Iron ion adsorption resin, preparation method and application thereof in removal of iron ions in solution

A technology for adsorbing resin and iron ions, applied in ion exchange, selective adsorption, ion exchange regeneration, etc., can solve problems such as process influence, and achieve the effect of high adsorption selectivity, easy analysis, and good removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

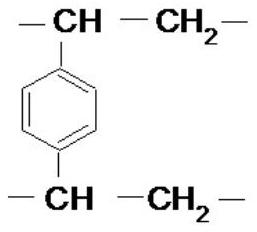

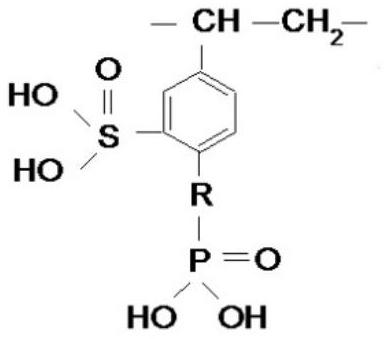

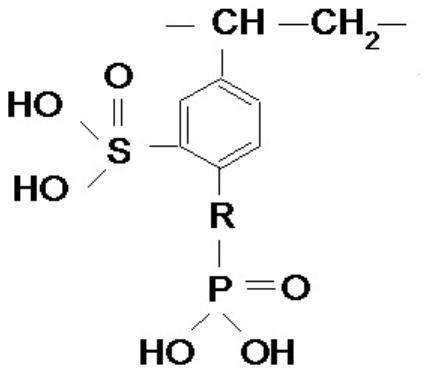

Method used

Image

Examples

Embodiment 1-5

[0029] Using different amounts of cross-linking agents to prepare different resin-based balls, the specific cross-linking dosage is:

[0030] 63%DVB / g 80%DVB / g Example 1 40 Example 2 55 Example 3 90 Example 4 85 Example 5 150

[0031] Other components of the oil phase: styrene: 740g, liquid paraffin: 320g, 200# gasoline: 165g, BPO: 9g, mix the above substances evenly and set aside;

[0032] Water phase: tap water: 2500g, gelatin: 30g; add water to a 5000L three-neck flask, start stirring, heat up to 45°C, add gelatin, keep warm at 45°C for 1 hour to dissolve the gelatin;

[0033] Stop stirring, slowly pour the mixed oil phase into a three-necked flask, let it stand for 10 minutes, and replace the air in the upper space of the flask with nitrogen; start stirring, adjust the stirring speed, so that the particle size of the oil beads is between 0.3 ~ 0.8mm, Start to heat up, raise the temperature to 70°C in 2 hours, keep i...

Embodiment 6-10

[0038]Use the method in Example 2 to prepare resin-based balls; put the resin-based balls in an oven and dry at 80°C until the water content is below 0.5%; weigh 100 g of the dried resin-based balls, and put them into the dried In the three-necked flask, add 100g of aluminum trichloride, respectively add the substances in the following table, stir and swell for 120min.

[0039] Chlorohydrin 3-chloropropanol 1-Chloro-2-propanol 4-Chlorobutanol 5-chloropentanol Example 6 150 Example 7 200 Example 8 260 Example 9 320 Example 10 400

[0040] Raise the temperature to 60°C for 10 hours, then filter out the resin, wash with ethanol, and wash with water to obtain a hydroxylated resin intermediate, and dry it in an oven at 80°C until the water content is less than 0.5% for later use;

[0041] Weigh 100g of the dried hydroxylated resin intermediate, put it into a dry three-necked flask, add 100...

Embodiment 11-15

[0044] Use the method in Example 2 to prepare resin-based balls; put the resin-based balls in an oven and dry at 80°C until the water content is below 0.5%; weigh 100 g of the dried resin-based balls, and put them into the dried In the three-necked flask, add 400g of phosphorous acid and 50g of aluminum trichloride, respectively add the substances listed in the following table, stir and swell for 120min:

[0045] Phosphorus trichloride Phosphorus pentachloride Example 11 100 Example 12 200 Example 13 300 Example 14 400 Example 15 500

[0046] Raise the temperature to 75°C for 10 hours, then filter out the resin, wash with ethanol, and wash with water to obtain a phosphorylated resin intermediate, and dry it in an oven at 80°C until the water content is less than 0.5% for later use;

[0047] Weigh 50g of the phosphorylated resin intermediate after drying, put it into the reaction kettle, add 50g of dichloroethane, soak f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com