Device and method for continuously preparing lithium fluorosulfonate

A technology for lithium fluorosulfonate and lithium fluoride, which is applied in the field of devices for continuous preparation of lithium fluorosulfonate, can solve the problems of hydrogen chloride gas affecting yield, affecting yield, large liquid holding capacity, etc., so as to reduce product refining pressure, The effect of stable product quality and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

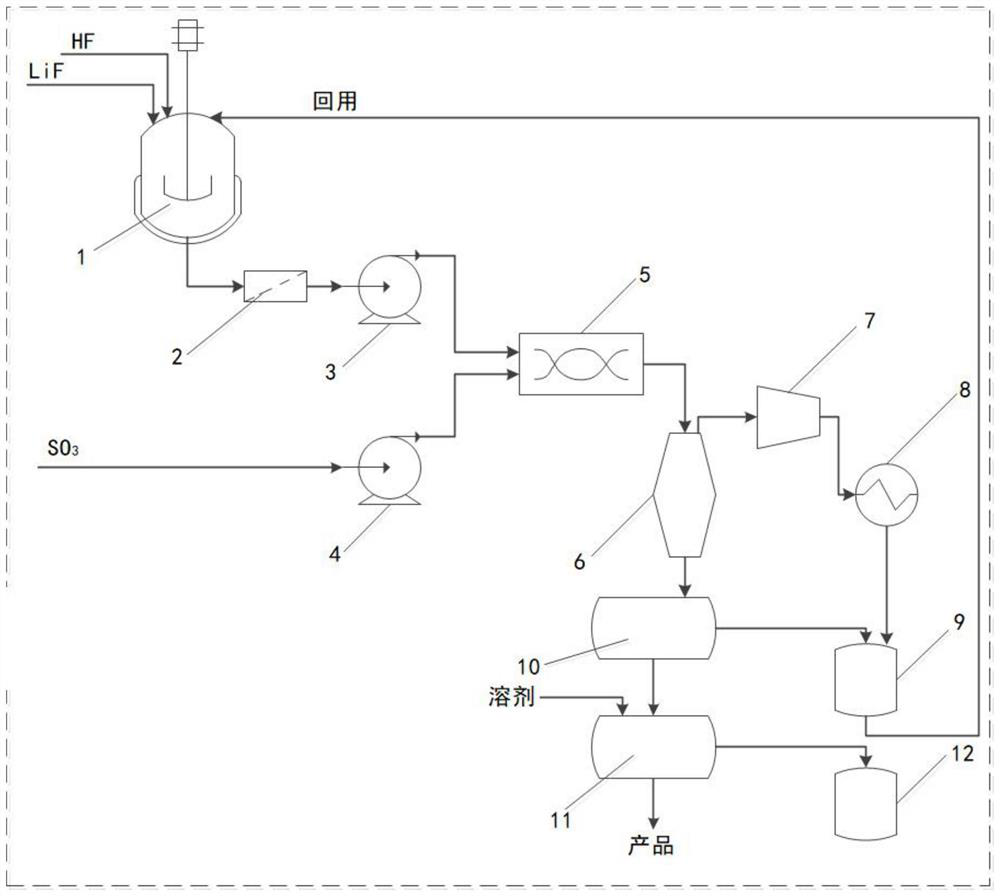

[0037] Embodiment 1: as figure 1As shown, a device for continuously preparing lithium fluorosulfonate includes a pressure-resistant dissolution tank 1, a filter 2, a first metering pump 3, a second metering pump 4, a microreactor 5, an evaporator 6, and a compressor 7. Condenser 8, recovery acid tank 9, crystallizer 10, recrystallizer 11 and solvent recovery tank 12, said pressure-resistant dissolution tank 1 is provided with two feeding ports, which are used to feed anhydrous hydrogen fluoride and fluoride respectively Lithium, the feed port on the second metering pump 4 is used for feeding sulfur trioxide; The pressure-resistant dissolving tank 1 is provided with a stirring device, and the discharge port at the bottom is connected to the inlet end of the filter 2 through a pipeline, The outlet end of described filter 2 is connected on the first metering pump 3 by pipeline, and the discharge port of described first metering pump 3 and the second metering pump 4 are all connec...

Embodiment 2

[0047] Embodiment 2: as figure 1 As shown, a device for continuously preparing lithium fluorosulfonate includes a pressure-resistant dissolution tank 1, a filter 2, a first metering pump 3, a second metering pump 4, a microreactor 5, an evaporator 6, and a compressor 7. Condenser 8, recovery acid tank 9, crystallizer 10, recrystallizer 11 and solvent recovery tank 12, said pressure-resistant dissolution tank 1 is provided with two feeding ports, which are used to feed anhydrous hydrogen fluoride and fluoride respectively Lithium, the feed port on the second metering pump 4 is used to add oleum; The pressure-resistant dissolving tank 1 is provided with a stirring device, and the discharge port at the bottom is connected to the inlet end of the filter 2 through a pipeline, The outlet end of described filter 2 is connected on the first metering pump 3 by pipeline, and the discharge port of described first metering pump 3 and the second metering pump 4 are all connected on the mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com