Serrate double-layer wire mesh corrugated packing

A wire mesh corrugated packing, double-layer metal technology, applied in chemical/physical/physical chemical process, chemical instrument and method, chemical/physical process, etc., can solve the problems of dead zone, easy formation of mass transfer, easy fracture of wire mesh, etc. , to reduce investment costs, improve mass transfer efficiency, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

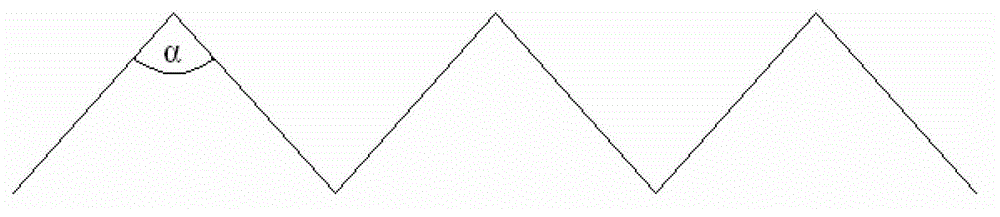

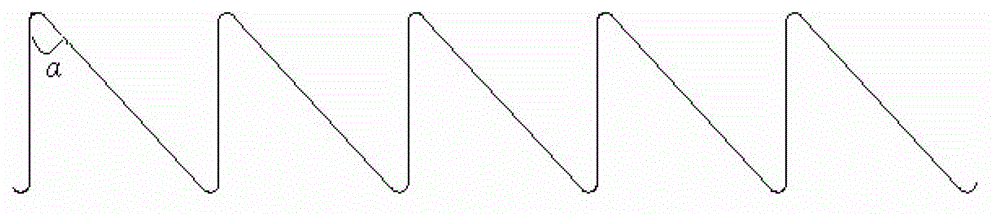

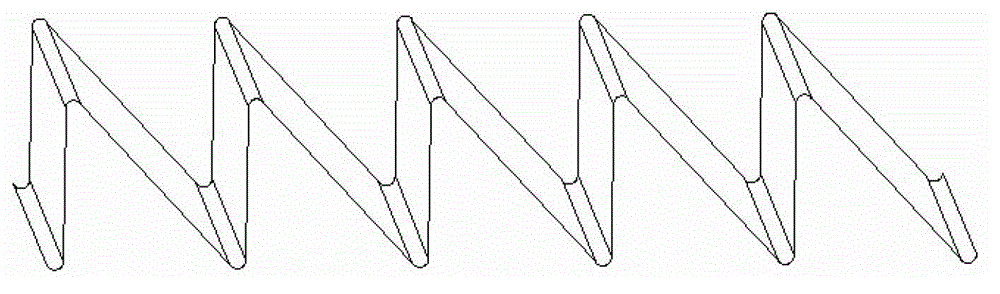

[0030] A kind of sawtooth double-layer metal wire mesh corrugated packing, its structure is as follows Figure 2-4 As shown, the packing is made of double-layer wire mesh material and mechanically rolled into a sawtooth corrugated packing sheet structure. The metal material used can be stainless steel, phosphor bronze or aluminum alloy, and the hole diameter of the wire mesh is 3-6mm. The crests and tops of the troughs of the corrugated packing sheet are connected by smooth arc surfaces, forming a curved zigzag corrugated structure with smooth tooth tips. The cross section of the corrugated packing sheet is a right triangle structure, and the peak height of the serrated corrugation is 1.5-8mm, the formed addendum angle is 15 - 75°, the radius of curvature at the top of the crest and trough is less than 1 / 4 of the height of the crest or trough, generally speaking, the radius of curvature is 0.5 - 2mm. The formed corrugation ridge line and the axial direction of the filler for...

Embodiment 2

[0032] Isopropanol-water rectification separation, vacuum distillation column diameter 1370mm. Punch holes with a diameter of 5 mm on the 80-mesh double-layer stainless steel wire mesh, with an opening rate of 10%, and roll the wire mesh as a whole to form a sawtooth corrugated packing with a peak height of 3.5 mm and an addendum angle α = 60°. Section as figure 2 shown. The corrugated plates are cut and assembled into packed discs with a diameter of 1300 mm and a disc height of 300 mm, and filled in the rectification tower. Under the same separation index, the separation efficiency of the packing technology of the present invention is 30% higher than that of the traditional metal plate corrugated packing, and the separation economic performance is greatly improved.

Embodiment 3

[0034] Preparation of Stable Isotopes by Cryogenic Distillation and Separation 13 c. Use 100-mesh double-layer stainless steel wire mesh to punch a hole with a diameter of 3mm, and the opening rate is 5%. Roll the wire mesh sheet as a whole to form a sawtooth corrugated packing with a peak height of 2.5mm and an addendum angle α=45°. The packing waveform Indicate as figure 2 shown. The corrugated plates are cut and combined into packing discs with a diameter of 30mm and a disc height of 30mm. Filled with CO cryogenic distillation 13 C's packed tower. Compared with the traditional corrugated packing with the same peak height of 2.5mm, its mass transfer and separation efficiency is increased by 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com