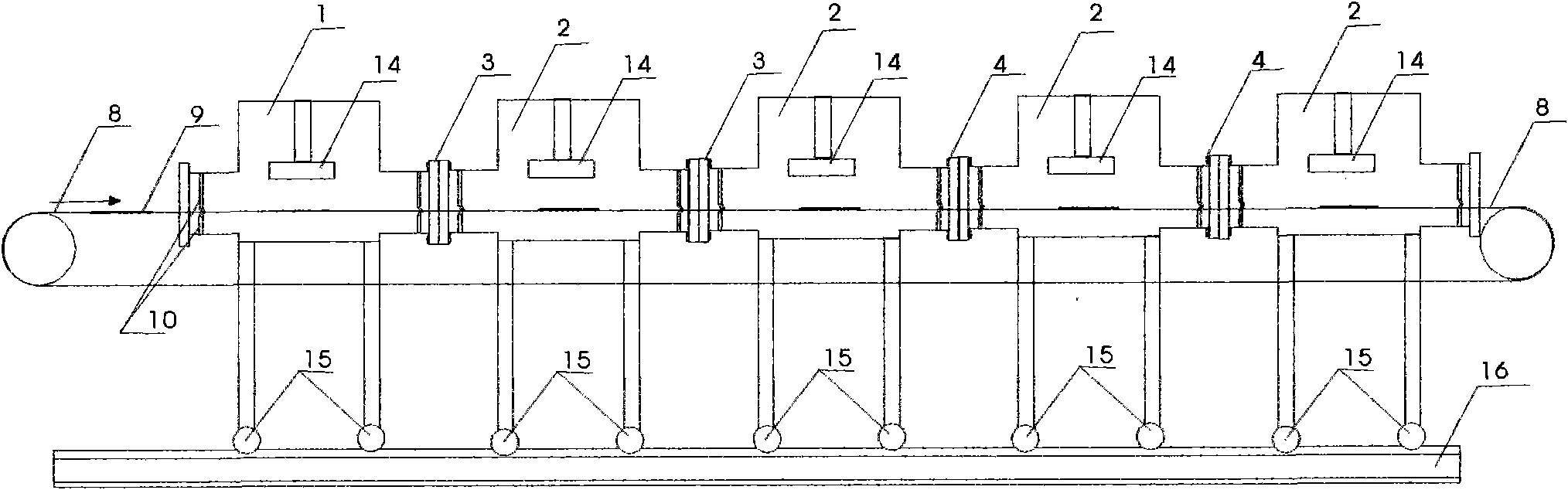

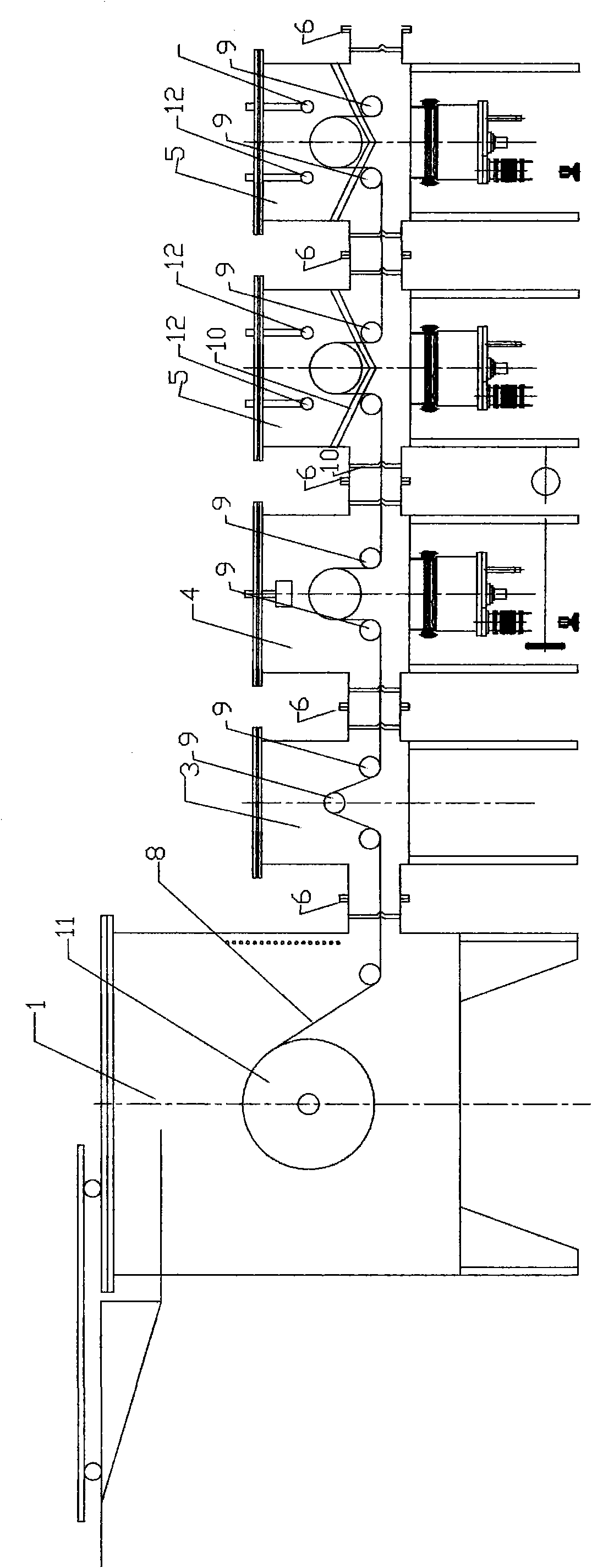

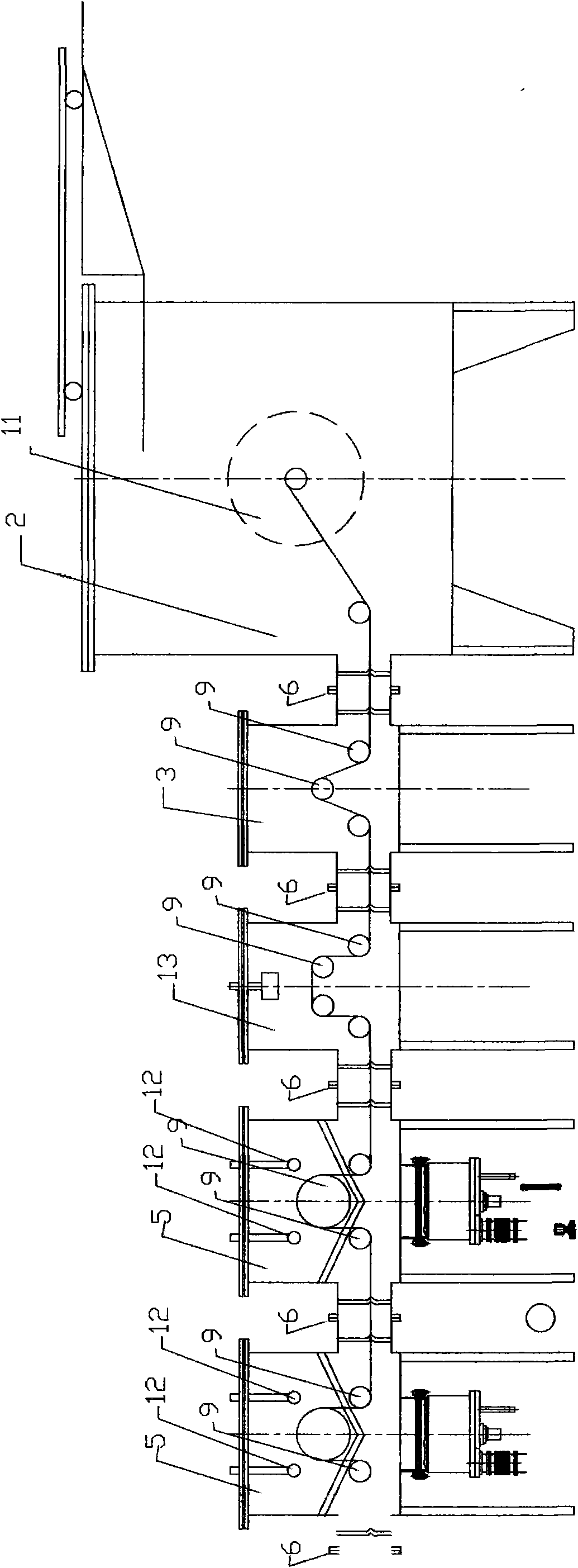

[0021] The design concept of the modularized equipment of the present invention can be applied to the improvement of existing equipment, and can also be used in brand new continuous coating equipment. Such as figure 1 Shown is a specific implementation of the present invention used in the improvement of existing equipment. For the existing coating production process, an independent studio is needed. This studio refers to the production equipment that can complete a single process step in the coating process. The previous equipment generally consists of a pretreatment chamber 1 and at least one process chamber 2. The pretreatment chamber 1 performs ion etching on the base material of the heat collector to clean up the impurities on the surface of the base material, and it can also be used for subsequent plating. The film layer has better adhesion and makes the film layer strong...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com