Low-spatter ultralow-hydrogen welding rod excellent in minus 100 DEG C impact toughness

A technology of impact toughness and ultra-low hydrogen, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems affecting the weld forming performance and destroying the arc stability, so as to improve low temperature toughness and enhance welding Process performance, effect of overcoming spatter problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

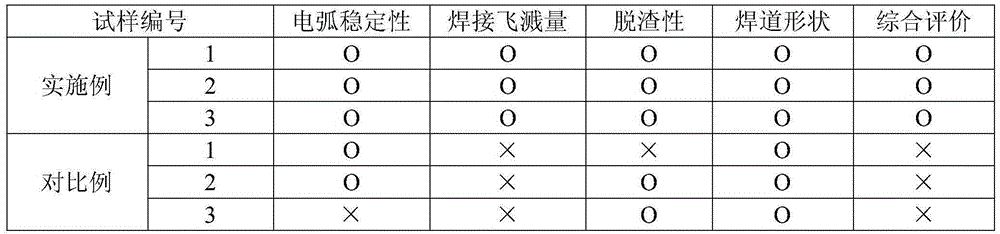

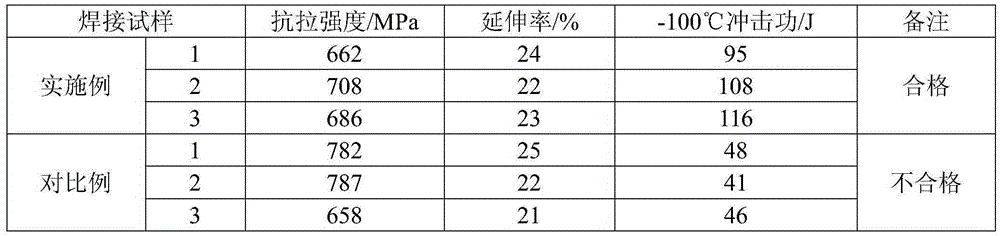

Examples

Embodiment 1

[0039] The composition (percentage by weight) of the coating includes: 12% marble, 4% fluorite, 14% cryolite, 3% strontium carbonate, 2% zirconium quartz, 0.2% boron iron, 1.8% nickel-magnesium alloy, 1.6% aluminum-silicon alloy, Rare earth oxide 1.2%, alginate 0.5%, feldspar 0.2%, and appropriate amount of binder.

[0040] After conversion, the sum of silicon content in zirconium quartz and aluminum-silicon alloy is 2.6%.

[0041] The welding core material (weight percentage) includes 0.02% C, 0.003% S, 0.004% P, 5% Ni, 1% Mo, 0.2% Nb, and the rest is Fe and unavoidable impurities.

[0042]After the above-mentioned coating is prepared, it is sent into a pressure coating machine to be wrapped on the welding core, and then dried and baked to produce the welding rod of the present invention.

Embodiment 2

[0044] The composition (percentage by weight) of the coating includes: 6% marble, 1% fluorite, 20% cryolite, 1% strontium carbonate, 0.2% zirconium quartz, 0.5% boron iron, 3% nickel-magnesium alloy, 3% aluminum-silicon alloy, 0.2% rare earth oxide, 0.8% alginate, 0.8% mica, 3% ferronickel, and appropriate amount of binder.

[0045] After conversion, the sum of silicon content in zirconium quartz and aluminum-silicon alloy is 2.5%.

[0046] The welding core material (weight percentage) includes 0.01% C, 0.002% S, 0.003% P, 0.5% Ni, 2% Mo, 0.1% Nb, and the rest is Fe and unavoidable impurities.

[0047] After the above-mentioned coating is prepared, it is sent into a pressure coating machine to be wrapped on the welding core, and then dried and baked to produce the welding rod of the present invention.

Embodiment 3

[0049] The composition (percentage by weight) of the coating includes: 18% marble, 5% fluorite, 5% cryolite, 5% strontium carbonate, 3% zircon quartz, 0.1% boron iron, 0.5% nickel-magnesium alloy, 0.6% aluminum-silicon alloy, Rare earth oxide 2%, alginate 0.2%, feldspar 0.4%, mica 0.4%, nickel iron 2%, molybdenum iron 1%, and an appropriate amount of binder.

[0050] After conversion, the sum of silicon content in zirconium quartz and aluminum-silicon alloy is 2.7%.

[0051] The welding core material (weight percentage) includes 0.01% C, 0.001% S, 0.004% P, 1.5% Ni, 1% Mo, 0.5% Nb, and the rest is Fe and unavoidable impurities.

[0052] After the above-mentioned coating is prepared, it is sent into a pressure coating machine to be wrapped on the welding core, and then dried and baked to produce the welding rod of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com