High-strength and high-toughness submerged arc horizontal welding agent and preparing method and application thereof

A high-strength, high-toughness, flux technology, used in arc welding equipment, welding equipment, welding equipment, etc., can solve problems such as excessive molten iron fluidity, dripping molten iron, and inability to fill K-shaped grooves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

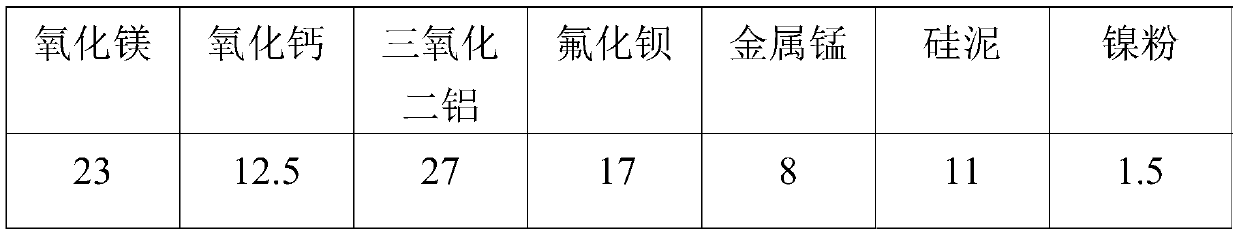

[0050] (1) The parts by weight of various raw materials in the flux powder are as follows: (parts)

[0051]

[0052] (2) Submerged arc welding flux is made according to the above ingredients, according to the national standard GB / T 36034-2018 "High-strength steel solid welding wire, flux-cored welding wire and welding wire-flux classification combination requirements for submerged arc welding" and GB / T47018-2017 Welding Materials Ordering Specifications for Pressure Equipment" is used to inspect the content of sulfur and phosphorus in flux and deposited metal, test the mechanical properties of deposited metal, as well as ray flaw detection of deposited metal and bend test of deposited metal.

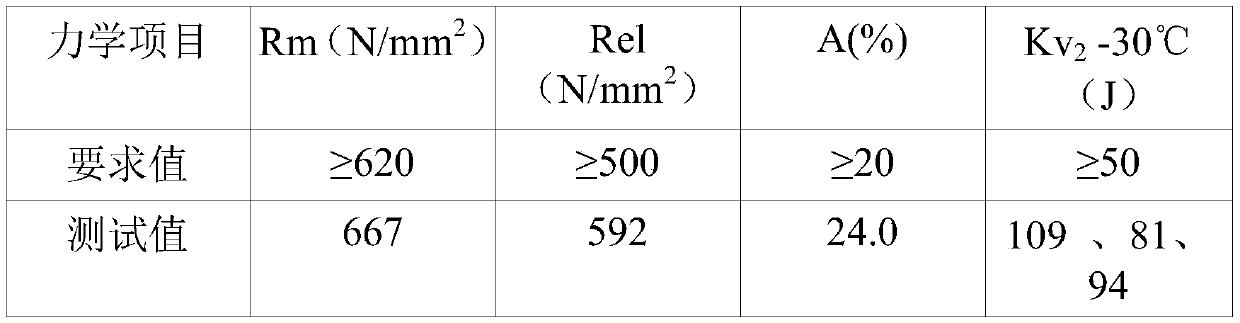

[0053] According to the above standard, the welding test is carried out with H08MnMoA welding wire with a diameter of 4.0mm for pressure. The final indicators are as follows.

[0054] ① Flux sulfur and phosphorus content:

[0055]

[0056] ② content of sulfur and phosphorus in de...

Embodiment 2

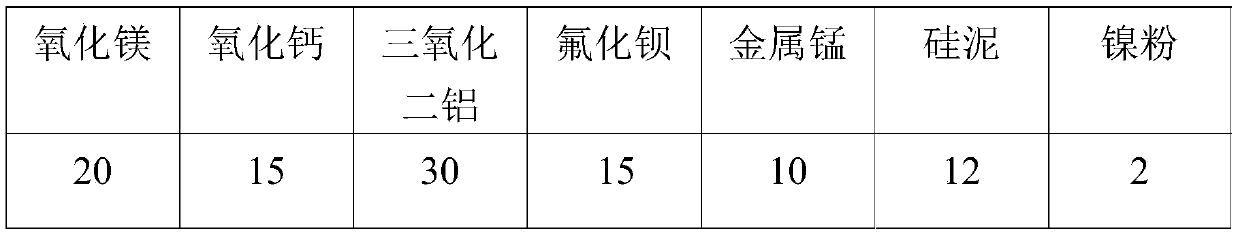

[0064] (1) The parts by weight of various raw materials in the flux powder are as follows: (parts)

[0065]

[0066] (2) The submerged arc welding flux prepared according to the above components is also tested according to the specifications of Example 1. The final indicators are as follows.

[0067] ① Flux sulfur and phosphorus content:

[0068]

[0069] ② content of sulfur and phosphorus in deposited metal

[0070]

[0071] ③Mechanical properties of deposited metal

[0072]

[0073] ④ Radiographic flaw detection inspection: After X-ray flaw detection, the quality level is first grade.

[0074] ⑤Longitudinal bending test: both face bending and back bending are qualified.

[0075] (3) After the finished product, the particle size of the flux powder is 30-60 mesh, and the particle size of 40-50 mesh accounts for 60%.

Embodiment 3

[0077] (1) The parts by weight of various raw materials in the flux powder are as follows: (parts)

[0078]

[0079] (2) The submerged arc welding flux prepared according to the above components is also tested according to the specifications of Example 1. The final indicators are as follows.

[0080] ① Flux sulfur and phosphorus content:

[0081]

[0082] ② content of sulfur and phosphorus in deposited metal

[0083]

[0084] ③Mechanical properties of deposited metal

[0085]

[0086] ④ Radiographic flaw detection inspection: After X-ray flaw detection, the quality level is first grade.

[0087] ⑤Longitudinal bending test: both face bending and back bending are qualified.

[0088] (3) After the finished product, the particle size of the flux powder is 30-60 mesh, and the particle size of 40-50 mesh accounts for 58%.

[0089] In order to reflect the effect between the various raw materials, the comparison ratio of the content of special elements that do not mee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com