Intumescent flame-retardant reinforced PC (Polycarbonate)/ABS (Acrylonitrile Butadiene Styrene) alloy and preparation method thereof

An intumescent and alloy technology, which is applied in the field of intumescent flame-retardant reinforced polycarbonate/acrylonitrile-styrene-butadiene alloy and its preparation, to reduce the defective rate of products and improve processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

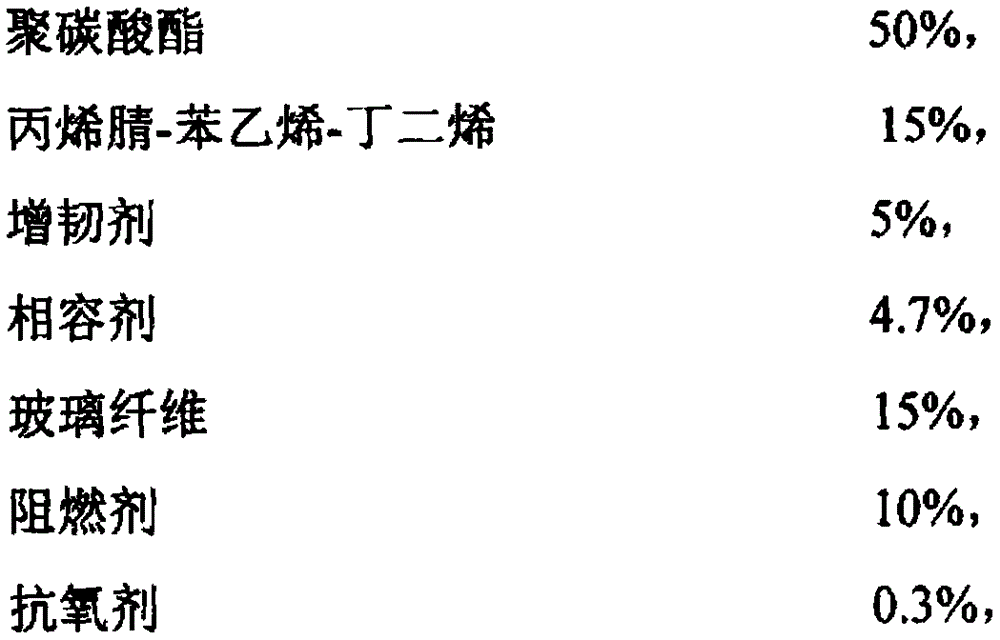

[0027] Weigh raw materials by weight ratio:

[0028] (1) polycarbonate / acrylonitrile-styrene-butadiene alloy, its parts by weight are composed as follows:

[0029]

[0030] Among them, the toughening agent used is ethylene octene copolymer, the flame retardant is an intumescent flame retardant, a mixture composed of polyaminocyclotriphosphazene and tris (2-hydroxyethyl) isocyanurate, poly Aminocyclotriphosphazene was 5% of the total formulation and tris(2-hydroxyethyl)isocyanurate was 5% of the total formulation. The antioxidant is 4,4'-thiobis(6-tert-butyl-3-methylphenol), the glass fiber is alkali-free long glass fiber whose surface is treated with silane coupling agent, and the compatibilizer is styrene bonded branched maleic anhydride.

[0031] The preparation process is as follows:

[0032] (2) Mix the above components evenly with a mixer, and add other raw materials except glass fiber from the main feed of the twin-screw extruder.

[0033] (3) The alkali-free long...

Embodiment 2

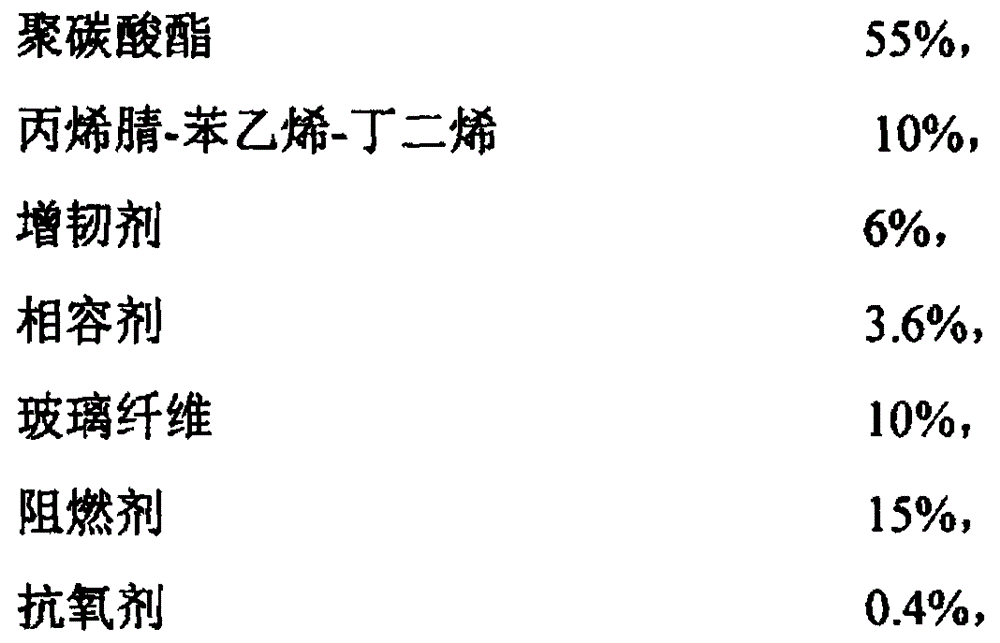

[0036] (1) polycarbonate / acrylonitrile-styrene-butadiene alloy, its parts by weight are composed as follows:

[0037]

[0038] Among them, the toughening agent used is ethylene butene copolymer, the flame retardant is an intumescent flame retardant, a mixture composed of polyaminocyclotriphosphazene and tris (2-hydroxyethyl) isocyanurate, poly Aminocyclotriphosphazene was 7.5% of the total formulation and tris(2-hydroxyethyl)isocyanurate was 7.5% of the total formulation. Antioxidant is β-(3,5-tertiary butyl-4-hydroxyphenyl) octadecyl propionate, glass fiber is alkali-free long glass fiber whose surface is treated with silane coupling agent, compatibilizer Styrene grafted maleic anhydride.

[0039] The preparation process is as follows:

[0040] (2) Mix the above components evenly with a mixer, and add other raw materials except glass fiber from the main feed of the twin-screw extruder.

[0041] (3) The alkali-free long glass fiber with a weight ratio of 10% is added fro...

Embodiment 3

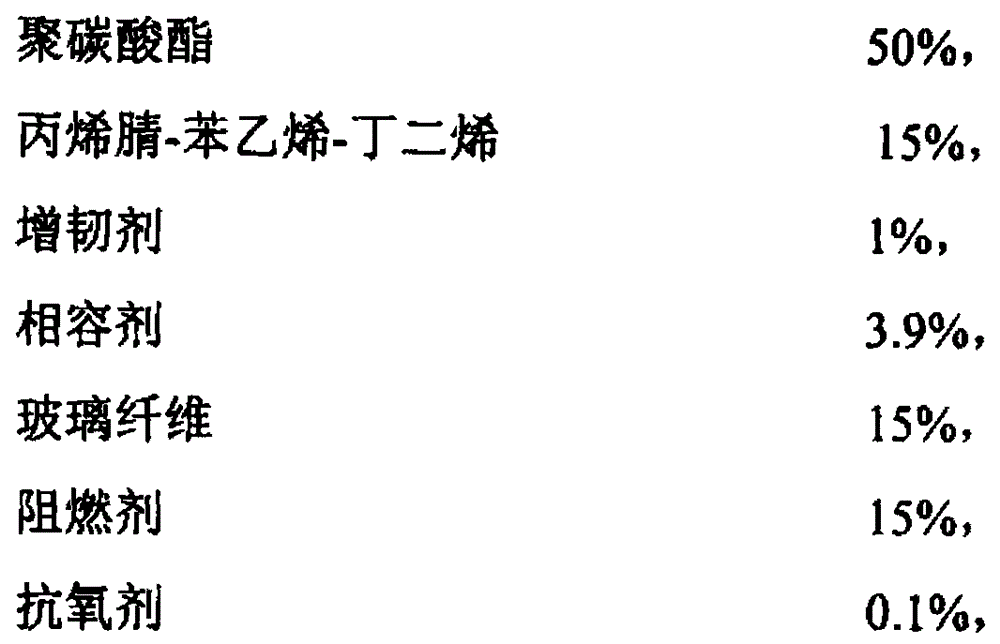

[0044] (1) polycarbonate / acrylonitrile-styrene-butadiene alloy, its parts by weight are composed as follows:

[0045]

[0046] Wherein, the toughening agent used is a mixture of ethylene butene copolymer and ethylene propylene copolymer. The flame retardant is an intumescent flame retardant, a mixture of polyaminocyclotriphosphazene and tris (2-hydroxyethyl) isocyanurate, polyaminocyclotriphosphazene is 7.5% of the total formula, three (2-Hydroxyethyl)isocyanurate was 7.5% of the total formulation. The antioxidant is a mixture of triphosphite (2,4-di-tert-butylphenyl) and bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite. The glass fiber is an alkali-free long glass fiber whose surface is treated with a silane coupling agent. The compatibilizer is styrene grafted maleic anhydride.

[0047] The preparation process is as follows:

[0048] (2) Mix the above components evenly with a mixer, and add other raw materials except glass fiber from the main feed of the twin-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com