A kind of metal porphyrin complex and its preparation method and application

A technology of metalloporphyrins and complexes, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve the problems of limited carrier transport capacity and affect the performance of optoelectronic materials, and improve the carrier transport capacity , Significant technical progress, improve the effect of photoelectric response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

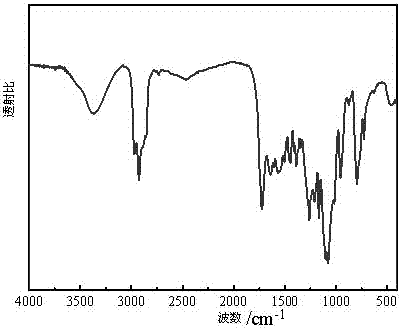

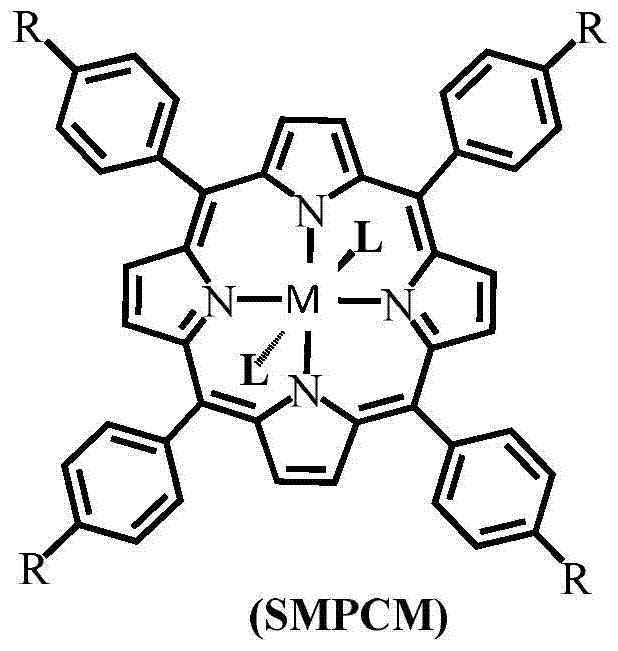

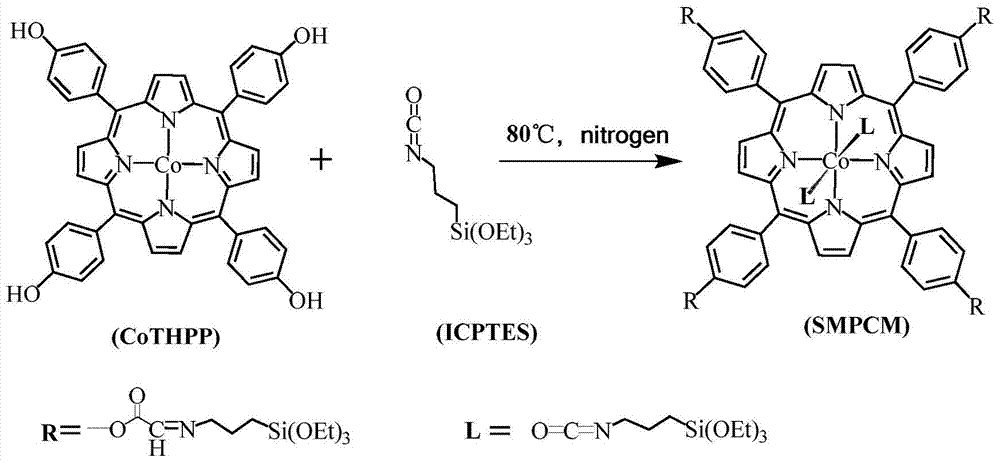

[0021] 1) Synthesis of 5,10,15,20-tetra(4-isocyanatopropyltriethoxysilane) cobalt porphyrin complex

[0022] Weigh 20 mg of 5,10,15,20-tetrahydroxyphenylporphyrin cobalt into a 100 mL three-necked flask, add 40 mL of anhydrous tetrahydrofuran and 15 mL of triethylamine, and stir to fully dissolve it. Then, add 20 mL of anhydrous tetrahydrofuran (pre-dissolved in it with 40.3 mL of 3-isocyanatopropyltriethoxysilane) to the above solution dropwise, and continue to react in an oil bath at 80°C for 4 hours to obtain axially coordinated 5,10,15,20-Tetra(4-isocyanatopropyltriethoxysilane) cobalt porphyrin complex.

[0023] 2) Preparation method of photoelectric film

[0024] To the tetrahydrofuran solution of the 5,10,15,20-tetra(4-isocyanatopropyltriethoxysilane) cobalt porphyrin complex, 80 μL of 0.1M hydrochloric acid solution was added, the temperature was raised to 60° C., and the temperature was kept for 4 hours. The obtained solution is coated on a glass sheet, FTO, ITO, or silico...

Embodiment 2

[0026] 1) Synthesis of 5,10,15,20-tetra(4-isocyanatopropyltriethoxysilane) iron porphyrin complex

[0027] Weigh 40 mg of 5,10,15,20-tetrahydroxyphenylporphyrin iron into a 200 mL three-necked flask, add 80 mL of anhydrous tetrahydrofuran and 30 mL of triethylamine, and stir to fully dissolve it. Then, add 40 mL of anhydrous tetrahydrofuran (pre-dissolved in it with 80 mL of 3-isocyanatopropyltriethoxysilane) to the above solution dropwise, and continue to react in an oil bath at 80°C for 4 hours to obtain an axially coordinated 5 ,10,15,20-Tetra(4-isocyanatopropyltriethoxysilane) iron porphyrin complex.

[0028] 2) Preparation method of photoelectric film

[0029] To the tetrahydrofuran solution of the 5,10,15,20-tetra(4-isocyanatopropyltriethoxysilane) iron porphyrin complex, 80 μL of 0.1M hydrochloric acid solution was added, the temperature was raised to 60° C., and the temperature was kept for 4 hours. The obtained solution is coated on a substrate such as FTO or ITO, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com