Preparation method and application of irradiation modified bismuth vanadate aptamer photoelectrochemical sensor

A kind of bismuth vanadate, photoelectrochemical technology, applied in the field of photoelectrochemistry, can solve the problems of cumbersome probe fixation, large sensor background signal, poor photoelectric performance, etc., to reduce the recombination of electrons and holes, high sensitivity and resolution , Improve the corresponding effect of photoelectric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

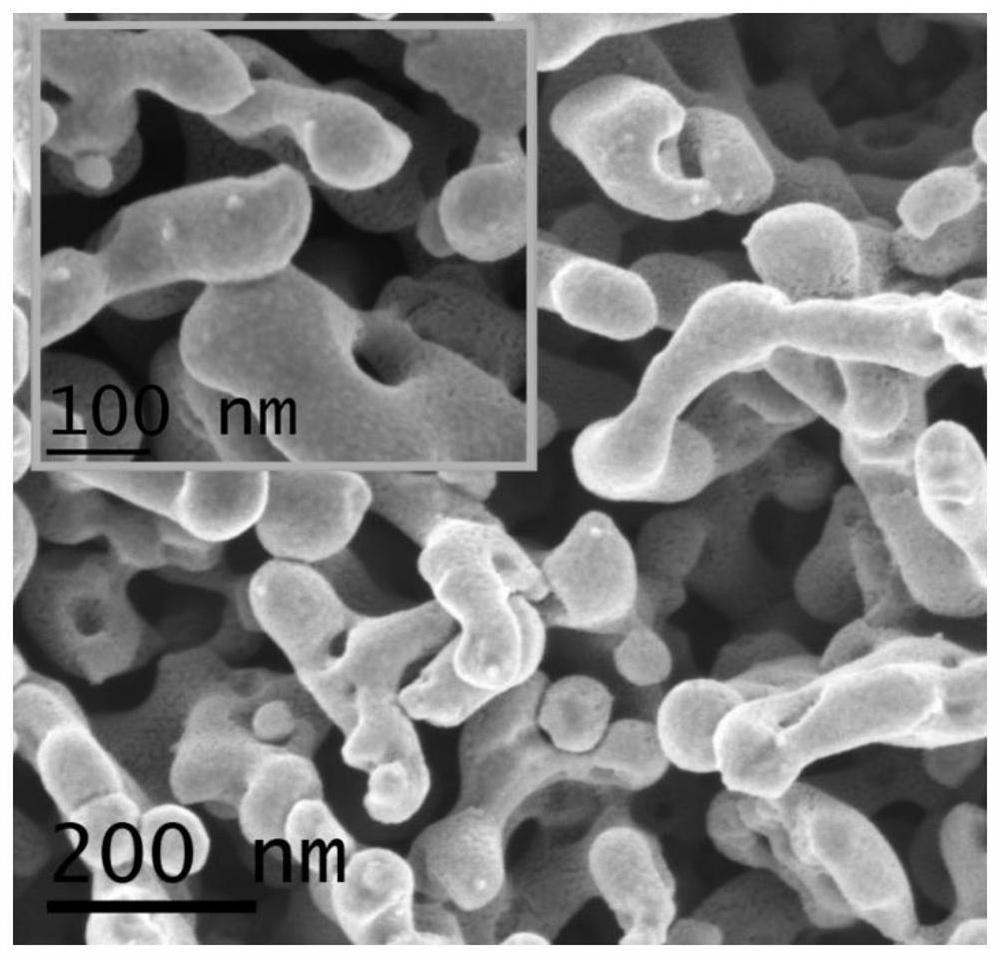

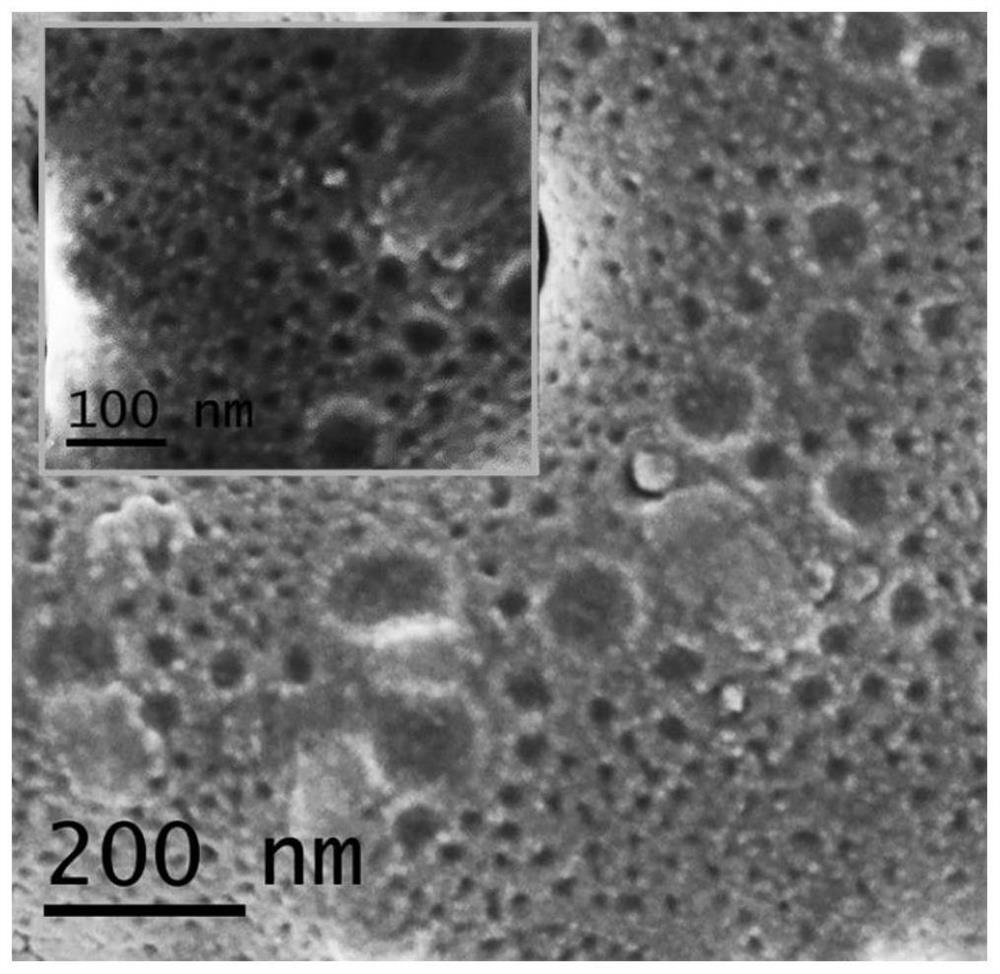

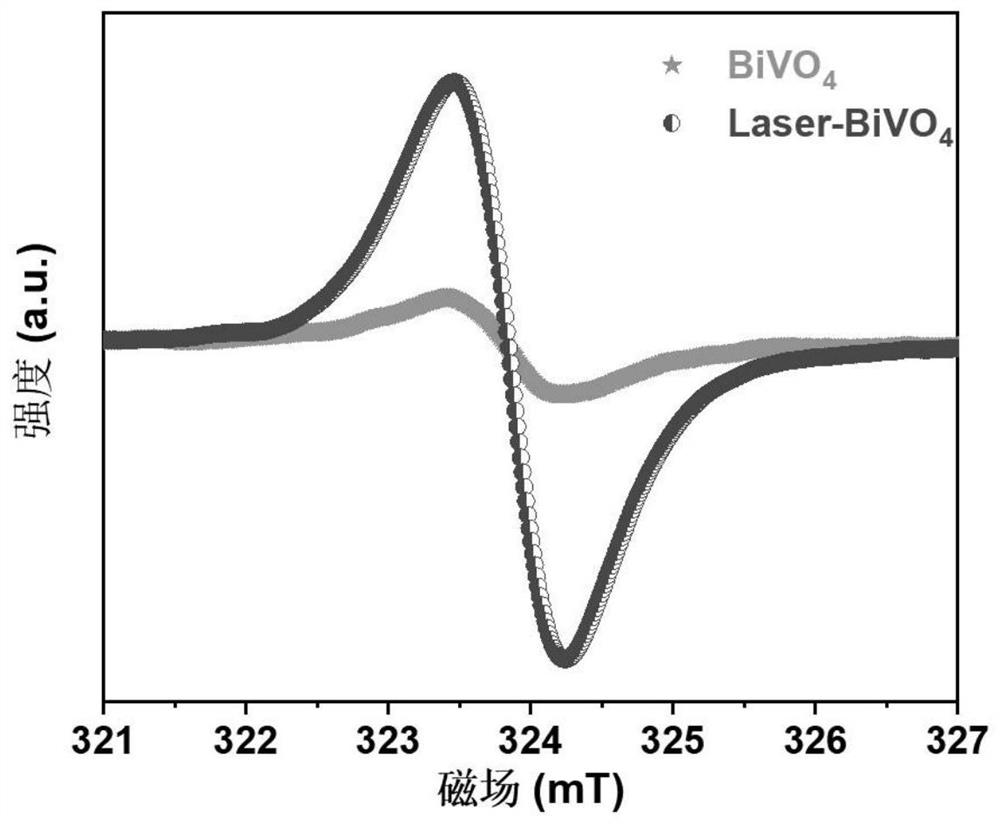

[0048] In this example, the photoelectrochemical anodic oxidation method is used to prepare BiVO on the conductive substrate first. 4 thin film, using infrared light to irradiate BiVO 4 Get Laser-BiVO 4 thin films, and then respectively in BiVO 4 and Laser-BiVO 4 Modified g-C on the film 3 N 4 Thin films, using g-C 3 N 4 Surface π-π adsorption of thin films immobilizes DNA aptamers for prostate-specific antigen PSA on g-C 3 N 4 On the thin film, the PEC aptamer sensor BiVO for the detection of prostate specific antigen PSA was prepared 4 / g -C 3 N 4 / PSA enhanced aptasensor and Laser-BiVO 4 / g -C 3 N 4 / PSA inhibitory aptasensor, the specific preparation process is as follows:

[0049] (1) Clean the surface of the FTO conductive glass (2cm × 1cm × 0.2cm) with a piranha solution configured with a mixture of concentrated sulfuric acid and 30% hydrogen peroxide (mass ratio is 7:3), then rinse repeatedly with ultrapure water and Blow dry with high-purity nitrogen fo...

Embodiment 2

[0078] In this example, the same method as in Example 1 was used to prepare a PEC aptamer sensor for detecting carcinoembryonic antigen CEA——BiVO 4 / g -C 3 N 4 / CEA Enhanced Aptasensor and Laser-BiVO 4 / g -C 3 N 4 / CEA inhibitory aptasensor, the specific preparation process is as follows:

[0079] (1) Clean the surface of the FTO conductive glass (2cm × 1cm × 0.2cm) with a piranha solution configured with a mixture of concentrated sulfuric acid and 30% hydrogen peroxide (mass ratio is 7:3), then rinse repeatedly with ultrapure water and Blow dry with high-purity nitrogen for later use;

[0080] (2) Weigh 2.9g Bi(NO 3 ) 3 ·5H 2 O and 12g NaI were dissolved in 200mL ultra-pure water and fully stirred and mixed. After the solution was clarified and uniform, the pH of the solution was adjusted to 1.2. 2.85g p-benzoquinone was dissolved in 90mL ethanol, and the p-benzoquinone was fully dissolved by ultrasonication for 30min, and then Mix the two solutions, stir for 30 minu...

Embodiment 3

[0092] In this example, the same method as in Example 1 was used to prepare a PEC aptamer sensor for detecting alpha-fetoprotein AFP——BiVO 4 / g -C 3 N 4 / AFP enhanced aptasensor and Laser-BiVO 4 / g -C 3 N 4 / AFP inhibitory aptasensor, the specific preparation process is as follows:

[0093] (1) Clean the surface of the FTO conductive glass (2cm × 1cm × 0.2cm) with a piranha solution configured with a mixture of concentrated sulfuric acid and 30% hydrogen peroxide (mass ratio is 7:3), then rinse repeatedly with ultrapure water and Blow dry with high-purity nitrogen for later use;

[0094] (2) Weigh 2.9g Bi(NO 3 ) 3 ·5H 2 O and 12g NaI were dissolved in 200mL ultra-pure water and fully stirred and mixed. After the solution was clarified and uniform, the pH of the solution was adjusted to 1.2. 2.85g p-benzoquinone was dissolved in 90mL ethanol, and the p-benzoquinone was fully dissolved by ultrasonication for 30min, and then Mix the two solutions, stir for 30 minutes unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com