Patents

Literature

230results about How to "No dripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature resistant flame-retarding textile

The invention aims to provide high-temperature resistant flame-retarding textile. The high-temperature resistant flame-retarding textile is weaved by high-temperature resistant flame-retarding yarns, and the high-temperature resistant flame-retarding yarns are blended with preoxidized fibers, high tenacity flame-retarding fibers and common flame-retarding fibers; and conducting fibers can also be used to weave the high-temperature resistant flame-retarding textile when the high-temperature resistant flame-retarding textile is prepared. The high-temperature resistant flame-retarding textile overcomes the drawback that the preoxidized fiber is difficultly spun, low in tenacity and only has single color of blackness; and the high-temperature resistant flame-retarding textile also has the advantages of high high-temperature resistance, high tenacity, good wearing comfortability, rich color, proper price and safety and reliability for the human body and is reasonable high-temperature resistant flame-retarding textile.

Owner:汕头市奥山服饰有限公司

High-flame-retardance high-heat-resistance halogen-free flame-retardant thermoplastic polyurethane elastomer cable material and preparation method thereof

InactiveCN102816427AImprove heat resistanceImprove brightnessInsulated cablesInsulated conductorsChemistryShore

The invention relates to a high-flame-retardance high-heat-resistance halogen-free flame-retardant thermoplastic polyurethane elastomer cable material and a preparation method thereof, belonging to the field of halogen-free flame-retardant cable materials. The cable material is prepared from the following raw materials in percentage by weight: 20-50% of thermoplastic polyurethane elastomer, 15-40% of styrene elastomer, 3-8% of plasticizer, 20-30% of expansion flame retardant, 4-7% of flatting agent, 0.5-1% of lubricant, 0.5-1% of antioxidant and 1.5-3% of master batch. The thermoplastic polyurethane elastomer is a polyether-type thermoplastic polyurethane elastomer of which the hardness range is Shore A 60-90. The invention improves the problem of too narrow processing temperature region for the thermoplastic polyurethane elastomer cable material, and also improves the heat resistance of the cable material. The thermoplastic polyurethane elastomer, which is used as a base, is subjected to melt blending with the high-temperature-resistant material; and the novel expansion flame retardant which is nonmigratory in contact with water is used as the flame retardant of the base.

Owner:BEIJING UNIV OF CHEM TECH +1

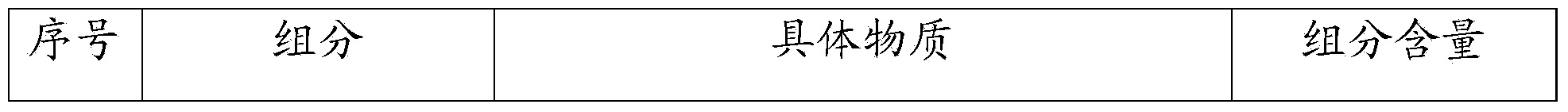

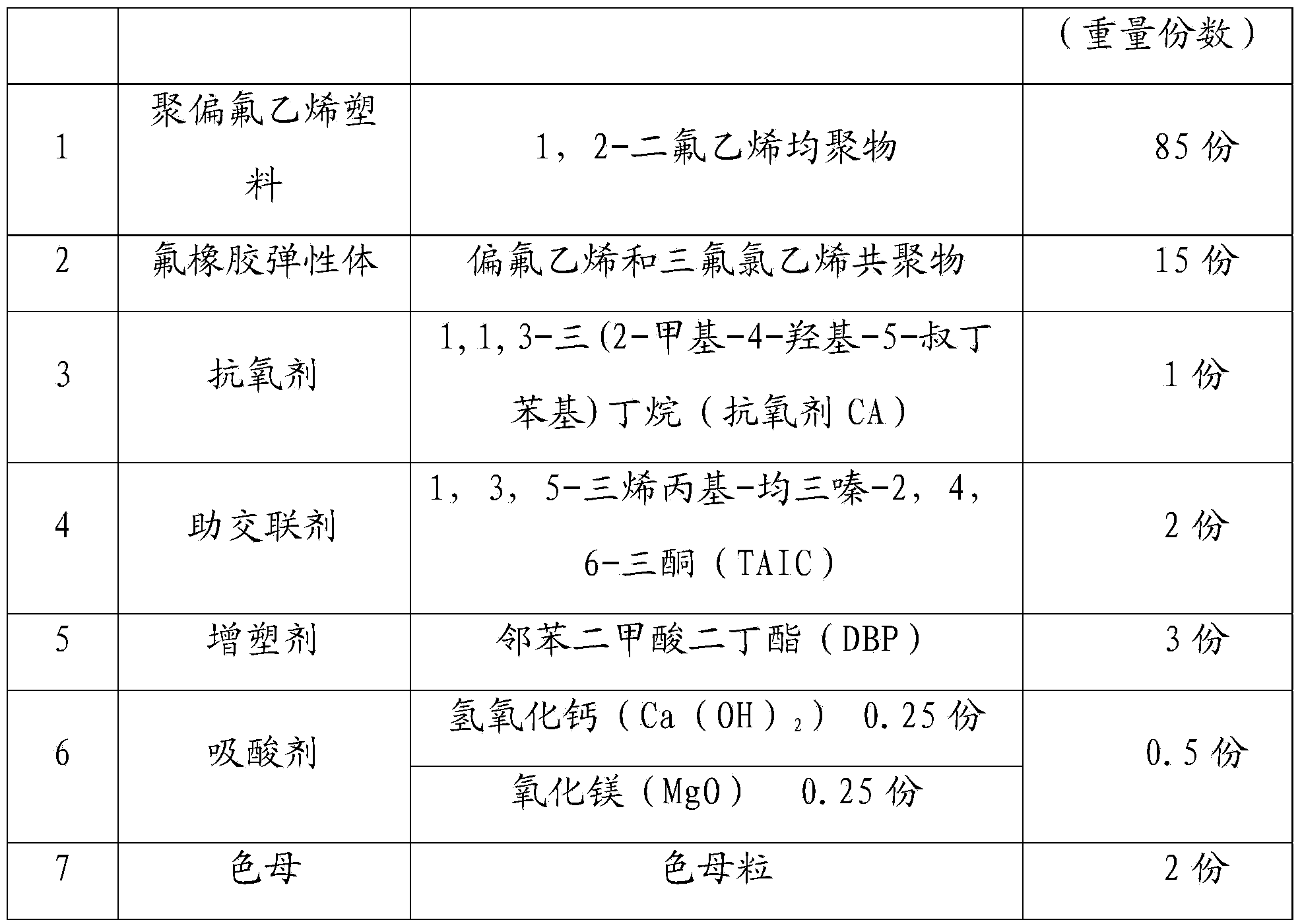

Elastic polyvinylidene fluoride heat-shrinkable sleeve and preparation method thereof

The invention relates to an elastic polyvinylidene fluoride heat-shrinkable sleeve which is composed of the following components in parts by weight: 85-95 parts of polyvinylidene fluoride plastic, 5-15 parts of fluororubber elastomer, 1-3 parts of antioxygen, 2-5 parts of assistant crosslinker, 3-8 parts of plasticizer, 0.5-2 parts of acid accepter and 2-5 parts of color master. The polyvinylidene fluoride plastic is one or two of the following matters: 1,2-difluoroethene homopolymer and 1,2-difluoroethene- hexafluoropropylene homopolymer. The fluororubber elastomer is one, two or more than two of the following matters: vinylidene fluoride and chlorotrifluor ethylene copolymer, vinylidene fluoride and hexafluoropropylene copolymer, vinylidene fluoride, tetrafluoroethylene and hexafluoropropylene terpolymer. According to the elastic polyvinylidene fluoride heat-shrinkable sleeve, such performances of fluoroplastic as wear resistance, mechanical damage resistance and the like are kept simultaneously, elasticity of the heat-shrinkable sleeve is improved, the elastic polyvinylidene fluoride heat-shrinkable sleeve has such specific performances of fluororubber as oil resistance simultaneously, application scope of the fluoride heat-shrinkable sleeve is broadened and risk in the process of use is reduced.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

Xylem filber-polyvinyl chloride composite material and method for producing the same

A wood fiber-polyvinyl chloride composite material and a preparation method thereof, which relate to a composite material and a preparation method thereof. It solves the problem that the wood fiber-polyvinyl chloride composite material has high flammability and produces a large amount of black smoke and toxic gas when burned. The wood fiber-polyvinyl chloride composite material is mainly composed of 100-600 parts of polyvinyl chloride resin, 30-700 parts of wood fiber material, 3-145 parts of intumescent flame retardant, 1-55 parts of copper oxide, 6 ~75 parts of heat stabilizer, 4~60 parts of plasticizer and 4~65 parts of compatibilizer. Preparation method: 1. premixed material; 2. extrusion molding. According to the GB / T8924-2005 standard test of the wood fiber-polyvinyl chloride composite material of the present invention, the oxygen index of the wood fiber-polyvinyl chloride composite material of the present invention is greater than 35%, the ignition time is long, no melting drops occur, and it belongs to the flame retardant grade Material. The preparation method of the wood fiber-polyvinyl chloride composite material of the invention is simple, easy to operate, has low requirements on equipment, and is convenient for popularization and application.

Owner:NORTHEAST FORESTRY UNIVERSITY

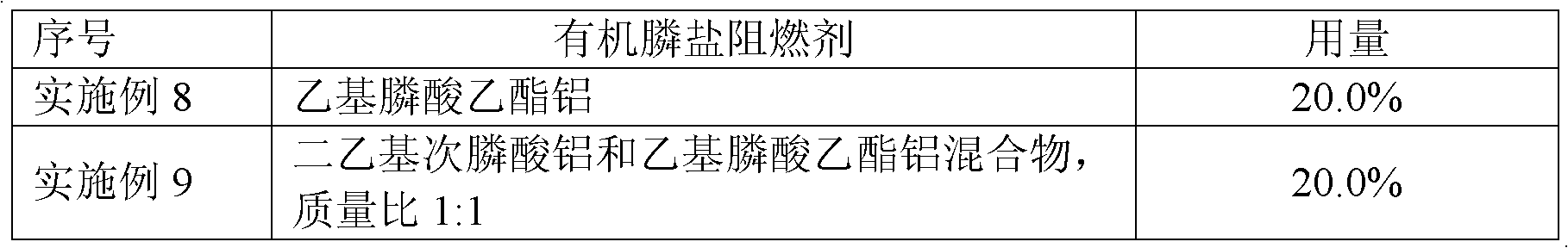

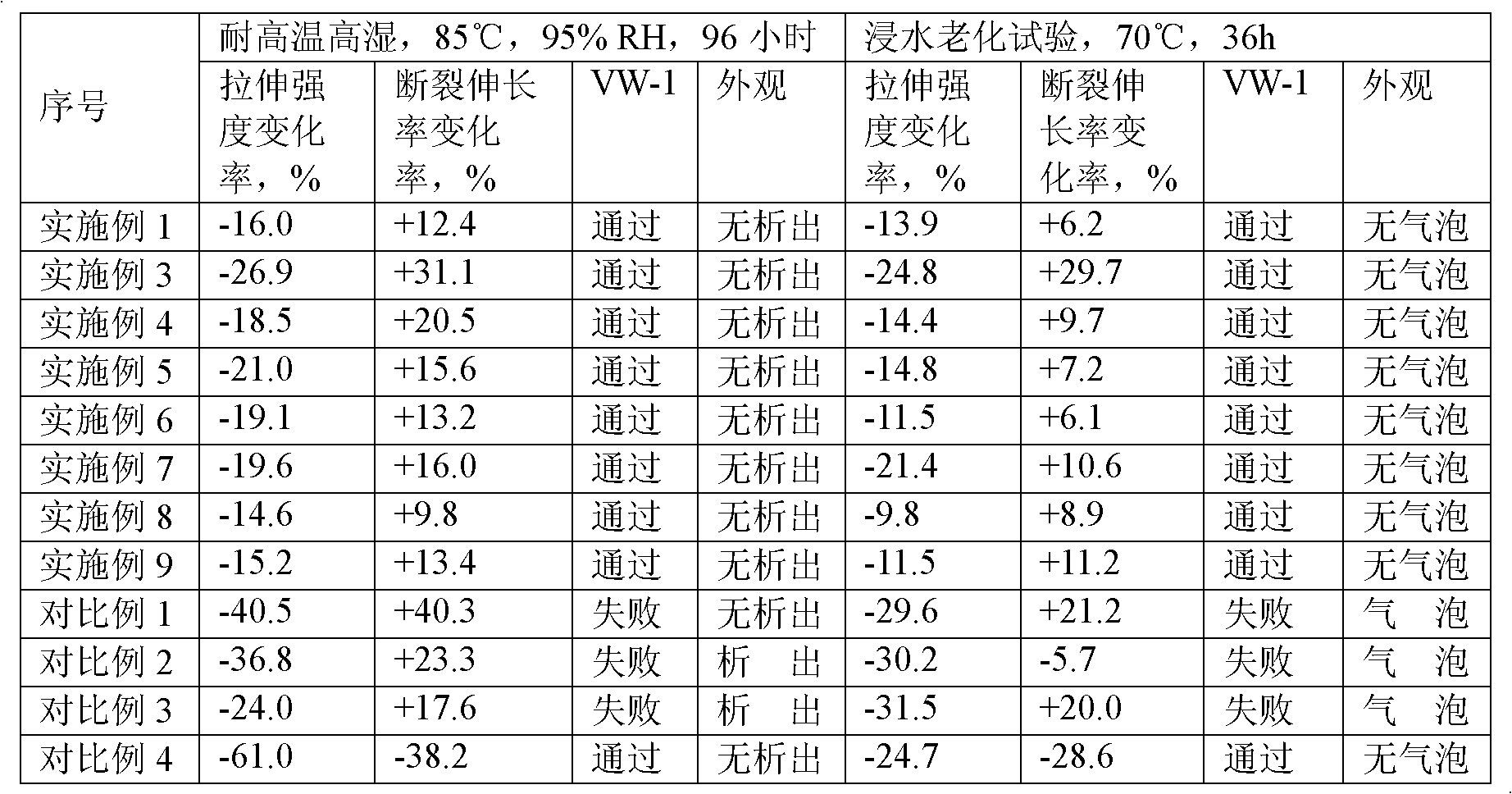

High-temperature-resistant high-moisture-resistant halogen-free flame-retardant polyester type polyurethane thermoplastic elastomer composition

ActiveCN102120875AImprove high temperature and high humidity precipitation performanceGood flame retardant performanceInsulated cablesInsulated conductorsHalogenChemistry

The invention relates to a high-temperature-resistant high-moisture-resistant halogen-free flame-retardant polyester type polyurethane thermoplastic elastomer composition. The invention aims to solve the technical problem of precipitation of the halogen-free flame-retardant polyester type polyurethane elastomer in a high-temperature high-moisture environment, maintain the softness and mechanical strength of the elastomer and conform to the RoHS instruction, thereby satisfying the requirements for high-performance electronic / electric appliance materials and the development characteristics of no halogen and flame retardancy. The invention is characterized in that the high-temperature-resistant high-moisture-resistant halogen-free flame-retardant polyester type polyurethane thermoplastic elastomer composition is prepared from the following components in percentage by weight: 5.0-40.0% of organic phosphonate flame retardant, 0.0-15.0% of nitrogen-containing compound, 1.0-15.0% of viscosity modifier, 0.1-1.5% of antioxidant and ultraviolet absorbent, and the balance of polyether type polyurethane thermoplastic elastomer. The components are premixed, extruded and granulated to obtain the product.

Owner:HANGZHOU JLS FLAME RETARDANTS CHEM

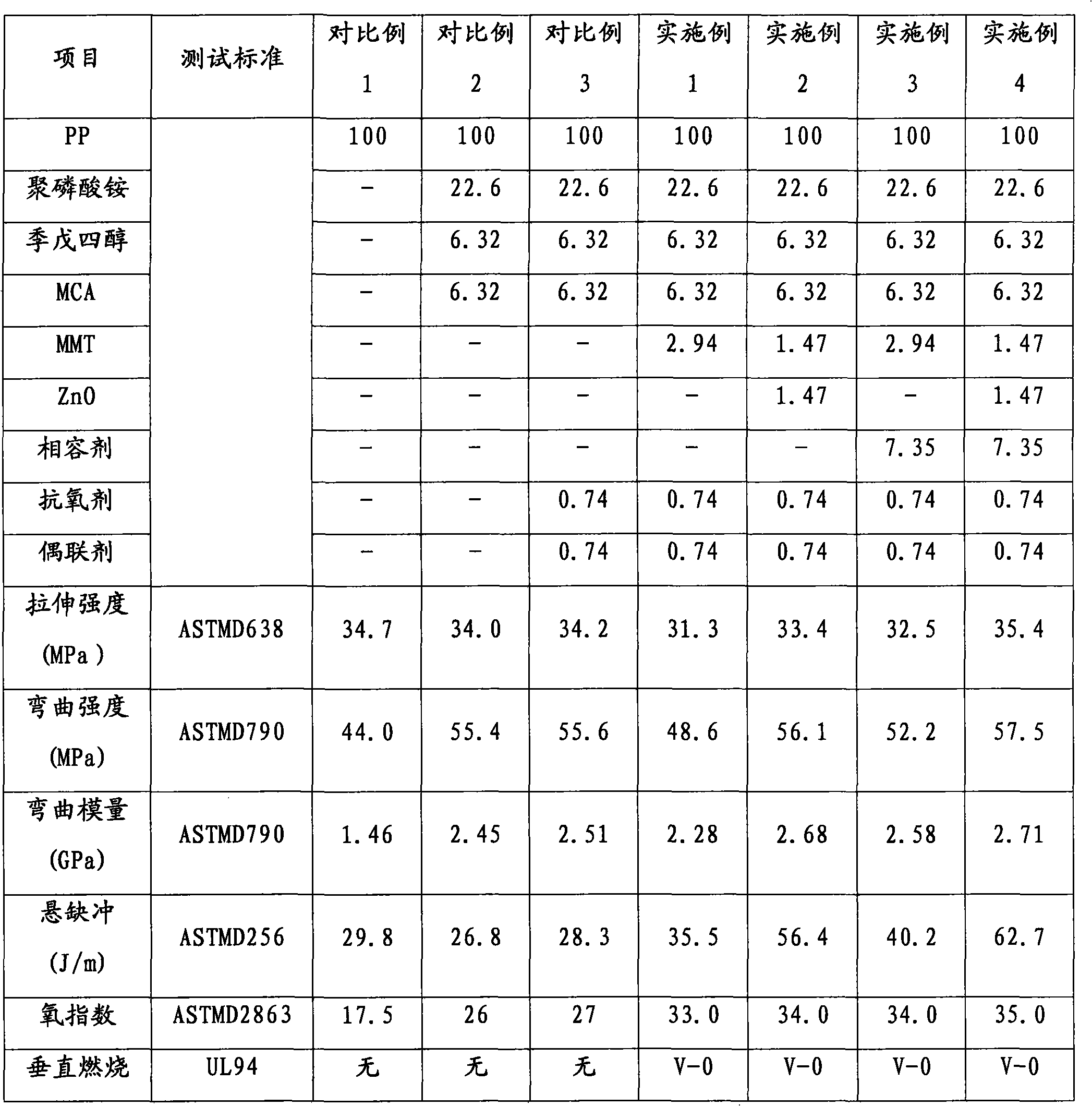

Expanded carbon flame-proof polypropelene composition and preparation method thereof

ActiveCN101293984AThe preparation method is simple and reliableGood flame retardant performanceAmmonium polyphosphateChemistry

The invention relates to an expansive char-forming flame-retardant polypropylene composition and a production method thereof. The composition comprises the following components: 100 weight parts of polypropylene, 10-30 weight parts of ammonium polyphosphate, 2.8-8.3 weight parts of pentaerythritol, 2.8-8.3 weight parts of melamine cyanurate and 0.5-5 weight parts of montmorillonite. The total additional amount of ammonium polyphosphate, pentaerythritol and melamine cyanurate is at least 31 weight parts. The production method comprises the following steps: proportioning all components (including polypropylene, ammonium polyphosphate, pentaerythritol, melamine cyanurate and montmorillonite) at the given ratios, melting, mixing, extruding and granulating. The composition has better flame retardation, good processability and mechanical property. The production method is simple and reliable.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-performance flame-retardant PLA (polylactic acid)/graphene nano-sheet composite material and preparation method thereof

The invention discloses a method for preparing a high-performance flame-retardant PLA (polylactic acid) / graphene nano-sheet composite material. The composite material comprises the following components in parts by weight: 30-100 parts of PLA, 10-30 parts of flame retardant, 5-10 parts of a flame retardant synergist, 1-5 parts of a nucleation accelerant, 2-6 parts of a flexibilizer, 1-6 parts of a graphene nano-sheet, 5-15 parts of carbon fibers, 10-20 parts of glass fiber, and 5-25 parts of talc powder. According to the preparation method, the mechanical performance of PLC can be improved by adopting the graphene nano-sheet which is subjected to surface treatment by a silane coupling agent. The composite material has the advantages that the compatibility of the graphene nano-sheet and PLA can be improved, the graphene nano-sheet can be well dispersed in matrix resin to play the effect of synergetic flame retardance.

Owner:JIANGSU YUEDA NEW MATERIALS TECH

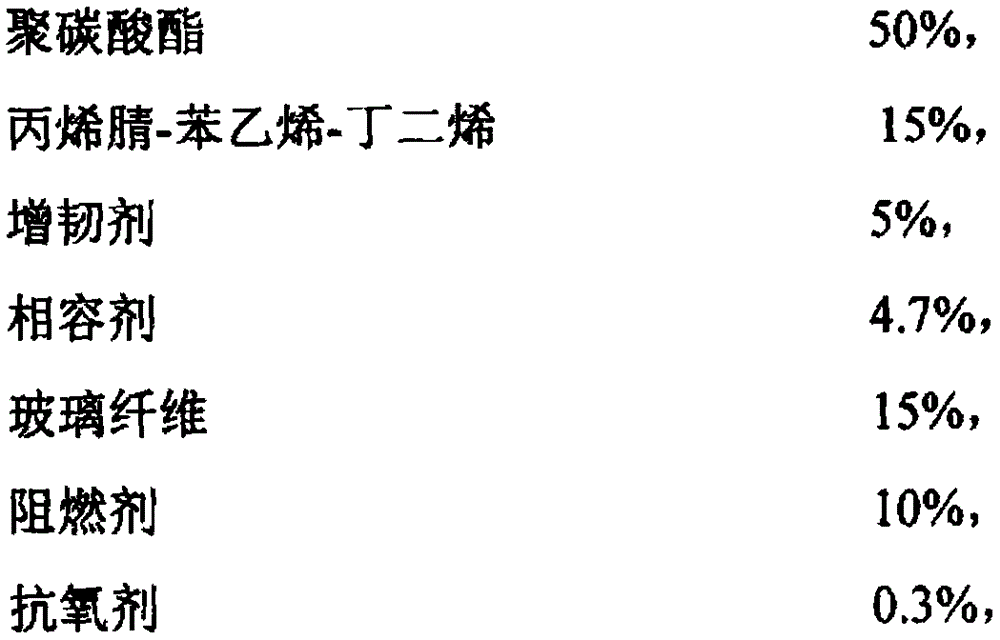

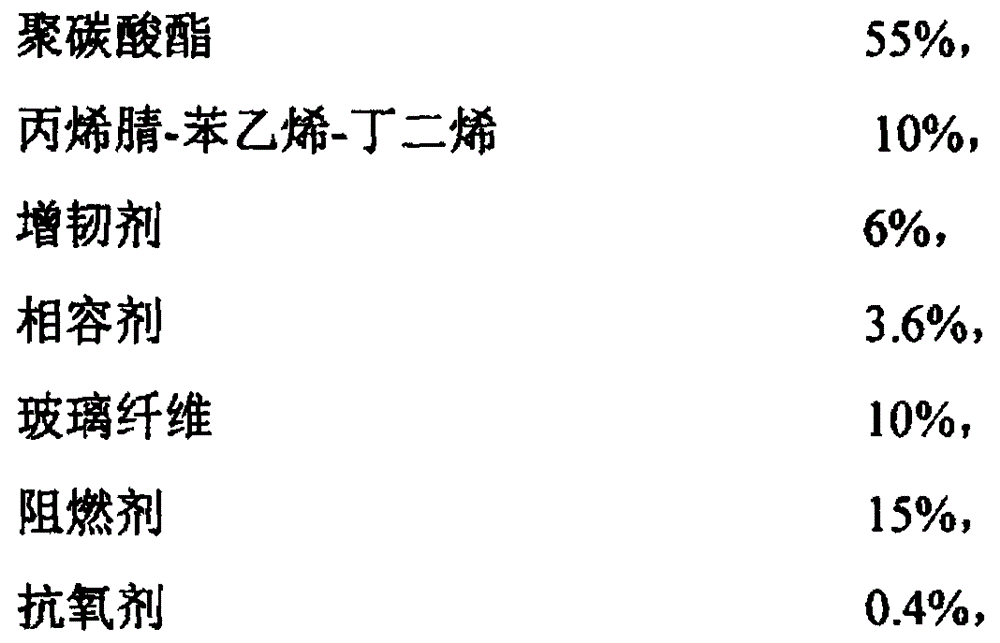

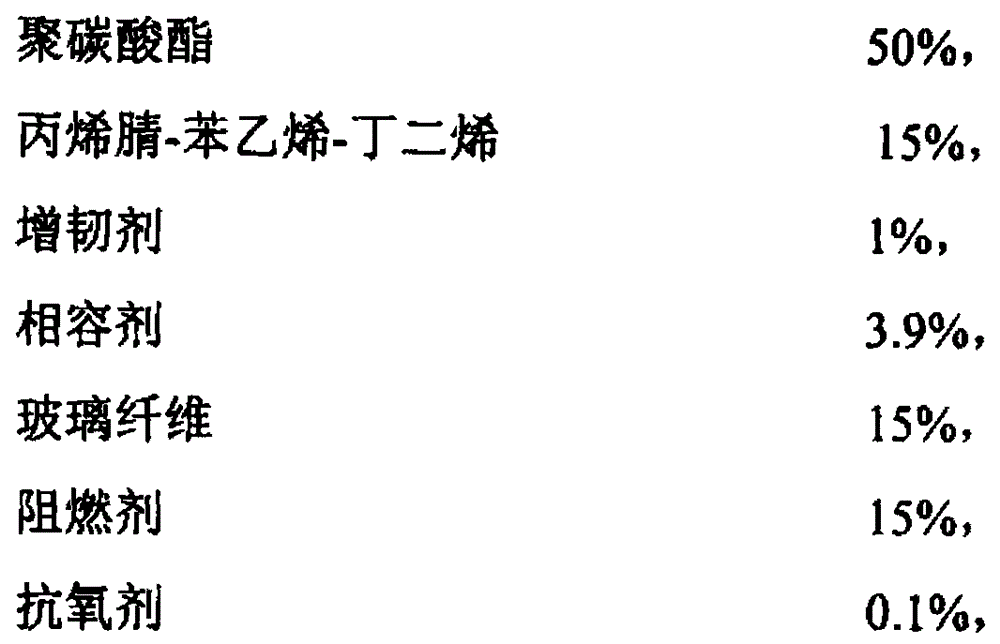

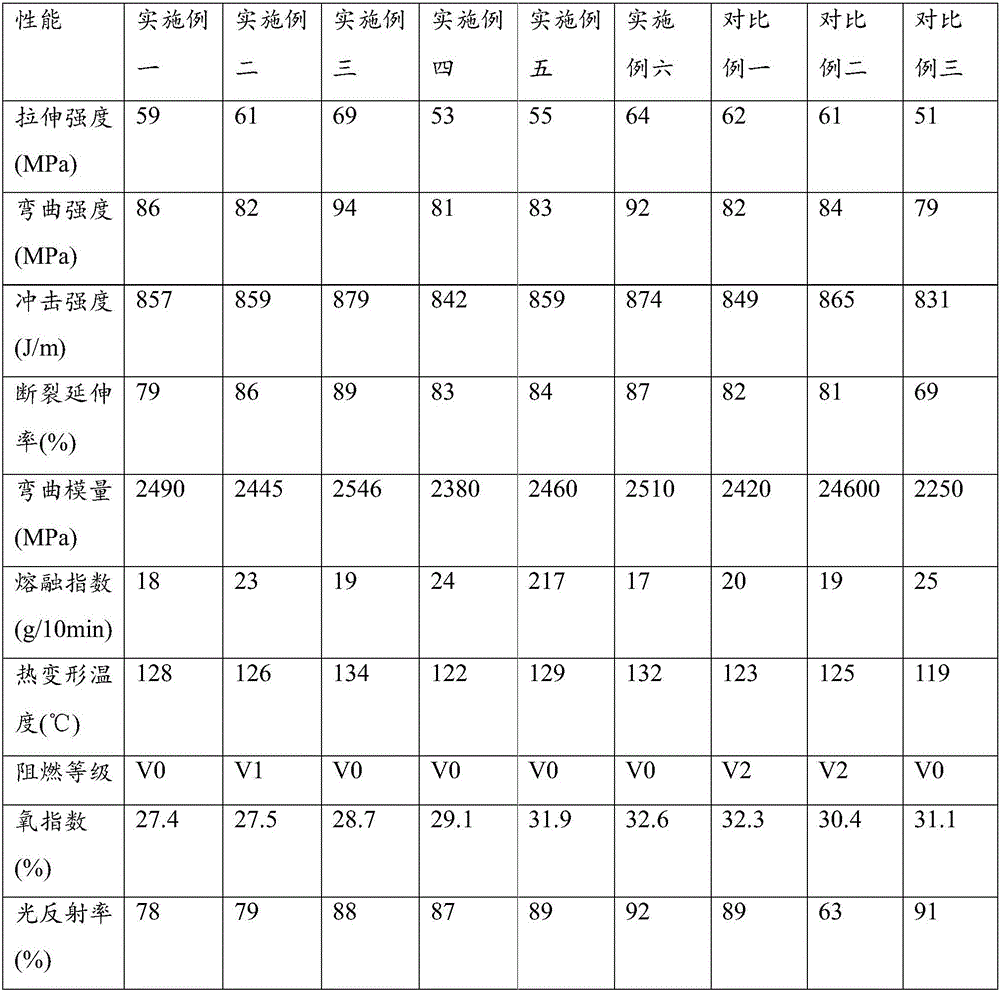

Intumescent flame-retardant reinforced PC (Polycarbonate)/ABS (Acrylonitrile Butadiene Styrene) alloy and preparation method thereof

The invention relates to an intumescent flame-retardant reinforced PC (Polycarbonate) / ABS (Acrylonitrile Butadiene Styrene) alloy and a preparation method thereof. The intumescent flame-retardant reinforced PC / ABS alloy is prepared from the following components in parts by weight: 40-60 parts of PC, 10-25 parts of ABS, 1-10 parts of toughening agent, 3-10 parts of compatilizer, 10-20 parts of glass fiber, 10-20 parts of flame retardant and 0.1-0.5 part of antioxidant. The preparation method comprises the steps of proportioning according to the weight ratio, placing other raw materials except for glass fiber into a high-speed mixer to mix for 2-5min, and adding the mixture through a first-section drum of a double-screw extruder; adding glass fiber through a fourth-section drum of the double-screw extruder; and controlling the rotating speed of the double-screw extruder at 300-500r / min, extruding and granulating to prepare the PC / ABS alloy. The vertical combustion grade of the intumescent flame-retardant reinforced PC (Polycarbonate) / ABS alloy is UL94V-0(3.2mm). In addition, the intumescent flame-retardant reinforced PC (Polycarbonate) / ABS alloy is free of pollution during combustion so as to be capable of generating nontoxic gases during combustion, favorable in environment friendliness, little in influence to the mechanical performance of a material and favorable in mechanical performance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Modified melamine formaldehyde resin-based EPS flame retardant thermal insulating board and preparation method thereof

ActiveCN103711211APrevent sinkingDoes not increase stirring mixing resistanceHeat proofingFire proofingThermal insulationAdhesive

The invention discloses a modified melamine formaldehyde resin-based EPS flame retardant thermal insulating board and a preparation method thereof. The modified melamine formaldehyde resin-based EPS flame retardant thermal insulating board is prepared by using modified melamine formaldehyde as binder and polystyrene foaming particles as foaming thermal insulating materials under certain process conditions. The flame retardant thermal insulating board has the advantages that the combustion performance of the flame retardant thermal insulating board can reach level A, combustion, collapse and dripping can be prevented when the board is grilled by open fire, and the potential fire hazard of outer wall outer thermal insulation is eliminated; the board has excellent thermal insulation performance and mechanical strength; the board can be fixed on the outer building envelope structure by means of adhesives, fixing anchor bolts, hot galvanizing zinc wire mesh, and the like to perform thermal insulation.

Owner:SUZHOU INST OF BUILDING SCI GRP CO LTD

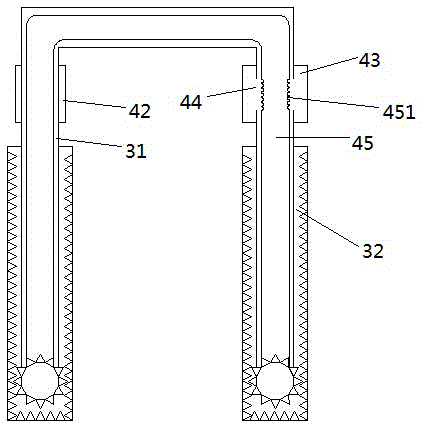

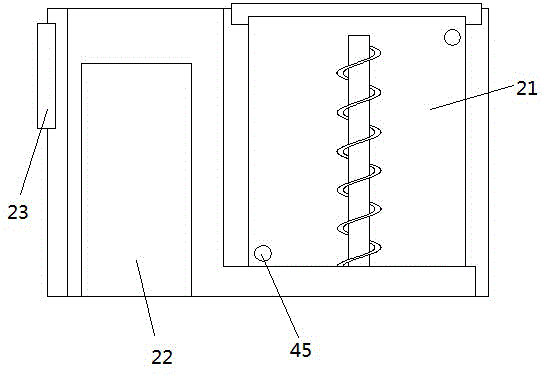

Delayed coagulation adhesive used for retard-bonded prestressed tendon

InactiveCN101570675AImprove stabilityImprove reinforcementNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesivePolyamide

The invention relates to a delayed coagulation adhesive used for retard-bonded prestressed tendon, comprising the components: 100 parts by weight of bisphenol-A type epoxide resin, 20-80 parts by weight of reactive diluent dihydric alcohol diglycidyl ether, 5-20 parts by weight of non-activated thinner, 5-25 parts by weight of low molecular weight polyamide resin curing agent, 0.1-5 parts by weight of thixotropic agent, 50-100 parts by weight of cement and 50-100 parts by weight of calcium carbonate. After being processed by an outer pack PE extrusion device, the delayed coagulation adhesive has no phenomenon of drippage and can be still evenly coated and wrapped around a steel stranded wire.

Owner:CHINA JINGYE ENG TECH CO LTD +1

Preparation method of toughening-modified phenolic resin and phenolic foam

The invention provides a preparation method of a toughening-modified phenolic resin and phenolic foam. The preparation method of the phenolic resin comprises the following steps: adding phenol and an alkali catalyst into a reaction kettle, heating to 65-75 DEG C while stirring, and adding a mixture 1, wherein the mol ratio of phenol to alkali catalyst to mixture 1 is 24.6:(0.03-0.09):(16-26.8). The preparation method of the phenolic foam comprises the following step: adding toughener-containing mineral inorganic powder capable of adsorbing and degrading free formaldehyde and free phenol in the resin, a foaming agent, a curing agent and a foam stabilizer into the prepared phenolic resin, thereby obtaining the phenolic foam. The phenolic resin prepared by the method provided by the invention has the advantages of high toughness, favorable flame retardancy, low contents of free formaldehyde and free phenol, and no waste water discharge in the production process. The phenolic resin foam prepared by the method provided by the invention has the advantages of low heat conductivity coefficient, high percentage of close area, favorable toughness, high oxygen index (up to higher than 50), no cracking, no shedding, no dropping, low smoke and no toxicity.

Owner:单成敏

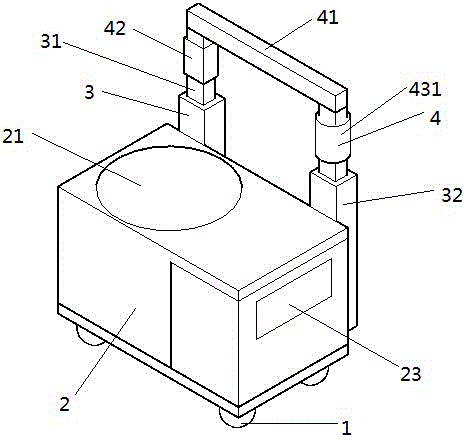

Brushing method of functional environment-friendly paint

InactiveCN104962183AAntioxidantFunctionalLiquid surface applicatorsAnti-corrosive paintsGlycerolAdipic acid

The invention discloses a brushing method of a functional environment-friendly paint, which comprises a mobile device, a carrying box arranged on the mobile device, a lifting device and a wall brushing device, wherein the lifting device is arranged on one side in the carrying box and used for lifting; the wall brushing device is arranged on the lifting device and used for wall brushing; a containing cavity for containing the paint and a power unit are arranged in the carrying box; one side of the carrying box is provided with a display control system; the lifting device comprises a first lifting bracket and a second lifting bracket; and the functional environment-friendly paint is automatically brushed on the wall surface through an automatic wall brushing machine. The paint comprises a raw material glycerol, pentaerythritol, trimethylolpropane, phthalic acid, adipic acid, trimellitie anhydride, maleic acid, triethylamine, a first solid additive, a second solid additive, a first composite regulator, a second composite regulator and a third composite regulator. The method has the advantages of low manufacturing cost and favorable wall brushing effect, and is suitable for wide application in the market.

Owner:ZHEJIANG QIAOXING CONSTR GRP

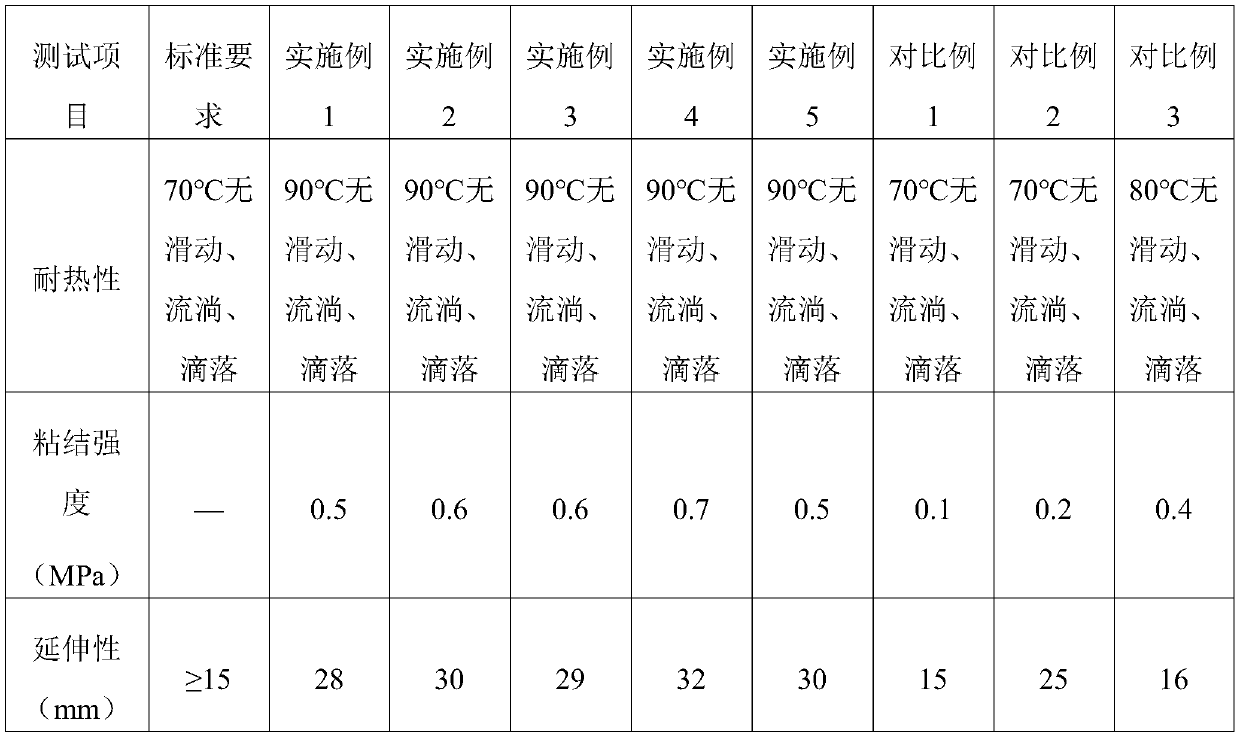

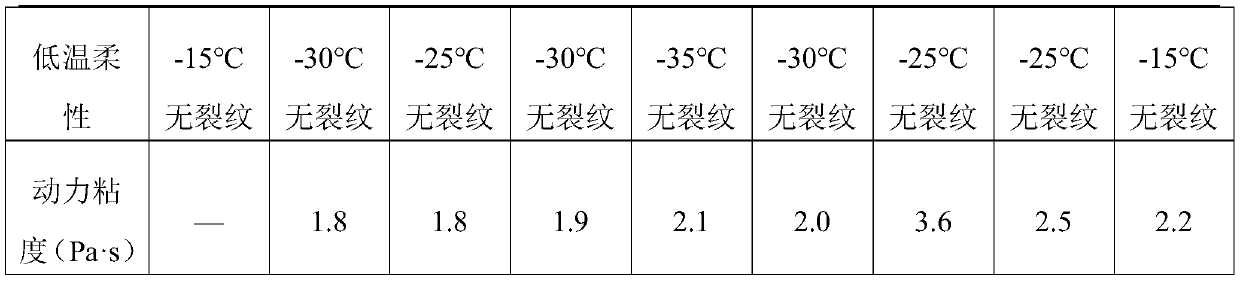

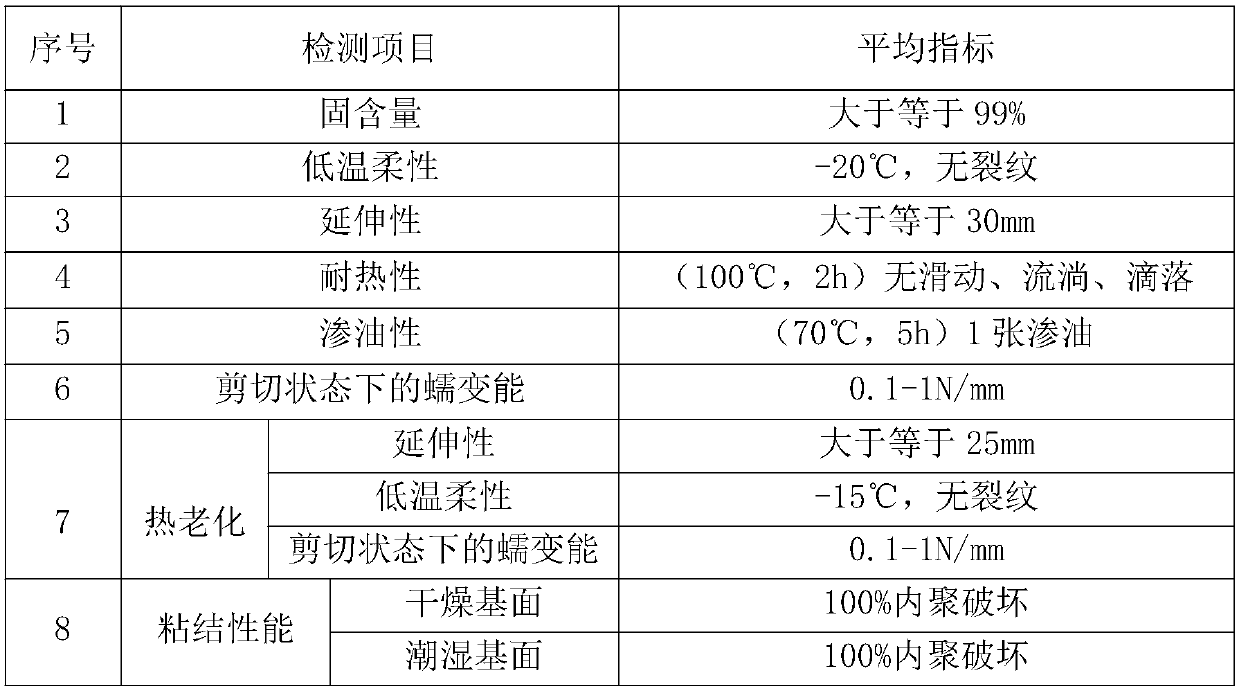

Novel high-temperature-resistant non-curing waterproof coating and preparation method thereof

InactiveCN110016291AImprove high temperature resistanceImprove adhesionFireproof paintsOther rubber coatingsPolymer sciencePolyamide

The invention belongs to the technical field of building materials, and provides a novel high-temperature-resistant non-curing waterproof coating. The coating is composed of the following components in percentage by weight: 25-35% of asphalt, 15-30% of rubber oil, 10-20% of waste tire rubber powder, 5-10% of styrene-butadiene rubber, 1-3% of styrene-butadiene-styrene (SBS), 4-10% of tackifying resin, 10-20% of fly ash, 2-5% of a high-temperature modifier and 2-5% of a viscosity reducer, wherein the high-temperature modifier is a BL modifier or polyamide wax. The preparation method is carried out by adopting a three-section-type feeding method and comprises the following steps: adding asphalt and rubber oil, carrying out heating to 150 DEG C, then adding the SBS, the styrene-butadiene rubber, the tackifying resin and the viscosity reducer, carrying out heating to 180 DEG C, then adding the fly ash and a high-temperature modifier, mixing the components at 180 DEG C to form a uniform liquid, and carrying out cooling and discharging to obtain the novel high-temperature-resistant non-curing waterproof coating. The invention solves the problem that a non-curing rubber asphalt waterproofcoating is poor in heat resistance.

Owner:河南驼峰防水科技有限公司

Civil aluminum alloy conductor, wiring and preparation method thereof

ActiveCN101937733AImprove corrosion resistanceStrong corrosion resistanceFlexible cablesMetal/alloy conductorsElectrical conductorManufacturing technology

The invention provides a method for manufacturing civil aluminum alloy wiring, belonging to the technical field of wire and cable design and manufacture. The manufacture method comprises the following steps: adding aluminum ingots, aluminum-iron master alloy, aluminum-boron master alloy and aluminum-rare earth master alloy into a shaft furnace; casting into a cast strip after smelting; rolling into an aluminum alloy rod through a rolling mill; preparing an aluminum alloy filament by the aluminum alloy through cold drawing; annealing, and performing extruded insulation on the aluminum alloy wire, wherein the insulation material is silane-crosslinked polyethylene; adding low halogen or halogen-free flame retardant during insulation; and performing warm water crosslinking or steam crosslinking treatment on the aluminum alloy wiring after the extruded insulation is completed. The aluminum alloy wiring has excellent conductivity, tensile property and bending performance; and the wire has better flame retardant performance and longer service life.

Owner:于贵良 +1

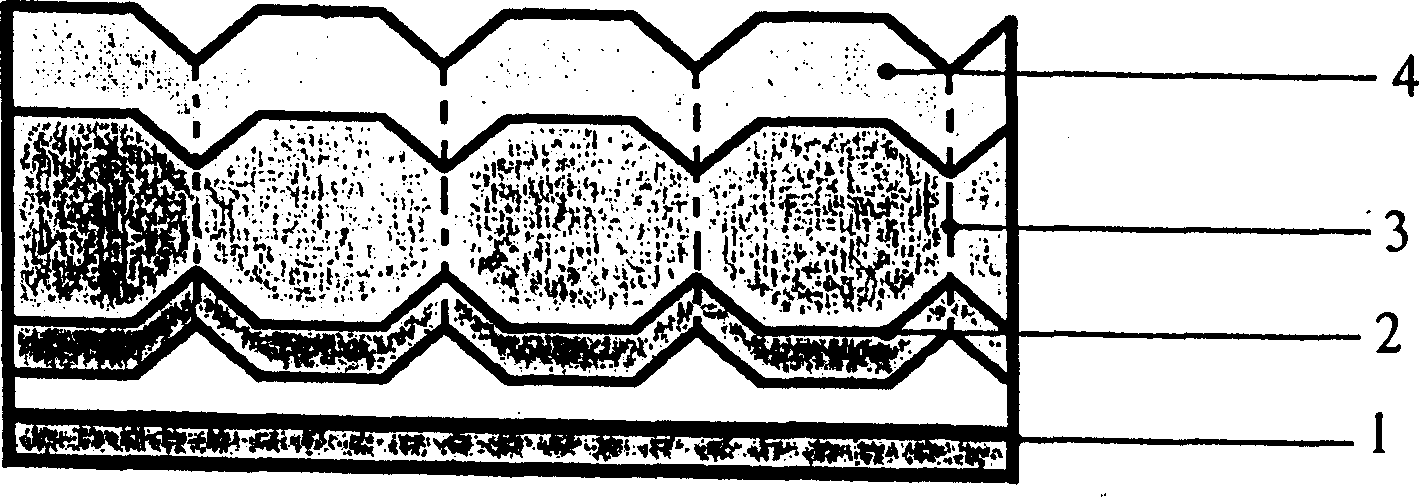

Fire-retardant, heat-isolating, waterproof and breathing comfortable fireman suit material

InactiveCN1548291AImprove fire extinguishing effectNo meltingSynthetic resin layered productsThermal stabilityFire retardant

The fire-retardant, heat-isolating, waterproof and breathing comfortable fireman suit material includes from outside to inside fireproof layer, waterproof and breathing layer, heat-isolating layer and comfortable layer. Owing to the reinforced fire-retardant and heat-isolating performance, the present invention can reduce the fire distinguishing distance to raise the fire distinguishing effect. The material has overall protecting performance of 30.7 cal / sq cm as well as high fire-retardant performance, high strength, water resisting resistance, etc.

Owner:SHANGHAI GARMENT GRP IMP & EXP

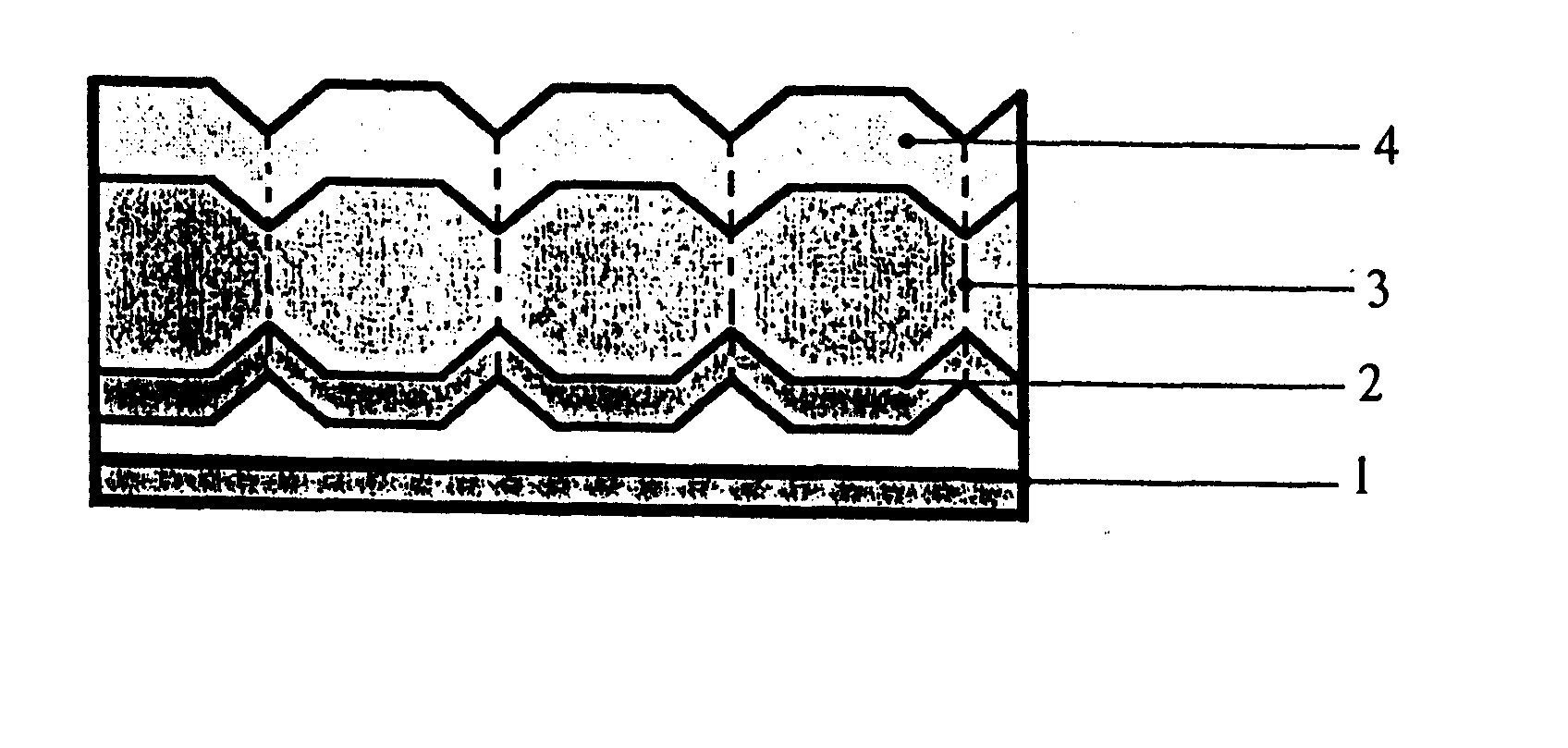

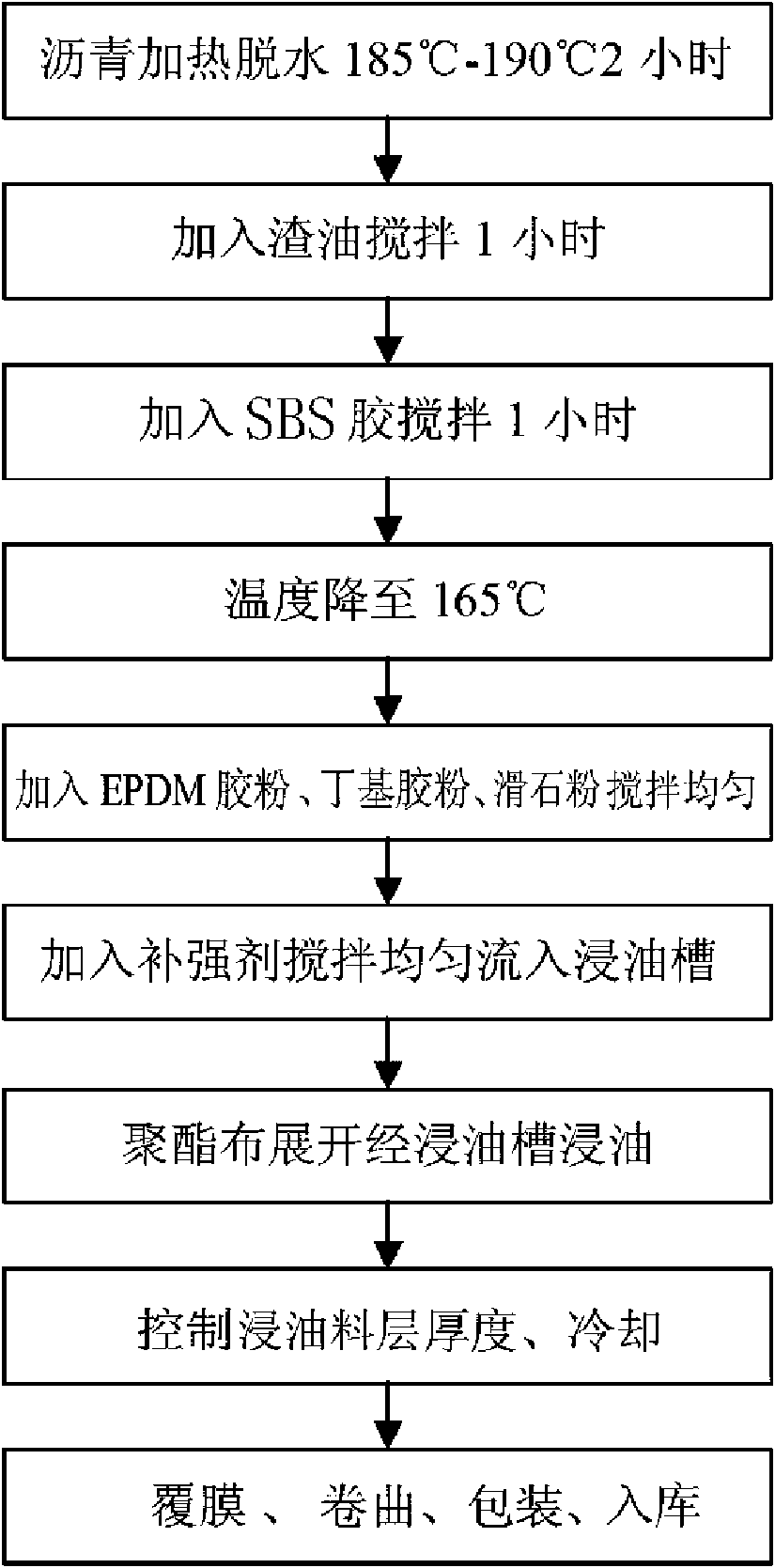

Styrene butadiene styrene (SBS) modified bituminous waterproof sheet material and preparation technology thereof

InactiveCN101644095AIncrease elasticityBright appearanceRoadwaysUnderground chambersBituminous waterproofingPolyester

The invention provides a styrene butadiene styrene (SBS) modified bituminous waterproof sheet material and preparation technology thereof. The waterproof sheet material comprises polyester cloths, animmersion oil coating layer and a film-mulching layer. The immersion oil coating layer comprises the following materials in parts by mass: 32-52 parts of bitumen, 12-22 parts of residual oil, 9-19 parts of EPDM rubber powder, 2-7 parts of butyl rubber powder, 11-21 parts of talc powder and 5.6-10.6 parts of SBS rubber. The bitumen is the mixture of 9-19 parts of 10# bitumen and 23-33 parts of 60#bitumen. The invention is characterized by wide high temperature and low temperature resistance range, good elasticity and good hardness, is not easy to deform and is suitable for various levels of waterproofing works of roofing of industrial and civil buildings, underground, bridges, highways, swimming pools and the like in the south and in the north.

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD

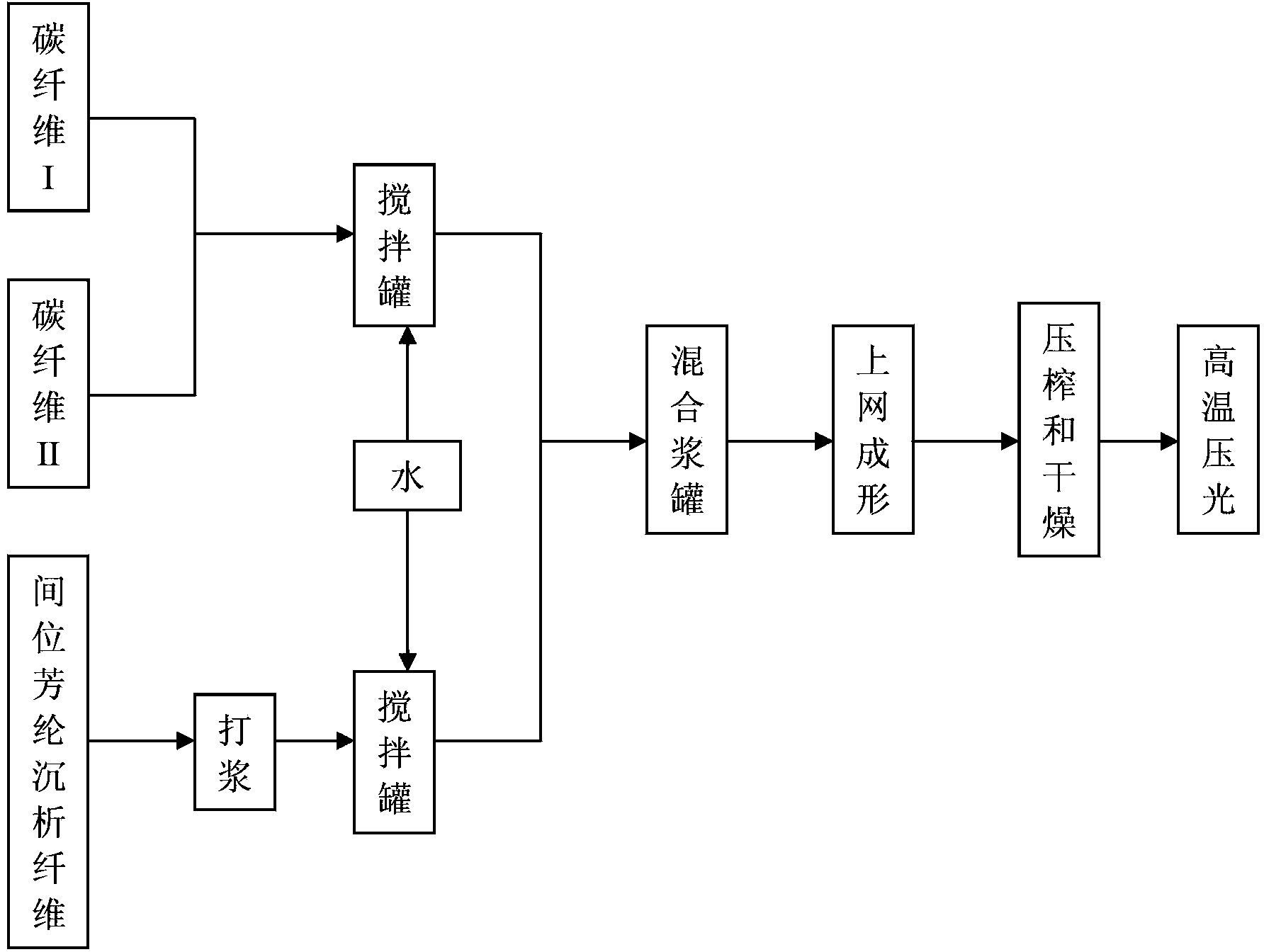

Electrothermal high-temperature-resistant carbon fiber paper and preparation method thereof

ActiveCN103451989AHigh mechanical strengthEasy to operateSynthetic cellulose/non-cellulose material pulp/paperFiberPapermaking

The invention discloses pulp of electrothermal high-temperature-resistant carbon fiber paper. Fiber in the pulp comprises the following components in percentage by weight: 40-70% of carbon fiber I, 5-30% of carbon fiber II and 5-30% of meta-aromatic acrylic fibrid, wherein the length of the carbon fiber I is 1-5mm, and the fiber number is 1.5D; the length of the carbon fiber II is 8-10mm, and the fiber number is 1.5D; the pulp beating degree of the meta-aromatic acrylic fibrid is 40-80 degree SR. The invention further discloses a preparation method of the pulp, meta-aromatic acrylic fibrid / carbon fiber composite electrothermal high temperature-resistant carbon fiber paper prepared by using the pulp and a preparation method thereof. According to the method disclosed by the invention, the mechanical strength and the operability of the composite paper are significantly improved, paper breaking during papermaking is reduced, the production efficiency is improved, the temperature resistance level and the flame retardance of the composite carbon fiber paper are simultaneously upgraded, and the safety performance is improved.

Owner:YANTAI METASTAR SPECIAL PAPER

Preparation method of modified phenolic resin and application thereof

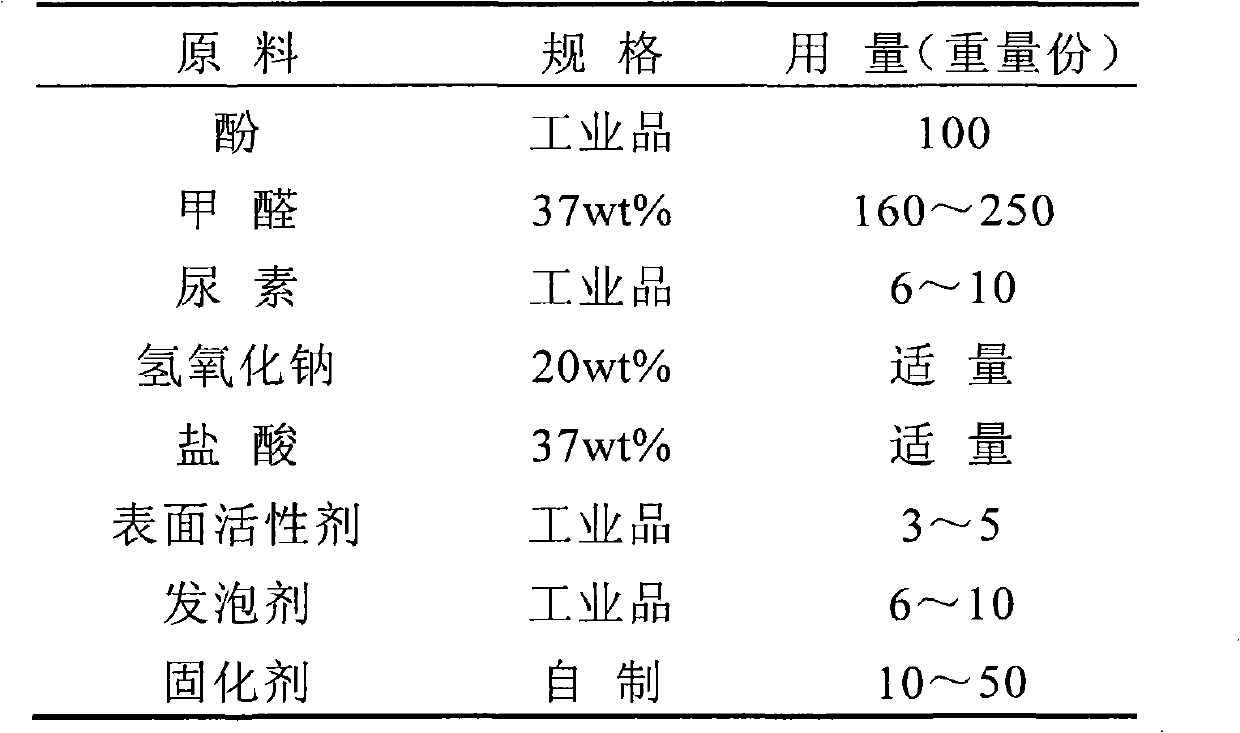

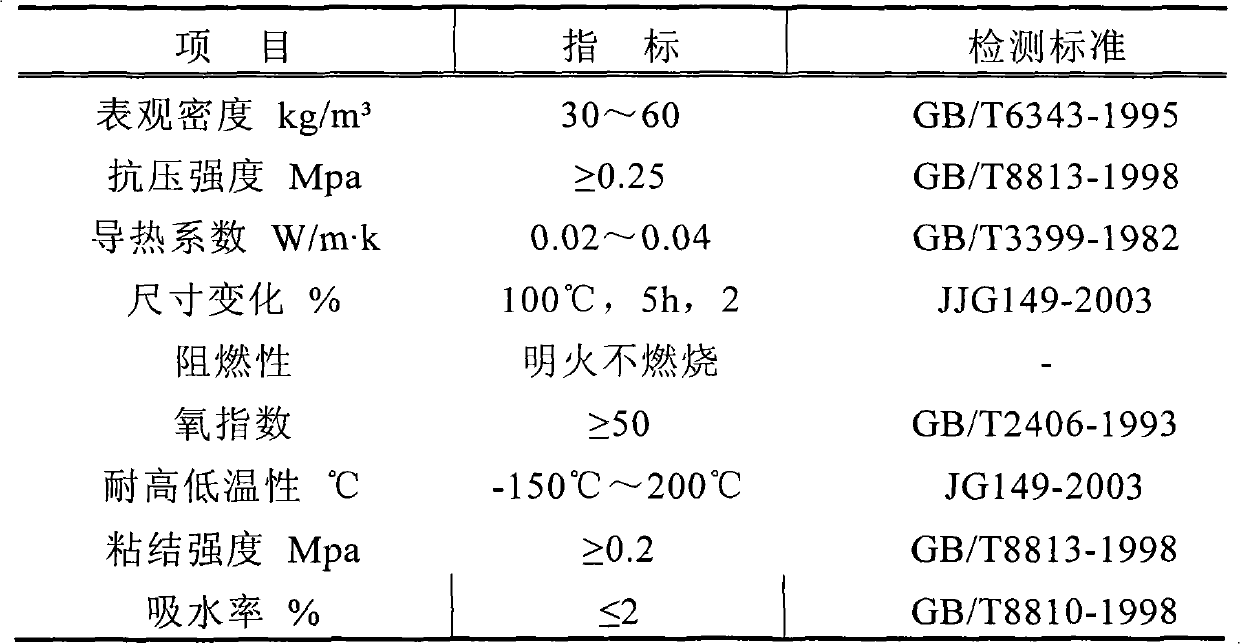

The invention discloses a preparation method of modified phenolic resin and an application thereof. The preparation method comprises the following steps of: firstly carrying out polycondensation on phenol, formaldehyde and urea under the conditions of a basic catalyst, the temperature of 85 to 95 DEG C and the pH value of 8 to 9, and regulating the pH value to 6.5 to 7.0 after the reaction is ended; then carrying out vacuum dehydration on polycondensation products under the vacuum condition, enabling the solid content to be 80 to 85 percent by weight, cooling to the room temperature, and regulating the viscosity to be 2.0 to 3.0Pa.s; and finally adding a surfactant and a foaming agent, stirring, discharging and packaging. Furthermore, a composite curing agent is also necessary to be mixed with the modified phenolic resin when in use according to the mass ratio of 100: 10 to 50. The prepared modified phenolic resin has the advantages of light weight, low toxicity, difficult combustion, low smoke, heat insulation, high temperature and low temperature resistance, and the like, can be widely used in the fields of building, transportation, shipping, chemical engineering, petroleum, and the like and has a certain social and economic benefits.

Owner:上海虞城新型建材有限公司 +1

Epoxy non-cured rubber asphalt waterproof coating and preparation method thereof

InactiveCN107739575ASolve the problem of heating to constructionEnsure safetyFireproof paintsOther rubber coatingsSelf-healingEpoxy

The invention discloses an epoxy non-cured rubber asphalt waterproof coating and a preparation method thereof and belongs to the field of coatings. The coating comprises a component A and a componentB, wherein the component A is prepared from asphalt, plasticizers, polymer modifiers and epoxy resin; the component B is prepared from epoxy curing agents. The problem that the non-cured rubber asphalt waterproof coating can be constructed after the coating is heated can be solved; the coating is energy-saving and environmentally friendly; the safety of constructors is ensured; the construction operation is simplified; the application range of the product is expanded; the coating is excellent in construction performance, does not need to be heated in the whole construction process, is excellent in high-temperature performance, can achieve obstacle-free construction under high temperature and low temperature, and is high in flexibility, high in elongation rate, excellent in creep property,high in self-healing capability, high in water channeling resistance and high in adhesion performance.

Owner:SICHUAN SHUYANG WATERPROOF MATERIAL

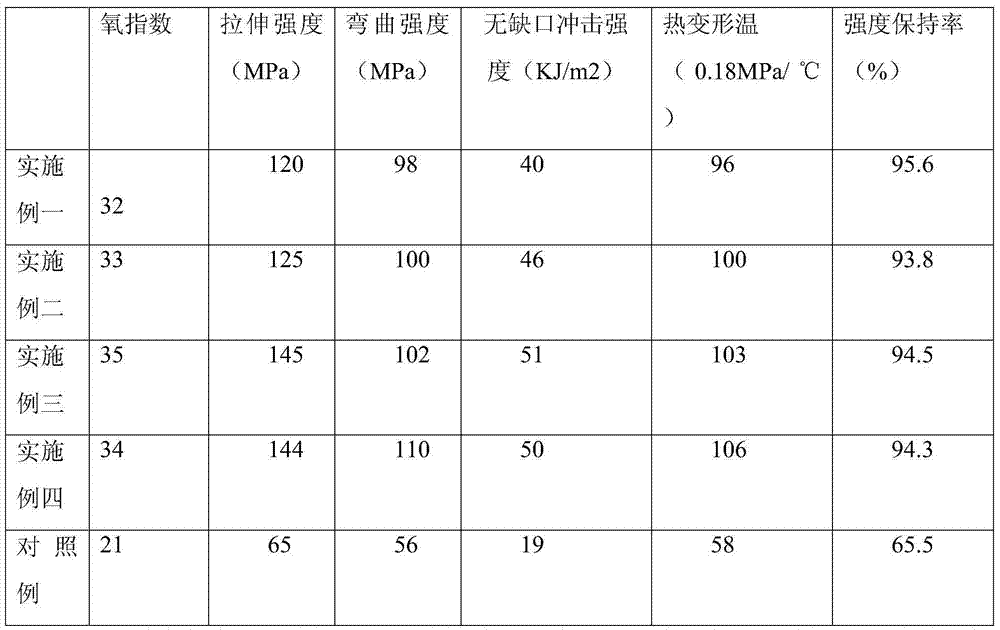

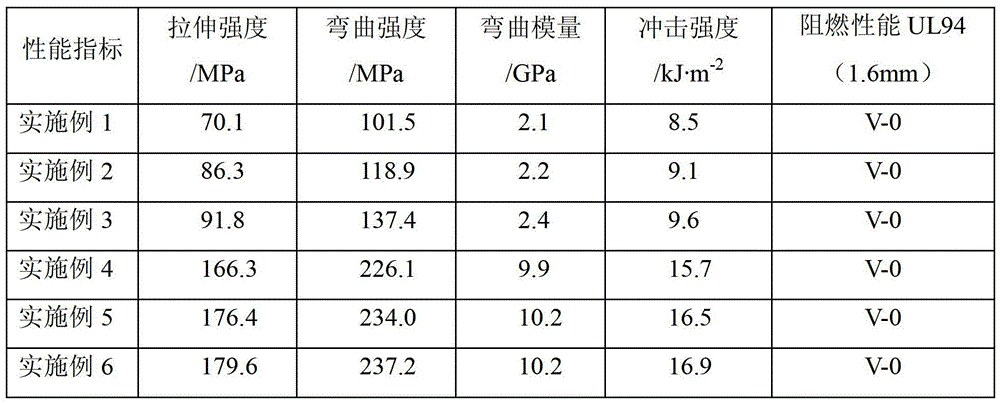

Fire retardant glass fiber reinforced nylon composite material, and preparation method thereof

InactiveCN103937229ASolve the problem of "candle wick effect"Improve charcoal abilityGlass fiberPolyphosphate

The invention belongs to the technical field of polymer composite materials, and relates to a glass fiber reinforced nylon composite material and a preparation method thereof. The composite material is composed of the following components in parts by weight: 100 parts of nylon, 35 to 50 parts of fire retardant, 7.5 to 15 parts of charring agent, 0.2 to 1.0 part of coupling agent, 0.1 to 0.5 part of antioxidant, 0.2 to 1.0 part of lubricant, and 400 to 100 parts of glass fiber. A fire retardant namely melamine polyphosphate is added so as to effectively solve the problem of candle wick effect of glass fiber reinforced nylon, and the modified nylon has the characteristics of strong charring performance, no dripping, no toxicity, and no corrosion. Moreover, a charring agent is added, and a synergetic fire retardant effect is generated by the cooperation of the charring agent and the melamine polyphosphate, so the fire-retardant performance of the nylon composite material is greatly improved.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Modified phenolic aldehyde insulation foamed material preparation method

The invention discloses a modified phenolic aldehyde insulation foamed material preparation method, which belongs to the foamed material field. According to the invention, an organic-inorganic nanocomposite is taken as a modifier, the modifier, a surfactant, a foaming agent and an acidic curing agent are added in phenolic resin, the resulting mixture is dumped in a die, mechanically stirred, and foamed at certain temperature to obtain the modified phenolic aldehyde insulation foamed material. According to the invention, agglomeration problem of the inorganic nano modifier can be effectively overcome, the compatibility of the inorganic nano particle and organic resin can be increased, the mechanical strength of phenolic aldehyde cystosepiment is effectively enhanced, and the technical problems of high toughness and efflorescence degree of the traditional phenolic aldehyde cystosepiment can be solved, the density of prepared phenolic aldehyde foamed material is moderate, and the phenolic aldehyde foamed material has characteristics of good flame resistance and toughness, and low efflorescence degree.

Owner:东北大学秦皇岛分校

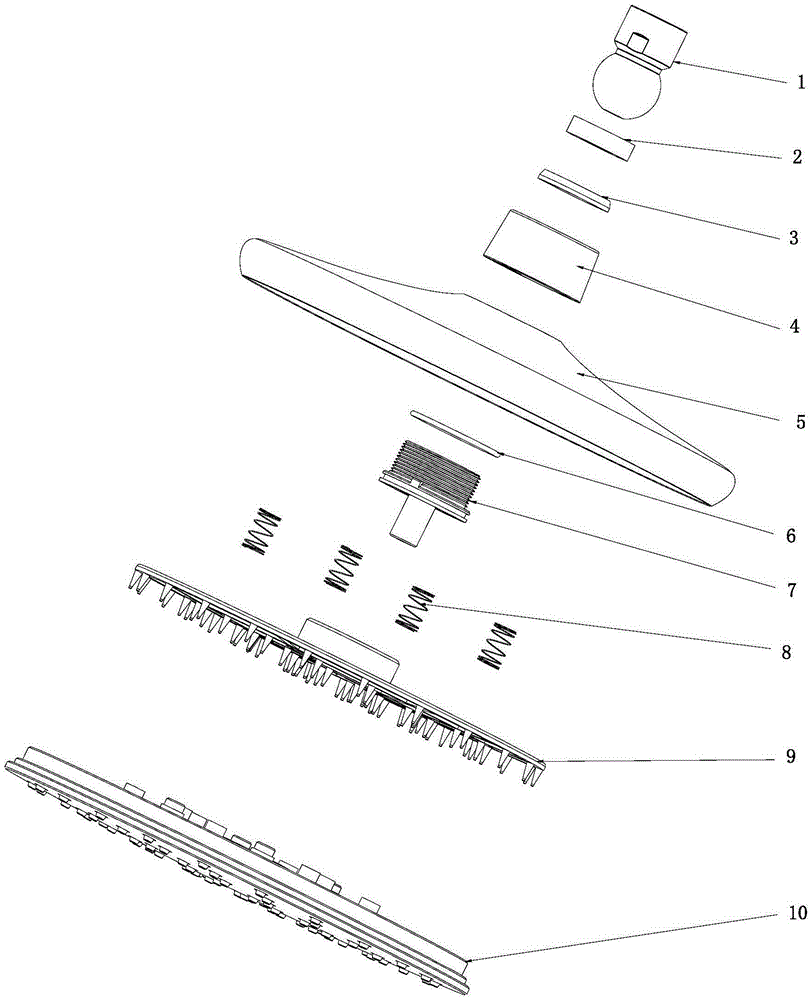

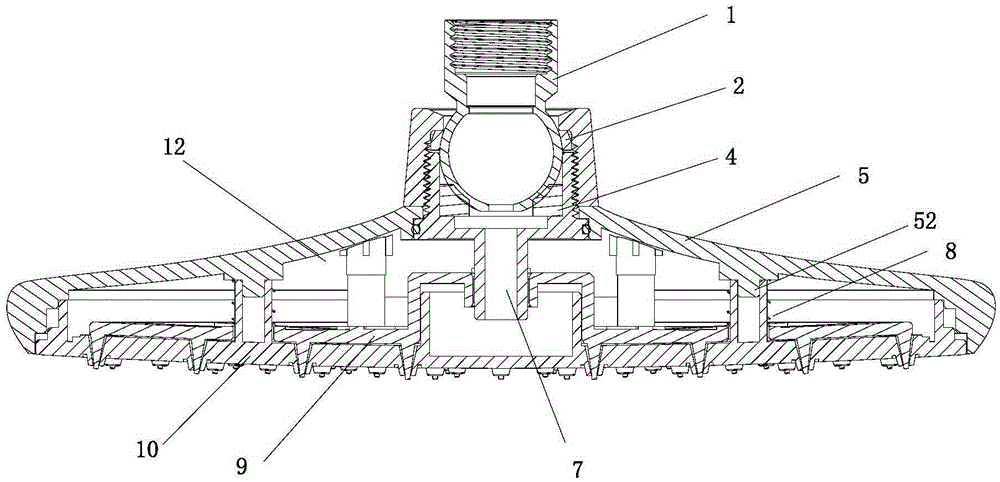

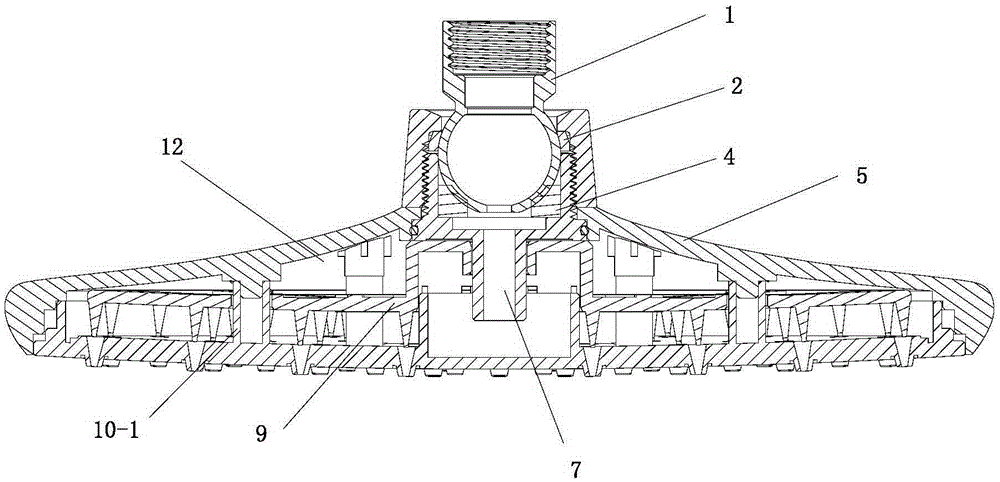

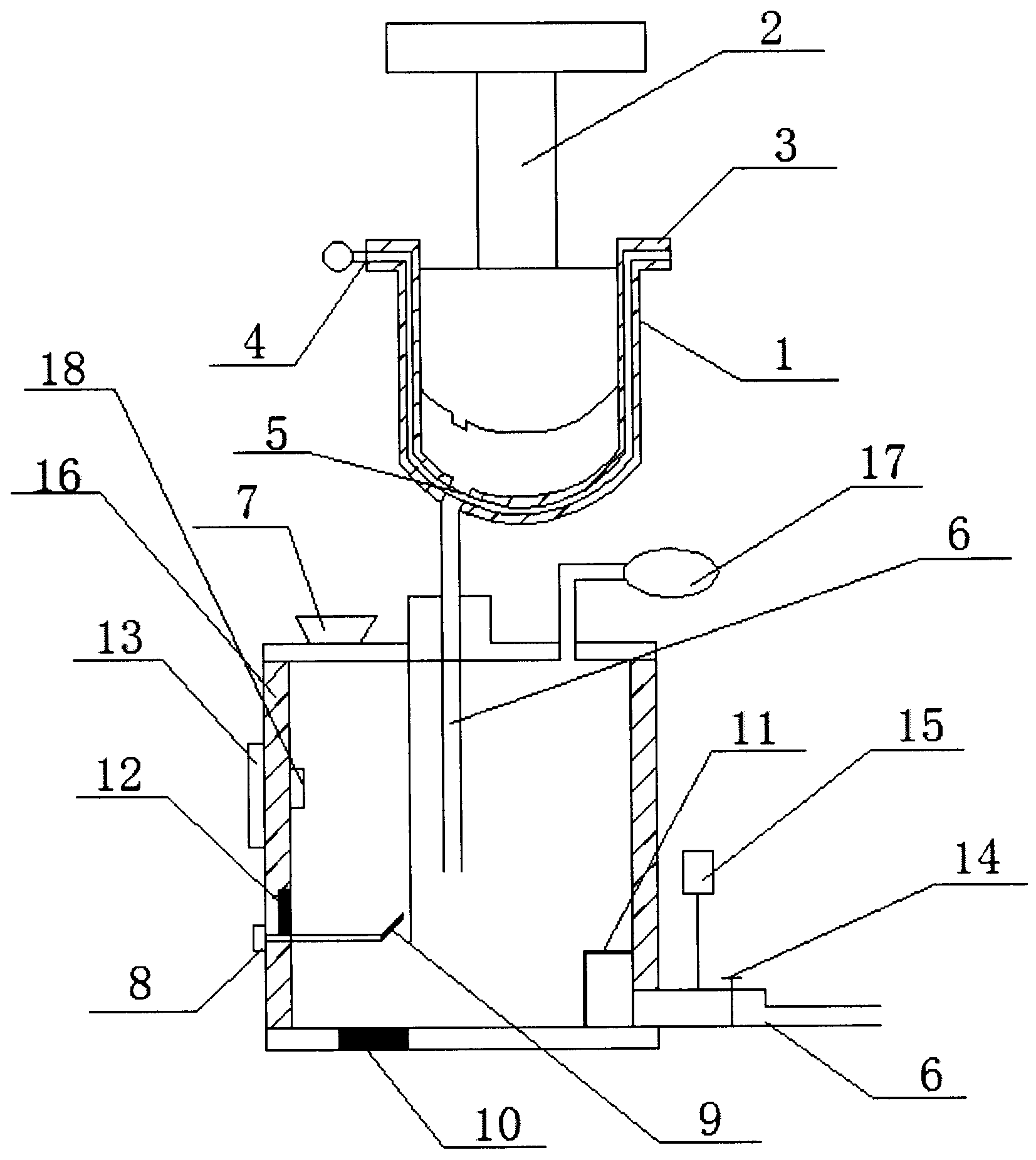

Self-cleaning sprinkler

The invention discloses a self-cleaning sprinkler. The self-cleaning sprinkler comprises a main body (5) and a water outlet panel (10) buckled with each other; an accommodating cavity (12) is formed between the main body (5) and the water outlet panel (10); a needle plate (9) is arranged in the accommodating cavity (12) above the water outlet panel; a dirt removing needle (9-2) is arranged on the needle plate (9); a water pressure cavity (9-4) is formed in the needle plate (9), and is provided with a water inlet hole (9-9) and a water overflowing hole (9-8); a water stopper (10-3) is arranged in the water pressure cavity (9-4) in a sliding manner; the needle plate (9) has an initial position and a water outlet position corresponding to the water outlet panel (10); in the initial position, the dirt removing needle of the needle plate is inserted in the water outlet hole of the water outlet panel, and the water overflowing hole is closed by the water stopper; and in the water outlet position, the dirt removing needle of the needle plate is upwards separated from the water outlet hole of the water outlet panel, and the water overflowing hole (9-8) is separated from the water stopper. The self-cleaning sprinkler can autonomously remove dirt.

Owner:BESTTER XIAMEN TECH

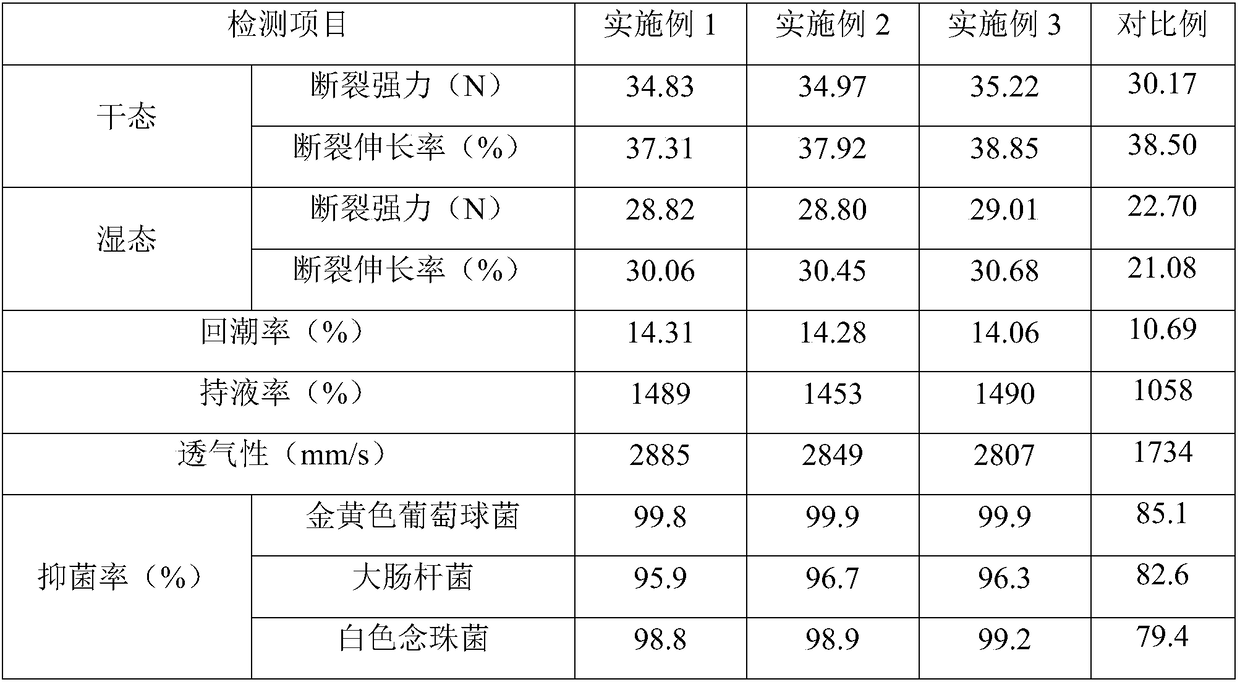

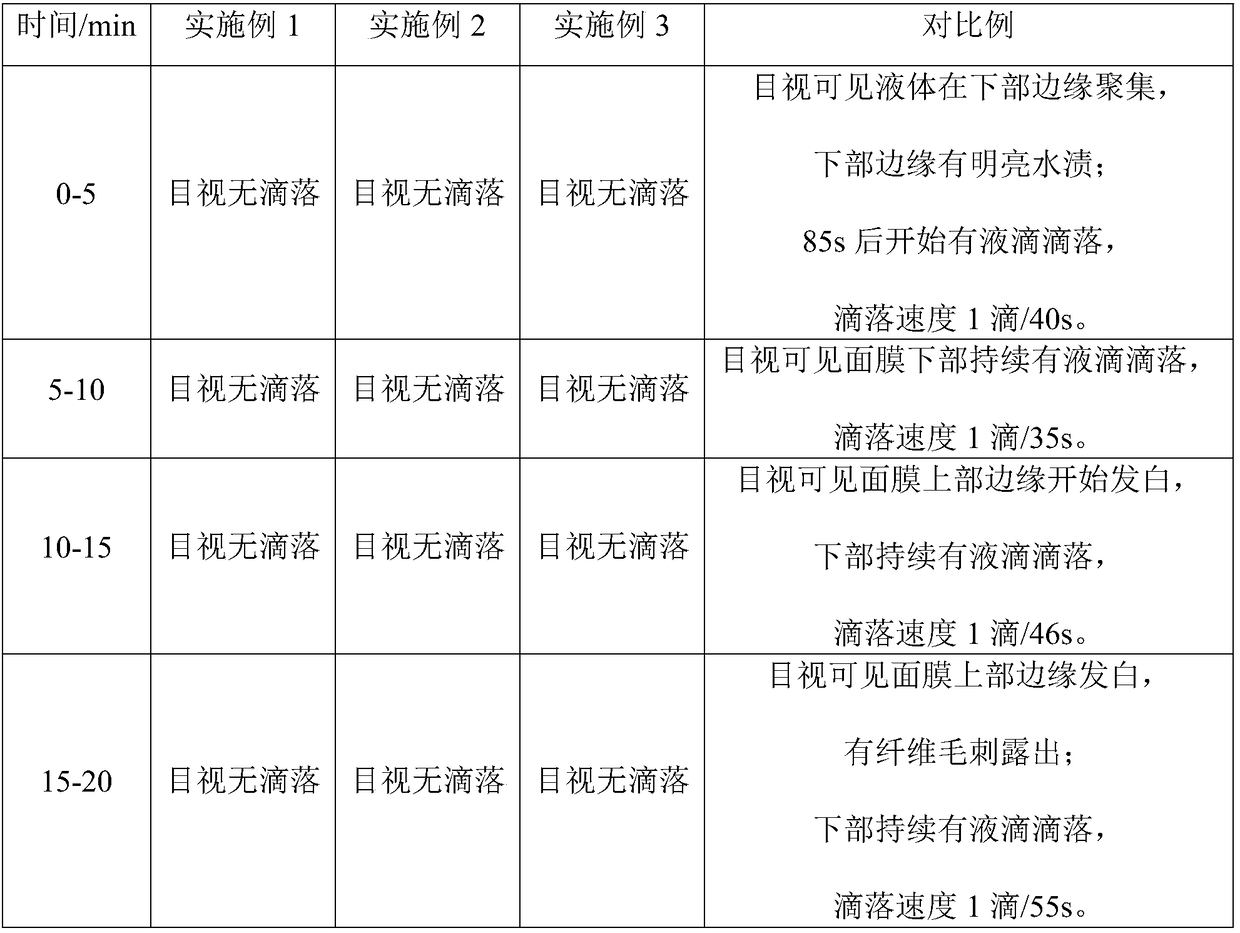

Bamboo charcoal viscose facial mask base cloth and high moisture retention and moisturizing facial mask

ActiveCN108403446AMeet physiological requirementsEliminates allergy riskCosmetic preparationsToilet preparationsCardingSlurry

The invention relates to a bamboo charcoal viscose facial mask base cloth and a high moisture retention and moisturizing facial mask. The bamboo charcoal viscose facial mask base cloth is prepared with the following method: 1) adding nanometer bamboo charcoal powder and sodium alga acid into dispersion solution to be dispersed evenly in bamboo charcoal serous fluid; 2) adding the bamboo charcoal serous fluid into viscose spinning solution to be dispersed evenly, and filtering and deforming to obtain mixed spinning solution; 3) carrying out wet method spinning on the mixed spinning solution toobtain the bamboo charcoal viscose, and carrying out opening, mixing, carding and lapping to obtain a bamboo charcoal viscose felt; 4) dissolving chitosan in acetic acid aqueous solution, adding gelatin to be dissolved to obtain finishing liquor, and dipping the bamboo charcoal viscose felt into the finishing liquor to carry out impregnation modification to obtain a compound fiber felt; 5) carrying out spunlace reinforcement on the compound fiber felt. The bamboo charcoal viscose facial mask base cloth has high constraint ability on serum and good water retention and moisture liberation performance; after the facial mask serum is loaded through a liquid hanging step, the high moisture retention and moisturizing facial mask is obtained, situation that serum loss due to dripping and droppingcan be avoided, and waste is avoided.

Owner:魏科峰

Polystyrene/melamine modified urea-formaldehyde resin syntactic foam and preparation method thereof

The invention discloses a polystyrene / melamine modified urea-formaldehyde resin syntactic foam and a preparation method thereof. Greater additive amount of a fire retardant and lower fire retarding efficiency are always important factors restricting the development of polystyrene materials. According to the polystyrene / melamine modified urea-formaldehyde resin syntactic foam, melamine modified urea-formaldehyde resin, an inorganic filler, a fire retardant and a fire retarding synergist form a melamine modified urea-formaldehyde resin mixed filler, the mass ratio of the melamine modified urea-formaldehyde resin mixed filler to pre-foamed polystyrene particles is 100:(20 to 70), and the melamine modified urea-formaldehyde resin mixed filler is evenly coated on the surface of the pre-foamed polystyrene particles. When flam contacts the syntactic foam, the melamine modified urea-formaldehyde resin mixed coated on the outer layer is char to form a protection layer to isolate the flame, thus achieving the aim of flame retarding by the syntactic foam.

Owner:HANGZHOU FANGYUAN PLASTICS MASCH CO LTD

Halogen-free flame retardation polycarbonate material and preparation method thereof

A halogen-free flame retardation polycarbonate material comprises, by weight, 70-90% of polycarbonate, 5-10% of other resins, 6-15% of a halogen-free flame retardant, 5-15% of a surface modifier, 3-10% of a flexibilizer, 0.6-2.5% of an antioxidant,0.4-2.5% of a lubricant and 0.3-1.2% of a weather resisting agent. The halogen-free flame retardation polycarbonate material fully performs a synergistic flame retardation effect, substantially improves the flame retardation performance of a PC material, has the advantages of high efficiency, no toxicity, low smoke and dropping resistance, excellent flame retardation performance, excellent mechanical performances, good processing fluidity, high thermal deformation temperature, good impact resistance, moderate cost, and suitableness for industrial application.

Owner:CIXI FALAIXIN PLASTIC FACTORY

Medicine feeder for medical nursing

The invention discloses a medicine feeder for medical nursing. The medicine feeder comprises a grinding barrel and a medicine bottle, the grinding barrel is composed of a grinding ball and a grinding seat, a medicine leaking hole is formed at the bottom of the grinding seat, the medicine bottle is connected with the grinding barrel through a guide pipe, a water tank is mounted on the left side of the medicine bottle, a heating device is mounted in a tank body of the water tank, a temperature sensor is mounted inside the water tank, a temperature display is mounted outside the water tank, and a water outlet is arranged at the bottom of the water tank; an air incoming hole is formed at the upper end of the medicine bottle and connected with an air blowing bag through the guide pipe, a vibrating motor is mounted at the bottom of the medicine bottle, a filtering net and a medicine outlet are arranged on the right side of the bottom of the medicine bottle, the medicine outlet is connected with a medicine feeding nozzle through the guide pipe, and a flowmeter and a medicine feeder switch are mounted on the guide pipe. The medicine feeder is simple in structure and convenient to use, tablets are ground and crushed and then diluted, a spoon is not needed, and spilling is avoided; the heating device is mounted, so that temperature of medicine liquid is guaranteed.

Owner:曹坤常

High-temperature-resistant modified asphalt waterproof coiled material and preparation method thereof

ActiveCN108081698AImprove thermal stabilityGood low temperature flexibilityFibre typesSynthetic resin layered productsThermal ageingFiber

The invention provides a high-temperature-resistant modified asphalt waterproof coiled material and a preparation method thereof. The modified asphalt waterproof coiled material comprises a tread baselayer, prepreg, a coating material and an isolating material; the tread base layer of the modified asphalt waterproof coiled material is fiberglass mesh cloth and polyester fiber composite tread base; and the prepreg is prepared from the following raw material components: 130# asphalt, chlorinated rubber, ethylene-vinyl acetate glyceride, elm tree wood powder and an anti-ageing agent. The modified asphalt waterproof coiled material has excellent thermal stability, thermal ageing resistance and low-temperature flexible performances.

Owner:富华防水科技股份有限公司

Tunnel lightweight inorganic fireproof composite material

ActiveCN101200380AMeet construction requirementsSignificantly reduce drynessLayered productsFiberFireproofing

The invention provides a light inorganic fireproofing composite material for tunnel, which is compounded by three layers of materials from inside to outside; the first layer is spray inorganic fireproofing material, the components of which comprise inorganic fireproofing fiber, expanded vermiculite powder, expanded graphite powder and ordinary Portland cement; the second layer is surface fireproofing material, the components comprises ordinary Portland cement, mica powder, gypsum and talcum powder; the third layer is fireproofing decorative material, which is a fire-retardant single-side composite aluminum foil. The composite material has the advantages that: the fire endurance is high; the thermal conductivity in hydrocarbon fire scene is extremely low; the fireproofing result is excellent; the self quality loss in fire is less without melting and dropping; the weight is light; the weathering is good; the sound-absorbing is good and the high-frequency drying reduction is obvious; the cost is low; the construction strength is less and the charge is low; furthermore, the ornament is good and the surface is smooth and beautiful surface, thereby the invention can mainly be used in the fire protection for the tunnel wall.

Owner:应急管理部四川消防研究所

Washing-resistant flame-retardant polyester cotton blended fabric and preparation method thereof

InactiveCN107201654AUniform and stable flame retardant qualityFlame retardant permanentWeft knittingWarp knittingFiberPolyester

The invention discloses a washing-resistant flame-retardant polyester cotton blended fabric and a preparation method thereof. The fabric contains flame-retardant terylene fiber and flame-retardant cotton fiber, and is characterized in that the outer surface of the formed fiber of the polyester cotton blended fabric is soaked by glue liquid containing fire retardants and crosslinking agents; then, the flame-retardant terylene fiber and flame-retardant cotton fiber with the outer surface soaked with the fire retardants and the crosslinking agents are subjected to grafting reaction to form a surface layer material; then, soaping, rinsing and drying are performed; the washing-resistant flame-retardant polyester cotton blended fabric is obtained. The washing-resistant flame-retardant polyester cotton blended fabric has the characteristics of flame-retardant performance, water washing resistance and the like; the production process is simple; the efficiency is high; wide application prospects are realized in the fields of decoration materials, individual protection garments and the like for industrial and traffic buildings with fireproof requirements in electric power, petroleum and the like; the practicability is high.

Owner:四川东方绝缘材料股份有限公司

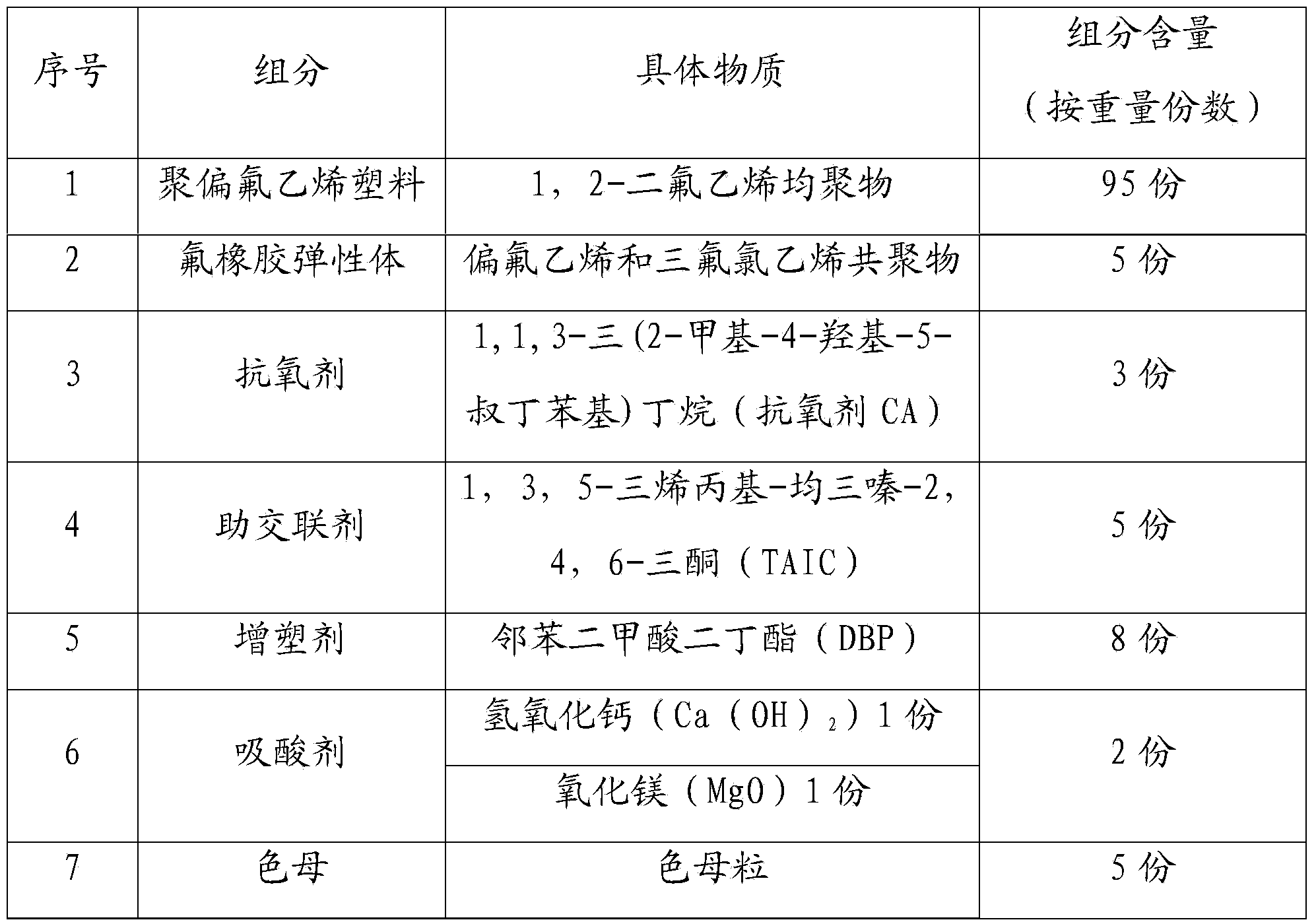

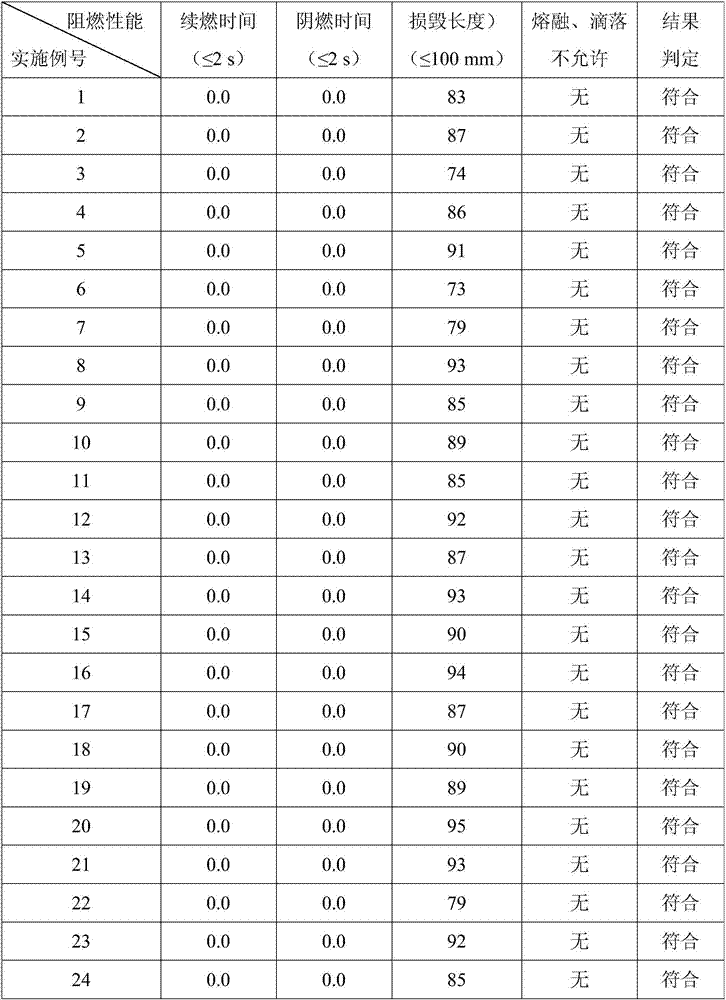

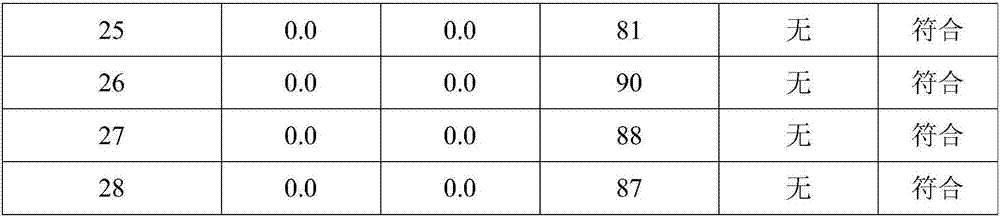

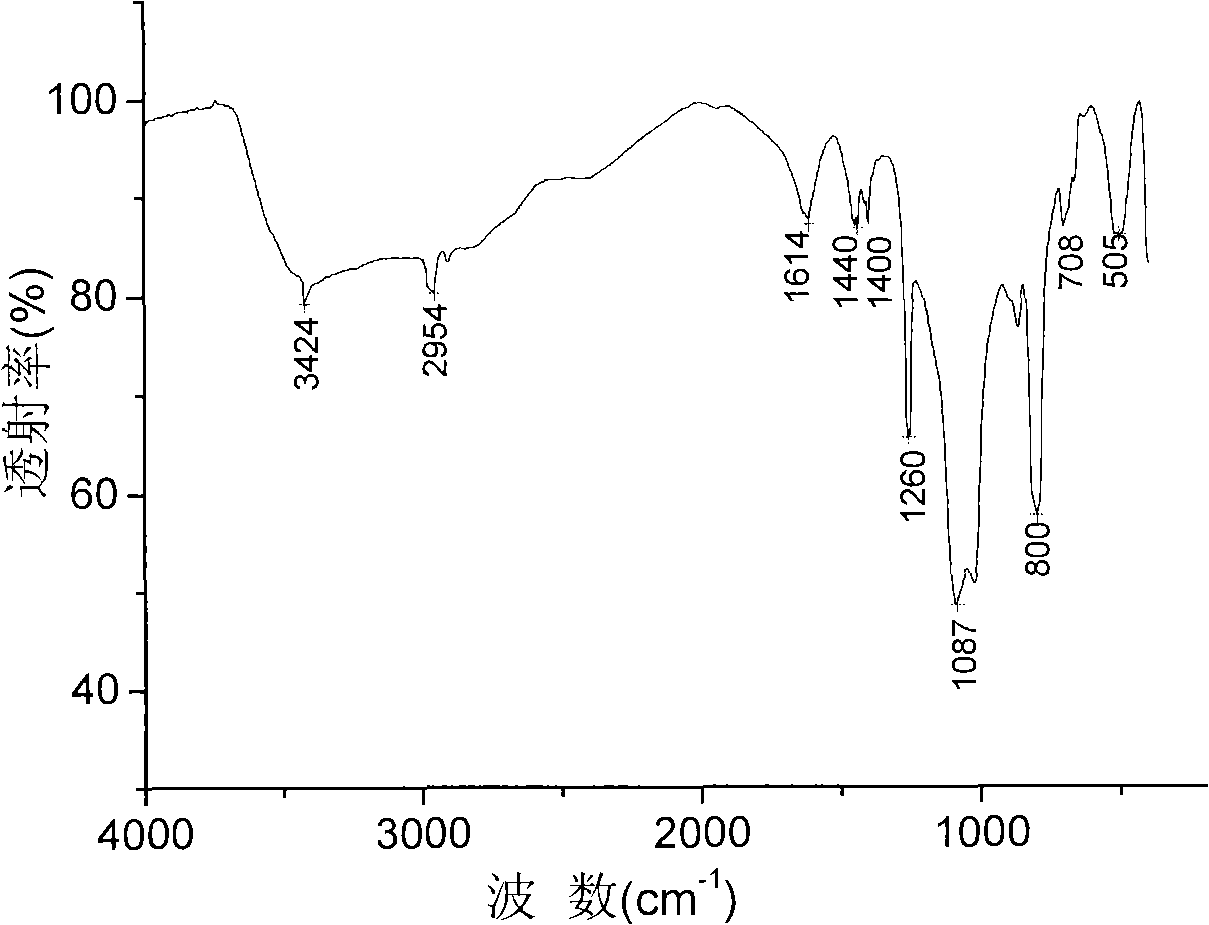

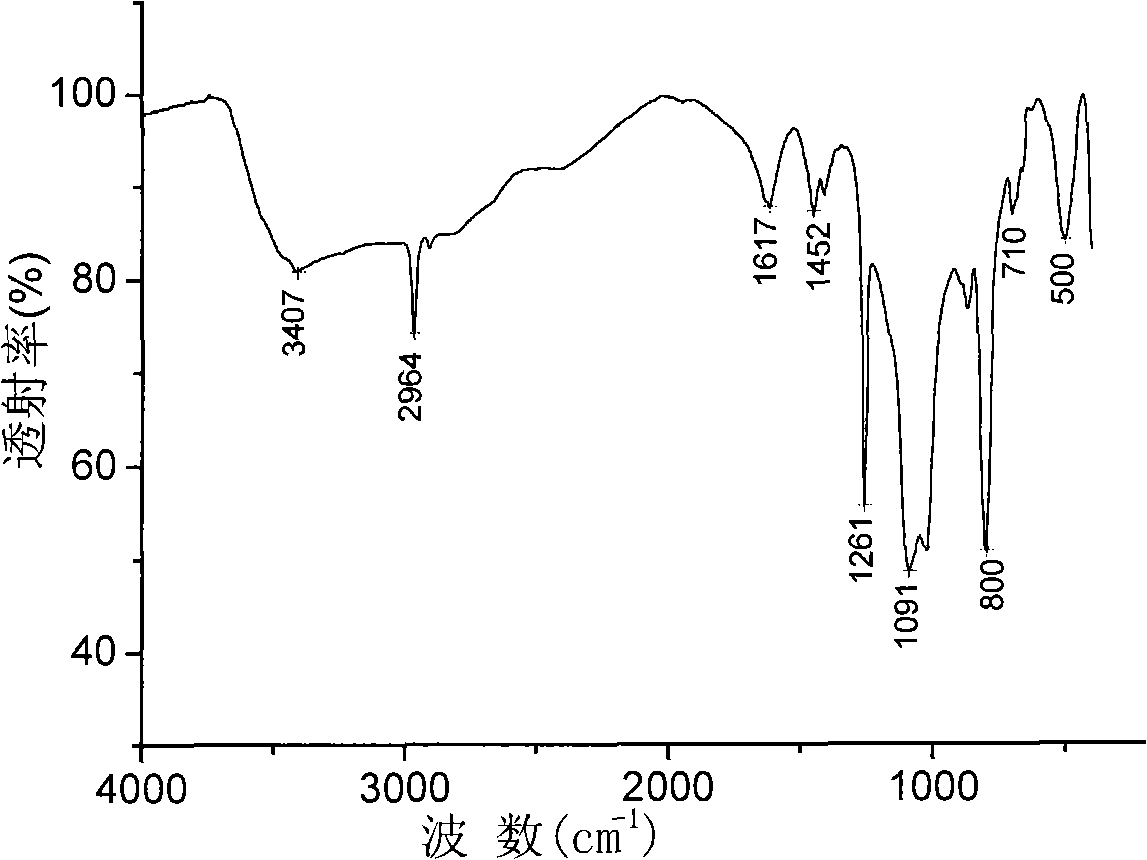

Combustion inhibitor for cellulose base fiber fabric and its synthesis method

InactiveCN101307565ANo drippingImprove performanceGroup 5/15 element organic compoundsVegetal fibresHalogenPolymer chemistry

The invention discloses flame retardant for cellulosic fiber fabric. The structure of the flame retardant can be expressed in the following general formula, wherein m is more than or equal to 1 and less than or equal to 4; n is more than or equal to 2 and less than or equal to 4. The flame retardant ensures that: fabrics after finishing can have good durability and flame retardant, as well as soft smooth hand feeling, and can not release free formaldehyde or contain halogen elements, thereby meeting the requirements of ecologic flame-retardant textiles. Meanwhile, the invention also discloses a method for preparing the flame retardant.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com