Low hydrogen type electrode and preparation method thereof

A low-hydrogen type, welding rod technology, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of unsuitability for all-position welding, uneven transition elements, poor arc blowing force, etc., to achieve smooth and dense appearance quality, arc The sound is uniform and stable, and the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

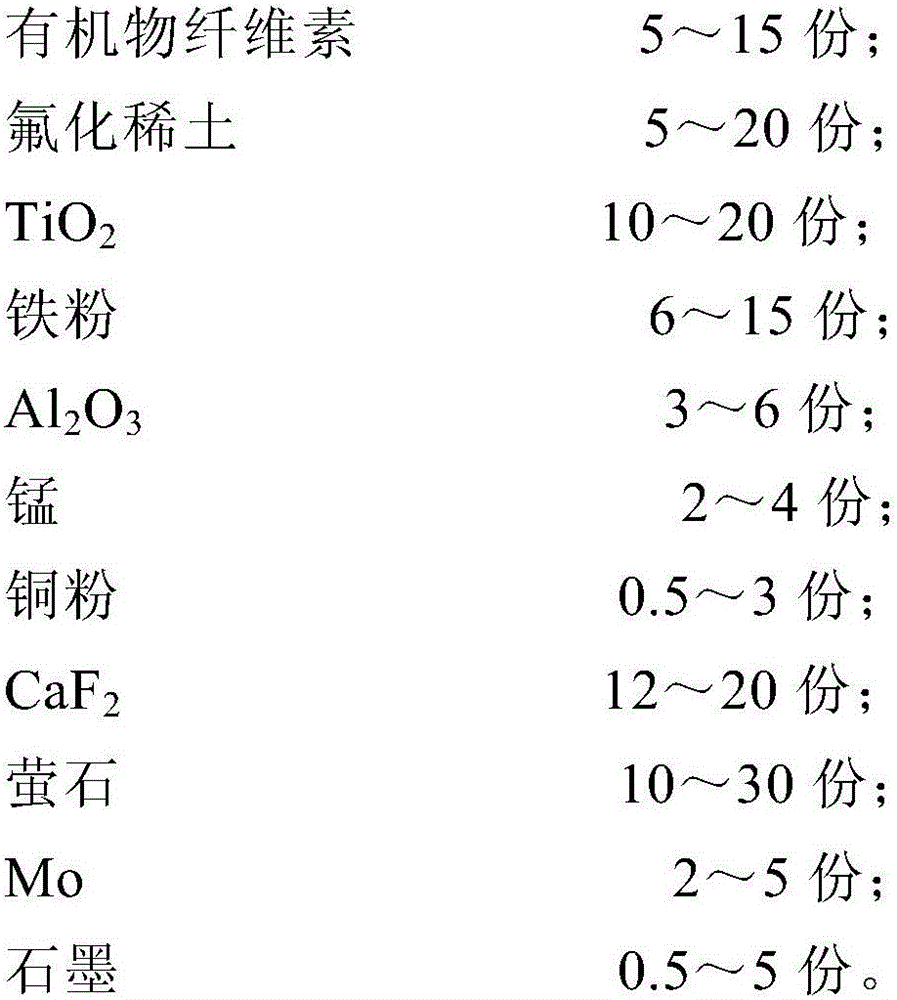

[0026] This embodiment discloses a low-hydrogen electrode, which includes a coating and a welding core, the welding core is low-alloy steel, and the coating is prepared from components with the following weight ratio:

[0027]

[0028] The organic cellulose is carboxymethyl cellulose. The ratio of the coating diameter to the welding core diameter is 1.2. The mass ratio of the coating to the welding core is 1.

[0029] The preparation method of the low-hydrogen type electrode of the present embodiment comprises the following steps:

[0030] 1) Mix the powder materials of the above components evenly to make a basic electrode coating, and pass through a 100-mesh sieve for use;

[0031] 2) In the electrode press coating machine, the alkaline electrode coating is coated on the carbon steel welding core with sodium water glass as a binder;

[0032] 3) Baking at a high temperature of 390-450° C., and keeping it warm for 1-2 hours to prepare a low-hydrogen type electrode.

[00...

Embodiment 2

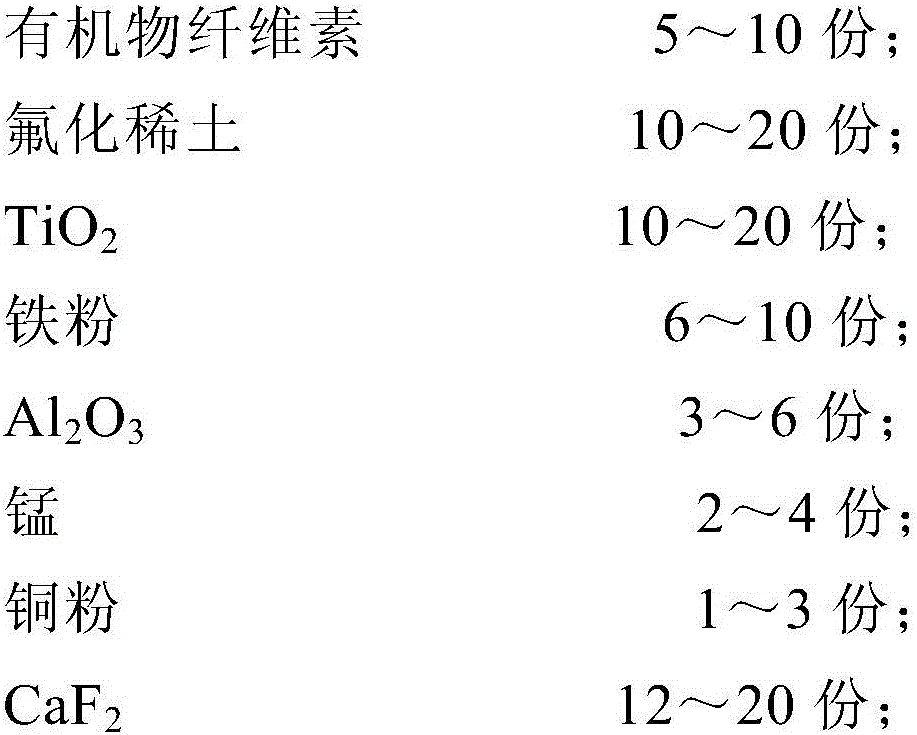

[0036] This embodiment discloses a low-hydrogen electrode, which includes a coating and a welding core, the welding core is low-alloy steel, and the coating is prepared from components with the following weight ratio:

[0037]

[0038] The organic cellulose is carboxymethyl cellulose. The ratio of the coating diameter to the welding core diameter is 1.4. The mass ratio of the coating to the welding core is 0.6.

[0039] The preparation method of the low-hydrogen type electrode of the present embodiment comprises the following steps:

[0040] 1) Mix the powder materials of the above components evenly to make a basic electrode coating, and pass through a 100-mesh sieve for use;

[0041] 2) In the electrode press coating machine, the alkaline electrode coating is coated on the carbon steel welding core with sodium water glass as a binder;

[0042] 3) Baking at a high temperature of 390-450° C., and keeping it warm for 1-2 hours to prepare a low-hydrogen type electrode.

[...

Embodiment 3

[0045] This embodiment discloses a low-hydrogen electrode, which includes a coating and a welding core, the welding core is low-alloy steel, and the coating is prepared from components with the following weight ratio:

[0046]

[0047]

[0048] The organic cellulose is carboxymethyl cellulose. The ratio of the coating diameter to the welding core diameter is 1.3. The mass ratio of the coating to the welding core is 1:1.

[0049] The preparation method of the low-hydrogen type electrode of the present embodiment comprises the following steps:

[0050] 1) Mix the powder materials of the above components evenly to make a basic electrode coating, and pass through a 100-mesh sieve for use;

[0051] 2) In the electrode press coating machine, the alkaline electrode coating is coated on the carbon steel welding core with sodium water glass as a binder;

[0052] 3) Bake at a high temperature of 390-450° C., and keep it warm for 1-2 hours to prepare a low-hydrogen type electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com