Manufacturing method of soluble alloy fracturing ball based on oil and gas development

A manufacturing method and soluble technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as difficult flowback and fracturing balls that cannot be dissolved by themselves, so as to increase added value, upgrade technology and equipment level, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

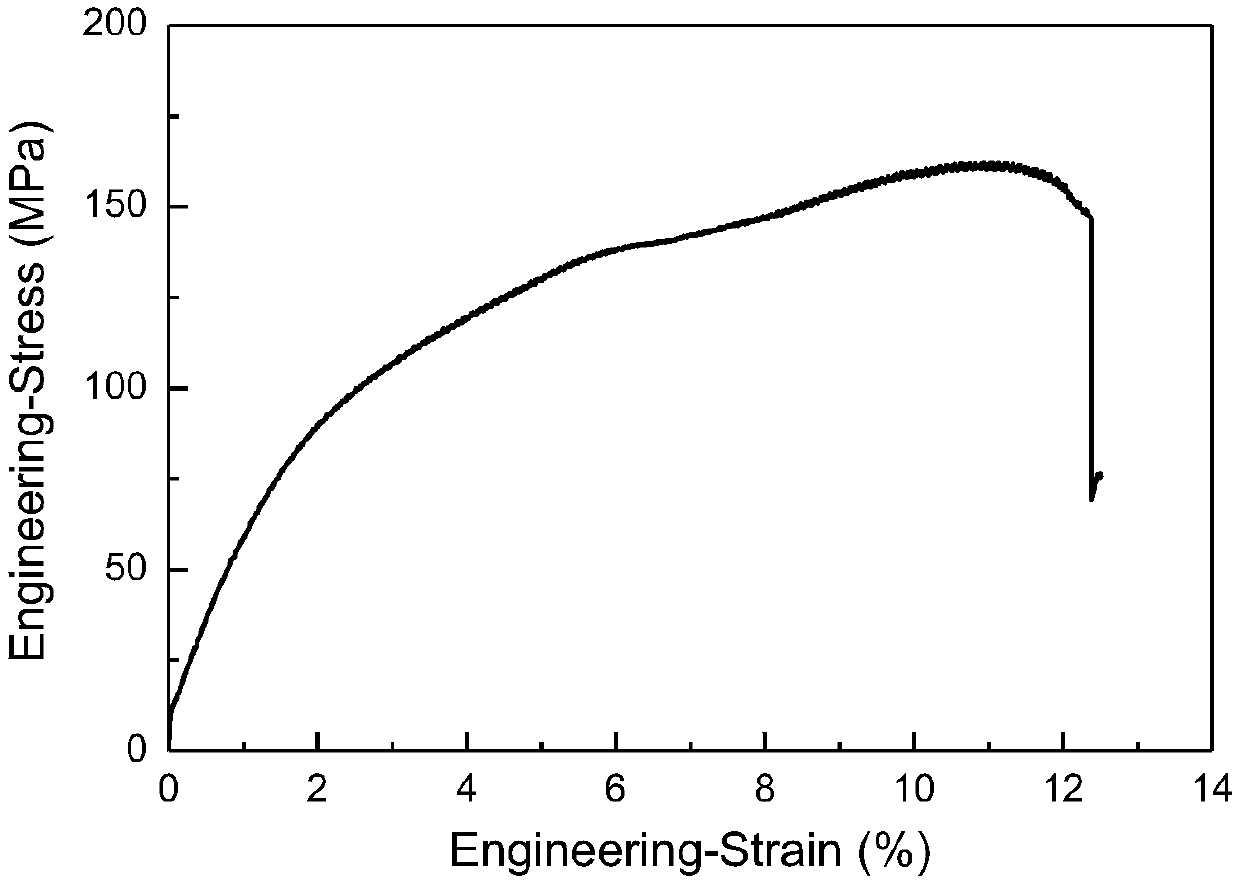

Embodiment 1

[0068] The manufacturing method of soluble alloy fracturing balls based on oil and gas development specifically includes the following steps: Weigh the following raw materials respectively: 5% zinc, 5% magnesium-calcium master alloy, 3% nickel, 3% copper, 2% ferric chloride, magnesium 2% aluminum master alloy, 2.5% magnesium-neodymium master alloy, 2% manganese, 0.8% zirconium compound, and the balance is magnesium. The sum of the parts by mass of the above components is 100%; Heat for 25 minutes to remove moisture; add the weighed magnesium and magnesium-calcium intermediate alloys into the crucible, heat the crucible to 690°C and let it stand for 18 minutes; add zinc and ferric chloride to the crucible, stir well, and continue to pour into the crucible Add zirconium compounds and let stand for 12 minutes; raise the temperature of the crucible to 710°C, then add nickel, copper, magnesium-neodymium master alloy, magnesium-aluminum master alloy and manganese into the crucible, s...

Embodiment 2

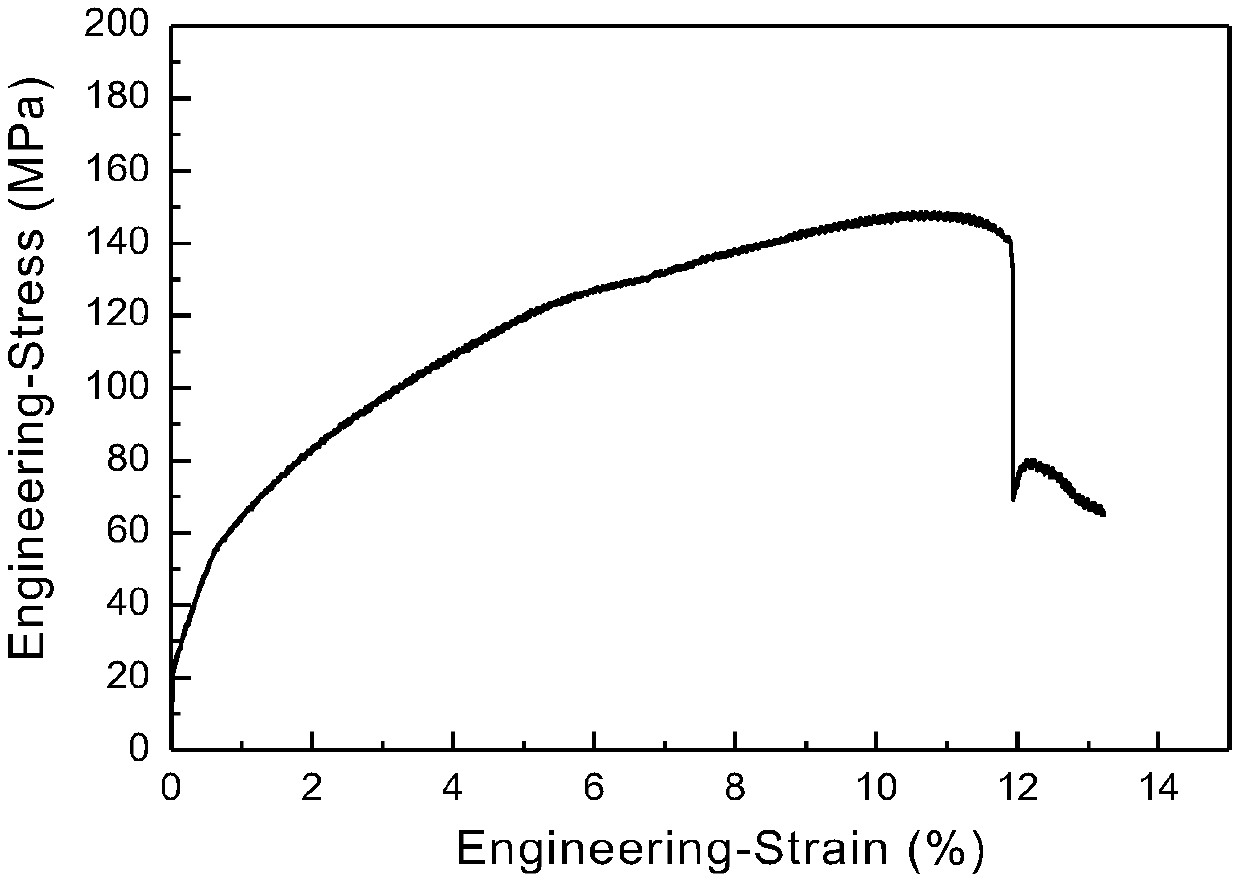

[0070] The manufacturing method of soluble alloy fracturing balls based on oil and gas development includes the following steps: Weigh the following raw materials respectively: 10% zinc, 1% magnesium-calcium master alloy, 1% nickel, 1% copper, 1% ferric chloride, magnesium 1% of aluminum master alloy, 0.5% of magnesium-neodymium master alloy, 0.5% of manganese, 0.4% of zirconium compound, and the balance is magnesium. The sum of the parts by mass of the above components is 100%. Heat for 20 minutes to remove water; add the weighed magnesium and magnesium-calcium master alloy into the crucible, heat the crucible to 680°C and let it stand for 15 minutes; add zinc and iron to the crucible, stir evenly, and continue to add zirconium into the crucible compound, stand still for 10 minutes; raise the crucible temperature to 700°C, then add nickel, copper, magnesium-neodymium master alloy, magnesium-aluminum master alloy and manganese into the crucible, stir evenly and let stand for 15...

Embodiment 3

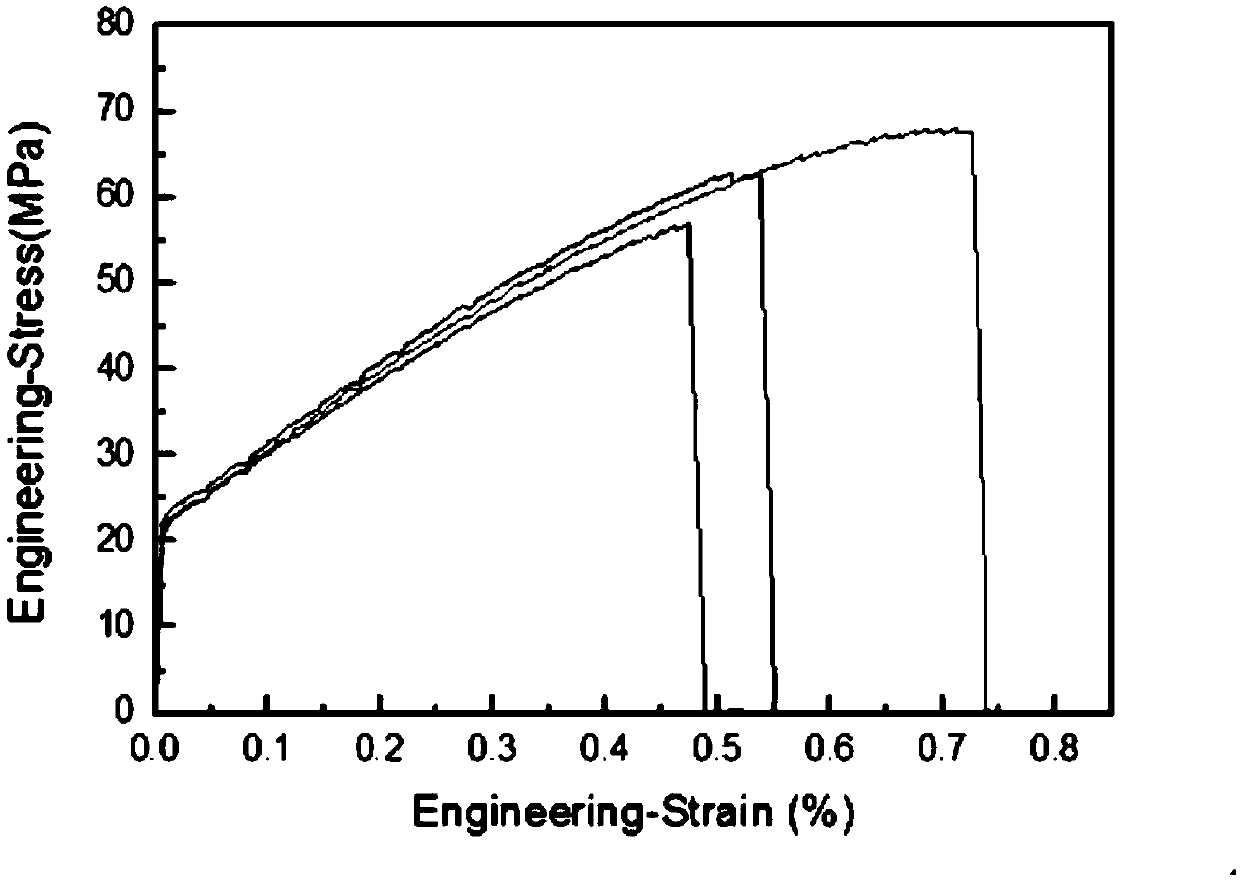

[0072] The manufacturing method of soluble alloy fracturing balls based on oil and gas development specifically includes the following steps: Weigh the following raw materials respectively: 1% zinc, 10% magnesium-calcium master alloy, 5% nickel, 6% copper, 3% ferric chloride, magnesium 3% aluminum master alloy, 4.5% magnesium-neodymium master alloy, 3.5% manganese, 1.1% zirconium compound, and the balance is magnesium. The sum of the parts by mass of the above components is 100%; Heat for 30 minutes to remove moisture; add the weighed magnesium and magnesium-calcium master alloy into the crucible, heat the crucible to 700°C and let it stand for 20 minutes; add zinc and iron to the crucible, stir evenly, and continue to add zirconium into the crucible compound, stand still for 15 minutes; raise the crucible temperature to 720°C, then add nickel, copper, magnesium-neodymium master alloy, magnesium-aluminum master alloy and manganese into the crucible, stir evenly and let stand fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com