A nickel-saving austenitic stainless steel welding rod for overlay welding of cr-mo steel flange forgings and preparation method thereof

A technology for austenitic stainless steel and flange forgings, applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as reducing manufacturing costs, reduce manufacturing costs, improve solubility, and improve crack resistance and corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

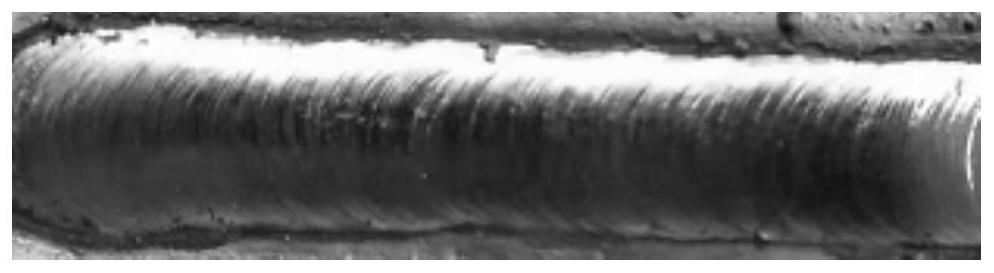

Image

Examples

Embodiment 1

[0024] Embodiment 1: A kind of nickel-saving type austenitic stainless steel welding rod used for overlay welding of Cr-Mo steel flange forgings of the present embodiment is made up of welding core and coating, and described coating is made of rutile 42%, mica powder by mass fraction 7%, potassium titanate 2%, electrolytic metal manganese 6%, fluorite 7%, potassium feldspar 12%, marble 10%, cryolite 1%, alkali 1%, metal chromium 10% and niobium powder 2%. The chemical composition and mass fraction of electrolytic metal manganese in the coating are Mn≥99.7%, C≤0.04%, S≤0.05%, P≤0.005%; the chemical composition and mass percentage of the welding core are C: 0.06%, Si: 0.51%, Mn: 7.22%, S: 0.004%, P: 0.035%, Cr: 18.75%, Ni: 3.09%, Cu: 2.12%, N: 0.26% and the balance Fe.

[0025] The method for preparing above-mentioned welding rod is carried out as follows:

[0026] 1. Weigh rutile, mica powder, potassium titanate, electrolytic metal manganese, fluorite, potassium feldspar, marb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com