Frame assembly of all-terrain vehicle

An ATV and frame technology, applied in the field of ATVs, can solve the problems of unreasonable arrangement of parts, increase the height of the center of gravity of the whole vehicle, unreasonable distribution of the whole vehicle mass, etc. Small intake stroke and intake resistance, beneficial to vehicle braking and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

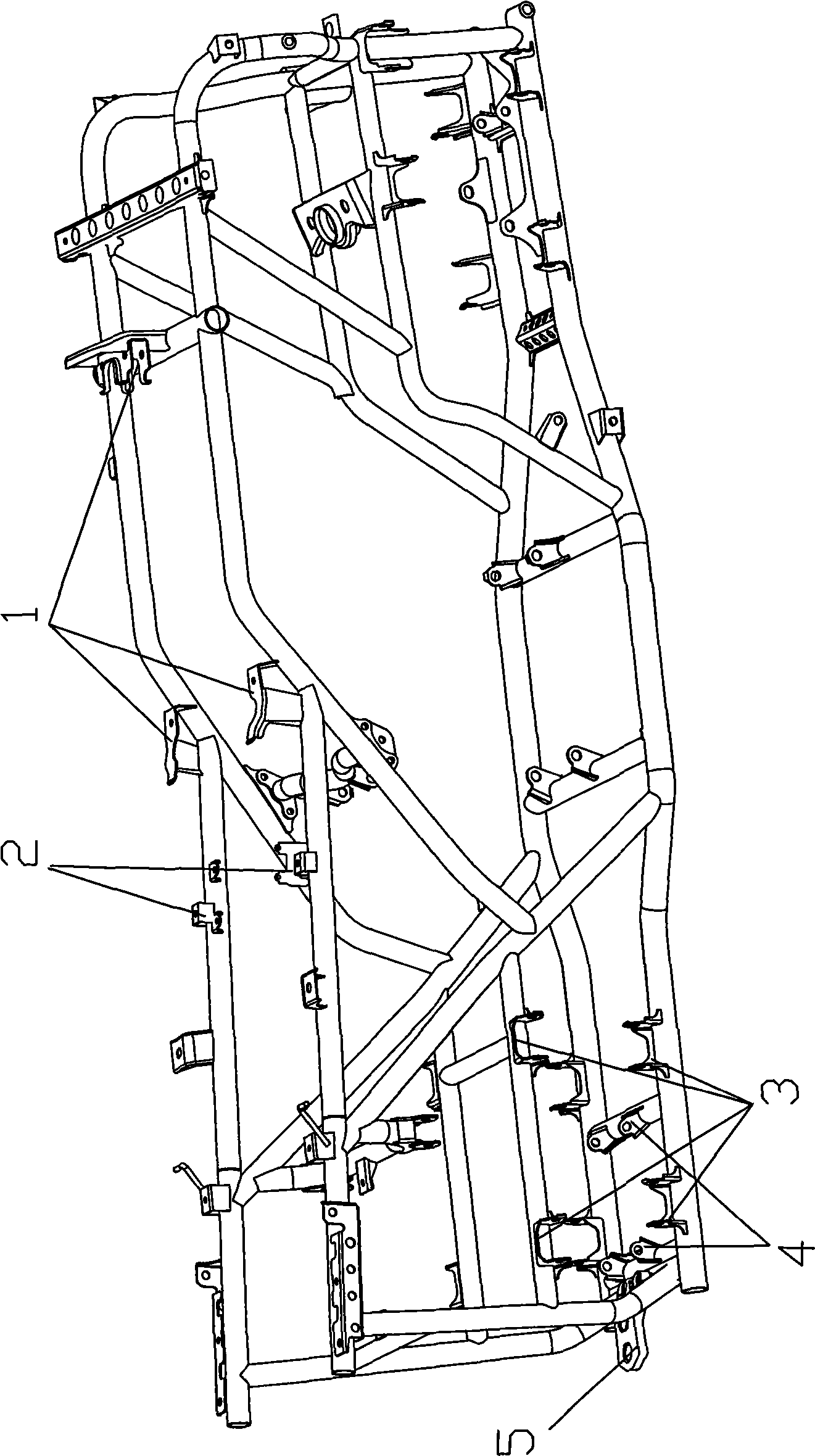

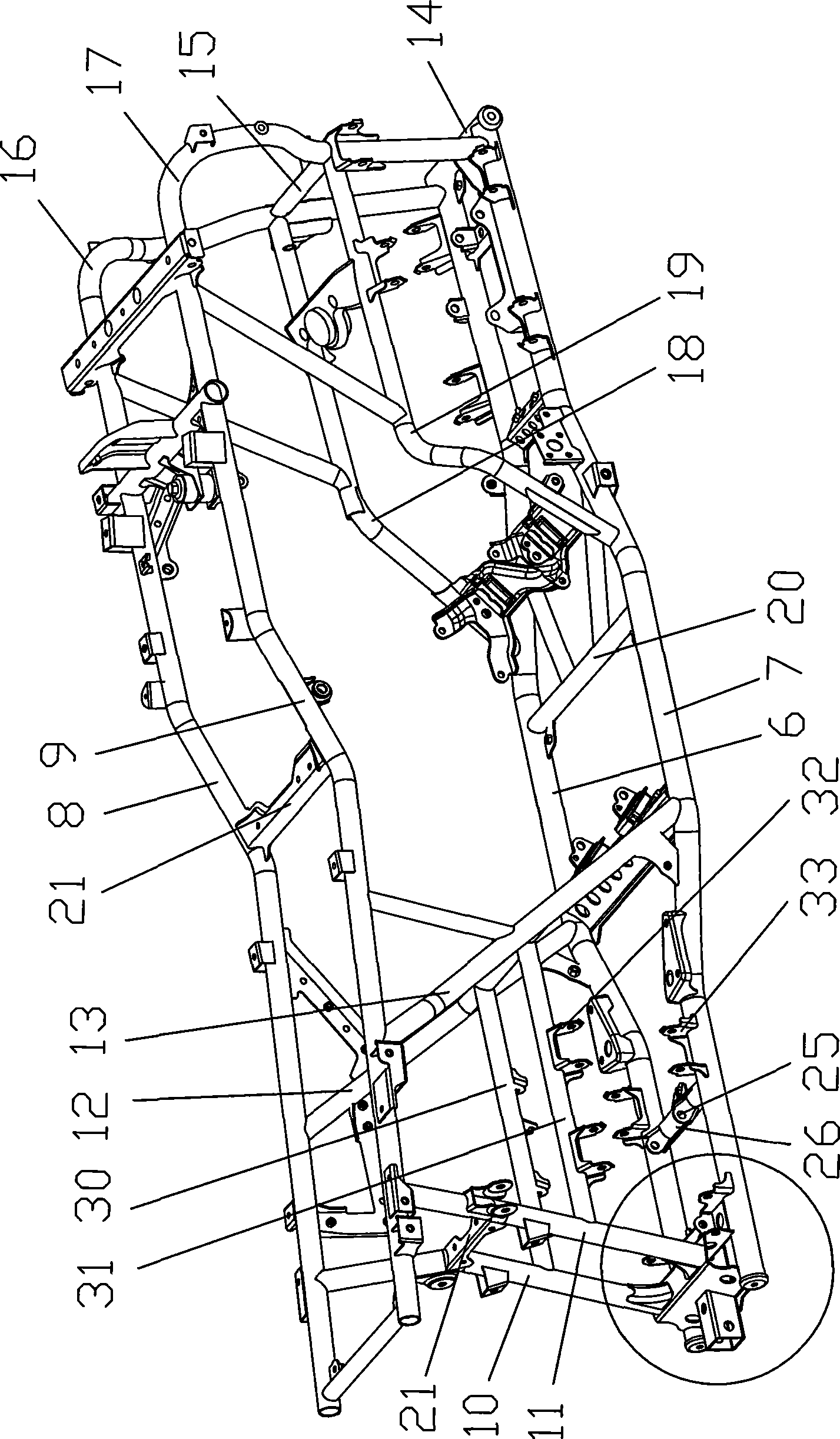

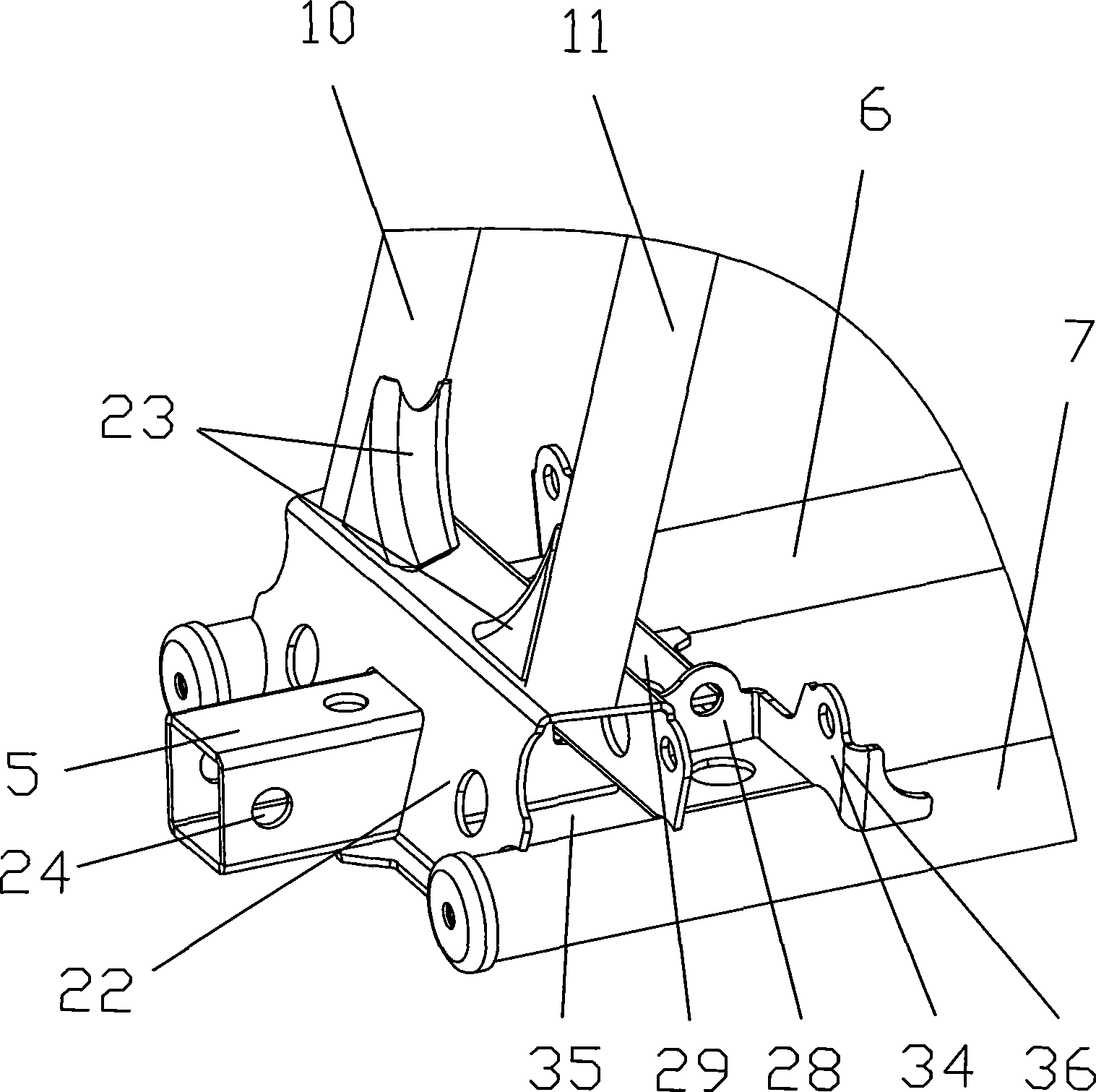

[0014] see figure 2 , as can be seen from the figure, the ATV frame assembly of the present invention includes a left lower bottom pipe 6, a right lower bottom pipe 7, a left upper pipe 8, a right upper pipe 9, a left rear standpipe 10, a right rear standpipe 11, Left rear diagonal support pipe 12, right rear diagonal support pipe 13, front lower horizontal pipe 14, front middle horizontal pipe 15, left upper front pipe 16, right upper front pipe 17, front middle left pipe 18, front middle right pipe 19, bottom middle Cross pipe 20, traction trailer 5, air filter mounting lug 1, fuel tank mounting plate 21, rear upper rocker arm mounting lug 32, rear lower rocker arm mounting lug, main reducer front mounting lug 25, main reducer Install lug 28 afterward. These components above are also the structures that the existing beach car frame assembly has.

[0015] There are fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com