Preparation method of modified phenolic resin and application thereof

A phenolic resin, modified technology, applied in the field of preparation of modified phenolic resin, can solve the problems of application limitation, low production efficiency, easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

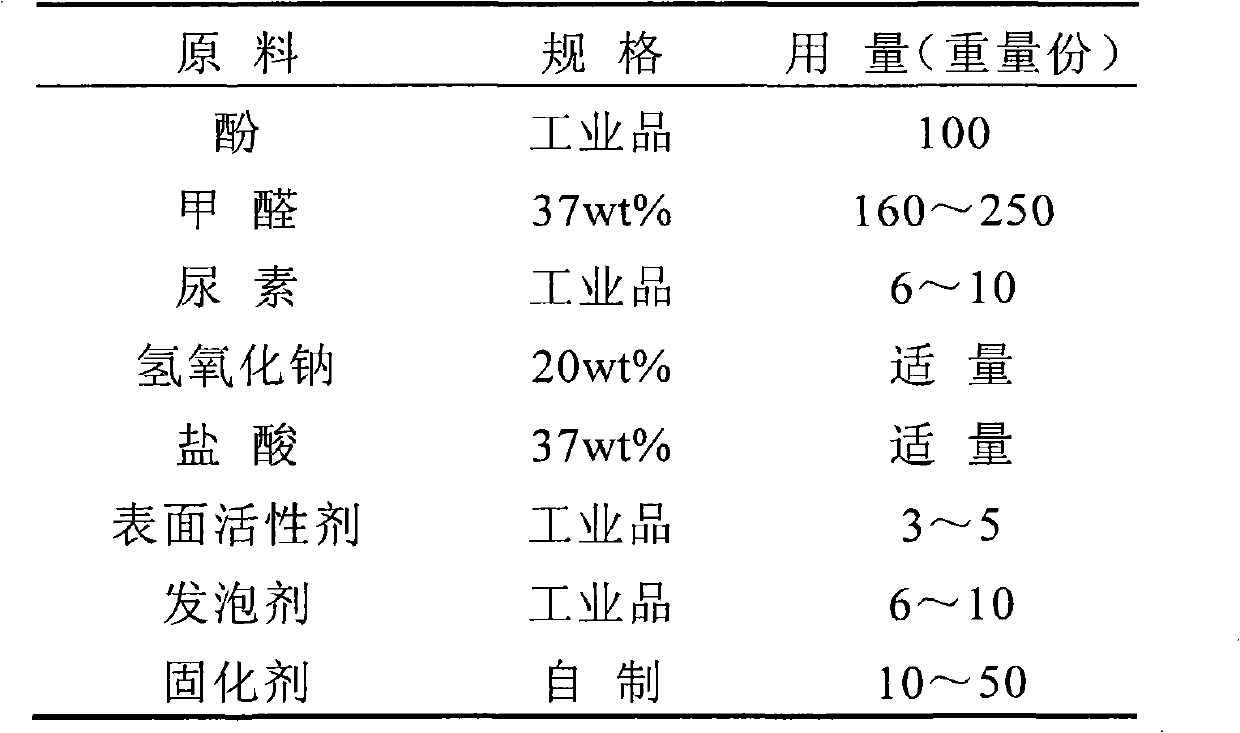

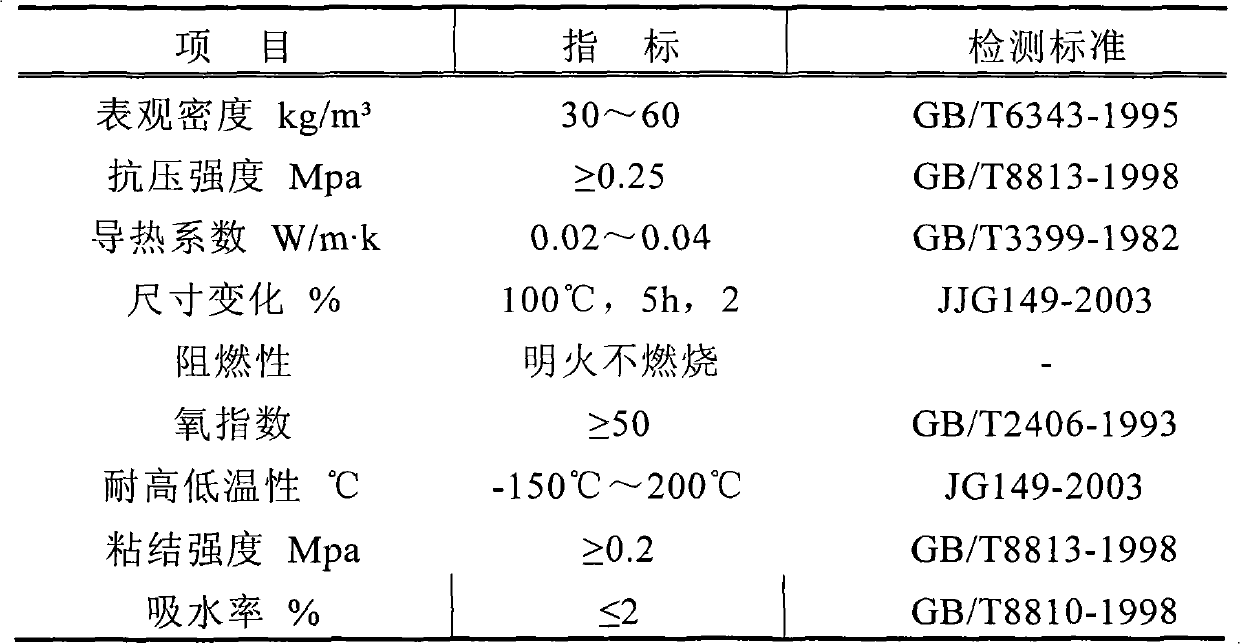

Method used

Image

Examples

Embodiment 1

[0023] 1) Preparation of modified phenolic resin:

[0024] Put 85g of phenol, 15g of cardanol, and 250g of formaldehyde (37wt%) into a three-necked beaker, adjust the pH to 8-9 with sodium hydroxide, stir and raise the temperature to 85°C, control the temperature at 85-95°C, react for 2 hours, then add 10 g of urea was reacted for 1 hour, adjusted to pH = 6.5-7.0 with hydrochloric acid, vacuum dehydrated, and the solid content reached 85 wt%. Cool down to normal temperature, measure the viscosity to 2.5Pa·s, add 4g of fatty alcohol polyoxyethylene ether, 7g of n-pentane, stir for 20 minutes, discharge, and pack.

[0025] 2) Preparation of composite curing agent:

[0026] Put 10g of phosphoric acid, 80g of sulfuric acid, and 10g of p-toluenesulfonic acid into a three-necked flask, stir for 20 minutes, wait until the p-toluenesulfonic acid is completely dissolved, discharge, and pack.

[0027] Take 100g of modified phenolic resin, mix with 12g of composite curing agent, and sp...

Embodiment 2

[0029] 1) Preparation of modified phenolic resin:

[0030] Add 90g of industrial phenol, 10g of cardanol, and 200g of formaldehyde (37wt%) into a three-necked flask, and stir with sodium hydroxide strips at pH=8-9 to raise the temperature to 85°C. Control the temperature at 85°C to 95°C, react for 2 hours, add 8g of urea, react for 1 hour, adjust the pH to 6.5 to 7 with hydrochloric acid, vacuum dehydrate until the solid content reaches 85wt%, drop to normal temperature, measure the viscosity to 3Pa·s, add Fatty alcohol polyoxyethylene ether 6g, isopentane 10g, discharge packing.

[0031] 2) Preparation of composite curing agent:

[0032] Put 10g of phosphoric acid, 200g of hydrochloric acid, and 10g of benzenesulfonic acid into a three-necked flask, stir for 20 minutes, wait until the benzenesulfonic acid is completely dissolved, and then discharge and pack.

[0033] Take 100g modified phenolic resin, 40g composite curing agent, mix and spray the interface.

Embodiment 3

[0035] 1) Preparation of modified phenolic resin:

[0036] Add 80g of phenol, 20g of cardanol, and 200g of formaldehyde (37wt%) into a three-neck flask, stir with sodium hydroxide pH=8-9 and raise the temperature to 85°C. Control the temperature at 85°C to 95°C, react for 2 hours, and then add 60g of urea to react for 1 hour. Adjust the pH to 6.5-7 with hydrochloric acid, vacuum dehydrate until the solid content reaches 85wt%, lower to normal temperature, measure the viscosity to 2.8Pa·s, add 5g of fatty alcohol polyoxyethylene ether and 6g of dichloroethane, discharge and pack.

[0037] 2) Preparation of composite curing agent:

[0038] Put 10g of phosphoric acid, 90g of sulfuric acid, and 5g of oxalic acid into a three-neck flask, stir for 20 minutes, wait until the oxalic acid is completely dissolved, and pack it.

[0039] Take 100g modified phenolic resin, 15g composite curing agent, mix and spray.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com