Continuous flow preparation method of diethyl methyl phosphite

A technology of diethyl methyl phosphite and methyl phosphorus dichloride, which is applied in the field of preparation of pesticide intermediates, can solve problems such as difficulty in realization, cumbersome recovery process, and low recovery rate, and achieve safe and efficient production, solve The effect of low efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-19

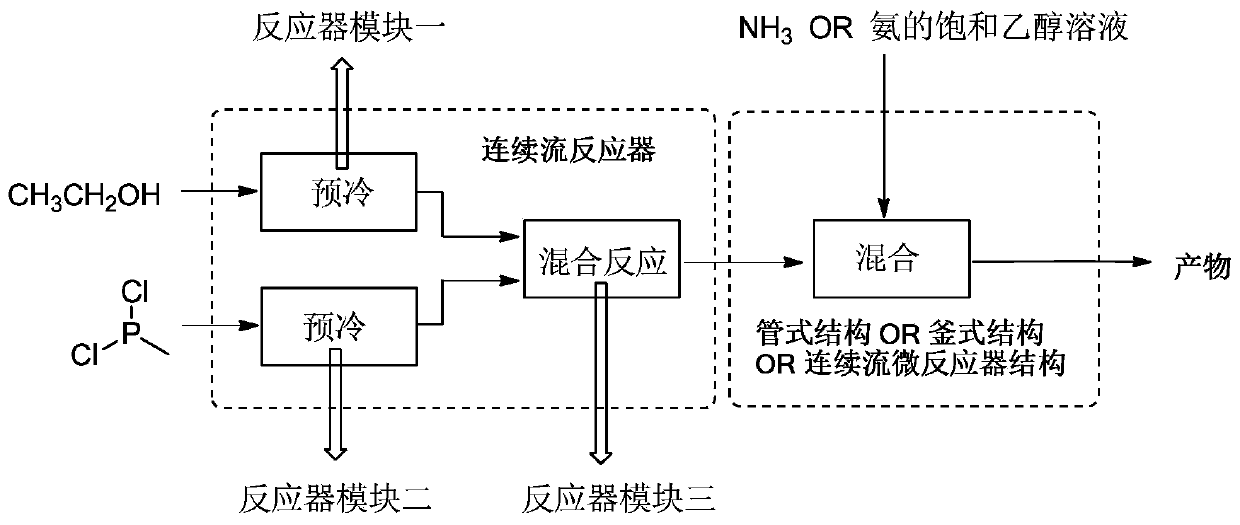

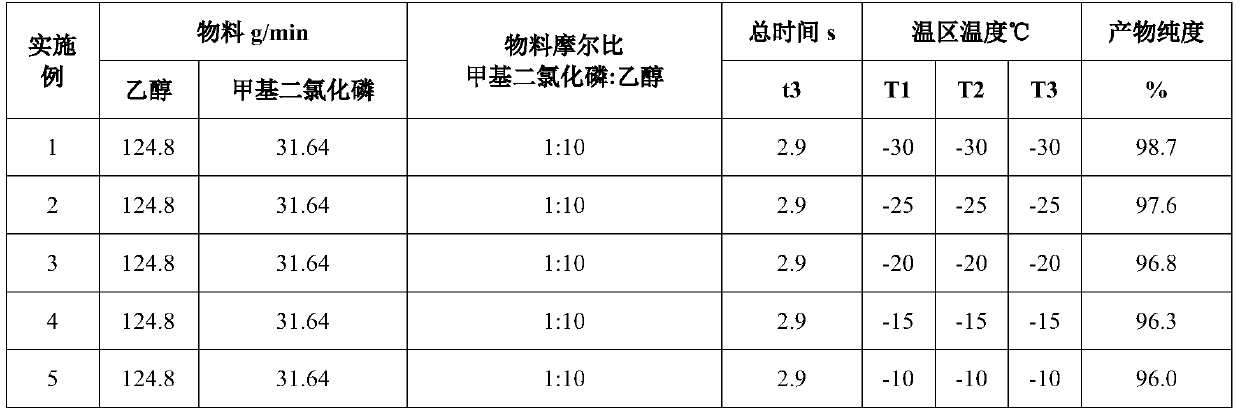

[0056] Such as figure 1 As shown, ethanol is passed into reactor module one for precooling, methylphosphorous dichloride is passed into reactor module two for precooling, and ethanol and methylphosphorous dichloride are in reactor module three Mixing, flow through reactor module three, completes the substitution reaction to generate a mixture containing diethyl methylphosphite and HCl.

[0057] The ammonia-saturated ethanol solution (the amount of ammonia is 25wt%) was filled in a three-necked bottle in advance, the bottle was corked, and placed in a -30°C cold bath environment. After the mixture exits the continuous flow microreactor, it is connected to a three-necked bottle containing ammonia-saturated ethanol solution, and the mixture is directly passed into the ammonia-saturated ethanol solution precooled to -30°C, and mixed with the ammonia-saturated ethanol solution.

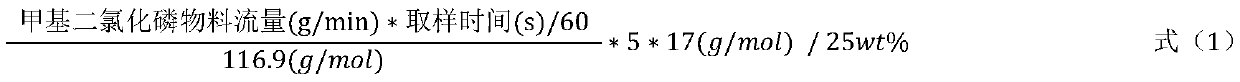

[0058] The calculation method of the amount of ammonia saturated ethanol solution is as follows:

[0...

Embodiment 16

[0077] Embodiment 16 is continuous mixing, and the molar ratio of ammonia to methyl phosphorus dichloride is 2.2:1 per unit time; The mol ratios of phosphorus dichloride are respectively 2.2:1 and 5:1; Embodiment 17 is the tank type mixing of additional ammonia gas again, and the mol ratio of ammonia total amount and methyl phosphorus dichloride in the ammonia-saturated ethanol solution is 2.2:1, the molar ratio of additional ammonia to methyl phosphorus dichloride is 0.05:1. The results show that the increase of ammonia consumption is beneficial to the control of product purity. Furthermore, the continuous mixing method of tubular structure is better.

[0078] According to the method of the foregoing embodiment, the continuous mixing method of the tubular structure is adopted, and the molar ratio of the fixed materials is methyl phosphorus dichloride:ethanol:ammonia=1:10:2.2. Different water contents are screened in methyl phosphorus dichloride, including 0.13wt%, 0.08wt%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com