High-wear-resistance flux-cored electrode and preparation method thereof

An electric welding rod, high wear-resistant technology, applied in the direction of welding equipment, welding medium, manufacturing tools, etc., can solve the problems of limited, tube skin melting, changing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment provides a high wear-resistant flux-cored electrode, which includes a pipe body, a flux core filled in the pipe body, and a coating covering the pipe body; wherein, the mass of the flux core is 11.0% of the total mass of the electrode, The mass of the pipe body is 26.5% of the total mass of the electrode, and the mass of the coating is 62.5% of the total mass of the electrode. The drug core is composed of the following components in weight percentage: 50.0% of regenerated tungsten carbide and 50.0% of boron carbide. The coating is composed of the following components in weight percentage: 40.0% of regenerated tungsten carbide, 3.0% of graphite powder, 21.0% of metal chromium, 13.0% of high potassium feldspar powder and 23.0% of atomized iron powder.

[0056] In the welding electrode of this embodiment, the wall thickness of the pipe body is 0.4 mm, the inner diameter is Φ4.0 mm, the outer diameter of the coating is Φ7.2 mm, and the length of the electrod...

Embodiment 2

[0062] This embodiment provides a highly wear-resistant flux-cored electrode, which differs from Embodiment 1 only in the formulation of the coating. The coating of this embodiment is composed of the following components in weight percentage: 41.0% of regenerated tungsten carbide, 5.0% of graphite powder, 23.0% of metallic chromium, 18.0% of high potassium feldspar powder and 13.0% of atomized iron powder.

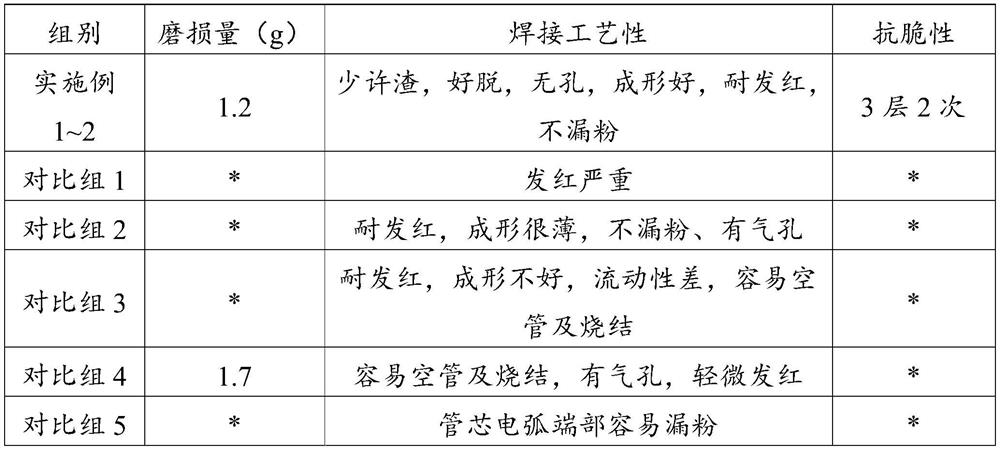

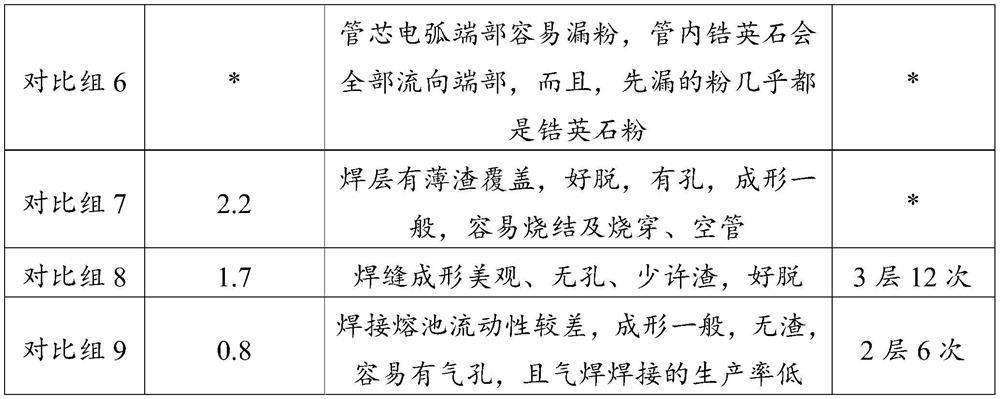

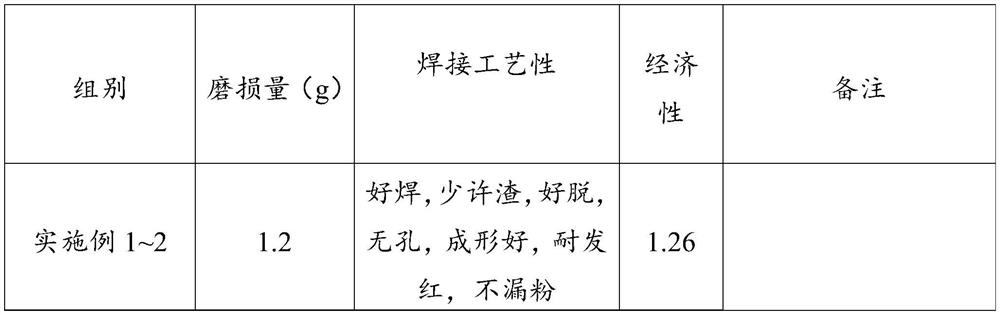

[0063] Test one:

[0064] In order to explore the influence of the flux core on the performance of the electrode, the following comparison groups 1 to 9 were set up:

[0065] Contrast group 1: The only difference from Example 1 is that the formulation of the drug core is different, and the drug core of the comparison group 1 is tungsten carbide.

[0066] Comparative group 2: The only difference from Example 1 is that the formulation of the drug core is different, and the drug core of the comparative group 2 is boron carbide.

[0067] Comparative group 3: the only differe...

Embodiment 3

[0100] This embodiment provides a highly wear-resistant flux-cored electrode, which differs from Embodiment 1 only in the formulation of the coating. The coating of this embodiment is composed of the following components in weight percentage: 42.0% of regenerated tungsten carbide, 7.0% of graphite powder, 26.0% of metallic chromium, 21.0% of high potassium feldspar powder and 4.0% of atomized iron powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com