Combustion inhibitor for cellulose base fiber fabric and its synthesis method

A technology of cellulose fibers and flame retardants, applied in the field of flame retardants and their synthesis, can solve the problems of product crude oil performance degradation, large amount of flame retardant additives, low flame retardant efficiency, etc., and achieve stable performance and good flame retardant The effect of simple performance and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

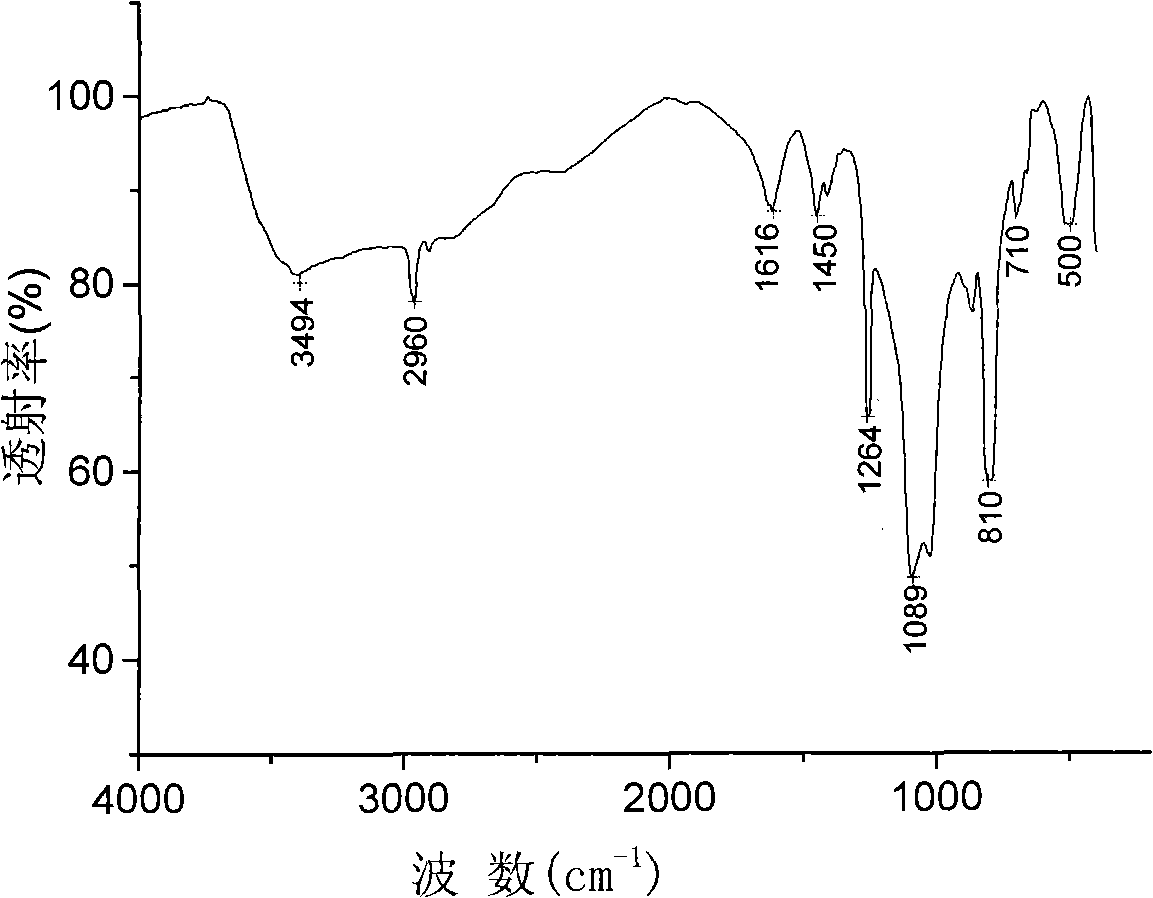

Embodiment 1

[0053] Weigh 2 moles of hydroxysilicone oil (the degree of polymerization is 2), and weigh the raw materials hydroxysilicone oil (the degree of polymerization is 2), phosphorus oxychloride, and diethanolamine according to the amount ratio of substances of 1:2:4;

[0054]First, hydroxysilicone oil and 1% catalyst anhydrous aluminum chloride, which account for 1% of the mass of hydroxysilicone oil, are added to the reaction vessel, the tail gas absorption device is installed, the reaction stirrer is turned on, and phosphorus oxychloride is slowly added dropwise at room temperature, within 2.5 hours After dropping, gradually warming up to about 65°C, heat preservation reaction at this temperature until no hydrogen chloride gas is emitted, to obtain intermediate product (I);

[0055] Then dihydropyran and diethanolamine are weighed according to the mass ratio of 1: 1.2, and the catalyst anhydrous cupric chloride accounting for 3% of the weight of diethanolamine is dissolved in the ...

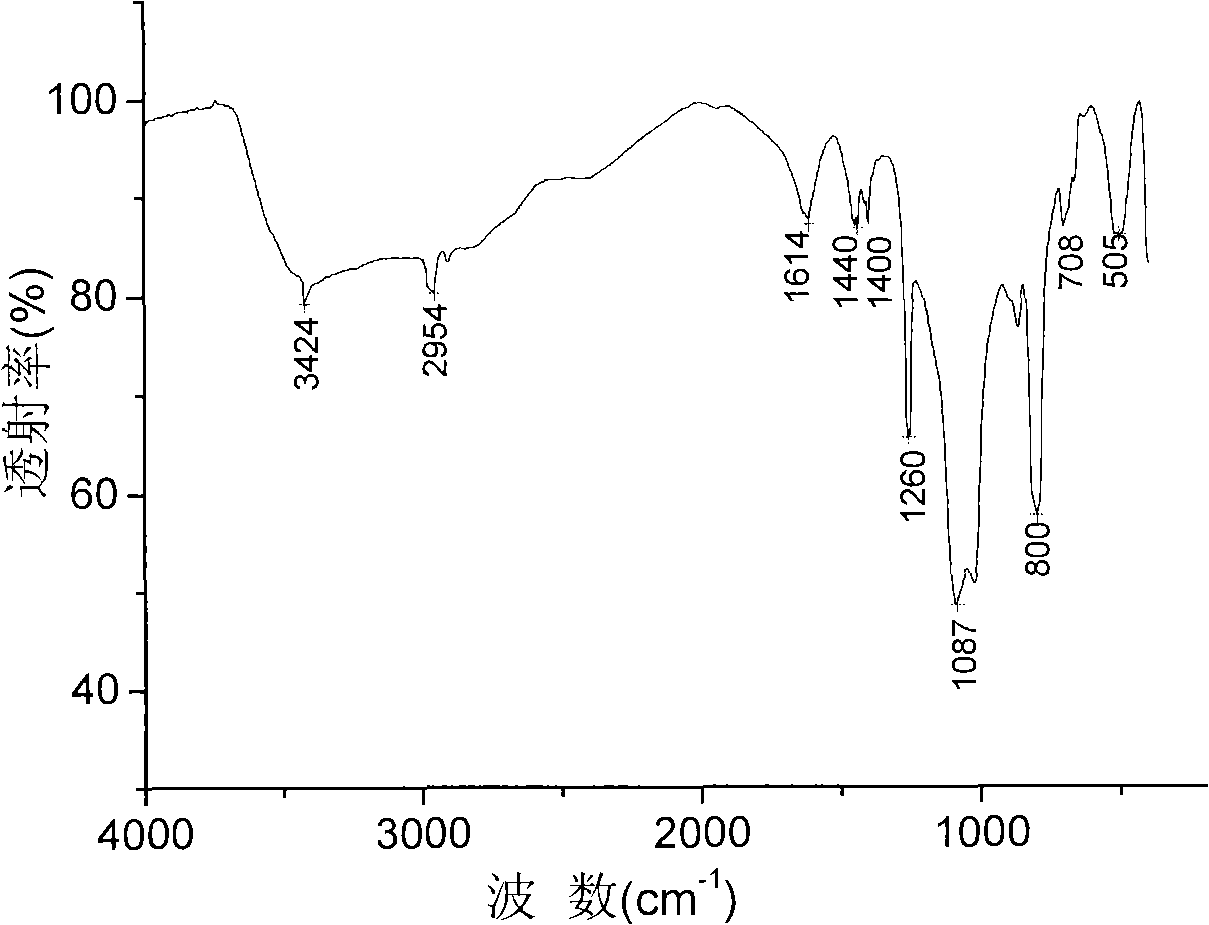

Embodiment 2

[0063] Weigh 2 moles of hydroxysilicone oil (the degree of polymerization is 3), and weigh the raw material hydroxysilicone oil (the degree of polymerization is 3), phosphorus oxychloride, and dimethanolamine according to the ratio of substances to 1:2:4;

[0064] First, hydroxysilicone oil and 3% catalyst anhydrous aluminum chloride, which accounts for 3% of the mass of hydroxysilicone oil, are added to the reaction vessel, the tail gas absorption device is installed, the reaction stirrer is turned on, and phosphorus oxychloride is slowly added dropwise at room temperature, within 3 hours After dripping, gradually warming up to about 68 ℃, heat preservation reaction at this temperature until no hydrogen chloride gas is released, to obtain the intermediate product (I);

[0065] Then dihydropyran and dimethanolamine are weighed according to the ratio of substance to 1: 1.2, and they are dissolved in the solvent dichloromethane together with the anhydrous catalyst cupric chloride...

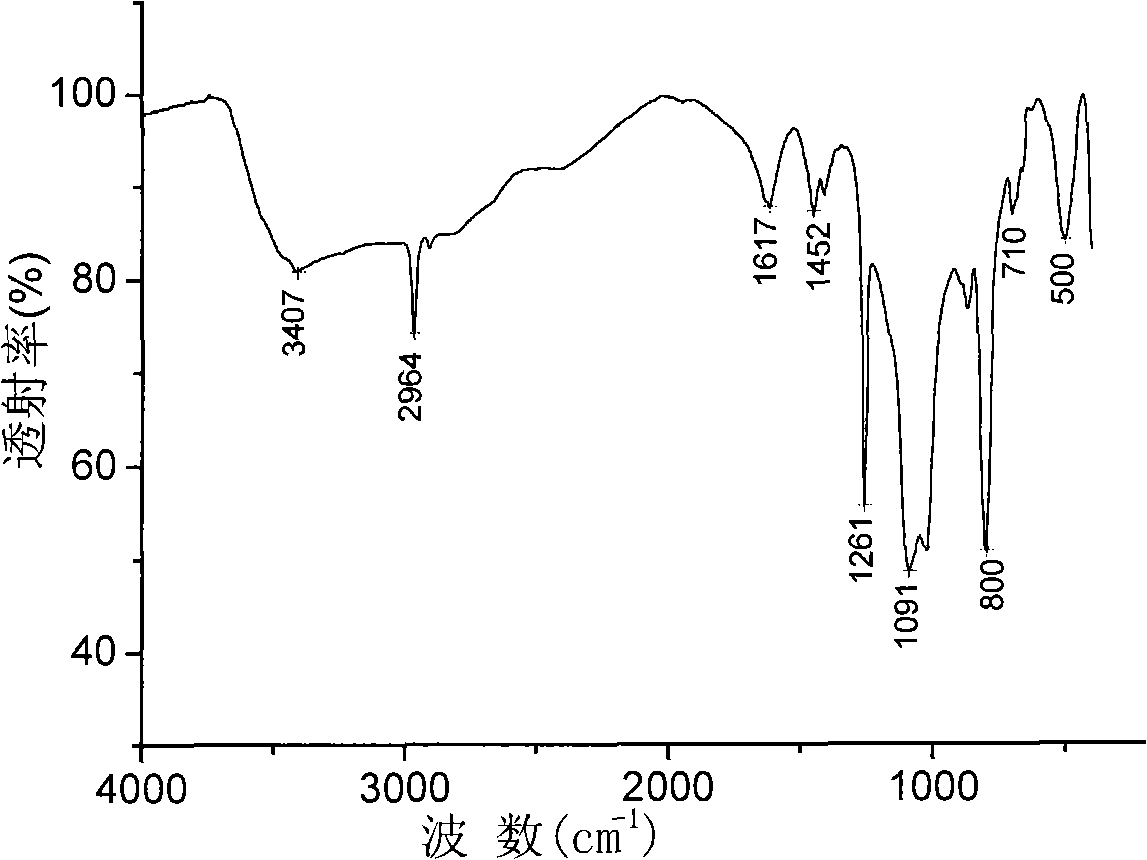

Embodiment 3

[0073] Weigh 2 moles of hydroxysilicone oil (the degree of polymerization is 4), and weigh the raw material hydroxysilicone oil (the degree of polymerization is 4), phosphorus oxychloride, and dipropanolamine according to the amount ratio of the substance to be 1:2:4;

[0074] First, hydroxysilicone oil and 2% catalyst anhydrous aluminum chloride accounting for the mass of hydroxysilicone oil are added to the reaction vessel, the tail gas absorption device is installed, the reaction stirrer is turned on, and phosphorus oxychloride is slowly added dropwise at room temperature, within 2 hours After dropping, gradually warming up to about 70°C, heat preservation reaction at this temperature until no hydrogen chloride gas is released, to obtain intermediate product (I);

[0075] Then dihydropyran and dipropanolamine are weighed as 1: 1.2 according to the mass ratio of dipropanolamine, and the catalyst anhydrous cupric chloride accounting for 1.5% of the mass of dipropanolamine is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com